Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1 1 3 A Vex

Caricato da

Alex PakTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1 1 3 A Vex

Caricato da

Alex PakCopyright:

Formati disponibili

Activity 1.1.

3 Gears – VEX

Introduction

You do not have to look far to see gears. You might not think of an object such as a

computer as having a lot of moving parts, but the CD tray on your computer is likely

controlled by gears. A traditional watch is full of gears. The watch has one source of

power or input that must move multiple hands continuously and at different speeds.

Some watches also keep track of the day of the month. This may be low-tech by

today’s standards, but imagine the challenge of choosing just the right gears to keep

a watch synchronized. In a watch the gears are used to manipulate rotational speed.

Gears are also used in many applications to control torque and rotational direction.

Equipment

VEX® PoE kit gears and support pieces

Calculator

Procedure

In this activity you will learn about gear ratios and how they affect speed and torque

within a system. You will also construct simple and compound gear systems.

Functions of Gears

Gears change the speed of rotation.

Gears change the direction of rotation.

Gears change torque values.

Gear Ratios

By joining together two or more gears of different sizes,

both the speed and the torque are changed from the input

gear to the output gear. The larger gear within a system will

always move slower and have more torque than the

smaller gear. Gear Ratio (GR) is a comparison between

the driver gear, also called the input (connected to the

power source), and the gear being driven, or the output.

Below are four ways to determine the gear ratio in Figure 1.

Method 1: The gear ratio can be determined by counting the number of teeth on

each gear. The ratio is expressed by dividing the number of teeth on the output gear

(nout) by the number of teeth on the input gear (nin).

nout 20 2

GR GR GR

nin 10 1

Gear ratios are often expressed using a colon. In this example the ratio is 2:1

(pronounced two to one). The gear ratio of 2:1 indicates that the driver gear is half

© 2012 Project Lead The Way, Inc.

Principles of Engineering Activity 1.1.3 Gears VEX – Page 1

the size of the driven gear, and that the driver gear will make two revolutions for

every one made by the driven gear.

Method 2: The gear ratio can be determined using the diameter of each gear.

Assume that the diameter of gear A is 2.5 in. (din), and the diameter of gear B is 5 in.

(dout).

dout 5 in . 2

GR GR GR

din 2.5 in . 1

Method 3: The gear ratio can be determined by recording and comparing the angular

velocity or speed at which each gear is turning. The lower case Greek letter ω is

used to represent angular velocity. A common way to measure angular velocity is

using revolutions per minute (rpm). Assume that the rpm of the input gear is 446 rpm

and the rpm of the output gear is 223 rpm.

in 446 rpm 2.00

GR GR GR

out 223 rpm 1

Method 4: The gear ratio can be determined by recording the torque at each gear.

Divide the torque at the output gear (τout) by the torque at the input gear (τint). A

common way to measure torque is to use foot pounds (ft·lb). Assume that the torque

force at the driver gear is 4 ft·lb and the force at the driven wheel is 8 ft·lb of torque.

out 8 ft lb 2

GR GR GR

in 4 ft lb 1

The above equations all solve for the gear ratio of the driver gear to the driven gear.

Based upon these formulas, the following is true.

GR n d

out out in out

1 nin din out in

Solving for Speed and Torque

In most applications you will know the speed and torque provided by your driver or

input gear. You will mesh another gear to achieve a specific output speed or output

torque to accomplish a task. Below are some examples that illustrate this.

Example 1: A motor is driving an axle with a 6-in.-diameter drive gear. The speed of

the motor is 20 rpm. A gear must be attached that increases the speed to 100 rpm.

What size diameter should the attached gear be?

dout in dout 20. rpm

120 in. 100.( dout )

din out 6.0 in. 100. rpm

120 in.

dout dout 1.2 in.

100.

Example 2: A motor is driving an axle with a 30-tooth drive gear. You know that the

maximum output torque of the motor is only 90 ft·lb. A gear must be attached that

© 2012 Project Lead The Way, Inc.

Principles of Engineering Activity 1.1.3 Gears VEX – Page 2

will increase the torque force to 300 ft·lb in order to lift a heavy object. How many

teeth should the attached gear have?

nout out n 300. ft lb

out 9000 90.( nout )

nin in 30n 90. ft lb

9000 nout

nout nout 100 n

90.

Gear Trains

A gear train consists of two or more

gears assembled in order to transfer

energy from one axis to others.

Idler Gears

When two gears are meshed together, each will

rotate in an opposite direction. If the desired rotation

for two gears is the same, an idler gear is

introduced. In Figure 3 the two outside gears will

move at the same speed and direction and will have

the same torque because of the idler gear between

them. If they were attached without the idler gear,

they would have matching speed and torque, yet

would be rotating in opposite directions.

Simple Gear Trains

A simple gear train connects two or more gears

in a row, each gear having its own axle.

Build a Simple Gear Train

In a group build a simple gear train that consists of four meshed gears each with its

own axle. At least three gears should have different sizes. Once the gears are

arranged, assume that the first gear, gear A, is the driver as seen in Figure 4. Attach

a crank to gear A and compare the speeds of gears B, C, and D as you turn gear A.

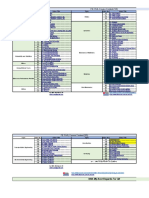

Complete the following tables based upon the simple gear train that you created.

© 2012 Project Lead The Way, Inc.

Principles of Engineering Activity 1.1.3 Gears VEX – Page 3

Number of Teeth per Gear

A (nin) B C D

n (teeth)

84 36 84 60

B:A C:B D:C

Gear

Ratio 3:7 7:3 5:7

(reduced)

Final

Product of

Gear

Gear Fractions

Ratio

Ratios as 3/7 7/3 5/7

Fractions

105/147 5/7

By multiplying the gear ratios between each set, you discover the ratio between

gears A and D.

Simple Gear Train Conclusion Questions

1. How many times will gear A rotate compared to gear D? How does this compare to

the gear ratio you just calculated in the table?

Gear A will rotate 1.4 times for every single rotation of gear D.

2. If 10 ft·lb of torque is applied at gear A, then what is the output at gear D?

Formula Substitute / Solve Final Answer

1.4/1=10 ft x lb Td= 14 ft x lb

GR/1=tout/tin

3. How can you make gears A and D rotate in the same direction?

There are several various methods to make gear A and D spin in the same direction.

For instance: you could remove gear B or C, you could switch gear A and B for gears B

and C, and you could stack gears B and C.

4. What will the gear ratio be if A is connected directly to D?

Gear ratio is 5/7

5. How does the ratio between A and D compare to the entire system?

Gear ratio A and D is the product of all of the gear ratios.

© 2012 Project Lead The Way, Inc.

Principles of Engineering Activity 1.1.3 Gears VEX – Page 4

6. If gear D is the final output, or where the load is attached, then how did gears B and

C impact the system?

Taking out gear B and C would disconnect the entire gear chain.

Compound Gear Trains

A compound gear train connects gears that may share axles or shafts. Two gears on

the same shaft share the same torque and speed although they are different sizes.

This allows more efficient manipulation of speed and torque throughout the system.

Figure 5 represents two simple gear trains and gear ratio for each set. The input for

the first set is gear A. The input for the second set is gear C.

Gear R atio of S et 1 Gear R atio of S et 2

nout B 20 n 2 nout D 24 n 3

GR GR

nin A 10 n 1 nin C 8 n 1

Figure 6 represents the two simple gear

trains above with gears B and C sharing the

same shaft. Gear A is the driver.

Solving for Compound Gear Trains

To solve for a compound gear train, determine the gear ratio of each simple gear

train. Next find the product of all sets. We know from the previous example that the

ratio between gears A and B is 1:2 and that the ratio between gears C and D is 1:3.

Gear Ratio of A : D The gear ratio of 6:1 indicates that

the driver gear A will make six

B D 2 3 6 revolutions for every one by the

GR driven gear D, and that gear D will

A C 1 1 1 have 6 times more torque than gear

A.

Build a Compound Gear Train

© 2012 Project Lead The Way, Inc.

Principles of Engineering Activity 1.1.3 Gears VEX – Page 5

In groups build a gear train that consists of four

differently-sized gears. The two gears in the

middle must share the same shaft. Once the

gears are arranged, assume that the driver is gear

A. Gear A is connected to gear B and will share

the shaft with gear C, which is connected to gear

D. Attach a crank to gear A and compare the

speeds of gears B, C, and D as you turn A.

Complete the following tables based upon the compound gear train that you created.

Number of Teeth per Gear

A (nin) B C D

n (teeth)

24 84 60 36

B:A D:C

Gear Ratio

(reduced) 7:2 3:5

Gear Ratios Product of Final Gear

as Fractions Ratio

Fractions 7/2 3/5

21/10 3/2

Compound Gear Train Conclusion Questions

1. How many times will gear A rotate compared to gear D?

Gear A will rotate 1.5 times for one rotation of gear D.

2. If 7 ft·lb of torque is applied at gear A, then what is the output at gear D?

Formula Substitute / Solve Final Answer

GR/1=tout/tin

3. Why might compound gear trains be better than two gears alone?

alsipak@gmail.com

jtstone919@gmail.com

4. Name and describe an application of a compound gear train.

© 2012 Project Lead The Way, Inc.

Principles of Engineering Activity 1.1.3 Gears VEX – Page 6

Potrebbero piacerti anche

- 1.1.3.a.vex - Ak GearsDocumento6 pagine1.1.3.a.vex - Ak GearsNaigel BennettNessuna valutazione finora

- Activity 1.1.3 Gears - VEX: N 2 GR G R N 1Documento6 pagineActivity 1.1.3 Gears - VEX: N 2 GR G R N 1Nate FrieslNessuna valutazione finora

- EDJ28503 - Lab 1 - Gear Train Open Ended Lab - 2023 - 2024Documento5 pagineEDJ28503 - Lab 1 - Gear Train Open Ended Lab - 2023 - 2024kashif safiyyNessuna valutazione finora

- MoM ManualDocumento79 pagineMoM ManualHamid CheemaNessuna valutazione finora

- EAT206 Design - Methods.applications Week 14Documento48 pagineEAT206 Design - Methods.applications Week 14Ahmed SaleemNessuna valutazione finora

- The Gear BoxDocumento21 pagineThe Gear BoxRuwan ChandraNessuna valutazione finora

- 1 1 4 A PulleydrivessprocketsDocumento4 pagine1 1 4 A Pulleydrivessprocketsapi-30839565067% (3)

- Unit 1.1 Mechanisms Activity 1.1.3 Gears - VEX: N 2 GR G R N 1Documento6 pagineUnit 1.1 Mechanisms Activity 1.1.3 Gears - VEX: N 2 GR G R N 1xRomero10Nessuna valutazione finora

- Gear Ratios TorqueDocumento12 pagineGear Ratios TorqueKavin BalasubramaniamNessuna valutazione finora

- Calculate SpeedDocumento4 pagineCalculate SpeedAbhishek NaikNessuna valutazione finora

- Clutches Transmissions and Drive 10Documento53 pagineClutches Transmissions and Drive 10Napau AdelinNessuna valutazione finora

- ME 2213 (Gear Train)Documento36 pagineME 2213 (Gear Train)tanvir2013004Nessuna valutazione finora

- Mechanical Power Transmission Fundamentals-R1Documento33 pagineMechanical Power Transmission Fundamentals-R1V SquareNessuna valutazione finora

- J5200 Mekanisma Penghantaran KuasaDocumento3 pagineJ5200 Mekanisma Penghantaran KuasaAriep AqimieNessuna valutazione finora

- The Gearbox (Transmission) : B A A B A B B A A BDocumento12 pagineThe Gearbox (Transmission) : B A A B A B B A A BVijay PanchalNessuna valutazione finora

- Purpose of GearsDocumento9 paginePurpose of GearsM Jobayer AzadNessuna valutazione finora

- 1 1 5 A Gearspulleydrivessprocketspracticeproblems-2Documento4 pagine1 1 5 A Gearspulleydrivessprocketspracticeproblems-2api-305927039100% (2)

- Gear Box Project Guide LinesDocumento12 pagineGear Box Project Guide LinesteddiyfentawNessuna valutazione finora

- Gear Box ReportDocumento39 pagineGear Box ReportNisar HussainNessuna valutazione finora

- Activity Report Making The Gears Use The Frais Machine Pt. Minanga OganDocumento8 pagineActivity Report Making The Gears Use The Frais Machine Pt. Minanga OganFirdaAtikaNessuna valutazione finora

- Gear Ratio and RPM CalculationsDocumento7 pagineGear Ratio and RPM CalculationsRaul Real GonzalezNessuna valutazione finora

- EoT Study MaterialsDocumento24 pagineEoT Study Materialsishika SHANDILYANessuna valutazione finora

- Faculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainDocumento7 pagineFaculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainJameel MalikNessuna valutazione finora

- Gear RatioDocumento9 pagineGear RatioLekha SejpalNessuna valutazione finora

- Lab Report 3Documento3 pagineLab Report 3Hassan MehmoodNessuna valutazione finora

- Projek Design Part 1Documento19 pagineProjek Design Part 1Muluken TemesgenNessuna valutazione finora

- MAE 211 MechatronicsDocumento74 pagineMAE 211 Mechatronicsapi-27637095100% (1)

- DTS - Unit - 2 PDFDocumento14 pagineDTS - Unit - 2 PDFmani100% (1)

- KOM May - June 2012Documento3 pagineKOM May - June 2012nazeerabiaNessuna valutazione finora

- 1.1.4.A PulleyDrivesSprockets FinishedDocumento4 pagine1.1.4.A PulleyDrivesSprockets FinishedJacob DenkerNessuna valutazione finora

- Epicyclic Gear Train ApparatusDocumento8 pagineEpicyclic Gear Train ApparatusGurmeet Mehma83% (6)

- Lecture #10 Types of Belts and Belt Selection: Course Name: Design of Machine Elements Course Number: MET 214Documento22 pagineLecture #10 Types of Belts and Belt Selection: Course Name: Design of Machine Elements Course Number: MET 214Anup M UpadhyayaNessuna valutazione finora

- Gear Ratio Basics for StudentsDocumento3 pagineGear Ratio Basics for StudentschetanhiremathNessuna valutazione finora

- Act. 1.1.5 Gears, Pulley Drives, and SprocketsDocumento4 pagineAct. 1.1.5 Gears, Pulley Drives, and SprocketsLandon StradcutterNessuna valutazione finora

- Ackerman Angle CalculationsDocumento17 pagineAckerman Angle CalculationsSiva Murugesan50% (2)

- Epicyclic Gear TrainDocumento5 pagineEpicyclic Gear TrainRachan PancheNessuna valutazione finora

- Gear & Gear RatioDocumento4 pagineGear & Gear RatioSouvik GhatakNessuna valutazione finora

- Lesson 2 5 Minute BotDocumento9 pagineLesson 2 5 Minute Botapi-273620669Nessuna valutazione finora

- GearsDocumento21 pagineGearsMunyahNessuna valutazione finora

- Compound Gear Trains: Transmissions Clutches & Manual Transmissions Manual TransmissionsDocumento3 pagineCompound Gear Trains: Transmissions Clutches & Manual Transmissions Manual TransmissionsAbhishek KumarNessuna valutazione finora

- Mechanical Power TransmissionsDocumento22 pagineMechanical Power TransmissionsrodrigoperezsimoneNessuna valutazione finora

- Project Report On Compound Gear TrainDocumento22 pagineProject Report On Compound Gear Trainsourabh singh tomer71% (7)

- BELT Lecture 01Documento56 pagineBELT Lecture 01mahaveer dasNessuna valutazione finora

- Kassahun Tadess GeerboxDocumento16 pagineKassahun Tadess Geerboxabubekery61Nessuna valutazione finora

- Wheel Balancing MachineDocumento26 pagineWheel Balancing MachinePatrick Marc Brunelle100% (2)

- Foundations of Physical Science: Workshop: GearsDocumento20 pagineFoundations of Physical Science: Workshop: GearsSreelal SreeNessuna valutazione finora

- Analysis of Davis Steering Gear Mechanism For Four Wheels and Six WheelsDocumento5 pagineAnalysis of Davis Steering Gear Mechanism For Four Wheels and Six WheelsIJIRSTNessuna valutazione finora

- Toothed Gearing Types and ApplicationsDocumento35 pagineToothed Gearing Types and ApplicationsSomnath Somadder100% (1)

- Tripod Joint and Drive ShaftDocumento10 pagineTripod Joint and Drive ShaftArnob DasNessuna valutazione finora

- Shaft Design and Flywheel DimensioningDocumento13 pagineShaft Design and Flywheel DimensioningihtishamuddNessuna valutazione finora

- Chevelle Performance Projects: 1964-1972Da EverandChevelle Performance Projects: 1964-1972Valutazione: 4.5 su 5 stelle4.5/5 (2)

- Chevy Differentials: How to Rebuild the 10- and 12-BoltDa EverandChevy Differentials: How to Rebuild the 10- and 12-BoltValutazione: 5 su 5 stelle5/5 (8)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsDa EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNessuna valutazione finora

- Control of DC Motor Using Different Control StrategiesDa EverandControl of DC Motor Using Different Control StrategiesNessuna valutazione finora

- Planar Linkage Synthesis: A modern CAD based approachDa EverandPlanar Linkage Synthesis: A modern CAD based approachNessuna valutazione finora

- Mechanical Aptitude & Spatial Relations Practice QuestionsDa EverandMechanical Aptitude & Spatial Relations Practice QuestionsNessuna valutazione finora

- Southern Marine Engineering Desk Reference: Second Edition Volume IiDa EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNessuna valutazione finora

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionDa EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionValutazione: 4 su 5 stelle4/5 (1)

- 1 3 1 A Vex Solarhydrogensystem PlainDocumento7 pagine1 3 1 A Vex Solarhydrogensystem Plainapi-264642523100% (1)

- 1 1 2 A Simplemachinespracticeproblems-3Documento7 pagine1 1 2 A Simplemachinespracticeproblems-3api-305927039Nessuna valutazione finora

- By: Emma Belscher & Yeiry ChaverraDocumento5 pagineBy: Emma Belscher & Yeiry Chaverraapi-305927039Nessuna valutazione finora

- SimplemachineprojectDocumento2 pagineSimplemachineprojectapi-305927039Nessuna valutazione finora

- 1 6 A Discoverengineering-1Documento3 pagine1 6 A Discoverengineering-1api-305927039Nessuna valutazione finora

- 1 1 5 A Gearspulleydrivessprocketspracticeproblems-2Documento4 pagine1 1 5 A Gearspulleydrivessprocketspracticeproblems-2api-305927039100% (2)

- Computer EngineerDocumento3 pagineComputer Engineerapi-305927039Nessuna valutazione finora

- Engineer 1Documento2 pagineEngineer 1api-305927039Nessuna valutazione finora

- Chapter 4 Matriculation STPMDocumento53 pagineChapter 4 Matriculation STPMJue Saadiah100% (1)

- HLN-11A Leeb Portable Hardness TesterDocumento2 pagineHLN-11A Leeb Portable Hardness TesterRaden RoyNessuna valutazione finora

- Forces, Motion, and Energy: ScienceDocumento39 pagineForces, Motion, and Energy: ScienceElizabeth Inocencio Facundo - SagotNessuna valutazione finora

- Compile of Lab Thin CylinderDocumento13 pagineCompile of Lab Thin CylinderKhairi Azri100% (4)

- FE CIVIL COURSE OVERVIEWDocumento4 pagineFE CIVIL COURSE OVERVIEWAmr HamedNessuna valutazione finora

- GT PreservationDocumento32 pagineGT PreservationJose Alberto Uribe Minier100% (5)

- Distribution Blocks PDFDocumento3 pagineDistribution Blocks PDFAbelino Vargas TenjoNessuna valutazione finora

- Node List & SIFDocumento2 pagineNode List & SIFCandraNessuna valutazione finora

- Magnetism Lecture NotesDocumento14 pagineMagnetism Lecture NotesPrashant D BijayNessuna valutazione finora

- Rao 1961Documento10 pagineRao 1961Sãröj ShâhNessuna valutazione finora

- Sweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperDocumento3 pagineSweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperCristian SchildNessuna valutazione finora

- "2020" Seminar Information: FORD 6R140W - 6R80Documento4 pagine"2020" Seminar Information: FORD 6R140W - 6R80Gina LópezNessuna valutazione finora

- Activated Sludge Rheology A Critical Review On Data Collection and ModellingDocumento20 pagineActivated Sludge Rheology A Critical Review On Data Collection and ModellingZohaib Ur RehmanNessuna valutazione finora

- Compendium of Design Office Problems-Volume IIIDocumento10 pagineCompendium of Design Office Problems-Volume IIIsaber javidNessuna valutazione finora

- Parts Catalog: Model NB3200AU/A (CE SPEC.) NB3300AU-E (CE SPEC.)Documento15 pagineParts Catalog: Model NB3200AU/A (CE SPEC.) NB3300AU-E (CE SPEC.)ManuelSilvaPedrosaNessuna valutazione finora

- Pneumatic Circuit TrainerDocumento5 paginePneumatic Circuit Trainerdipsankar chatterjeeNessuna valutazione finora

- HSC01 SM10 MEC07 00002: Duty SpecificationDocumento5 pagineHSC01 SM10 MEC07 00002: Duty Specificationwarmaster81Nessuna valutazione finora

- Catalogo Medidor Gt3Documento12 pagineCatalogo Medidor Gt3luis_d_mNessuna valutazione finora

- ZEXEL test values for diesel fuel-injection equipment parametersDocumento4 pagineZEXEL test values for diesel fuel-injection equipment parametersBest Auto TechNessuna valutazione finora

- NADCA-Introduction To Die Casting PDFDocumento116 pagineNADCA-Introduction To Die Casting PDFMichael Naím Dévora Quintanar100% (6)

- Product: Whirling Hygrometer °C Brand: Zeal Model: Zeal Made: Uk: Handy CaseDocumento1 paginaProduct: Whirling Hygrometer °C Brand: Zeal Model: Zeal Made: Uk: Handy CaseTahir NizamNessuna valutazione finora

- g6099 250kw Spec Sheet KohlerDocumento8 pagineg6099 250kw Spec Sheet Kohlerwilliam000111Nessuna valutazione finora

- Nine9 Indexable Milling CutterDocumento16 pagineNine9 Indexable Milling Cutterعبدالله محمدNessuna valutazione finora

- Advanced Numerical Methods for Process Safety AssessmentsDocumento13 pagineAdvanced Numerical Methods for Process Safety Assessmentsandi suntoroNessuna valutazione finora

- Sulzer RTA air start valve operating principleDocumento5 pagineSulzer RTA air start valve operating principleHrishikesh More100% (1)

- FEM9.756 Engl PDFDocumento57 pagineFEM9.756 Engl PDFserkanNessuna valutazione finora

- Commissioning Air PreheaterDocumento14 pagineCommissioning Air Preheaterarvidkumar87060Nessuna valutazione finora

- (MINI) Manual de Despiece Mini InglesDocumento247 pagine(MINI) Manual de Despiece Mini InglesNahir ProtasioNessuna valutazione finora

- Heat and Moisture TransferDocumento14 pagineHeat and Moisture TransferTooba GhouriNessuna valutazione finora

- Catálogo de Pecas - MotorDocumento29 pagineCatálogo de Pecas - MotorHenriqueNessuna valutazione finora