Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Datasheet Zincalume G550

Caricato da

adihindTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Datasheet Zincalume G550

Caricato da

adihindCopyright:

Formati disponibili

ZINCALUME® G550 steel

Technical Data Sheet Document No. 008 Revision - 0 April 2015

This literature supersedes all previous issues.

Product Typical Uses

ZINCALUME® G550 steel is a hot-dipped Al-Zn alloy coated Roofing, Cladding, Structural sections

structural steel with a regular spangle surface and guaranteed

Standard*

minimum yield strength of 550 MPa with limited ductility. Suitable

for roll forming to a minimum internal diameter of 4t. AS 1397

*Other standards (e. g. ASTM A 792M, ISO 9364, IS15961, etc.)

and grades on specific agreement

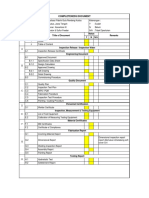

Properties of Steel Base Chemical Composition of Steel Base

Mechanical Properties Guaranteed Minimum Element Guaranteed Max# (%)

Logitudinal Tensile Carbon (C) 0.20

Yield Strength, MPa 550 Manganese (Mn) 1.20

Tensile Strength, MPa 550 Phosphorus (P) 0.04

Elongation on 80 mm, % 2 a

Sulphur (S) 0.03

Hardness, HR30T - # Values shown refer to relevant standard unless specifically agreed to

# Other elements that are not harmful for the application may be present

a) For thickness =/> 0.60 mm

Coating Class Coating Adhesion - 1800 Bend Test

Minimum Coating - Total Both Surfaces, g/m2

Coating Class Guaranteed Minimum

Coating Class Triple Spot Test Single Spot Test

AZ150 150 135 AZ150 / AZ200 2t

AZ200 200 180

Dimension Range & Tolerances (AS/NZS 1365)**

Base Metal Thickness (mm) Width (mm)

Range Tolerance Range Tolerance

Width ≤ 1200 Width > 1200

0.30 - 0.50 ± 0.03 ± 0.04 < 900 (in slit edge) +1 / -0

0.51 - 0.80 ± 0.04 ± 0.05 914 - 1000 +4/-0

0.81 - 1.20 ± 0.05 ± 0.06 1001 - 1250 +5/-0

> 1.20 ± 0.06 ± 0.07

**For requirements beyond the standard product range & tolerance, please contact Tata BlueScope Steel Office

Fire Hazard Properties (AS/NZS 1530.3)

Index Range Rating

Ignitability Index 0-20 0

Spread of Flame Index 0-10 0

Heat Evolved Index 0-10 0

Smoke Developed Index 0-10 0-1

ZINCALUME® G550 steel

Technical Data Sheet Document No. 008 Revision - 0 April 2015

This literature supersedes all previous issues.

Supply Conditions

Supply Condition Normal Optional

Surface Condition Spangled –

Coating Class AZ150i AZ200ii

Surface Treatment Passivated and Resin coated Passivated (for post painting / paint line feed)

Branding Branded Unbranded

Tolerance Class iii

1. Dimensions A Class –

2. Flatness A Class –

i) Metallic coating of minimum 150 g/m2, ii) Metallic coating of minimum 200 g/m2, iii) Dimensional and shape tolerances as per AS/NZS 1365

Fabrication Performance

Method Rating# Method Rating#

Drawing - Lock Forming NR

Pressing - Welding 4

Bending 1 Painting with Pre-treatment 5

Roll-forming 3

# where 1 = limited to 5 = excellent, NR = not recommended

Material should be used promptly (within 6 months) to avoid the possibility of improper storage related corrosion & change in performance due to ageing

Typical Property Ranges (For Normal Supply Product)

Yield Strength (MPa)

Minimum Maximum

0.35 580 710

0.42 570 700

0.60 560 700

1.00 550 670

1.20 550 650

Tensile Strength (MPa)

0.35 600 790

0.42 590 770

0.60 590 760

1.00 580 700

1.20 580 680

Total Elongation on 80mm (%)

0.35 1 3

0.42 1 4

0.60 2 7

1.00 2 8

1.20 4 11

CS/PM/Anvita/4.1/0415

Tata BlueScope Steel Ltd.

Note: CIN : U45209PN2005PLC020270

“©2015 Tata BlueScope Steel Ltd. All rights reserved. This brochure and its content is copyright of Tata BlueScope Steel Ltd. No part of this Regd. Office: The Metropolitan, Final Plot No. 27,

brochure may be reproduced or transmitted in any form or by any means, electronic or mechanical including photocopy, recording, or any Survey No. 21, Wakdewadi, Shivaji Nagar,

information storage and retrieval system, without permission in writing from Tata BlueScope Steel Ltd “ Pune - 411005. INDIA. Tel: +91 20 6621 8000

ZINCALUME® steel is a registered trademark of BlueScope Steel Limited under license to Tata BlueScope Steel Limited. Website: www.tatabluescope-cs.com

Email: coatedsteel@tatabluescopesteel.com

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Deep DrawDocumento4 pagineDeep DrawBalvinder PrajapatiNessuna valutazione finora

- Forging HW at IUTDocumento1 paginaForging HW at IUTNabil Haidar100% (1)

- Zincalume® G550 Technical Datasheet MalaysiaDocumento2 pagineZincalume® G550 Technical Datasheet MalaysiaJeffrey RonquilloNessuna valutazione finora

- Zincalume G550 Steel: Metallic Coated - MC Structural - SDocumento1 paginaZincalume G550 Steel: Metallic Coated - MC Structural - SEwo50 New0% (1)

- Zincalume Ultra Activate Technical Data Sheet Rev2 151221Documento4 pagineZincalume Ultra Activate Technical Data Sheet Rev2 151221Nam Hoàng HảiNessuna valutazione finora

- Zincalume G300 Steel: Metallic Coated - MC Structural - SDocumento2 pagineZincalume G300 Steel: Metallic Coated - MC Structural - SPranatia Wisnu HeryudaNessuna valutazione finora

- ZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCDocumento3 pagineZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCEwo50 NewNessuna valutazione finora

- Colorbond Ultra Datasheet New V8Documento2 pagineColorbond Ultra Datasheet New V8Gireesh Krishna KadimiNessuna valutazione finora

- Zincalume G550 G550S PDFDocumento2 pagineZincalume G550 G550S PDFkartikkeyyanNessuna valutazione finora

- Metal-Coated - Galvsteel: Data SheetDocumento2 pagineMetal-Coated - Galvsteel: Data SheetjcvalenciaNessuna valutazione finora

- Galvaspan G450Documento2 pagineGalvaspan G450khurshedlakhoNessuna valutazione finora

- EI ServicesDocumento2 pagineEI ServicesAnonymous P8Bt46mk5INessuna valutazione finora

- Galvaspan G550Documento2 pagineGalvaspan G550eli abdul rohimNessuna valutazione finora

- GALVSTEEL® G300 SteelDocumento2 pagineGALVSTEEL® G300 SteelTulus Ztx ZaputroNessuna valutazione finora

- Colorbond XRW Datasheet New V8Documento2 pagineColorbond XRW Datasheet New V8Gireesh Krishna KadimiNessuna valutazione finora

- Zinc Hi-Ten g450-450s SteelDocumento2 pagineZinc Hi-Ten g450-450s SteelPurnomo MbangunNessuna valutazione finora

- COLORBOND Spectrum Series Datasheet New V8Documento2 pagineCOLORBOND Spectrum Series Datasheet New V8eng.ahmadrihawiNessuna valutazione finora

- Galvabond G2 G2SDocumento2 pagineGalvabond G2 G2SMichael ChongNessuna valutazione finora

- Zincform G300 G300SDocumento2 pagineZincform G300 G300SBaziNessuna valutazione finora

- Metallic Coated MC Structural S Zincalume G300 Steel G300S SteelDocumento2 pagineMetallic Coated MC Structural S Zincalume G300 Steel G300S SteelEwo50 NewNessuna valutazione finora

- Datasheet BOHLER DCMS-IG TIGDocumento1 paginaDatasheet BOHLER DCMS-IG TIGDaniele DuarteNessuna valutazione finora

- As 3678 Steel Grade 350Documento3 pagineAs 3678 Steel Grade 350gsoaresrj80Nessuna valutazione finora

- Hot-Rolled - Plate: Data SheetDocumento2 pagineHot-Rolled - Plate: Data SheetRichard Vica CalvoNessuna valutazione finora

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocumento3 pagineAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNessuna valutazione finora

- 100crmnsi6-4: Steel GradeDocumento3 pagine100crmnsi6-4: Steel GradeSama UmateNessuna valutazione finora

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocumento3 pagineAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesMellierNessuna valutazione finora

- Cold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesDocumento2 pagineCold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesBaziNessuna valutazione finora

- RC1005F561CSDocumento2 pagineRC1005F561CSDarwin SipayungNessuna valutazione finora

- BOEHLER Q T 309L TIG RodDocumento1 paginaBOEHLER Q T 309L TIG RodbrayanNessuna valutazione finora

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Documento2 pagineAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNessuna valutazione finora

- 20Mncr5: Steel GradeDocumento4 pagine20Mncr5: Steel GradeAhmad ShujaNessuna valutazione finora

- CZLLCW511L TN enDocumento4 pagineCZLLCW511L TN endrgilleNessuna valutazione finora

- 48CrMoNi4 10Documento4 pagine48CrMoNi4 10FernandoiNessuna valutazione finora

- 1.4435 - C Stainless Steel DetailsDocumento3 pagine1.4435 - C Stainless Steel DetailsmeenakshiNessuna valutazione finora

- Böhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Documento1 paginaBöhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Thanh TamNessuna valutazione finora

- TRUECORE® Steel G550 Datasheet Aug 2019Documento2 pagineTRUECORE® Steel G550 Datasheet Aug 2019Julio de Andrade WerkNessuna valutazione finora

- item22-LNT 502Documento1 paginaitem22-LNT 502VVan TanNessuna valutazione finora

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDocumento3 pagineStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulNessuna valutazione finora

- Data Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enDocumento2 pagineData Sheet ASTM A514 Grade B 2017-04-19 221 371857150 enkanteron6443Nessuna valutazione finora

- Pf-Emco#218-63p Rev.bDocumento6 paginePf-Emco#218-63p Rev.bPhung Cam VanNessuna valutazione finora

- SA/AS1548 - 7 - 460R: XlerplateDocumento3 pagineSA/AS1548 - 7 - 460R: XlerplatenavNessuna valutazione finora

- LFBCW510L TN enDocumento4 pagineLFBCW510L TN endrgilleNessuna valutazione finora

- Annealed Engineering Steel C45E / 1042 (ASTMDocumento2 pagineAnnealed Engineering Steel C45E / 1042 (ASTMkazdoelahNessuna valutazione finora

- Cu ZN 10Documento2 pagineCu ZN 10wjjt6chgtmNessuna valutazione finora

- Cu ZN 15Documento2 pagineCu ZN 15wjjt6chgtmNessuna valutazione finora

- TDZ AlloyDocumento1 paginaTDZ AlloyIan MacMoyNessuna valutazione finora

- Specification For Galvanized Steel: Raw Material SpecificationsDocumento2 pagineSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNessuna valutazione finora

- Arosta309H EngDocumento1 paginaArosta309H Engrusf123Nessuna valutazione finora

- Medintech MedintoneDocumento2 pagineMedintech MedintoneJose Luis Cortes CamperoNessuna valutazione finora

- Aero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200Documento2 pagineAero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200erikaNessuna valutazione finora

- 18nicrmo14-6: Steel GradeDocumento4 pagine18nicrmo14-6: Steel Gradesmith willNessuna valutazione finora

- ASTM A514 Grade S: General Product DescriptionDocumento2 pagineASTM A514 Grade S: General Product DescriptionAGUSTINNessuna valutazione finora

- Rod - Union I Crmo 910Documento1 paginaRod - Union I Crmo 910Rushita SolankiNessuna valutazione finora

- Typical Chemical Composition (Weight %)Documento3 pagineTypical Chemical Composition (Weight %)strip1Nessuna valutazione finora

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocumento2 pagineAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamNessuna valutazione finora

- Kme STOL76 C19010 enDocumento1 paginaKme STOL76 C19010 enMattia Terri TerrandoNessuna valutazione finora

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Documento4 pagineSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNessuna valutazione finora

- Quenched and Tempered Alloyed Engineering Steel DINDocumento2 pagineQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNessuna valutazione finora

- LFBCW510L ST enDocumento4 pagineLFBCW510L ST endrgilleNessuna valutazione finora

- Load CombinationDocumento48 pagineLoad CombinationadihindNessuna valutazione finora

- Civil & Structural Department Check Lists - 1Documento15 pagineCivil & Structural Department Check Lists - 1adihindNessuna valutazione finora

- Jb1220 Colum SpliceDocumento3 pagineJb1220 Colum SpliceadihindNessuna valutazione finora

- Calculation For Shear Connection (Shear and Axial) : Inputs in Shaded CellsDocumento3 pagineCalculation For Shear Connection (Shear and Axial) : Inputs in Shaded CellsadihindNessuna valutazione finora

- Support Spring Calculations-11.10.17 For Cooling Tower AreaDocumento12 pagineSupport Spring Calculations-11.10.17 For Cooling Tower AreaadihindNessuna valutazione finora

- Green Atom ScopeDocumento107 pagineGreen Atom ScopeadihindNessuna valutazione finora

- Design of Chequered Plate DesignDocumento2 pagineDesign of Chequered Plate DesignadihindNessuna valutazione finora

- 1267 - JSW - DRg. RELEASED - 18.01.13Documento21 pagine1267 - JSW - DRg. RELEASED - 18.01.13adihindNessuna valutazione finora

- Premium Receipt Parvesh VaishDocumento1 paginaPremium Receipt Parvesh VaishadihindNessuna valutazione finora

- ROLL24Documento1 paginaROLL24adihindNessuna valutazione finora

- Credit Card Charges FormatDocumento2 pagineCredit Card Charges FormatadihindNessuna valutazione finora

- Office of The Cantonment Board CannanoreDocumento1 paginaOffice of The Cantonment Board CannanoreadihindNessuna valutazione finora

- Rolling Load Analysis On Simply Supported Beams Date:18-01-2018Documento1 paginaRolling Load Analysis On Simply Supported Beams Date:18-01-2018adihindNessuna valutazione finora

- Sheet1 A-B Bay CM: Properties of Gantry SectionDocumento2 pagineSheet1 A-B Bay CM: Properties of Gantry SectionadihindNessuna valutazione finora

- Premium Receipt Pawan VaishDocumento1 paginaPremium Receipt Pawan VaishadihindNessuna valutazione finora

- 2518Documento2 pagine2518adihind0% (1)

- Plan View: SL No. Description Qty. MakeDocumento1 paginaPlan View: SL No. Description Qty. MakeadihindNessuna valutazione finora

- Analysis & Design of Tubular Structures: A DissertationDocumento55 pagineAnalysis & Design of Tubular Structures: A DissertationadihindNessuna valutazione finora

- Molding Defects Silver StreaksDocumento1 paginaMolding Defects Silver StreaksDaniel RazlanNessuna valutazione finora

- EBS 315 L2 - Intro Hydrometallurgy (13 Sept 2012)Documento55 pagineEBS 315 L2 - Intro Hydrometallurgy (13 Sept 2012)Amy AckerNessuna valutazione finora

- Record of Welder Performance Qualification: PictureDocumento2 pagineRecord of Welder Performance Qualification: PictureRhannie GarciaNessuna valutazione finora

- Ramos Copper Piping For The Refrigeration System Layout2Documento1 paginaRamos Copper Piping For The Refrigeration System Layout2Piolo Gabrielle RamosNessuna valutazione finora

- Brochure Coating ConstructionDocumento16 pagineBrochure Coating ConstructionALİ ÖRSNessuna valutazione finora

- Unit 2 180322020126Documento81 pagineUnit 2 180322020126TANVEER SINGH SOLANKINessuna valutazione finora

- Shaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and ApplicationDocumento13 pagineShaper Machine: Definition, Working, Types, Operations, Specification, Advantages, Disadvantages, and ApplicationDr Chhabi Ram MatawaleNessuna valutazione finora

- Rotary Drilling ProductsDocumento27 pagineRotary Drilling Productsabbas ansariNessuna valutazione finora

- ASTM A194-A194M 2010 (Carbon and Alloy Steek Nuts For Bolts)Documento11 pagineASTM A194-A194M 2010 (Carbon and Alloy Steek Nuts For Bolts)Acricia PereiraNessuna valutazione finora

- Nori and LeetsDocumento1 paginaNori and LeetspbarsingNessuna valutazione finora

- Casting notes-EME-1Documento23 pagineCasting notes-EME-1AndrewNessuna valutazione finora

- ACCT ITM 6 SheetMetalCuttingToolsPowerPointDocumento11 pagineACCT ITM 6 SheetMetalCuttingToolsPowerPointZwingCAD AcademyNessuna valutazione finora

- Contoh Jadwal MaterialDocumento1 paginaContoh Jadwal MaterialRamanda SetiawanNessuna valutazione finora

- Intercryl 520Documento4 pagineIntercryl 520Doby YuniardiNessuna valutazione finora

- Refining ProcessDocumento22 pagineRefining Processramadoss_alwar7307Nessuna valutazione finora

- FINAL GRP Catalogue Feb2024 v3Documento70 pagineFINAL GRP Catalogue Feb2024 v3Riki AngganaNessuna valutazione finora

- Welding Defects and DiscontinuitiesDocumento103 pagineWelding Defects and DiscontinuitiesHR TusherNessuna valutazione finora

- Glossary of Corrosion & Metallurgy Terminology: J W MartinDocumento7 pagineGlossary of Corrosion & Metallurgy Terminology: J W MartinSlim.BNessuna valutazione finora

- Review Dokumen PG. RendengDocumento10 pagineReview Dokumen PG. RendengFarhan PutraNessuna valutazione finora

- 107 Weldox 700 Uk Data SheetDocumento2 pagine107 Weldox 700 Uk Data Sheetleonardo_sarria_1Nessuna valutazione finora

- 117BP - CNC Technologies PDFDocumento8 pagine117BP - CNC Technologies PDFvenkiscribd444Nessuna valutazione finora

- Welding Workshop ManualDocumento16 pagineWelding Workshop ManualMuhammad FarooqNessuna valutazione finora

- Technical Terms in WeldingDocumento14 pagineTechnical Terms in WeldingEgghead YTCNessuna valutazione finora

- Galvanised Steel: From Ancient Alchemy To The Infrastructure of The FutureDocumento5 pagineGalvanised Steel: From Ancient Alchemy To The Infrastructure of The FuturekhurshedlakhoNessuna valutazione finora

- CHE112P Lecture Recycle - BypassDocumento22 pagineCHE112P Lecture Recycle - BypassYzeNessuna valutazione finora

- Chemiguard Epoxy 1905 Topcoat HBDocumento3 pagineChemiguard Epoxy 1905 Topcoat HBeromax10% (1)

- DB Injection Moulding1Documento155 pagineDB Injection Moulding1bramhananda ukeyNessuna valutazione finora

- Alccofast (CE)Documento2 pagineAlccofast (CE)Siddhesh Kamat MhamaiNessuna valutazione finora