Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Western Power Dcwi 4 1 Earth Testing

Caricato da

Vp SreejithCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Western Power Dcwi 4 1 Earth Testing

Caricato da

Vp SreejithCopyright:

Formati disponibili

DCWI 4.

1 – Earthing system resistance testing (all equipment)

OBSERVE SAFETY LIFESAVERS

DISTRIBUTION COMMISSIONING WORK INSTRUCTION

4.1 – EARTHING SYSTEM RESISTANCE TESTING (ALL EQUIPMENT)

Purpose: This instruction covers testing of the earth resistance of electrodes or earth systems. Good

earthing systems are essential for the protection of personnel from electrical shock and the protection of

electrical equipment from dangerous overvoltage and excess current.

Note: The following tests must be carried out on all replacements or new installations before they are put into service. If testing

whether existing earth electrodes are connected to the network, refer to the Work Practice Manual.

Note: Bolts and screws in all electrical connections across the Western Power network must be properly tightened.

Address/Pole No.:___________________________________________________________________

Work Package No.:_________________ SPIDAWeb Pick ID:_______________________________

1. PRE-TEST CHECK

Rated system voltage Volts

Equipment being protected by the earth system (e.g. transformer, pole-top

switch)

No. of earth electrodes per earthing point #

Approximate depth of

a) b) Metres

earth electrodes

Size of earth cables mm2

Visual inspection Check that the earth conductors are correctly installed to the earth bar (if applicable) and that

there are no signs of damage.

Check that the earth electrodes are properly installed and connected to the earth system by

earth conductors.

Check that the earth pits are properly installed, access to the earth electrode is possible and

the earth pit lids are in good condition.

Check that the compound earth grid is bonded to the substation screening fence (not a

customer property bounded fence) and connected to a MEN / N–E connections or earth

terminals bar (if applicable).

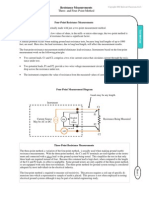

2. EARTHING SYSTEM RESISTANCE TEST

Test Equipment: Earth Resistance Tester (three-pole fall of potential method)

The earth electrode under test (electrode 1) must be disconnected from the earthing system.

This test involves two test instrument electrodes (electrode 2 and electrode 3).

If the depth of electrode 1 is d, then the test probe P (electrode 3) of the tester must be placed at a

minimum of 2 x d from the earth electrode 1 and the C probe (electrode 2) must be minimum 3.2 x d

from the earth electrode 1(in that ratio where P is 62% of the distance between the earth electrode

and C probe). This ensures an accurate earth resistance measurement. Otherwise, the measurement

Fall of potential method would result in higher resistance readings due to summation of the zones of influence of the earth

electrode and the C probe.( see probe spacing table 1 below)

In the case that the electrode under test (electrode 1) is unknown, install the electrode 2 at a distance

of 50 metres away, and electrode 3 at a distance of 31 metres (around 62% of the distance between

electrodes 1 and 2) in a straight line.

This test is repeated by moving the electrode 3 a distance of 3 metres forwards and backwards from

its initial position and in straight line.

The final test result is the average of the three test results. (See diagram 1 below.)

First Test Second Test Third Test

Initiate test: Reposition electrode 3: Reposition electrode 3:

Electrode 2 at C metres + 3 metres from initial position - 3 metres from initial position

Electrode 3 at 0.62C metres

Test results

Record value: Record value: Record value:

Ω Ω Ω

Average the value of the three tests and record. Ω

Network Standard 11/2013 DM# 1647382 1 of 3

4.1 – Earthing system resistance testing (all equipment) DCWI

Description Maximum Allowable Resistance

High voltage system – overhead systems (each electrode) max 30 Ω

Low voltage system: transformer rating up to 63 kVA max30 Ω

Acceptable values Low voltage system: pole-top transformer not greater than 315 kVA max30 Ω

(Distribution Substation

Manual) Low voltage system: pad-mounted transformer rating 160 kVA or

max 10 Ω

greater (each electrode)

High voltage system: underground system (ground mounted

max 10 Ω

equipment) (each electrode)

Combined HV-LV earthing system (e.g. transformers) max 1 Ω

ELECTRODE DEPTH Test Lead lengths from Earth Electrode

Potential Probe (P) Current Probe (C)

<15m 30m 50m

15 - 30m 60m 100m

30 - 45m 90m 150m

45 - 60m 120m 190m

60 - 75m 150m 240m

75 - 100m 200m 320m

Straight line probe spacing table 1

(Western Power Network)

3. HANDOVER OF RESPONSIBILITY

2 of 3 DM# 1647382 Network Standard 11/2013

DCWI 4.1 – Earthing system resistance testing (all equipment)

I hereby certify that all items have been completed with satisfactory results and transfer control to the project manager.

Commissioning officer:________________________________________________ NAC #:__________________________

Signature:_____________________________________________________ Date & time:__________________________

1. Ensure the work area is left tidy and no hazards to the public.

2. Hand over responsibility to the operating authority.

3. Return this form to the project file as a record of the commissioning/handover certificate.

4. After the on-site project officer signs off on the DCWI, send a scanned copy to the relevant manager: the construction manager

(for work performed by Western Power employees); the service manager (for contractors); or the project manager (for the

Future Grid).

Network Standard 11/2013 DM# 1647382 3 of 3

Potrebbero piacerti anche

- Distribution Commissioning Form 41 Earthing System Resistance Testing All Equipment 20190923 PDFDocumento3 pagineDistribution Commissioning Form 41 Earthing System Resistance Testing All Equipment 20190923 PDFkiet eelNessuna valutazione finora

- Earthing SystemDocumento25 pagineEarthing SystemVaneet Gupta100% (1)

- Methods of Earth Resistance Testing (Part-2) - Electrical Notes & ArticlesDocumento8 pagineMethods of Earth Resistance Testing (Part-2) - Electrical Notes & ArticlesVenkataramanan SNessuna valutazione finora

- Insulation ResistanceDocumento41 pagineInsulation Resistancekhozema_goodluck75% (4)

- WS Testing SummariesDocumento6 pagineWS Testing SummarieszespunkNessuna valutazione finora

- Measurement of Earth Electrode ResistanceDocumento8 pagineMeasurement of Earth Electrode ResistanceTarunNessuna valutazione finora

- Methods of Earth Resistance TestingDocumento6 pagineMethods of Earth Resistance Testingsubu100% (1)

- Ground TestingDocumento31 pagineGround TestingabdulkadhirNessuna valutazione finora

- Earth Loop Impedance Tests PDFDocumento20 pagineEarth Loop Impedance Tests PDFnishanthaindikaNessuna valutazione finora

- Earth Resistance TesterDocumento8 pagineEarth Resistance TesterAnonymous vcadX45TD7Nessuna valutazione finora

- Ground TestDocumento7 pagineGround TestHemendra JaniNessuna valutazione finora

- MeggerDocumento10 pagineMeggershahanbashaNessuna valutazione finora

- IEC 61000 4 2 EMC Workshop Sep 2019Documento28 pagineIEC 61000 4 2 EMC Workshop Sep 2019rianteri1125Nessuna valutazione finora

- Abdalla Aly Issa - 4915Documento8 pagineAbdalla Aly Issa - 4915Abdalla El DemrdashNessuna valutazione finora

- Electrical Safety ManualDocumento6 pagineElectrical Safety ManualRose ParkNessuna valutazione finora

- Megger DET2Documento2 pagineMegger DET2Sudipta ChakrabortyNessuna valutazione finora

- Insulation Resistance (IR) ValuesDocumento14 pagineInsulation Resistance (IR) ValuesHimdad Tahir100% (3)

- earthingFAQ PDFDocumento7 pagineearthingFAQ PDFAsif Ullah KhanNessuna valutazione finora

- Exp. 5-Earth Electrode Resistance Measurement AimDocumento5 pagineExp. 5-Earth Electrode Resistance Measurement Aimrishika chhibberNessuna valutazione finora

- Measurement of FLUKE Insulation Resistance MeggerDocumento22 pagineMeasurement of FLUKE Insulation Resistance MeggerEmmanuel S SombilonNessuna valutazione finora

- IEEE Presentation Sep 11Documento97 pagineIEEE Presentation Sep 11Katamba RogersNessuna valutazione finora

- Ground System TestingDocumento31 pagineGround System TestingJellyn BaseNessuna valutazione finora

- Engineering Encyclopedia: Ground System TestingDocumento31 pagineEngineering Encyclopedia: Ground System TestingAhmed OusamaNessuna valutazione finora

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocumento29 pagineInsulation Resistance (IR) Values - Electrical Notes & ArticlesNikhil Chakravarthy Vatsavayi100% (1)

- Earth Ground Resistance FlukeDocumento29 pagineEarth Ground Resistance FlukeSamyakShahSamyakNessuna valutazione finora

- Megger TestsDocumento14 pagineMegger TestsJoao Silva100% (1)

- Three-And Four-Point Method: Resistance MeasurementsDocumento8 pagineThree-And Four-Point Method: Resistance MeasurementsbcqbaoNessuna valutazione finora

- Ground Testing TechniquesDocumento11 pagineGround Testing TechniquesAlliver SapitulaNessuna valutazione finora

- Cesc HTDocumento4 pagineCesc HTAbhijit Guha RoyNessuna valutazione finora

- Grounding PresentationDocumento29 pagineGrounding Presentationykresna1631Nessuna valutazione finora

- Sardar Patel Institute of Technology: Applied Physics - I Handbook Semester - I ACADEMIC YEAR 2013-2014Documento13 pagineSardar Patel Institute of Technology: Applied Physics - I Handbook Semester - I ACADEMIC YEAR 2013-2014Shoaib ShaikNessuna valutazione finora

- 05 MR H Jaykumar PDFDocumento24 pagine05 MR H Jaykumar PDFRajendra Prasad ShuklaNessuna valutazione finora

- Eps Lab ManualDocumento31 pagineEps Lab Manualpspramila2002Nessuna valutazione finora

- Supriyanto - English VersionDocumento9 pagineSupriyanto - English VersionSupriyantoNessuna valutazione finora

- Measurement of Insulation Resistance IR Part 1Documento5 pagineMeasurement of Insulation Resistance IR Part 1hafizg100% (1)

- LV Dielectric TestingDocumento2 pagineLV Dielectric TestingwaseemsamsodienNessuna valutazione finora

- Earth Impedance TestDocumento2 pagineEarth Impedance TestnitinrajuNessuna valutazione finora

- Sat TR Earth Gen (Rev. 0 2009)Documento3 pagineSat TR Earth Gen (Rev. 0 2009)Abhinav SinhaNessuna valutazione finora

- DCResistivity Measurement PDFDocumento52 pagineDCResistivity Measurement PDFHaritsari DewiNessuna valutazione finora

- Earthing and TestingDocumento5 pagineEarthing and TestingdestawNessuna valutazione finora

- DT-5300 ManualDocumento20 pagineDT-5300 Manualleo_j9Nessuna valutazione finora

- Resistiivty Imaging Text PDFDocumento6 pagineResistiivty Imaging Text PDFSayed Jamaluddin HematNessuna valutazione finora

- Comment Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocumento41 pagineComment Insulation Resistance (IR) Values - Electrical Notes & ArticlesMunazar HussainNessuna valutazione finora

- Measurement of ResistanceDocumento2 pagineMeasurement of ResistanceSEC ExamcellNessuna valutazione finora

- Earthing (Check-1) PDFDocumento4 pagineEarthing (Check-1) PDFZin BoNessuna valutazione finora

- A Measurement System For Very Fast Transients in GIS Power SubstationsDocumento4 pagineA Measurement System For Very Fast Transients in GIS Power SubstationsRommel DestacamentoNessuna valutazione finora

- Experiment No.:-1: AIM:-To Measure Output Voltage W.R.T The Displacement of The Core On The LVDT Kit andDocumento29 pagineExperiment No.:-1: AIM:-To Measure Output Voltage W.R.T The Displacement of The Core On The LVDT Kit andSanjeev kumarNessuna valutazione finora

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocumento28 pagineInsulation Resistance (IR) Values - Electrical Notes & ArticlesjengandxbNessuna valutazione finora

- EPR ZoneDocumento5 pagineEPR ZonedgrsriNessuna valutazione finora

- Large Earthing TestDocumento7 pagineLarge Earthing TestsaravanakumartbNessuna valutazione finora

- The Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDocumento10 pagineThe Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDaily FunNessuna valutazione finora

- Class What?: Clause 2.3.3.1 - Earth ContinuityDocumento5 pagineClass What?: Clause 2.3.3.1 - Earth ContinuityfuckyasNessuna valutazione finora

- Earth Electrode and Loop Booklet V2 PDFDocumento40 pagineEarth Electrode and Loop Booklet V2 PDFIqbal UsmaniNessuna valutazione finora

- Insulation Resistance NotesDocumento27 pagineInsulation Resistance NotessdvijayNessuna valutazione finora

- Pamphlet - Measurement & Application of Earth Fault Loop ImpedanceDocumento6 paginePamphlet - Measurement & Application of Earth Fault Loop ImpedanceassefaNessuna valutazione finora

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocumento31 pagineInsulation Resistance (IR) Values - Electrical Notes & ArticlesKush SharmaNessuna valutazione finora

- FET+BJT Terminal Characteristics Measurement (3) - Lab Report - ECN-242Documento5 pagineFET+BJT Terminal Characteristics Measurement (3) - Lab Report - ECN-242Ajinkya YawalkarNessuna valutazione finora

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocumento13 pagineInsulation Resistance (IR) Values - Electrical Notes & ArticlesSharath Teja ReddyNessuna valutazione finora

- Employability Skills: Brush up Your ElectronicsDa EverandEmployability Skills: Brush up Your ElectronicsNessuna valutazione finora

- Scan 64 1Documento1 paginaScan 64 1Vp SreejithNessuna valutazione finora

- Apar Industries LTD: S-4 T: LexcablesDocumento1 paginaApar Industries LTD: S-4 T: LexcablesVp SreejithNessuna valutazione finora

- Maintenance ScheduleDocumento3 pagineMaintenance ScheduleVp SreejithNessuna valutazione finora

- Comparison of ACSR Wolf and AAAC AL7 Dog ConductorDocumento1 paginaComparison of ACSR Wolf and AAAC AL7 Dog ConductorVp SreejithNessuna valutazione finora

- Scan 64 2Documento1 paginaScan 64 2Vp SreejithNessuna valutazione finora

- ABCDocumento44 pagineABCVp SreejithNessuna valutazione finora

- Wbsetcl Sop Final Report212Documento163 pagineWbsetcl Sop Final Report212Vp SreejithNessuna valutazione finora

- AR Porta CabinDocumento2 pagineAR Porta CabinVp SreejithNessuna valutazione finora

- 30A IEC60309 Serie II (EN)Documento24 pagine30A IEC60309 Serie II (EN)Vp SreejithNessuna valutazione finora

- Gujarat Energy Transmission Corporation Limited Safety ManualDocumento82 pagineGujarat Energy Transmission Corporation Limited Safety ManualPiyush BorkarNessuna valutazione finora

- 228 2973 18Documento1 pagina228 2973 18Vp SreejithNessuna valutazione finora

- 78 2602 18Documento1 pagina78 2602 18Vp SreejithNessuna valutazione finora

- Volume 4 Municipal Electric Works SSR2012Documento122 pagineVolume 4 Municipal Electric Works SSR2012Vp SreejithNessuna valutazione finora

- 2690EDocumento23 pagine2690EVp SreejithNessuna valutazione finora

- 440 V Apfc PanelDocumento3 pagine440 V Apfc Paneljoydeep_d3232Nessuna valutazione finora

- Ta Rates KseblDocumento2 pagineTa Rates KseblVp SreejithNessuna valutazione finora

- 4 Electric Lighting Design TechniquesDocumento34 pagine4 Electric Lighting Design TechniquesWaleed Mohammed Fekry100% (1)

- Faq PDFDocumento33 pagineFaq PDFVp SreejithNessuna valutazione finora

- Ex Equipment GuideDocumento4 pagineEx Equipment GuideRoadieNessuna valutazione finora

- LT APFC Manual PDFDocumento0 pagineLT APFC Manual PDFVp SreejithNessuna valutazione finora

- Marine Electrical SystemsDocumento4 pagineMarine Electrical SystemsMike SteeleNessuna valutazione finora

- NEMA Enclosure Types 11-05-2Documento9 pagineNEMA Enclosure Types 11-05-2Duron SaavedraNessuna valutazione finora

- Kora 3T 09Documento1 paginaKora 3T 09Vаleriy шефNessuna valutazione finora

- Group 4 - Cadbury - Final ProjectDocumento11 pagineGroup 4 - Cadbury - Final ProjectPravalika ReddyNessuna valutazione finora

- Separating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationDocumento4 pagineSeparating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationAndrea SobredillaNessuna valutazione finora

- Rubric On Baking CakesDocumento3 pagineRubric On Baking CakesshraddhaNessuna valutazione finora

- Types of Shops Shopping: 1. Chemist's 2. Grocer's 3. Butcher's 4. Baker'sDocumento1 paginaTypes of Shops Shopping: 1. Chemist's 2. Grocer's 3. Butcher's 4. Baker'sMonik IonelaNessuna valutazione finora

- Handover Paper Final 22 3 16 BJNDocumento13 pagineHandover Paper Final 22 3 16 BJNsisaraaah12Nessuna valutazione finora

- 2.2 WaterDocumento32 pagine2.2 WaterHelena GlanvilleNessuna valutazione finora

- All About Ocean Life-Rachel BladonDocumento6 pagineAll About Ocean Life-Rachel BladonRichard TekulaNessuna valutazione finora

- 6L45, 6L50, 6L80, 6L90: Time Tested - Industry TrustedDocumento1 pagina6L45, 6L50, 6L80, 6L90: Time Tested - Industry TrustedCelso BidinotiNessuna valutazione finora

- International Trade Law: AssignmentDocumento2 pagineInternational Trade Law: AssignmentQuỳnh PhạmmNessuna valutazione finora

- 8DJ - 8DH Katalog en PDFDocumento32 pagine8DJ - 8DH Katalog en PDFJosue Espinoza YachachinNessuna valutazione finora

- Solved Rail Chapter 1Documento7 pagineSolved Rail Chapter 1spectrum_48Nessuna valutazione finora

- Banco de Oro (Bdo) : Corporate ProfileDocumento1 paginaBanco de Oro (Bdo) : Corporate ProfileGwen CaldonaNessuna valutazione finora

- MCQDocumento5 pagineMCQJagdishVankar100% (1)

- 2006 SM600Documento2 pagine2006 SM600Ioryogi KunNessuna valutazione finora

- Resectoscopio 8677 Richard WolfDocumento25 pagineResectoscopio 8677 Richard WolfManuel FloresNessuna valutazione finora

- Nuclear Over Hauser Enhancement (NOE)Documento18 pagineNuclear Over Hauser Enhancement (NOE)Fatima AhmedNessuna valutazione finora

- Sacrament ChartDocumento3 pagineSacrament ChartXam PerezNessuna valutazione finora

- Yume Beauty Price ListDocumento1 paginaYume Beauty Price ListjessicaelaNessuna valutazione finora

- Types of Business OwnershipDocumento2 pagineTypes of Business Ownershipprelovedseller bnNessuna valutazione finora

- X FEDEX EIDocumento13 pagineX FEDEX EINISREEN WAYANessuna valutazione finora

- IGACOS Marine Sanctuary Park and ResortDocumento74 pagineIGACOS Marine Sanctuary Park and ResortPlusNessuna valutazione finora

- JEE Mains 2024 Question Paper Shift 2 27 JanDocumento4 pagineJEE Mains 2024 Question Paper Shift 2 27 JanAnjali SahooNessuna valutazione finora

- NOTIFIER ERCES-Bi-Directional Amplifier Systems (BDA) Webinar 6-4-2019Documento50 pagineNOTIFIER ERCES-Bi-Directional Amplifier Systems (BDA) Webinar 6-4-2019culeros1Nessuna valutazione finora

- BS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctDocumento60 pagineBS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctRamiAl-fuqahaNessuna valutazione finora

- Atomic Structure Worksheet: Name PeriodDocumento4 pagineAtomic Structure Worksheet: Name Periodapi-496534295100% (1)

- The D - Block ElementsDocumento30 pagineThe D - Block ElementsNandya AristaNessuna valutazione finora

- Radfet DatasheetDocumento6 pagineRadfet DatasheetNicholas EspinozaNessuna valutazione finora

- 3926 An Premium DxiDocumento400 pagine3926 An Premium DxiMartin Bugár100% (2)

- Neurology and Special Senses: High-Yield SystemsDocumento72 pagineNeurology and Special Senses: High-Yield SystemsMahmoud Abu MayalehNessuna valutazione finora