Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Actuador de Timón - Model S Steering Gear

Caricato da

Nolberto ValdezDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Actuador de Timón - Model S Steering Gear

Caricato da

Nolberto ValdezCopyright:

Formati disponibili

Photo courtesy of ChingFu Shipyard.

Jastram Model S Steering Gear

The Jastram Model S Actuators are specifically certified for use in

commercial marine hydraulic steering systems. Their rugged steel

construction includes many standard features resulting from our long

experience in the manufacture, operation and service of steering

systems.

Model S Actuators include features many manufacturers do not

provide but are essential to a high quality, reliable steering gear for

commercial marine application:

• Micro-honed heavy wall cylinder barrel

• Precision ground, chrome-plated piston rod

• Oversize piston and piston rod bearings

• Piston rod wiper

• Tie-rod construction

• Self-aligning spherical bearings

• SAE outlet ports

Type Approved Product; see details on back page

Engineered For Life At Sea

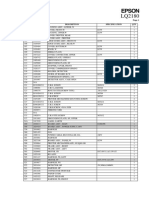

STEERING SYSTEM SPECIFICATIONS (INCH) STEERING SYSTEM SPECIFICATIONS (METRIC)

SINGLE TWIN SINGLE TWIN

RATED TORQUE RATED TORQUE

STEERING K RUDDER RUDDERS STEERING K RUDDER RUDDERS

STEERING ACTUATOR STEERING ACTUATOR

GEAR DISPL. A B C D E F G H J (Bolt M M GEAR DISPL. A B C D E F G H J (Bolt M M

ANGLE MODEL ANGLE MODEL

MODEL T.M. LBF.FT. Dia) L (Max L (Max MODEL T.M. LBF.FT. Dia) L (Max L (Max

Dia) Dia) Dia) Dia)

S2-11 1.1 8,130 45 S-300-11 130 7.44 28.49 5.07 ¾"-16 5.27 4.54 4.18 3.61 S2-11 1.1 8,130 45 S-300-11 2,130 189 724 129 ¾"-16 134 115 106 92

S2-16 1.6 11,450 35 128 9.04 28.49 7.22 SAE 5.91 5.09 4.69 4.04 S2-16 1.6 11,450 35 2,098 230 724 183 SAE 150 129 119 103

3.06 3.06 5.50 4.63 2.19 ½ 78 78 140 117 56 M12

S2-18 1.8 12,737 45 S-300-17 204 11.65 37.73 7.95 straight 6.12 5.28 4.86 4.19 S2-18 1.8 12,737 45 S-300-17 3,343 296 958 202 straight 156 134 123 106

S2-25 2.5 17,931 35 201 14.16 37.73 11.31 thread 6.86 5.92 5.45 4.70 S2-25 2.5 17,931 35 3,294 360 958 287 thread 174 150 138 119

S2-23 2.3 16,441 45 S-400-12 263 8.46 34.23 5.77 6.67 5.75 5.29 4.56 S2-23 2.3 16,441 45 S-400-12 4,310 215 869 147 169 146 134 116

S2-32 3.2 23,146 35 259 10.28 34.23 8.21 7.47 6.44 5.93 5.11 S2-32 3.2 23,146 35 4,244 261 869 209 190 164 151 130

S2-28 2.8 20,469 45 S-400-15 327 10.51 38.72 7.17 11/16"-12 7.17 6.18 5.69 4.91 S2-28 2.8 20,469 45 S-400-15 5,359 267 983 182 11/16"-12 182 157 145 125

S2-40 4.0 28,787 35 322 12.78 38.72 10.20 SAE 8.03 6.93 6.38 5.50 S2-40 4.0 28,787 35 5,277 325 983 259 SAE 204 176 162 140

3.69 3.88 7.00 5.75 2.63 ǫ 94 98 178 146 67 M16

S2-36 3.6 25,699 45 S-400-19 411 13.22 44.67 9.02 straight 7.74 6.67 6.14 5.29 S2-36 3.6 25,699 45 S-400-19 6,735 336 1135 229 straight 197 169 156 134

S2-50 5.0 36,165 35 405 16.07 44.67 12.83 thread 8.67 7.47 6.88 5.93 S2-50 5.0 36,165 35 6,637 408 1135 326 thread 220 190 175 151

S2-45 4.5 32,259 45 S-400-24 516 16.58 52.03 11.31 8.35 7.19 6.62 5.71 S2-45 4.5 32,259 45 S-400-24 8,456 421 1322 287 212 183 168 145

S2-63 6.3 45,351 35 508 20.15 52.03 16.09 9.35 8.06 7.42 6.40 S2-63 6.3 45,351 35 8,325 512 1322 409 237 205 188 162

S2-57 5.7 41,084 45 S-500-20 658 13.53 48.51 9.23 9.05 7.80 7.18 6.19 S2-57 5.7 41,084 45 S-500-20 10,783 344 1232 234 230 198 182 157

S2-80 8.0 57,864 35 648 16.45 48.51 13.13 11/16"-12 10.14 8.74 8.05 6.94 S2-80 8.0 57,864 35 10,619 418 1232 334 11/16"-12 258 222 204 176

S2-71 7.1 51,391 45 S-500-25 822 16.92 55.94 11.54 SAE 9.75 8.40 7.74 6.67 S2-71 7.1 51,391 45 S-500-25 13,470 430 1421 293 SAE 248 213 196 169

4.56 5.06 8.50 7.00 3.63 ¾ 116 129 216 178 92 M20

S2-100 10.0 72,330 35 811 20.56 55.94 16.42 straight 10.92 9.42 8.67 7.47 S2-100 10.0 72,330 35 13,290 522 1421 417 straight 277 239 220 190

S2-94 9.4 67,629 45 S-500-32 1,069 21.99 67.07 15.00 thread 10.68 9.21 8.48 7.31 S2-94 9.4 67,629 45 S-500-32 17,518 559 1704 381 thread 271 234 215 186

S2-130 13.0 94,029 35 1,054 26.73 67.07 21.35 11.92 10.28 9.46 8.16 S2-130 13.0 94,029 35 17,272 679 1704 542 303 261 240 207

S2-114 11.4 82,239 45 S-600-27* 1,316 18.80 68.12 12.82 11.40 9.83 9.05 7.80 S2-114 11.4 82,239 45 S-600-27* 21,565 478 1730 326 290 250 230 198

S2-160 16.0 115,728 35 1,297 22.85 68.12 18.25 12.78 11.01 10.14 8.74 S2-160 16.0 115,728 35 21,254 580 1730 463 325 280 258 222

1" SAE 1" SAE

S2-128 12.8 92,583 45 S-600-31* 1,480 21.15 73.28 14.43 11.86 10.22 9.41 8.11 S2-128 12.8 92,583 45 S-600-31* 24,253 537 1861 366 301 260 239 206

4-bolt 6.25 6.25 12.00 10.25 4.50 ¾ 4-bolt 159 159 305 260 114 M20

S2-180 18.0 130,194 35 1,459 25.70 73.28 20.53 13.29 11.45 10.55 9.09 S2-180 18.0 130,194 35 23,909 653 1861 521 338 291 268 231

flange flange

S2-156 15.6 113,052 45 S-600-38* 1,809 25.85 83.59 17.63 12.68 10.93 10.06 8.67 S2-156 15.6 113,052 45 S-600-38* 29,644 657 2123 448 322 278 256 220

S2-220 22.0 159,126 35 1,783 31.42 83.59 25.09 14.21 12.25 11.28 9.72 S2-220 22.0 159,126 35 29,218 798 2123 637 361 311 286 247

S2-176 17.6 127,301 45 S-800-24* 2,056 16.52 68.29 11.27 13.19 11.37 10.47 9.02 S2-176 17.6 127,301 45 S-800-24* 33,692 420 1735 286 335 289 266 229

S2-250 25.0 180,825 35 2,026 20.08 68.29 16.04 14.83 12.78 11.77 10.14 S2-250 25.0 180,825 35 33,200 510 1735 407 377 325 299 258

1¼"SAE 1¼"SAE

S2-228 22.8 164,551 45 S-800-31* 2,632 21.16 78.45 14.43 14.37 12.38 11.40 9.83 S2-228 22.8 164,551 45 S-800-31* 43,131 537 1993 366 365 315 290 250

4-bolt 7.50 8.00 16.00 13.00 5.75 1 4-bolt 191 203 406 330 146 M24

S2-320 32.0 231,456 35 2,594 25.71 78.45 20.53 16.10 13.88 12.78 11.01 S2-320 32.0 231,456 35 42,508 653 1993 522 409 352 325 280

flange flange

S2-284 28.4 205,418 45 S-800-38* 3,288 26.43 90.02 18.03 15.47 13.34 12.28 10.58 S2-284 28.4 205,418 45 S-800-38* 53,880 671 2287 458 393 339 312 269

S2-400 40.0 289,321 35 3,241 32.12 90.02 25.65 17.34 14.95 13.76 11.86 S2-400 40.0 289,321 35 53,110 816 2287 652 440 380 350 301

S2-355 35.5 256,989 45 S-1000-31* 4,112 21.15 88.79 14.43 16.67 14.37 13.23 11.40 S2-355 35.5 256,989 45 S-1000-31* 67,383 537 2255 366 423 365 336 290

S2-500 50.0 361,651 35 4,054 25.71 88.79 20.53 18.68 16.10 14.83 12.78 S2-500 50.0 361,651 35 66,433 653 2255 521 474 409 377 325

S2-448 44.8 323,894 45 S-1000-39* 5,183 26.66 100.88 18.18 18.00 15.52 14.29 12.32 S2-448 44.8 323,894 45 S-1000-39* 84,934 677 2562 462 457 394 363 313

1½"SAE 1½"SAE

S2-630 63.0 455,680 35 5,109 32.40 100.88 25.88 20.17 17.39 16.01 13.80 S2-630 63.0 455,680 35 83,721 823 2562 657 512 442 407 351

4-bolt 10.00 10.50 21.00 18.00 7.50 1½ 4-bolt 254 267 533 457 191 M36

S2-568 56.8 411,124 45 S-1000-49* 6,578 33.84 116.63 23.08 19.49 16.81 15.47 13.34 S2-568 56.8 411,124 45 S-1000-49* 107,794 860 2962 586 495 427 393 339

flange flange

S2-800 80.0 578,641 35 6,484 41.13 116.63 32.84 21.85 18.83 17.34 14.95 S2-800 80.0 578,641 35 106,253 1,045 2962 834 555 478 440 380

S2-711 71.1 513,906 45 S-1000-62* 8,222 42.30 135.19 28.85 21.00 18.10 16.67 14.37 S2-711 71.1 513,906 45 S-1000-62* 134,734 1,074 3434 733 533 460 423 365

S2-1000 100.0 723,301 35 8,105 51.41 135.19 41.06 23.53 20.29 18.68 16.10 S2-1000 100.0 723,301 35 132,817 1,306 3434 1,043 598 515 474 409

TORQUE RATING IS DETERMINED AT 1500 PSI (103 BAR) TORQUE RATING IS DETERMINED AT 1500 PSI (103 BAR)

Note: Hoses, shut-off valves and tiller pins are not supplied with Model S Actuators Note: Hoses, shut-off valves and tiller pins are not supplied with Model S Actuators

Dimensions A-M are all in inches Dimensions A-M are all in millimeters

¹ Model S2 indicates 2 actuators are used. S4 indicates 4 actuators MODEL S STEERING GEAR CODE ¹ Model S2 indicates 2 actuators are used. S4 indicates 4 actuators

² Other steering angles are also available Example: S2 - 320 - 2 - 35 ² Other steering angles are also available

³ Other actuator stroke lengths are available upon request ³ Other actuator stroke lengths are available upon request

* These actuators require 6 tail mounting bolts (K on chart) NO. OF ACTUATORS RUDDER ANGLE * These actuators require 6 tail mounting bolts (K on chart)

All other actuators require 4 tail mounting bolts (K) S2=Two steel actuators TORQUE All other actuators require 4 tail mounting bolts (K)

S4=Four steel actuators In T.M. x 10 NO. OF RUDDERS

Description of Model S2-320-2-35 Steering Gear:

Two S-800-31 actuators producing a torque of 32.0 T.M. on two rudders at 2 x 35°

Steering Gear Arrangements

Single Rudder Twin Rudder

Two Actuators Arrangement option 1

Four Actuators Arrangement Option 2

Jastram Model S steering gears are supplied with either two The S Model Actuators are Type Approved for under the following

or four Model S actuators and can be used with single, twin standards:

or multiple rudders. These actuators and tillers are are • ABS Type Approved Product under 2006 Building and Classing

designed and manufactured to meet the standards of all Steel Vessels 4-3-4/7.3.

major classification societies. Model S hydraulic actuators • DNV Type Approved for Classification of Ships on the Model S-300,

have passed rigorous inspection and testing and are S-400, S-500, S-600, S-800 & S-1000 hydraulic actuators.

CERTIFIED UNDER THE ABS, DNV & GL TYPE APPROVAL • GL Type Approved for "Rules for Classification and Construction"

PROGRAMS. Part 1, Chapter 2 Section 14A "Steering Gears", Edition 2008.

Data is subject to change without notice.

Jastram Engineering Ltd. 135 West Riverside Drive | North Vancouver BC | Canada V7H 1T6 | T 604 988 1111 | F 604 986 0334

E marketing@jastram.com | www.Jastram.com

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Ogheneruemu Emmanuel Engine Overhauling SlideDocumento16 pagineOgheneruemu Emmanuel Engine Overhauling SlideLilCent MmanuelNessuna valutazione finora

- FME OP BrochureDocumento2 pagineFME OP BrochureMartin KratkyNessuna valutazione finora

- Evolution BrochureDocumento4 pagineEvolution Brochurelucas28031978Nessuna valutazione finora

- Glow Plug System - ID4 2.2L Diesel - : Item NM LB-FTDocumento7 pagineGlow Plug System - ID4 2.2L Diesel - : Item NM LB-FTRichard Andrianjaka LuckyNessuna valutazione finora

- Paper Id (Me302) : Nav'.O (Documento2 paginePaper Id (Me302) : Nav'.O (RaJan GargNessuna valutazione finora

- Definition of PumpDocumento14 pagineDefinition of Pumpimate77Nessuna valutazione finora

- How To Build A Thruster For A Homemade SubmersibleDocumento9 pagineHow To Build A Thruster For A Homemade SubmersiblejumpupdnbdjNessuna valutazione finora

- Reciprocating Compressor Condition Monitoring - GEDocumento6 pagineReciprocating Compressor Condition Monitoring - GEBao-Phuc NguyenNessuna valutazione finora

- Parking Brake Shoes Removal and Installation PDFDocumento4 pagineParking Brake Shoes Removal and Installation PDFMichael Hernandez100% (1)

- Conceptual Design of Planetary Gearbox System ForDocumento11 pagineConceptual Design of Planetary Gearbox System ForAthoriq Dias MuyasarNessuna valutazione finora

- Pigtails Connector Catalog 2015 PDFDocumento59 paginePigtails Connector Catalog 2015 PDFClifton Jamison100% (1)

- Ajuste de Bomba VRZDocumento37 pagineAjuste de Bomba VRZJose David Huanca Taype100% (1)

- C208BTechnical BriefingDocumento94 pagineC208BTechnical BriefingEvans Ev100% (1)

- CHAPTER 7: Control Panels: Section I: Overview ControlsDocumento19 pagineCHAPTER 7: Control Panels: Section I: Overview ControlsabilrajprNessuna valutazione finora

- 2012 Spring Ford Tractor Parts Catalog PDFDocumento64 pagine2012 Spring Ford Tractor Parts Catalog PDFLuís Fidalgo0% (1)

- Tech Info: Vacuum TankDocumento6 pagineTech Info: Vacuum Tankjorge Angel LopeNessuna valutazione finora

- Cartuchos Sandvik PDFDocumento16 pagineCartuchos Sandvik PDFJefatura de Planta Invemet PeruNessuna valutazione finora

- Caterpillar 14m16m Motor Grader Global Service LearningDocumento10 pagineCaterpillar 14m16m Motor Grader Global Service Learningbelinda100% (48)

- DoosanDocumento2 pagineDoosanJeffrey Dela CruzNessuna valutazione finora

- Abb Parts - ASAP AM SparesDocumento17 pagineAbb Parts - ASAP AM SparesJoe FaruquiNessuna valutazione finora

- Transmission and Bevel Gears - Remove and Install (M0076745-04)Documento9 pagineTransmission and Bevel Gears - Remove and Install (M0076745-04)alejandro castañoNessuna valutazione finora

- Wilroy Manual 30958Documento24 pagineWilroy Manual 30958Sutink9069Nessuna valutazione finora

- Experiment No.: 1: Engine & Working PrinciplesDocumento10 pagineExperiment No.: 1: Engine & Working PrinciplesJatin prasad TandanNessuna valutazione finora

- Ahs Indure Smi ListDocumento2 pagineAhs Indure Smi ListSuresh AketiNessuna valutazione finora

- Daikin Applied Product Line Card - ASP 31-312LRDocumento6 pagineDaikin Applied Product Line Card - ASP 31-312LROscar MauroNessuna valutazione finora

- PHC VALEO Clutch Catalogue 2018-2019Documento424 paginePHC VALEO Clutch Catalogue 2018-2019Gsp Tony71% (24)

- Hybrid VehicleDocumento26 pagineHybrid VehicleakashNessuna valutazione finora

- 17 Special Tools-N900 Series JMCDocumento16 pagine17 Special Tools-N900 Series JMCRusonegroNessuna valutazione finora

- Flygt DL: Submersible Sewage Pump, 50 HZDocumento4 pagineFlygt DL: Submersible Sewage Pump, 50 HZAndrey GyrychNessuna valutazione finora

- REF Part No Description Specification QTYDocumento7 pagineREF Part No Description Specification QTYNma ColonelnmaNessuna valutazione finora