Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

QSK60G Temp Control Guidelines

Caricato da

Muhammad IshfaqCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

QSK60G Temp Control Guidelines

Caricato da

Muhammad IshfaqCopyright:

Formati disponibili

Service/Parts Date: Application:

11.06.2007 Generator Unit

Topics

No: Fuel Type: File Group

ESB-SPB 21 Natural Gas 08

CUMMINS CONFIDENTIAL

ESB Internal Circulation, Approved Distributors and Partners Only

Author: D. McNeil

Subject: Operation Guidelines for Temperature Control of the Low

Temperature (LT) and High Temperature (HT) Cooling Systems

Publications Affected by This Service/Parts Topic

Engine Operation and Troubleshooting Shop Other

Maintenance and Repair

NOTE: Publications identified as Other include the following: ¹Parts

Catalogue, ²Wiring Diagram.

Warranty Impact

None

The purpose of this Service / Parts Topic is to provide a guide for the

operation of the QSK60G Natural Gas fuelled Genset with regard to

temperature control of the Low Temperature (LT) and High Temperature (HT)

cooling systems.

Cummins Inc. Box 3005, Columbus, Indiana 47202-3005

Cummins Engine Co. Ltd., Daventry, Northants, England, NN11 8NU

Registered Office: Unit 1-B Uniongate, Ridgeway Trading Estate, Iver, Buckinghamshire SL0 9HX, England

Registered No. 573951 England

Copyright © 2006 Cummins Inc.

All rights reserved Page 1 of 4

Service/Parts Date: Application:

11.06.2007 Generator Unit

Topics

No: Fuel Type: File Group

ESB-SPB 21 Natural Gas 08

LT Coolant Circuit

The LT circuit is pumped through the second-stage section of the Charge Air Cooler

and is temperature modulated by a single thermostat at the outlet of the cooler. Off-

engine cooling should be sized and controlled to provide stable coolant return

temperature within a range suitable for maintaining the desired operating

temperatures listed in this document.

Operating Parameters

The normal operating range for LT coolant temperature can be obtained from Table

1; values should be selected on the LT circuit specification:

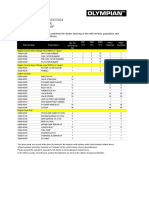

Table 1

LT Inlet Intake Manifold

Temperature Temperature

LT Circuit °C °C

Specification Minimum Maximum Minimum Maximum

3332156 ’40 C’ 32 38 38 44

4085995 ’50 C’ 42 48 48 54

Note: The Intake Manifold Temperature is dependant on achieving an LT Inlet

temperature within the specified range. The range above represents the

upper 50% of the thermostat operation range.

Additional control and/or tuning of the heat rejection system may be required

to achieve the correct operating range.

Values stated in the table are as read from the engine sensors and displayed

on the Genset HMI. LT temperature shown on the HMI is Inlet temperature.

Condition Monitoring LT System

Data from the engine sensors can be collected to monitor the effectiveness of the

Charge Air Cooler in transferring heat from the Charge-air side to the Coolant side.

A reduction in cooling efficiency can indicate a problem in the Coolant side cooling

passages or a problem with the fins on the Air side, or a low coolant flow rate.

Data Presentation & Calculation LT System:

The data can be collected manually direct from the HMI screen or through the

Cummins Service Tools INSITE & Quest for Gas.

The data should be presented in a columnar form, as Table 2 below, to allow easy

visual tracking over time:

Cummins Inc. Box 3005, Columbus, Indiana 47202-3005

Cummins Engine Co. Ltd., Daventry, Northants, England, NN11 8NU

Registered Office: Unit 1-B Uniongate, Ridgeway Trading Estate, Iver, Buckinghamshire SL0 9HX, England

Registered No. 573951 England

Copyright © 2006 Cummins Inc.

All rights reserved Page 2 of 4

Service/Parts Date: Application:

11.06.2007 Generator Unit

Topics

No: Fuel Type: File Group

ESB-SPB 21 Natural Gas 08

Table 2

Set ID

Date

Engine Hours

LT Coolant Inlet Temperature – A

(°C)

Intake Manifold Temperature - B

(°C)

Kilowatt Load (kW)

Temperature Delta ( B – A )

(°C)

Notes:

Data must be taken at the same load each time for representative values to

be collected.

Temperature Delta Data Interpretation at or Near Full Load:

Temperature Delta Condition

Value

< 6°C Correctly Operating Charge Cooling

6°C to 10°C Charge Cooling Efficiency Reduced

> 10°C Urgent Investigation Required

HT Coolant Circuit

The HT circuit is pumped through the Oil coolers and first-stage charge air cooler in

parallel; then all flow passes through the cylinder block and heads. Outlet from the

engine is modulated by 6 thermostats. Off-engine cooling should be sized and

controlled to provide stable coolant return temperature within a range suitable for

maintaining the desired operating temperatures listed in this document.

Operating Parameters

The normal operating range for HT temperature can be obtained from Table 3;

values should be selected on the HT circuit specification:

Cummins Inc. Box 3005, Columbus, Indiana 47202-3005

Cummins Engine Co. Ltd., Daventry, Northants, England, NN11 8NU

Registered Office: Unit 1-B Uniongate, Ridgeway Trading Estate, Iver, Buckinghamshire SL0 9HX, England

Registered No. 573951 England

Copyright © 2006 Cummins Inc.

All rights reserved Page 3 of 4

Service/Parts Date: Application:

11.06.2007 Generator Unit

Topics

No: Fuel Type: File Group

ESB-SPB 21 Natural Gas 08

Table 3

HT Out

Temperature

HT Circuit °C

Specification Minimum Maximum

135675 ’90C’ 84 90

3629205 ’95C’ 89 95

Note: The range above represents the upper 50% of the thermostat operation

range.

Additional control and/or tuning of the heat rejection system may be required

to achieve the correct operating range.

Values stated in the table are as read from the engine sensors and displayed

on the Genset HMI. HT temperature displayed on the HMI is Outlet

temperature.

Cummins Inc. Box 3005, Columbus, Indiana 47202-3005

Cummins Engine Co. Ltd., Daventry, Northants, England, NN11 8NU

Registered Office: Unit 1-B Uniongate, Ridgeway Trading Estate, Iver, Buckinghamshire SL0 9HX, England

Registered No. 573951 England

Copyright © 2006 Cummins Inc.

All rights reserved Page 4 of 4

Potrebbero piacerti anche

- Hyundai D6GA Engine Mechanical System PDFDocumento97 pagineHyundai D6GA Engine Mechanical System PDFbrayandparavicinoNessuna valutazione finora

- 005-012 Fuel Injection Pumps, In-Line: InstallDocumento14 pagine005-012 Fuel Injection Pumps, In-Line: InstallMuhammad Ishfaq100% (3)

- Contactors ENTRELEC PDFDocumento111 pagineContactors ENTRELEC PDFembasianNessuna valutazione finora

- Adzer CZDeutz F2 L912Documento82 pagineAdzer CZDeutz F2 L912Alex Robledo OlarteNessuna valutazione finora

- Preservation and Represervation PDFDocumento51 paginePreservation and Represervation PDFAnonymous gr5Pr9AVNessuna valutazione finora

- Machine Profiles: 789, 789B and 789C Construction and Mining TrucksDocumento8 pagineMachine Profiles: 789, 789B and 789C Construction and Mining TrucksJavier Pagan TorresNessuna valutazione finora

- EK 99-00 Wire Harness Instructions 4.0Documento29 pagineEK 99-00 Wire Harness Instructions 4.0Hybrid Racing100% (4)

- Commander III Chapter Viii TroubleshootingDocumento78 pagineCommander III Chapter Viii TroubleshootingFilippos100% (4)

- Cummins HDKBB Parts ManualDocumento80 pagineCummins HDKBB Parts ManualBojan KitanovskiNessuna valutazione finora

- 2007-2010 Outlander Renegade PDFDocumento646 pagine2007-2010 Outlander Renegade PDFDiego Garagem P7Nessuna valutazione finora

- QSK60 Over Head Valve Setting PerformaDocumento2 pagineQSK60 Over Head Valve Setting PerformaMuhammad Ishfaq100% (1)

- 125 and 160kva Material Cost For 3 YearDocumento1 pagina125 and 160kva Material Cost For 3 Yearnirav patelNessuna valutazione finora

- S6R2MPTKDocumento3 pagineS6R2MPTKvikas_ojha54706100% (4)

- P625E3 Manual de Partes Perkins 2500Documento612 pagineP625E3 Manual de Partes Perkins 2500Jonathan Bareño75% (8)

- Mtu 12v4000 Spec Sheet PDFDocumento6 pagineMtu 12v4000 Spec Sheet PDFSomadbsiNessuna valutazione finora

- TR100 Cu 7831 IPC Aug 2015 15504394Documento600 pagineTR100 Cu 7831 IPC Aug 2015 15504394Ricardo GarciaNessuna valutazione finora

- Mtu - Technical Documentation: ServiceDocumento7 pagineMtu - Technical Documentation: Servicekarbaran1391Nessuna valutazione finora

- Daihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Cooling System PDFDocumento19 pagineDaihatsu Type K3 Engine Service Manual No.9737 No.9332 No. 9237 Cooling System PDFMozes SimataaNessuna valutazione finora

- Saa6d170e-3 Engine PDFDocumento90 pagineSaa6d170e-3 Engine PDFamin100% (3)

- Catalogue Cummins 6BTAA5.9 G2 163kVADocumento4 pagineCatalogue Cummins 6BTAA5.9 G2 163kVATarek Farouk100% (1)

- Q - Pump Injection N NDocumento2 pagineQ - Pump Injection N NIK33% (3)

- KTA50 G12 G14 Parts CatalogDocumento161 pagineKTA50 G12 G14 Parts CatalogPedro Jim Farley Guedes Mesquita100% (1)

- Hd465-7eo SM Sen01081-08 PDFDocumento1.613 pagineHd465-7eo SM Sen01081-08 PDFJorge Rodolfo Yanez EscuderoNessuna valutazione finora

- Marine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIDocumento3 pagineMarine SiteContent en Binary Asset Attachments Products CCEC N855 CCEC Performance Curves FR11169 NT855 325 1800 IMOIIOscar Eduardo Parra GuerreroNessuna valutazione finora

- Engine 2.0D-VGT (Chevrolet Captiva '06-'10) Service IntroDocumento61 pagineEngine 2.0D-VGT (Chevrolet Captiva '06-'10) Service IntroDangLuyen100% (2)

- Hummer H2 2004 Cooling System Mechanical/electricalDocumento140 pagineHummer H2 2004 Cooling System Mechanical/electricalHendrik CastensNessuna valutazione finora

- Farm RecordsDocumento22 pagineFarm RecordsMuhammad IshfaqNessuna valutazione finora

- Mt4400ac PDFDocumento4 pagineMt4400ac PDFabpr2008Nessuna valutazione finora

- PL Ese560 - Vw-AsDocumento10 paginePL Ese560 - Vw-AsDaniel MuratallaNessuna valutazione finora

- QSK60 Maintenance ScheduleDocumento11 pagineQSK60 Maintenance ScheduleMuhammad Ishfaq100% (4)

- Cat 3516Documento4 pagineCat 3516Muhammad IshfaqNessuna valutazione finora

- Ssp431 Audi Rs 6Documento44 pagineSsp431 Audi Rs 6gil_cs100% (1)

- MTU Gendrive S4000 NOMENCLATURE PDFDocumento9 pagineMTU Gendrive S4000 NOMENCLATURE PDFmohsen_cumminsNessuna valutazione finora

- SI Engines & Its MaintenanceDocumento42 pagineSI Engines & Its MaintenanceMuhammad FawadNessuna valutazione finora

- EasyLogic RangeDocumento2 pagineEasyLogic RangeJuan MoralesNessuna valutazione finora

- Q-Block DoneDocumento4 pagineQ-Block DoneIKNessuna valutazione finora

- MEO Class 1 ProjectDocumento2 pagineMEO Class 1 ProjectAshish Ranjan0% (1)

- Part ManualDocumento89 paginePart ManualThe Dat100% (1)

- Fuel Consumption CalculationDocumento4 pagineFuel Consumption CalculationTariqMaqsoodNessuna valutazione finora

- Cummins QSK60 Engine Spare Parts CatalogDocumento22 pagineCummins QSK60 Engine Spare Parts CatalogMamadou lyNessuna valutazione finora

- Module 4 - Ignition Systems - QSK60GDocumento18 pagineModule 4 - Ignition Systems - QSK60GMuhammad Ishfaq100% (1)

- S 1647Documento11 pagineS 1647Donald Santana BautistaNessuna valutazione finora

- KPC Master Catalog Parts v1!08!27 12Documento77 pagineKPC Master Catalog Parts v1!08!27 12nachoNessuna valutazione finora

- стр 73-76 A001064 - 09EDocumento127 pagineстр 73-76 A001064 - 09EKyrylo TerokhinNessuna valutazione finora

- Technical Data: 400 Series 404D-22GDocumento6 pagineTechnical Data: 400 Series 404D-22Grofaria100100% (1)

- Assembly Section: Mast - Contact Combilift Quoting The Truck Serial Number For Mast Parts ManualDocumento145 pagineAssembly Section: Mast - Contact Combilift Quoting The Truck Serial Number For Mast Parts ManualJulianNessuna valutazione finora

- Section 9 Information PartsDocumento14 pagineSection 9 Information PartsNikkikumar Maisuriya100% (1)

- QSK60 Starting SystemDocumento4 pagineQSK60 Starting SystemagvassNessuna valutazione finora

- QSV Oil Analysis Guidelines, Rev. 02Documento7 pagineQSV Oil Analysis Guidelines, Rev. 02Muhammad IshfaqNessuna valutazione finora

- Technical Sales Document: - Product DataDocumento27 pagineTechnical Sales Document: - Product DataLuis AyalaNessuna valutazione finora

- Sebp6163 11 02 AllcdDocumento547 pagineSebp6163 11 02 AllcdMahmoodNessuna valutazione finora

- JGC 620 GS-S.L: Technical Description Container GensetDocumento36 pagineJGC 620 GS-S.L: Technical Description Container Gensetammad uddinNessuna valutazione finora

- 2506A E15TAG3 (TPD1581e2)Documento14 pagine2506A E15TAG3 (TPD1581e2)Rurouni Martínez100% (1)

- 6btaa5 9G2Documento3 pagine6btaa5 9G2Budi Nais100% (2)

- Marine and Industrial qsk60Documento10 pagineMarine and Industrial qsk60Muhammad IshfaqNessuna valutazione finora

- Fuel System 4Documento5 pagineFuel System 4Falgon IslamNessuna valutazione finora

- ST1000 Brochure PDFDocumento6 pagineST1000 Brochure PDFFranNessuna valutazione finora

- Aspire Catalogue PDFDocumento13 pagineAspire Catalogue PDFJose BaptistaNessuna valutazione finora

- Cummins QSK45 Engine Spare Parts Catalog: Part Number DescriptionDocumento19 pagineCummins QSK45 Engine Spare Parts Catalog: Part Number Descriptionsaeedt538Nessuna valutazione finora

- OPERATION & MAINTENANCE MANUAL 50 HZ: G625 - G690 - G750XW/XFDocumento106 pagineOPERATION & MAINTENANCE MANUAL 50 HZ: G625 - G690 - G750XW/XFErmias BeyeneNessuna valutazione finora

- Varifuel AppDocumento3 pagineVarifuel AppDuy DK100% (1)

- New 3500 Main&Connecting Rod BearingsDocumento2 pagineNew 3500 Main&Connecting Rod BearingsmkNessuna valutazione finora

- B3.3 Series: Diesel Generator SetDocumento4 pagineB3.3 Series: Diesel Generator SetCarlos PerezNessuna valutazione finora

- Radiator Assembly S3.8-G4andG6Documento13 pagineRadiator Assembly S3.8-G4andG6mohsen_cumminsNessuna valutazione finora

- Rubia S10 20 LT 20 LT 80 LT Castrol CRB Monograde 10W Rubia S 10W 208 LT 208 LT 4368 LTDocumento6 pagineRubia S10 20 LT 20 LT 80 LT Castrol CRB Monograde 10W Rubia S 10W 208 LT 208 LT 4368 LTRovshan GasimovNessuna valutazione finora

- 6M26 Series: Powerkit EngineDocumento2 pagine6M26 Series: Powerkit EngineDuc Thao VuNessuna valutazione finora

- Aftercooler Parts For Qsk60 Gas EngineDocumento3 pagineAftercooler Parts For Qsk60 Gas EngineMuhammad IshfaqNessuna valutazione finora

- Cummins KTA38M2 Part List FullDocumento130 pagineCummins KTA38M2 Part List FullClarence ClarNessuna valutazione finora

- 1250 1500kvaDocumento4 pagine1250 1500kvaAngon BhattacharjeeNessuna valutazione finora

- J - Ponuda PDFDocumento8 pagineJ - Ponuda PDFAjdin Herc AhmetovicNessuna valutazione finora

- Fujian Aspire Electron Co.,Ltd: Model: MX341 Model: R220Documento13 pagineFujian Aspire Electron Co.,Ltd: Model: MX341 Model: R220Jose BaptistaNessuna valutazione finora

- Recommended Stock List: Critical Service Parts / Recommended For RepairsDocumento2 pagineRecommended Stock List: Critical Service Parts / Recommended For RepairsAmmar BaigNessuna valutazione finora

- Altronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)Documento36 pagineAltronic DD-40NTV-II Installation Instructions (FORM DD-40NTV II)francis_mouille_iiNessuna valutazione finora

- Cummins - Fleetguard Filter Specifications 018-024Documento3 pagineCummins - Fleetguard Filter Specifications 018-024Miller Andres Aroca100% (1)

- Engine Model Alternator Model LL5014J Engine Build: 1606A-E93TAG4 WU5530PDocumento2 pagineEngine Model Alternator Model LL5014J Engine Build: 1606A-E93TAG4 WU5530PairtupasNessuna valutazione finora

- QSK60 G6 PDFDocumento2 pagineQSK60 G6 PDFShahzad Ali100% (2)

- BF C275DDocumento7 pagineBF C275DLebahMaduNessuna valutazione finora

- 37Documento1 pagina37MikeCao1384Nessuna valutazione finora

- LS LV Generator 4 PoleDocumento19 pagineLS LV Generator 4 PoleIee XpNessuna valutazione finora

- QSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene AudioDocumento3 pagineQSKV 45/60: Heads: CYLINDER HEAD - Familiarization Scene Audionugraha kurniawanNessuna valutazione finora

- Pressure Switch - 12PSIDocumento1 paginaPressure Switch - 12PSIMR BEA100% (1)

- LLC Water Contentas For MGS Ver7Documento2 pagineLLC Water Contentas For MGS Ver7saiful islam100% (1)

- Assembly and Parts Album: KDE12000TDocumento1 paginaAssembly and Parts Album: KDE12000TCeryo SantilliNessuna valutazione finora

- Cummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishDocumento14 pagineCummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishjosephvanbacNessuna valutazione finora

- C32 Syc03519 - PSRPT - 2019-11-06 - 17.53.14 PDFDocumento4 pagineC32 Syc03519 - PSRPT - 2019-11-06 - 17.53.14 PDFiprahim202066100% (1)

- Air Fuel Setup 2107766Documento10 pagineAir Fuel Setup 2107766Amr SherifNessuna valutazione finora

- Cense Cakibration ManulDocumento9 pagineCense Cakibration Manulagh78Nessuna valutazione finora

- R2 - Offer - 1 MWDocumento23 pagineR2 - Offer - 1 MWShankar RajaNessuna valutazione finora

- Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsDocumento23 pagineVibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsMuhammad Ishfaq100% (1)

- Cyl. Head Unit No. 6 PmeDocumento5 pagineCyl. Head Unit No. 6 PmeMuhammad IshfaqNessuna valutazione finora

- qst30 System SpecificationsDocumento24 pagineqst30 System SpecificationsMuhammad IshfaqNessuna valutazione finora

- 003-004 Overhead Set: General InformationDocumento12 pagine003-004 Overhead Set: General InformationMuhammad IshfaqNessuna valutazione finora

- qsk23 Data SheetDocumento2 pagineqsk23 Data SheetMuhammad IshfaqNessuna valutazione finora

- Loctite 577™: Technical Data SheetDocumento4 pagineLoctite 577™: Technical Data SheetCristian SerbovNessuna valutazione finora

- CatDocumento4 pagineCatMuhammad IshfaqNessuna valutazione finora

- 243 New-EnDocumento4 pagine243 New-Enjaskaran singhNessuna valutazione finora

- Power House 1Documento2 paginePower House 1Muhammad IshfaqNessuna valutazione finora

- CPGS - Power House PDFDocumento2 pagineCPGS - Power House PDFMuhammad IshfaqNessuna valutazione finora

- 1000-0099B enDocumento3 pagine1000-0099B enMuhammad Ishfaq100% (2)

- Fiji Power ServiceDocumento2 pagineFiji Power ServiceMuhammad IshfaqNessuna valutazione finora

- Top 40 Reasons For Motor Oil Consumption PDFDocumento6 pagineTop 40 Reasons For Motor Oil Consumption PDFMuhammad IshfaqNessuna valutazione finora

- Cummins 161110083846 PDFDocumento18 pagineCummins 161110083846 PDFMuhammad IshfaqNessuna valutazione finora

- Aftercooler Parts For Qsk60 Gas EngineDocumento3 pagineAftercooler Parts For Qsk60 Gas EngineMuhammad IshfaqNessuna valutazione finora

- Cucumber Hybrid Seed Production (Hilights)Documento8 pagineCucumber Hybrid Seed Production (Hilights)Muhammad IshfaqNessuna valutazione finora

- Hybrid Varieties and Saving Seed - Archives - Aggie HorticultureDocumento3 pagineHybrid Varieties and Saving Seed - Archives - Aggie HorticultureMuhammad IshfaqNessuna valutazione finora

- Exhaust Temp K394Documento1 paginaExhaust Temp K394Muhammad IshfaqNessuna valutazione finora

- Tomato Paste PulpDocumento26 pagineTomato Paste PulpYousef TahnonNessuna valutazione finora

- c7 168 KW Spec Sheet Abby PDFDocumento4 paginec7 168 KW Spec Sheet Abby PDFAlfonzo PerezNessuna valutazione finora

- FICHA TECNICA Planta Emerigencia Consumo C400D6Documento3 pagineFICHA TECNICA Planta Emerigencia Consumo C400D6Caro PereraNessuna valutazione finora

- Panel For Control and Protection of Irrigation Motor PumpsetDocumento8 paginePanel For Control and Protection of Irrigation Motor PumpsetIvf ValentinaNessuna valutazione finora

- Dimensions: Guascor SFGLD 560 Lean Burn GensetDocumento2 pagineDimensions: Guascor SFGLD 560 Lean Burn GensetTithy MoniNessuna valutazione finora

- Rexroth-RD 500 RD52 Drive Control Device Field-Oriented Vector Control Application ManualDocumento270 pagineRexroth-RD 500 RD52 Drive Control Device Field-Oriented Vector Control Application ManualNuma Key LumaNessuna valutazione finora

- 2300 Series: 2306C-E14TAG2Documento2 pagine2300 Series: 2306C-E14TAG2Jovan100% (1)

- Data Sheet: Diesel Generator 1500Kw 50HZ/1500RPM PERKINS MODEL: 4012-46TAG3ADocumento9 pagineData Sheet: Diesel Generator 1500Kw 50HZ/1500RPM PERKINS MODEL: 4012-46TAG3AmualiminNessuna valutazione finora

- 8210 SRi27 DS P4A048011E Jan04 PDFDocumento2 pagine8210 SRi27 DS P4A048011E Jan04 PDFBidonsBidonsNessuna valutazione finora

- Automatic Transmission NAG1 - Fluid and FilterDocumento4 pagineAutomatic Transmission NAG1 - Fluid and FilterKrivega88Nessuna valutazione finora

- Martin Power: Www. TTS-martin - SKDocumento3 pagineMartin Power: Www. TTS-martin - SKiona gybNessuna valutazione finora

- Owner S and Operator S Manual: Vertical, Water-Cooled 4-Cycle Diesel EngineDocumento44 pagineOwner S and Operator S Manual: Vertical, Water-Cooled 4-Cycle Diesel EnginethuanNessuna valutazione finora