Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E Dies Astm d5963 Cuttingdies

Caricato da

Nate MercerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

E Dies Astm d5963 Cuttingdies

Caricato da

Nate MercerCopyright:

Formati disponibili

BACK REQUEST FOR QUOTATION (RFQ) REQUEST FOR INFORMATION (RFI) ADOBE ® DOWNLOAD HOME

CCSi Ultra-Life Specimen Cutting Dies: ASTM D5963

CCSi manufactures this high quality Specimen Cutting Die for

evaluating resistance to abrasion of rubber materials through the

measure of volumetric loss of a specimen exposed to the action

of a normalized abrasive medium secured to a rotating cylinder,

as described in ASTM D5963 ‘Standard Test Method for Rubber

Property-Abrasion Resistance (Rotary Drum Abrader)’.

The rotary drum type abrader is commonly referred to as the

“DIN Abrader” as it complies with DIN 53516 “Testing of rubber

and elastomers; determination of abrasion resistance.” These

two test methods are technically identical, and may be used

interchangeably.

Ultra-Life D5963 Rotating Die

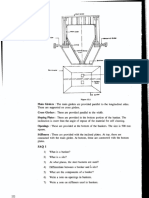

The test methods require a cylindrical specimen, having a diameter of 16 ± 0.2 mm (0.630 ± 0.008

in.) and a minimum thickness of 6 mm (0.24 in.) be prepared by a hollow drill (circular cutting

tool) of the design shown above. The rotational frequency of the drill should be approximately

2.65 rad/s (1000 rpm) for specimens having a durometer hardness of D2240 Type A 50+, higher for

softer materials.

CCSi features the Gibitre™ DIN Abrader and the Hung Ta™ DIN Abrader, both of which are suitable

for this application and comply with the requirements of both the ASTM and DIN standards.

CCSi Ultra-Life Specimen Dies: Quality Manufacturing

CCSi Ultra-Life specimen cutting dies are manufactured from homogenous, solid, high carbon

content A2 tool steel. Each undergoes multi-axis precision grinding and conventional, plunge, or

wire EDM (Electrical Discharge Machining) processes ... producing a world-class, close tolerance die.

Precision grinding and EDM processes ensure true parallelism and multi-plane dimensional accuracy.

The quality of materials, design, and engineering serve to provide the highest specimen quality

possible, over an extended service life.

Where highly technical manufacturing techniques and processes end ... old-world craftsmanship

begins!

CCSi Ultra-Life specimen cutting dies are individually serialized, hand-honed, and mirror polished. A

protective coating of industrial enamel is applied to the non-cutting surfaces before undergoing a

rigorous final inspection.

Each Ultra-Life specimen cutting die includes a detailed final report and certification to the

applicable standard, traceable to NIST, and compliant with ISO 9001:2000 and ISO/IEC 17025. The

specimen dies are placed in a plastic, blow-molded, ‘clam shell’ style case with a foam lining to

protect the die during transport and storage.

CCSi Ultra-Life Specimen Dies: Features

The CCSi Specimen Cutting Dies Feature:

z Exclusive Ultra-Life cutting edge technology;

z Designed with advanced 3D solid modeling;

z High carbon content A2 tool steel;

z Manufactured using computerized systems and techniques;

z EDM (Electrical Discharge Machining);

z CNC (Computer Numerical Control) 4 axis machining;

z Precision ground;

z Expertly honed;

z Finely polished;

z Protective industrial enamel coating;

z Plastic, foam lined, protective case;

z Traceability of dimensional measurement to NIST;

z Certification to ASTM D5963;

z Compliance with ISO 9001:2000 and ISO/IEC 17025.

Available in:

z ASTM D5963 Hollow Drill configuration.

CCSi Ultra-Life ASTM D5963 Specimen Cutting Dies: Specifications & Pricing

Part Number Description Dimensions

Ø 16 ± 0.2 mm x 6 mm

CCSi-D5963-Hd D5963 Hollow Drill Configuration

(Ø 0.630 ± 0.008 x 0.24 in.)

Please Request a Quotation for current pricing and delivery.

Copyright © 2006 CCSi, Inc. • All Rights Reserved • Published February, 2006

Corporate Consulting, Service & Instruments, Incorporated

221 Beaver Street • Akron, Ohio 44304 USA

Telephone: 800.742.8535 / 330.376.3600 • Facsimile: 800.229.9329 / 330.376.8500

• WWW.CCSI-INC.COM • WWW.ORECOZONE.NET •

Potrebbero piacerti anche

- Norlok Introduction To ClinchingDocumento33 pagineNorlok Introduction To ClinchingViraj NemaneNessuna valutazione finora

- Harvest Moon - Friend's of Mineral TownDocumento63 pagineHarvest Moon - Friend's of Mineral TownNate Mercer100% (1)

- DR KAISER Grinding WheelsDocumento20 pagineDR KAISER Grinding Wheelsnestor333Nessuna valutazione finora

- SB Drill Collar PDFDocumento51 pagineSB Drill Collar PDFSiva GanaNessuna valutazione finora

- Recipes From The Perfect Scoop by David LebovitzDocumento10 pagineRecipes From The Perfect Scoop by David LebovitzThe Recipe Club100% (7)

- Gamak MotorDocumento34 pagineGamak MotorCengiz Sezer100% (1)

- Gravity Die CastingDocumento30 pagineGravity Die Castingwebmash100% (2)

- Diamond and CBN English 07Documento26 pagineDiamond and CBN English 07Vk PrabakranNessuna valutazione finora

- C955 09Documento4 pagineC955 09jacr27Nessuna valutazione finora

- Durometers TypesDocumento2 pagineDurometers Typesadrianrdeitos100% (1)

- Biophoton RevolutionDocumento3 pagineBiophoton RevolutionVyavasayaha Anita BusicNessuna valutazione finora

- Stepan Formulation 926Documento2 pagineStepan Formulation 926Moaz SiddigNessuna valutazione finora

- Implicit Explicit SignalsDocumento8 pagineImplicit Explicit SignalsVersoza Nel100% (2)

- Honeycomb Kevlar 49 (Hexcel)Documento3 pagineHoneycomb Kevlar 49 (Hexcel)Julia GarciaNessuna valutazione finora

- Turning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelDa EverandTurning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelValutazione: 4.5 su 5 stelle4.5/5 (3)

- Data Sheet 15379Documento1 paginaData Sheet 15379Nur Rahim BimaNessuna valutazione finora

- JC Series Jaw Crusher PDFDocumento8 pagineJC Series Jaw Crusher PDFgarrybieber100% (1)

- Hydro-Catalogue-08 09 2020Documento74 pagineHydro-Catalogue-08 09 2020Prince MiwaNessuna valutazione finora

- P Compression Astm d395 BfixtureDocumento1 paginaP Compression Astm d395 BfixtureHossam SallamNessuna valutazione finora

- CDP 6503Documento2 pagineCDP 6503GiovanniNessuna valutazione finora

- CDP 4666 Wearplates Castodur Diamond PlatesDocumento2 pagineCDP 4666 Wearplates Castodur Diamond PlatesFrederico MeirelesNessuna valutazione finora

- Technical Data Sheet (ABS) - SmithsDocumento1 paginaTechnical Data Sheet (ABS) - SmithsKelvin Tai Wei LimNessuna valutazione finora

- DR-KAISER - Hybrid Grinding Wheels Ex Stock ENDocumento4 pagineDR-KAISER - Hybrid Grinding Wheels Ex Stock ENamisculeseiliviuNessuna valutazione finora

- Thermoplastic Elastomers - Tension'.: ASTM D412Documento2 pagineThermoplastic Elastomers - Tension'.: ASTM D412techzonesNessuna valutazione finora

- Cross-Cut Tester: Dual Metal Shim Assembly ModelDocumento3 pagineCross-Cut Tester: Dual Metal Shim Assembly ModelCad AutocadNessuna valutazione finora

- 17 262 Specimen Blanking Machines For Specimen Preparation of Metals PI enDocumento5 pagine17 262 Specimen Blanking Machines For Specimen Preparation of Metals PI enDanan GentleNessuna valutazione finora

- BA5139 Bellows PDFDocumento1 paginaBA5139 Bellows PDFMuhammad ZuhairizNessuna valutazione finora

- BS1400 AB2: Technical DatasheetDocumento1 paginaBS1400 AB2: Technical DatasheetBhargav PatelNessuna valutazione finora

- CMP Flat BandDocumento2 pagineCMP Flat BandJustin HowdyNessuna valutazione finora

- 17tooling by Design - Definning Acceptable Burr HeightDocumento3 pagine17tooling by Design - Definning Acceptable Burr HeightSIMONENessuna valutazione finora

- Cssbi B13-19Documento81 pagineCssbi B13-19Jose L MexiaNessuna valutazione finora

- Arcfix Arc StudDocumento21 pagineArcfix Arc StudKiran Kumar KondapalliNessuna valutazione finora

- TK Materials Australia ProductCatalogue LOCKEDDocumento24 pagineTK Materials Australia ProductCatalogue LOCKEDSugianto BarusNessuna valutazione finora

- Hard Chrome PlatingDocumento1 paginaHard Chrome PlatingKishora BhatNessuna valutazione finora

- Briney Tooling Systems 2012Documento81 pagineBriney Tooling Systems 2012brineytoolingNessuna valutazione finora

- Tricentric BD Series: Triple Offset Butterfly ValvesDocumento20 pagineTricentric BD Series: Triple Offset Butterfly ValvesSrinivasanArumugamvenkatachalamNessuna valutazione finora

- Elastomeric Materials m17Documento5 pagineElastomeric Materials m17Mad WonderNessuna valutazione finora

- Struers - Discos de Corte (Cut - offWheelsBrochureEnglish)Documento4 pagineStruers - Discos de Corte (Cut - offWheelsBrochureEnglish)gerardcalabreseNessuna valutazione finora

- Diamond America Catalog 0221Documento16 pagineDiamond America Catalog 0221panama sunpowerNessuna valutazione finora

- Support Industrial Rack Catalogue PDFDocumento12 pagineSupport Industrial Rack Catalogue PDFbelal545Nessuna valutazione finora

- Brosur MCJDocumento24 pagineBrosur MCJPrinan TonoNessuna valutazione finora

- Gas CylinderDocumento37 pagineGas CylinderAshraf AmalNessuna valutazione finora

- The Determination of In-Place Stiffness by The Dynamic Cone Penetrometer (DCP)Documento7 pagineThe Determination of In-Place Stiffness by The Dynamic Cone Penetrometer (DCP)GogoNessuna valutazione finora

- Casting Material CE3MN SS2507Documento3 pagineCasting Material CE3MN SS2507dkaranthsNessuna valutazione finora

- IC72 Panel Spec Data 1100367 PDFDocumento3 pagineIC72 Panel Spec Data 1100367 PDFNiral PanchalNessuna valutazione finora

- Yp Yp Yp Yp YpDocumento8 pagineYp Yp Yp Yp YpShantaram ZanwarNessuna valutazione finora

- Creusabro MDocumento4 pagineCreusabro MhealgoseNessuna valutazione finora

- Data Sheet PVC FillingDocumento3 pagineData Sheet PVC FillingYe Wunna TunNessuna valutazione finora

- BCP Technical ConstructionDocumento22 pagineBCP Technical ConstructionKarthik KarthikNessuna valutazione finora

- BMD Plug Gauges: Technical GuideDocumento52 pagineBMD Plug Gauges: Technical Guidekunalkp88Nessuna valutazione finora

- Hard Turning, Tool Life, and Surface Quality Manufacturing EngineeringDocumento3 pagineHard Turning, Tool Life, and Surface Quality Manufacturing EngineeringRahul MishraNessuna valutazione finora

- Bs 6004 624 y Twin and Earth PVC CableDocumento3 pagineBs 6004 624 y Twin and Earth PVC CableharmlesdragonNessuna valutazione finora

- Sitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Documento24 pagineSitecollectiondocuments Downloads Global Brochures En-Gb C-2940-131Rudra DasNessuna valutazione finora

- Wear of Coated and Uncoated Carbides in Turning Tool SteelDocumento6 pagineWear of Coated and Uncoated Carbides in Turning Tool Steelking9sunNessuna valutazione finora

- Synergy CatalogueDocumento8 pagineSynergy CatalogueTino JuNessuna valutazione finora

- Mould MaterialsDocumento22 pagineMould MaterialsArun PrasadNessuna valutazione finora

- Lecture 10Documento9 pagineLecture 10Ron JosephNessuna valutazione finora

- Load-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesDocumento4 pagineLoad-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesJesús Luis Arce GuillermoNessuna valutazione finora

- Composition of PCDDocumento3 pagineComposition of PCDHarsha MPNessuna valutazione finora

- 05 50 00csbDocumento9 pagine05 50 00csbJerico NamucoNessuna valutazione finora

- Arc Studwelding SystemsDocumento24 pagineArc Studwelding SystemsTan Chee DingNessuna valutazione finora

- Seco ToolsDocumento24 pagineSeco ToolscortelinirosaNessuna valutazione finora

- Hard Part Turning With CBNDocumento44 pagineHard Part Turning With CBNenamicul50Nessuna valutazione finora

- Standar Keramik DuniaDocumento41 pagineStandar Keramik DuniaYudhi AdiNessuna valutazione finora

- Din RailDocumento4 pagineDin RailraoNessuna valutazione finora

- For Solid Concrete Interlocking Paving UnitsDocumento7 pagineFor Solid Concrete Interlocking Paving UnitsomerNessuna valutazione finora

- Specimen BlankingDocumento3 pagineSpecimen BlankingAguayo JavierNessuna valutazione finora

- Opportunities and Challenges of Profile Extrusion Dies Produced by Additive Manufacturing ProcessesDocumento6 pagineOpportunities and Challenges of Profile Extrusion Dies Produced by Additive Manufacturing ProcessesNate MercerNessuna valutazione finora

- 0309 Altered and en Harmonic ModulationDocumento1 pagina0309 Altered and en Harmonic ModulationNate MercerNessuna valutazione finora

- Treated Coconut Shell Reinforced Unsaturated Polyester CompositesDocumento10 pagineTreated Coconut Shell Reinforced Unsaturated Polyester CompositesNate MercerNessuna valutazione finora

- Soxhlet Extraction Method: EPA 3540CDocumento11 pagineSoxhlet Extraction Method: EPA 3540CNate MercerNessuna valutazione finora

- Conflict of Interest COI Quick Guide and Case StudiesDocumento16 pagineConflict of Interest COI Quick Guide and Case StudiesNate MercerNessuna valutazione finora

- Major Exam # 1Documento4 pagineMajor Exam # 1Nate MercerNessuna valutazione finora

- Goldhofer FTV 850 BrochureDocumento2 pagineGoldhofer FTV 850 BrochureMauroNessuna valutazione finora

- Chapter 7 - Muscular SystemDocumento29 pagineChapter 7 - Muscular SystemlNessuna valutazione finora

- Comparing Exponential NumbersDocumento5 pagineComparing Exponential NumbersMaya RahayuNessuna valutazione finora

- LG250CDocumento2 pagineLG250CCarlosNessuna valutazione finora

- Manual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and ProcessingDocumento1 paginaManual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and Processingdrg gocNessuna valutazione finora

- The Broadband ForumDocumento21 pagineThe Broadband ForumAnouar AleyaNessuna valutazione finora

- 1962 Gibson Johnny SmithDocumento5 pagine1962 Gibson Johnny SmithLuisNessuna valutazione finora

- Main Girders: CrossDocumento3 pagineMain Girders: Crossmn4webNessuna valutazione finora

- Assignment Booklet July 2021Documento22 pagineAssignment Booklet July 2021Saksham TiwariNessuna valutazione finora

- Ficha Tecnica-Skyjack SJ3219 8mtDocumento2 pagineFicha Tecnica-Skyjack SJ3219 8mtLESLY MILENA MORENO CORALNessuna valutazione finora

- Food Taste Panel Evaluation Form 2Documento17 pagineFood Taste Panel Evaluation Form 2Akshat JainNessuna valutazione finora

- Flight Vehicle Design:: Example 2 (Uav)Documento43 pagineFlight Vehicle Design:: Example 2 (Uav)Anmol KumarNessuna valutazione finora

- FemDocumento4 pagineFemAditya SharmaNessuna valutazione finora

- Cost Analysis - Giberson Art GlassDocumento3 pagineCost Analysis - Giberson Art GlassSessy Saly50% (2)

- TNM History Updated June2017Documento2 pagineTNM History Updated June2017Lucas AndreoNessuna valutazione finora

- Douluo Dalu Volume 05 - Star Dou Forest PDFDocumento141 pagineDouluo Dalu Volume 05 - Star Dou Forest PDFRay Joseph LealNessuna valutazione finora

- Shree New Price List 2016-17Documento13 pagineShree New Price List 2016-17ontimeNessuna valutazione finora

- LET General Math ReviewerDocumento7 pagineLET General Math ReviewerMarco Rhonel Eusebio100% (1)

- 18 Ray Optics Revision Notes QuizrrDocumento108 pagine18 Ray Optics Revision Notes Quizrraafaf.sdfddfaNessuna valutazione finora

- NAT-REVIEWER-IN-PHYSICAL EDUCATIONDocumento4 pagineNAT-REVIEWER-IN-PHYSICAL EDUCATIONMira Rochenie CuranNessuna valutazione finora

- PEH Q3 Long QuizDocumento1 paginaPEH Q3 Long QuizBenedict LumagueNessuna valutazione finora

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDocumento8 pagineConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준Nessuna valutazione finora

- Amnaya Sutra (English)Documento458 pagineAmnaya Sutra (English)Assam Bhakti SagarNessuna valutazione finora