Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Input of Dimensions: Objectives

Caricato da

David Bumbalough0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

8 visualizzazioni1 paginaTitolo originale

11-00

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

8 visualizzazioni1 paginaInput of Dimensions: Objectives

Caricato da

David BumbaloughCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

11 INPUT OF DIMENSIONS

Objectives

Any CNC program depends on the correct input of dimensional data, found in the part drawing. The purpose of

the projects and exercises for subjects described in this chapter, is to enable the reader to understand and apply

these basic elements of programming.

Overview and Applications

Inputting dimensions in a CNC program means the correct way of writing - inputting - dimensional data, gener-

ally found in the part drawing. This does not mean just the linear or radial dimensions, it also means the use of

proper units (metric or English) and the proper reference of dimensions (absolute or incremental). Many addresses

in the program are affected by the proper selection, such as cutting feedrates, offset input values, and various

screen position displays.

In terms of units, metric units are selected by the G21 command, English units are selected by the G20 command.

Absolute dimensions are set by the G90 command, incremental dimensions by the G91 command. Selecting one

from each option and using it in the program will establish the mode of operation. Each command in the pair can-

cels the other command. Although it is quite common to switch from absolute to incremental in the same program,

switching between metric and English units in the same program is definitely not recommended.

As a rule, the absolute mode of dimensional input is preferred, unless there is a need to use the incremental mode,

for example, in subprograms. Absolute mode indicates the location from part origin, incremental mode indicates

the actual distance and direction from the current location. The XYZ data must correspond to the mode selected.

There are differences between milling and turning programs, mainly in two features. One is that on most CNC

lathes, the X axis represents the diameter, and the feedrate in measured per revolution, rather than per time, which

is typical for the milling systems.

Another important aspect of a dimensional input is the decimal point. Early machine controls did not use decimal

point at all, and all modern controls convert any dimensional input without a decimal point. How each control in-

terprets the dimension without a decimal point depends on the units used and the method of zero suppression.

Knowledge of these features is very important in programming.

When the decimal point is used in the program, which is the common method, the number of decimal places are

determined by the units selection, as well as the minimum and maximum amount of increment.

Correct using of dimensional data in a part program is one of the most elementary requirements of a CNC pro-

grammer and operator.

Recommended Resources

& CNC Programming Handbook - Chapter 11 Input of Dimensions

Chapter 13 Feedrate Function

Chapter 7 Format Notation

Chapter 8 Preparatory Commands

Peter Smid CNC Programming Handbook Chapter 11 [ 1 ]

Potrebbero piacerti anche

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Da EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Valutazione: 5 su 5 stelle5/5 (1)

- Jit, Jimma University: Computer Aided Engineering AssignmentDocumento8 pagineJit, Jimma University: Computer Aided Engineering AssignmentGooftilaaAniJiraachuunkooYesusiinNessuna valutazione finora

- CNC Machine Programming CourseDocumento33 pagineCNC Machine Programming CourseHemant MeenaNessuna valutazione finora

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopDa EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopValutazione: 5 su 5 stelle5/5 (3)

- Unit Two NC Programming 2015Documento31 pagineUnit Two NC Programming 2015elnat feyisaNessuna valutazione finora

- Nterpolation Ethods: Linear InterpolationDocumento16 pagineNterpolation Ethods: Linear InterpolationMohammad UmairNessuna valutazione finora

- Turning Programming (PC Based) PDFDocumento56 pagineTurning Programming (PC Based) PDFSRAVANNessuna valutazione finora

- Practical No1Documento8 paginePractical No1Dept. Of Mechanical Engg.Nessuna valutazione finora

- Unit 4 Fundamentals of Part Programming: StructureDocumento20 pagineUnit 4 Fundamentals of Part Programming: StructureAzaath AzuNessuna valutazione finora

- Part Program NotesDocumento18 paginePart Program NotesRakshith B Industrial EngineeringNessuna valutazione finora

- Lab Manual CNC LatheDocumento10 pagineLab Manual CNC LatheSai Naga Sri Harsha100% (1)

- CNC Program and Programming of CNC MachiDocumento5 pagineCNC Program and Programming of CNC Machicjjeus9Nessuna valutazione finora

- Computer-Aided CNC Programming For The Machining of Non-Typical PartsDocumento16 pagineComputer-Aided CNC Programming For The Machining of Non-Typical PartsPham LongNessuna valutazione finora

- Unit 4 57 PDFDocumento20 pagineUnit 4 57 PDFVimal ZizouNessuna valutazione finora

- Computer Numerical Control: Part Programming For NC SystemsDocumento30 pagineComputer Numerical Control: Part Programming For NC SystemsibraheemNessuna valutazione finora

- GTTC ReportDocumento27 pagineGTTC ReportDhavan Y Kumar100% (2)

- Module - 4Documento71 pagineModule - 4Anand ANessuna valutazione finora

- CNC MachineDocumento21 pagineCNC MachineKuhely GhoshNessuna valutazione finora

- A Mechatronics Approach To Design A General CNC Controller: September 2015Documento7 pagineA Mechatronics Approach To Design A General CNC Controller: September 2015Tony K PaulNessuna valutazione finora

- A Parametric Programming Technique For Efficient CNC Machining Op PDFDocumento4 pagineA Parametric Programming Technique For Efficient CNC Machining Op PDFpocerilloNessuna valutazione finora

- Part ProgrammingDocumento15 paginePart ProgrammingBhuvnesh SinghNessuna valutazione finora

- Unit 3Documento17 pagineUnit 3rufeenaNessuna valutazione finora

- D2D Workshop ReportDocumento15 pagineD2D Workshop ReportEr Parth PrajapatiNessuna valutazione finora

- 1.1 Computer-Aided Manufacturing: Department of Mechanical Engineering, R.V.R. & J.C.College of Engineering, Guntur-19Documento38 pagine1.1 Computer-Aided Manufacturing: Department of Mechanical Engineering, R.V.R. & J.C.College of Engineering, Guntur-19Madhu SudhanNessuna valutazione finora

- Report Untuk Budak Mekanik Sem 2Documento3 pagineReport Untuk Budak Mekanik Sem 2Muhammad HafizNessuna valutazione finora

- Chapter 6Documento56 pagineChapter 6gashawletaNessuna valutazione finora

- Summer Internship Sem-8Documento23 pagineSummer Internship Sem-8sanskar pithadiaNessuna valutazione finora

- Tech Ascend CNC Student ManualDocumento42 pagineTech Ascend CNC Student ManualabyzenNessuna valutazione finora

- CenturionDocumento11 pagineCenturionGuzzito Rey NU0% (1)

- Cam Lab 1Documento40 pagineCam Lab 1Madhusudhan Rao KNessuna valutazione finora

- CAM Assignment 2Documento10 pagineCAM Assignment 2Jonathan JulianNessuna valutazione finora

- STEP-NC Standard For Integration of Cad and Cam: Upadhyaydhaval@yahoo - Co.inDocumento6 pagineSTEP-NC Standard For Integration of Cad and Cam: Upadhyaydhaval@yahoo - Co.inDhaval UpadhyayNessuna valutazione finora

- Unit 5 Numerical ControlDocumento70 pagineUnit 5 Numerical Controlmsaqibraza93Nessuna valutazione finora

- Question No 01:: Identify The Machine Given in The Picture. Write Down Any Three Features of ItDocumento35 pagineQuestion No 01:: Identify The Machine Given in The Picture. Write Down Any Three Features of ItRafiaNessuna valutazione finora

- ASSIGNMENT 1 Cad PDFDocumento8 pagineASSIGNMENT 1 Cad PDFSasank SaiNessuna valutazione finora

- Lecture Cad CamDocumento84 pagineLecture Cad Camismail_69Nessuna valutazione finora

- Efficiently Than Other Countries. in Other Words, A Country That Has An AbsoluteDocumento4 pagineEfficiently Than Other Countries. in Other Words, A Country That Has An AbsoluteJan Razel RasNessuna valutazione finora

- Dr. V.Chittaranjan Das Professor, Department of Mechanical Engineering, GunturDocumento23 pagineDr. V.Chittaranjan Das Professor, Department of Mechanical Engineering, GunturPraveen VundrajavarapuNessuna valutazione finora

- 9.2 Part Programming For NC SystemsDocumento6 pagine9.2 Part Programming For NC SystemsWeween IbrahimNessuna valutazione finora

- Feedrate Q+A: # Answer 1Documento2 pagineFeedrate Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- Program CNC - 1Documento17 pagineProgram CNC - 1Georgino SilvaNessuna valutazione finora

- Complete Production-II ESE Mains 2021 Study Material With Video Lectures PDFDocumento431 pagineComplete Production-II ESE Mains 2021 Study Material With Video Lectures PDFmohitNessuna valutazione finora

- Jefferson R. Medina BSME-2 Machine Shop Theory 1.G Code?Documento4 pagineJefferson R. Medina BSME-2 Machine Shop Theory 1.G Code?Jeff MedinaNessuna valutazione finora

- A Parametric Programming Technique For Efficient CNC Machining OpDocumento4 pagineA Parametric Programming Technique For Efficient CNC Machining OpHarsha Chaitanya GoudNessuna valutazione finora

- Unit 4 & 5 ME8691 Computer Aided Design and ManufacturingDocumento26 pagineUnit 4 & 5 ME8691 Computer Aided Design and ManufacturingMECHGOKUL KRISHNA KNessuna valutazione finora

- User's Manual HEIDENHAIN Conversational Format ITNC 530Documento747 pagineUser's Manual HEIDENHAIN Conversational Format ITNC 530Mohamed Essam Mohamed100% (2)

- CNC Lab Manual 2023 Med 3102Documento66 pagineCNC Lab Manual 2023 Med 3102G. RajeshNessuna valutazione finora

- ObjectiveDocumento18 pagineObjectiveSaad AliKhanNessuna valutazione finora

- Lesson Eleven TextDocumento9 pagineLesson Eleven TextVignesh WaranNessuna valutazione finora

- Module - 4Documento106 pagineModule - 4Anand ANessuna valutazione finora

- Unit - III CNC Part ProgrammingDocumento39 pagineUnit - III CNC Part ProgrammingNarayana PerumalNessuna valutazione finora

- NC CNC Main 2021Documento117 pagineNC CNC Main 2021mohitNessuna valutazione finora

- Definition of Numerical ControlDocumento5 pagineDefinition of Numerical ControlRanjan Kumar SinghNessuna valutazione finora

- CNC - Machines PresentationDocumento31 pagineCNC - Machines PresentationSascha SchranzNessuna valutazione finora

- CarburettorDocumento67 pagineCarburettorKarthi KeyanNessuna valutazione finora

- Bhel InternshipDocumento37 pagineBhel InternshipLakshmi Kandula100% (1)

- 2nd AssignmentDocumento37 pagine2nd AssignmentRafiaNessuna valutazione finora

- Gun Control and The Founding Fathers Intent - The - Truth - and - JusticeDocumento9 pagineGun Control and The Founding Fathers Intent - The - Truth - and - JusticeDavid BumbaloughNessuna valutazione finora

- This Little Weed Is One of The Most Useful Medicines On The PlanetDocumento6 pagineThis Little Weed Is One of The Most Useful Medicines On The PlanetDavid BumbaloughNessuna valutazione finora

- Tomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDocumento11 pagineTomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDavid BumbaloughNessuna valutazione finora

- 12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDocumento21 pagine12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDavid BumbaloughNessuna valutazione finora

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocumento17 pagineThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNessuna valutazione finora

- How To Become Untrackable - Part 1 - SurvivopediaDocumento12 pagineHow To Become Untrackable - Part 1 - SurvivopediaDavid Bumbalough100% (1)

- Scaling Function Q+A: # Answer 1Documento2 pagineScaling Function Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- Tortort Manufacturing 80% Milled Receivers AK47Documento6 pagineTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNessuna valutazione finora

- Exercises After Abdominal SurgeryDocumento5 pagineExercises After Abdominal SurgeryDavid BumbaloughNessuna valutazione finora

- Feedrate Q+A: # Answer 1Documento2 pagineFeedrate Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- HK94, MP5, Parts KitsDocumento6 pagineHK94, MP5, Parts KitsDavid BumbaloughNessuna valutazione finora

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocumento1 paginaBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNessuna valutazione finora

- Providers - PrivacytoolsDocumento7 pagineProviders - PrivacytoolsDavid BumbaloughNessuna valutazione finora

- 15-01 Reference Points - MillDocumento1 pagina15-01 Reference Points - MillDavid BumbaloughNessuna valutazione finora

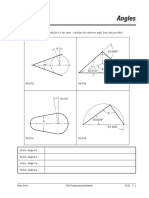

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocumento1 paginaAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNessuna valutazione finora

- 44-01 Machining With TailstockDocumento1 pagina44-01 Machining With TailstockDavid BumbaloughNessuna valutazione finora

- Scaling Exercise: Use T01 Ø20 End MillDocumento1 paginaScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNessuna valutazione finora

- Verifying Programs Q+A: # Answer 1Documento2 pagineVerifying Programs Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- 49-01 Documenting Programs Q+A PDFDocumento1 pagina49-01 Documenting Programs Q+A PDFDavid BumbaloughNessuna valutazione finora

- 49-01 Documenting Programs Q+ADocumento1 pagina49-01 Documenting Programs Q+ADavid BumbaloughNessuna valutazione finora

- 53-02 Locators PDFDocumento1 pagina53-02 Locators PDFDavid BumbaloughNessuna valutazione finora

- 53-03 Contour Points 1Documento1 pagina53-03 Contour Points 1David BumbaloughNessuna valutazione finora

- 53-04 Contour Points 2Documento1 pagina53-04 Contour Points 2David BumbaloughNessuna valutazione finora

- 46-01 Horizontal MachiningDocumento1 pagina46-01 Horizontal MachiningDavid BumbaloughNessuna valutazione finora

- CNC Machining Q+A: # Answer 1Documento2 pagineCNC Machining Q+A: # Answer 1David BumbaloughNessuna valutazione finora

- Unknown Radius: Chine Shop MagazineDocumento1 paginaUnknown Radius: Chine Shop MagazineDavid BumbaloughNessuna valutazione finora

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocumento1 paginaBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNessuna valutazione finora

- 20-02 Rapid Motion FormulasDocumento2 pagine20-02 Rapid Motion FormulasDavid BumbaloughNessuna valutazione finora

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocumento1 paginaTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNessuna valutazione finora

- 19-01 Tool LengthDocumento1 pagina19-01 Tool LengthDavid BumbaloughNessuna valutazione finora

- References For Units and ConstantsDocumento63 pagineReferences For Units and Constants10C 27 SAI VISHWA JETHNessuna valutazione finora

- Instrumentation and Control (I&C) Design - InstrumentationToolsDocumento38 pagineInstrumentation and Control (I&C) Design - InstrumentationToolsAnurag GuptaNessuna valutazione finora

- PtsDocumento7 paginePtsNazeri NasaruddinNessuna valutazione finora

- f1 - Chapter 1Documento50 paginef1 - Chapter 1fadzlin84100% (1)

- Adge CompiledDocumento18 pagineAdge CompiledNovelyn LumboyNessuna valutazione finora

- Shop Manual 6M70 Diesel Engine EURO 3Documento294 pagineShop Manual 6M70 Diesel Engine EURO 3Renzyross Villaruz100% (8)

- Ista 1aDocumento3 pagineIsta 1ashashiNessuna valutazione finora

- EMG 2505 - Measurement and Instrumentation PDFDocumento159 pagineEMG 2505 - Measurement and Instrumentation PDFVasda VinciNessuna valutazione finora

- Conference Template A4Documento3 pagineConference Template A4doyanNessuna valutazione finora

- PkemDocumento42 paginePkemGarcia RaphNessuna valutazione finora

- Encyclopedia of Controlled Drug Delivery (2 Vols) - E. Mathiowitz (Wiley, 1999) WWDocumento903 pagineEncyclopedia of Controlled Drug Delivery (2 Vols) - E. Mathiowitz (Wiley, 1999) WWCiontu Valentin100% (4)

- DsaqoijsdqoiwdDocumento59 pagineDsaqoijsdqoiwdAcademicBMNessuna valutazione finora

- DS48A - (1978) Compilation of Odor and Taste Threshold Values DataDocumento510 pagineDS48A - (1978) Compilation of Odor and Taste Threshold Values DataJacques BlueqNessuna valutazione finora

- Circuits-Module 1Documento36 pagineCircuits-Module 1John Rey DecanoNessuna valutazione finora

- Bs en 764-2-2002 Pressure Equipment Part 2 Quantities SymbolsDocumento10 pagineBs en 764-2-2002 Pressure Equipment Part 2 Quantities SymbolsHopeNessuna valutazione finora

- Grade 7 CBC Complete Integrated Science Notes.Documento66 pagineGrade 7 CBC Complete Integrated Science Notes.Top Chuol100% (10)

- Physics Grade 7 A. Multiple ChoiceDocumento4 paginePhysics Grade 7 A. Multiple ChoiceLimihNessuna valutazione finora

- Mathy6 UNIT 8Documento6 pagineMathy6 UNIT 8Selvamani SelvaNessuna valutazione finora

- Rigsense V. 3.0 Rig Site Information SystemDocumento2 pagineRigsense V. 3.0 Rig Site Information Systemmr3478Nessuna valutazione finora

- Chapter 2 - Introduction To Units and DimensionDocumento52 pagineChapter 2 - Introduction To Units and DimensionAin SuhailaNessuna valutazione finora

- Drid 1300Documento628 pagineDrid 1300Tony KututoNessuna valutazione finora

- Math g5 m1 Topic A Lesson 4Documento16 pagineMath g5 m1 Topic A Lesson 4ariel aguasNessuna valutazione finora

- Weight and Dimension of Ems ArticlesDocumento6 pagineWeight and Dimension of Ems ArticlesVijaysNessuna valutazione finora

- Dogar General MCQs Physics PDF SolvedDocumento59 pagineDogar General MCQs Physics PDF SolvedMuhammad Noman HameedNessuna valutazione finora

- Physical World Unit Dimensions ErrorDocumento20 paginePhysical World Unit Dimensions ErrorkakuNessuna valutazione finora

- Quality Assurance in The Analytical Chemistry Laboratory PDFDocumento321 pagineQuality Assurance in The Analytical Chemistry Laboratory PDFaqeel1970Nessuna valutazione finora

- 9th Science Sample Guide by Sura Guide - English MediumDocumento81 pagine9th Science Sample Guide by Sura Guide - English MediumKowshikNessuna valutazione finora

- Exploded View Parts List (UE40F5370SSXZG) PDFDocumento11 pagineExploded View Parts List (UE40F5370SSXZG) PDFgeorgedragosNessuna valutazione finora

- Automatic Control Mode Sprinklers For Fire ProtectionDocumento130 pagineAutomatic Control Mode Sprinklers For Fire ProtectionMichael Belinsky100% (1)

- Dokumen - Tips - Toyota 8fbchu25 Forklift Service Repair ManualDocumento15 pagineDokumen - Tips - Toyota 8fbchu25 Forklift Service Repair Manualyoujihwan100% (2)

- Calculus Workbook For Dummies with Online PracticeDa EverandCalculus Workbook For Dummies with Online PracticeValutazione: 3.5 su 5 stelle3.5/5 (8)

- Quantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsDa EverandQuantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsValutazione: 4.5 su 5 stelle4.5/5 (3)

- Basic Math & Pre-Algebra Workbook For Dummies with Online PracticeDa EverandBasic Math & Pre-Algebra Workbook For Dummies with Online PracticeValutazione: 4 su 5 stelle4/5 (2)

- How Math Explains the World: A Guide to the Power of Numbers, from Car Repair to Modern PhysicsDa EverandHow Math Explains the World: A Guide to the Power of Numbers, from Car Repair to Modern PhysicsValutazione: 3.5 su 5 stelle3.5/5 (9)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDa EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchValutazione: 4 su 5 stelle4/5 (10)

- Mental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)Da EverandMental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)Nessuna valutazione finora

- Mathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingDa EverandMathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingValutazione: 4.5 su 5 stelle4.5/5 (21)

- Build a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Da EverandBuild a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Valutazione: 5 su 5 stelle5/5 (1)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsDa EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsValutazione: 5 su 5 stelle5/5 (1)