Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MF420EX

Caricato da

YolandaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MF420EX

Caricato da

YolandaCopyright:

Formati disponibili

MULTIFLO®

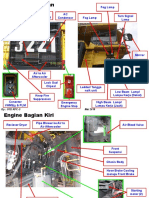

MF Heavy Duty Mine Dewatering Pumps MF-420EX

Multiflo® MF vacuum primed dewatering pump The heavy duty, auto

Weir Minerals Multiflo is the market leader for high quality vacuum primed Multiflo®

mine dewatering pump units, leading with the heavy duty ‘MF’

range of auto vacuum primed, diesel driven pump units. The

mine pit dewatering pump.

Multiflo® MF pump units are custom-built to ensure the very best

performance for your operation and survival under the toughest

operating conditions.

Multiflo® MF pump features include:

• Engineered pump solution

• Fully customized to your needs

• Built for mining

• Highest quality build

• VisMode® pump management system

• Vactronic® auto vacuum prime

• Heavy duty steel fabricated pump base and canopy

• All welds are continuous (no stitch welding that traps water

causing rust in inaccessible places)

• Multiflo® specified two pack epoxy paint system

• Comprehensive operations and spare parts manuals

Multiflo® MF-420EX

Vactronic® Auto Vacuum Priming System

When the Multiflo® MF pump unit is started, the Vactronic®

priming system will quickly and efficiently evacuate the air and

allow the water to enter the priming tank and the pump will

then be primed. Once the water in the priming tank contacts the Multiflo® MF pump benefits to the

upper probe, the drive to the vacuum pump will disengage. If customer

at any time the level in the priming tank drops below the upper

probe, the drive will re-engage and allow the water to re-enter • Reliability

back to the probe level. With this system, the vacuum pump life is • On-site service and support

prolonged as it is only operating when required. • Built to last

Waterloss shutdown • Tailored to the application

• Long term cost/benefit solution

Waterloss shutdown is another feature of the Vactronic® priming

system. If there is no more water to be pumped, the level in the

priming tank will fall below the lower probe and activate a six Customer Options

minute timer to shut down the pump unit. • Wear resistant materials

• Stainless steel wetted parts

MULTIFLO® 420EX • Choice of engine manufacturer

Pump

Model

Impeller

420EX Vanes 4 IMP Dia (mm)

Curve

660 Revision 0

• Suction hose

Discharge (mm) 150 Type Closed Max PRM 1700

Suction (mm) 200 Material H7A Max Solids (mm) 50mm

• Suction boom & Winch

240

220

• Discharge pipe

200 • Hydrau-Flo® safety refueling valves

180

160

• Auto lubrication

• Service lights

Head, H (m)

140

120

100

Cat C32 'B' rated Max • Strobe lights

Cat C27 'A' rated Max

80

60

• High lift skid

40 • Pontoon

20

0

• Auto start/stop system

0

20

40

60

80 120

100 140

160 200

180 220

240 280

260 300

320

340 380

360 400

420

440

460

Flow Rate, Q (L/s)

• Engineered custom options

Data for clean cold water only

Model MF-420EX

Ratings Metric (US/IMP) Pump Pump Impeller Data

Pump Inlet 200 mm (8”) 200x150 single stage Type - Closed

centrifugal

Pump Outlet 150 mm (6”) Material – H7A

Frame – FFY

Shut-Off Head 220 m (722ft) Imp. ø – 660 mm

Seal – Gland Packed

Max Flow 300 l/s (4755 US Gpm) Max. RPM – 1700

Engine KW (at 1700 RPM) 590 kW (787 Hp) Vanes - 4

Fuel Tank 4000 ltr. (1057 US Gal) Max. Solid – 50 mm

Construction

Pump Casing – A48

Shaft – 1045 Stainless Steel

Engine

Caterpillar® C27 ACERT (standard)

Caterpillar® C32 ACERT (optional)

For aggressive water applications, all wetted parts are available in stainless steel

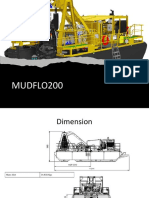

Dimensions

A B C D E F G H I Mass Wet Mass Inc Skid Mass Inc Pont

mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) mm (inch) kg (lbs) kg (lbs) kg (lbs)

6240 2040 3470 8516 2121 3886 10710 5120 4750 18000 21300 28990

(246) (80) (137) (335) (83) (153) (422) (202) (187) (39683) (46958) (63912)

Skids and pontoon options available upon request.

Standard models available in the Multiflo® CF range Electric models in the Multiflo® ME range Submersible pumps available in the Warman® SJ range

Weir Minerals Offices

The Weir Group PLC, founded

in Scotland in 1871, is a

leading global engineering

company with more than 8000

employees worldwide and is

listed on the London Stock

Exchange.

Weir Minerals Multiflo is part

Balikpapan

of the Weir Minerals Division

Banjarbaru Coolum and has primary global design

responsibility for the Multiflo®

self-prime dewatering pump

product range and Hydrau-Flo®

fuel filler valve.

Weir Minerals Multiflo and PT Weir Minerals Multiflo are business units of Weir Minerals Australia Ltd.

Weir Minerals Multiflo P.T. Weir Minerals Multiflo

15 Dacmar Road Jl. Mulawarman No. 29A Batakan Kecil Kel. Manggar Balikpapan

Coolum Beach QLD 4573 — East Kalimantan

Tel +61 7 5449 3000 Tel +62 542 746098 (Hunting) Fax +62 542 746099 Excellent

Fax +61 7 5446 4304

multiflo@weirminerals.com Branch Office Minerals

Jl. Ahmad Yani Km. 33,6 No. 04 RT.003 RW.001 Kel. Loktabat Selatan

www.weirminerals.com

Banjarbaru 70712 — South Kalimantan

Solutions

Tel +62 511 4773027 / 4772357 Fax +62 511 4773583

The products and systems which are described in this publication are manufactured and sold by Weir Minerals Australia Ltd and its business

units, and are covered by both patents and designs which are pending or granted worldwide in the name of Weir Minerals Australia Ltd.

WARMAN, MULTIFLO, HYDRAU-FLO, VISMODE and VACTRONIC are registered trademarks of Weir Minerals Australia Ltd. All rights reserved.

CATERPILLAR and CUMMINS are not trademarks of Weir Minerals Australia Ltd. Weir Minerals Australia Ltd sells its products fitted with

authorised products sourced from the brand owners of CATERPILLAR and CUMMINS.

©

Copyright 2012. Weir Minerals Australia Ltd. All rights reserved.

Issued August, 2012

Potrebbero piacerti anche

- WMM MF-385G SS Spare PartDocumento41 pagineWMM MF-385G SS Spare PartJeniverRanyC.Awombo100% (1)

- MF-420E Technical DataDocumento3 pagineMF-420E Technical DataSylvester S. Turnip100% (3)

- HH220i Smaster ManualDocumento60 pagineHH220i Smaster Manualjacklyn ade putra100% (1)

- Handbook Multiflo Australia (Spec Pumps)Documento32 pagineHandbook Multiflo Australia (Spec Pumps)Vivi Nurhayati87% (15)

- WMM CF-48 IOM & Parts Manual, October 2010Documento135 pagineWMM CF-48 IOM & Parts Manual, October 2010Sandison stl100% (1)

- CP150 SMDocumento50 pagineCP150 SMjacklyn ade putra100% (1)

- Motobomba SykesDocumento144 pagineMotobomba Sykesmuahdib100% (1)

- J H Hooper Confectionery Packaging EquipmentDocumento283 pagineJ H Hooper Confectionery Packaging Equipmentphucborso1Nessuna valutazione finora

- Multiflo Rf420exhv Spec SheetDocumento2 pagineMultiflo Rf420exhv Spec SheetIvo Mario100% (1)

- Multiflo rf85mv Dewatering Pump Spec SheetDocumento2 pagineMultiflo rf85mv Dewatering Pump Spec SheetAjyNessuna valutazione finora

- Pengenalan DNDDocumento53 paginePengenalan DNDAfiffudin Mukhlis Adtya100% (2)

- Attachment 2 - Multiflo® 420EXHV Pump Performance CurveDocumento1 paginaAttachment 2 - Multiflo® 420EXHV Pump Performance Curveachmadj1405Nessuna valutazione finora

- Model Mfc-420: Multiflo PumpsDocumento2 pagineModel Mfc-420: Multiflo PumpsKevin Hill100% (2)

- Model MF-390 Diesel Powered, Self Priming Pump Unit: Weir Minerals MultifloDocumento12 pagineModel MF-390 Diesel Powered, Self Priming Pump Unit: Weir Minerals Multiflobayu enasora100% (1)

- G&H - Specification of MultiFlo Pump AustraliaDocumento38 pagineG&H - Specification of MultiFlo Pump AustraliaHans Waterist100% (2)

- Sykes XH200-1750Documento2 pagineSykes XH200-1750hendrynNessuna valutazione finora

- 826 Weir Multiflo CF48H Curve RELDocumento1 pagina826 Weir Multiflo CF48H Curve RELMichael ChandraNessuna valutazione finora

- Dnd200-Mhx: Medium Head Dewatering PumpDocumento3 pagineDnd200-Mhx: Medium Head Dewatering PumpMuhammad Jaka Surya100% (1)

- HH220 IDocumento2 pagineHH220 Iprimelly0% (1)

- 794 - Metso HH 200 C5 Curve RELDocumento1 pagina794 - Metso HH 200 C5 Curve RELHumberto GoncalvesNessuna valutazione finora

- Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2Documento1 paginaWpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2 Wpa86a04/2risa ridmaNessuna valutazione finora

- G H Specification of MultiFlo Pump Australia PDFDocumento38 pagineG H Specification of MultiFlo Pump Australia PDFMuhammad Didik100% (1)

- Kajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Documento8 pagineKajian Efisiensi Bahan Bakar HD465 (Devi Diansyah R. Pratama - 10070112045)Devi RahmaditaNessuna valutazione finora

- Vibratory Soil Compactor: Stage II CompliantDocumento12 pagineVibratory Soil Compactor: Stage II Compliantguillermo springNessuna valutazione finora

- Model Mfc-160: General Information ConstructionDocumento3 pagineModel Mfc-160: General Information Constructionyosuatogi panjaitan100% (1)

- Tipe Dozer Berat Unit (Ton) Kapasitas Blade (m3) Tinggi Blade (M) Lebar Blade (M) Tinggi Total (M) Panjang Total (M)Documento7 pagineTipe Dozer Berat Unit (Ton) Kapasitas Blade (m3) Tinggi Blade (M) Lebar Blade (M) Tinggi Total (M) Panjang Total (M)mufqi fauziNessuna valutazione finora

- Shanbao PE600x900 Crusher Parts ManualDocumento1 paginaShanbao PE600x900 Crusher Parts ManualTomas Chien100% (2)

- COATES INDONESIA - Godwin Presentation BaturajaDocumento22 pagineCOATES INDONESIA - Godwin Presentation BaturajaAyu FijriNessuna valutazione finora

- Dnd200-5Hx: Medium Head Dewatering PumpDocumento3 pagineDnd200-5Hx: Medium Head Dewatering Pumphendryn100% (1)

- Presentasi DND KSBDocumento50 paginePresentasi DND KSBBlank Kusuma100% (2)

- Single Toggle Jaw Crusher OTSUKATEC-2Documento7 pagineSingle Toggle Jaw Crusher OTSUKATEC-2moddysNessuna valutazione finora

- Attachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 BoosterDocumento1 paginaAttachment 3 - Warman® 86AH Pump Performance Curve - Condition 1 Boosterachmadj1405Nessuna valutazione finora

- Mfau3600-01 Rf-85mv Pama Iom v1.0Documento183 pagineMfau3600-01 Rf-85mv Pama Iom v1.0JOKO DHARMO NINGRATNessuna valutazione finora

- Ft20kl-Scania P360CB (Sis) (Ra020ar3-1905010)Documento3 pagineFt20kl-Scania P360CB (Sis) (Ra020ar3-1905010)tiko fajarNessuna valutazione finora

- 385 Multiflow Ops Manuas March 2010Documento32 pagine385 Multiflow Ops Manuas March 2010lao florentinoNessuna valutazione finora

- Fast Fill Fuel KitsDocumento8 pagineFast Fill Fuel Kitsjgmanaure3105Nessuna valutazione finora

- M Mining P Pump 415 S: Model Number Sukses Inti SolusindoDocumento15 pagineM Mining P Pump 415 S: Model Number Sukses Inti Solusindohendryn100% (2)

- Komponen HD 785-7Documento23 pagineKomponen HD 785-7Wahyu IskandarNessuna valutazione finora

- Komponen Utama BuldozerDocumento1 paginaKomponen Utama BuldozerHery Cahyadi100% (5)

- Shanbao PE600x900H Crusher Parts ManualDocumento2 pagineShanbao PE600x900H Crusher Parts ManualTomas ChienNessuna valutazione finora

- Cornell BR Mine DewateringDocumento8 pagineCornell BR Mine Dewateringtan_dat2003Nessuna valutazione finora

- WasimanDocumento2 pagineWasimanHermanto Al-banaNessuna valutazione finora

- DND 150 Volvo Tad1343veDocumento8 pagineDND 150 Volvo Tad1343veSupriyo AdiNessuna valutazione finora

- Dewatering Pump Handbook 50Hz - ENG PDFDocumento100 pagineDewatering Pump Handbook 50Hz - ENG PDFnasser Khattab100% (1)

- 4140D Motor Grader: Tough World. Tough EquipmentDocumento2 pagine4140D Motor Grader: Tough World. Tough EquipmentAmirul Wiyatno100% (1)

- Crusher Cross-Section (AC-Svedala)Documento1 paginaCrusher Cross-Section (AC-Svedala)Juan ArosNessuna valutazione finora

- DND 100 SpecuficationDocumento8 pagineDND 100 SpecuficationIrfan FauzieNessuna valutazione finora

- MotorGraderL&TKomatsuGD511A 1 TechnicalSpecificationsDocumento2 pagineMotorGraderL&TKomatsuGD511A 1 TechnicalSpecificationst1meNessuna valutazione finora

- Hyva Gear Pump: ALPHA Gear Pump BI - 4H5 Bi-Rotational / Flange ISO 4 HolesDocumento2 pagineHyva Gear Pump: ALPHA Gear Pump BI - 4H5 Bi-Rotational / Flange ISO 4 HolesRidlon PrimatamaNessuna valutazione finora

- X-Pro Vessel: Quality That Is Easy To SeeDocumento4 pagineX-Pro Vessel: Quality That Is Easy To Seealfan cita nyalaNessuna valutazione finora

- WMM - CF - 48h Iom Revision 3Documento170 pagineWMM - CF - 48h Iom Revision 3Sandison stlNessuna valutazione finora

- Weir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedureDocumento10 pagineWeir Minerals Multiflo Electro-Magnetic (Robatic) Clutch Disassembly AND Assembly ProcedurePutra JawaNessuna valutazione finora

- Mudflo200 & MF-125 MEB-86 Techical AspekDocumento46 pagineMudflo200 & MF-125 MEB-86 Techical Aspekachmadj1405Nessuna valutazione finora

- Bw211d-40 Technical SpecsDocumento2 pagineBw211d-40 Technical SpecsCESARALARCON10% (1)

- PDF Multiflo Mf420ex - CompressDocumento2 paginePDF Multiflo Mf420ex - CompressUwa XebexNessuna valutazione finora

- Dokumen - Tips - Multiflo Mfbrochure Nov 2010Documento12 pagineDokumen - Tips - Multiflo Mfbrochure Nov 2010elizabeththeresanaomNessuna valutazione finora

- Lawrence Pumps VPL3600: Vertical Lineshaft, Slurry PumpDocumento8 pagineLawrence Pumps VPL3600: Vertical Lineshaft, Slurry PumpjnNessuna valutazione finora

- Multiflo rf210mv Spec SheetDocumento2 pagineMultiflo rf210mv Spec Sheetricky pradanaNessuna valutazione finora

- Ps 10 29 Ea4 PDFDocumento8 paginePs 10 29 Ea4 PDFisidriskyNessuna valutazione finora

- Slurry Pump The KproDocumento11 pagineSlurry Pump The Kpro4lk0nNessuna valutazione finora

- Between Bearings, Axially Split, Multistage Pump: ISO 13709/API 610 (BB3)Documento8 pagineBetween Bearings, Axially Split, Multistage Pump: ISO 13709/API 610 (BB3)ChristianReinoso100% (1)

- HTO AssignmentDocumento5 pagineHTO AssignmentMadhumita KumarNessuna valutazione finora

- 1400SRM0046 (06 2017) Uk en PDFDocumento46 pagine1400SRM0046 (06 2017) Uk en PDFCosmin GîrleanuNessuna valutazione finora

- LNG. Cargo OperationsDocumento13 pagineLNG. Cargo OperationsFernando GrandaNessuna valutazione finora

- Peugeot 307 1600cc E3 NfuDocumento4 paginePeugeot 307 1600cc E3 NfuZoli BorbelyNessuna valutazione finora

- Welder Qualification PDFDocumento7 pagineWelder Qualification PDFnarutothunderjet216Nessuna valutazione finora

- Hwang Et All Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam Column Joints For Seismic PDFDocumento14 pagineHwang Et All Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam Column Joints For Seismic PDFEduardo MarquesNessuna valutazione finora

- DTC IndexDocumento34 pagineDTC IndexArturoRatierNessuna valutazione finora

- TKC40升降机维修说明书TKC Man Lift Maintenance ManualDocumento36 pagineTKC40升降机维修说明书TKC Man Lift Maintenance Manualkiên phạm trungNessuna valutazione finora

- BHELDocumento17 pagineBHELSumit KumarNessuna valutazione finora

- Emp 006Documento2 pagineEmp 006Brian FreemanNessuna valutazione finora

- Problem Set 2.projectile MotionDocumento9 pagineProblem Set 2.projectile MotionChristian OconNessuna valutazione finora

- 800 PDFDocumento155 pagine800 PDFdnageshm4n244Nessuna valutazione finora

- Vapor Compression Refrigeration CycleDocumento21 pagineVapor Compression Refrigeration CycleUSHA PAWARNessuna valutazione finora

- PHD Thesis Optimization of Bow Shape For Large, Slow Ships by NordåsDocumento84 paginePHD Thesis Optimization of Bow Shape For Large, Slow Ships by NordåsPrasad PatilNessuna valutazione finora

- Welcome To Chemical Engineering An Introductory Course To All Chemical Engineering Students in Year 1Documento41 pagineWelcome To Chemical Engineering An Introductory Course To All Chemical Engineering Students in Year 1Fong Cai YingNessuna valutazione finora

- An Infinite Row of Collinear Cracks in An Infinite Elastic SheetDocumento5 pagineAn Infinite Row of Collinear Cracks in An Infinite Elastic SheetXI CHENNessuna valutazione finora

- RR320306 HeattransferDocumento8 pagineRR320306 HeattransferAnil Frivolous AbstemiousNessuna valutazione finora

- HW 1 ForcesDocumento2 pagineHW 1 ForcesRebecca LuNessuna valutazione finora

- Gas Engine - Vibration and NoiseDocumento30 pagineGas Engine - Vibration and NoiseCamilo Andres Cardozo FajardoNessuna valutazione finora

- Peng 305: Drilling Engineering 1 Lecture NotesDocumento30 paginePeng 305: Drilling Engineering 1 Lecture Noteskwesimark100% (1)

- Mohr's Circle Part 3Documento6 pagineMohr's Circle Part 3zidaaanNessuna valutazione finora

- SaeDocumento8 pagineSaeahmadNessuna valutazione finora

- Pump System Labby 2015Documento6 paginePump System Labby 2015Azril DahariNessuna valutazione finora

- Tadano TM Zr500xlDocumento6 pagineTadano TM Zr500xlRafael Durio EtgarNessuna valutazione finora

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesDocumento9 pagineDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- Asphalt Reinforcement With ARTER GTA A 50-50-35 GeogridsDocumento13 pagineAsphalt Reinforcement With ARTER GTA A 50-50-35 GeogridssgondoschNessuna valutazione finora

- Chapter-2 (Steel Design)Documento22 pagineChapter-2 (Steel Design)danica ledesmaNessuna valutazione finora

- Turcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealDocumento14 pagineTurcon Glyd Ring T: Double Acting Rubber Energized Plastic Faced SealPhong DuongNessuna valutazione finora