Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Spec PDF

Caricato da

crysTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Spec PDF

Caricato da

crysCopyright:

Formati disponibili

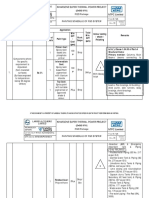

SPECIFICATIONS

Available

Not available Only materials not registered with official standards

Official standard or KOBE STEEL standard

Products shapes Chemical composition, mass%

Corresponding Tensile properties Bend properties

Official Nominal Final

No. Classification Features KOBE STEEL Applications Coils Tensile 0.2% proof Elongation, Reduction Internal radius, mm (min) annealing etc.

standards composition Welded Wires strength, strength, of area, Bend angle, Main elements N C H Fe O

standard Sheets Forgings %

tubes Rods Mpa % degree t (Thickness) (min/max) (max) (max) (max) (max) (max)

Heavy plates (min) Mpa (min) (min) 1.8 t 4.75

1.8

Excellent

formability PHE

KS40S Press formed parts

1 Excellent ASTM Gr.1 KS40 240 170-310 24 30 105 1.5T 2T Annealing bal.Ti 0.03 0.08 0.015 0.20 0.18

corrosion Roofs

resistance Walls

Condensor tubes

Commercially Heat transfer tubes

pure titanium Relatively high Pipings,

2 ASTM Gr.2 KS60 Ti-Fe-O Linings 345 275-450 20 30 105 2T 2.5T Annealing bal.Ti 0.03 0.08 0.015 0.30 0.25

strength

Excellent Electrolysis vessels

corrosion Chemical use

3 resistance ASTM Gr.3 KS70 Tube sheets 450 380-550 18 30 105 2T 2.5T Annealing bal.Ti 0.05 0.08 0.015 0.30 0.35

4 ASTM Gr.4 KS85 Airplane parts 550 483-655 15 25 105 2.5T 3T Annealing bal.Ti 0.05 0.08 0.015 0.50 0.40

5 KS100 650 min550 15 180 T 5, 3T Annealing bal.Ti 0.07 0.08 0.013 0.45 0.50

Scratch

resistance Wrist watches

Easy to polish Cutlery

6 KS120SI Ti-Fe-O-Si Golf club heads 750 min650 10 180 T 5, 3T Annealing Si 0.50/0.70, bal.Ti 0.07 0.08 0.013 0.60 0.37

High strength

7 ASTM Gr.7 345 275-450 20 30 105 2T 2.5T Annealing Pd 0.12/0.25, bal.Ti 0.03 0.08 0.015 0.30 0.25

Titanium alloy with Ti-0.15Pd

8 low alloy elements ASTM Gr.11 KS40PDA Condensor tubes 240 170-310 24 30 105 1.5T 2T Annealing Pd 0.12/0.25, bal.Ti 0.03 0.08 0.015 0.20 0.18

Super- Heat transfer tubes

9 corrosion ASTM Gr.12 KSG12 Ti0.3Mo-0.8Ni Pipings 483 min345 18 25 105 2T 2.5T Annealing Mo 0.2/0.4, Ni 0.6/0.9, bal.Ti 0.03 0.08 0.015 0.30 0.25

resistance Linings Ru 0.02/0.04,

Ti-0.4Ni- Electrolysis vessels

10 ASTM Gr.33 KS60AKOT 0.015Pd- 345 275-450 20 30 105 2T 2.5T Annealing Pd 0.01/0.02, Cr 0.1/0.2, 0.03 0.08 0.015 0.30 0.25

0.025Ru-0.14Cr Ni 0.35/0.55, bal.Ti

11 Heat resistance KSTI-1.5AL Ti-1.5Al Exhaust systems 345 215-450 20 30 105 2T 2.5T Annealing Al 1.0/2.0, bai.Ti 0.03 0.08 0.015 0.30 0.25

alloy Ti-6Al-2Sn-4Zr- Jet engine parts Al 5.5/6.5, Zr 3.6/4.4, Mo1.8/2.2,

12 Heat resistance AMS4976 KS6-2-4-2 Engine Valves 896 min827 10 25 STA 0.05 0.05 0.015 0.10 0.15

2Mo Sn 1.8/2.2, Si 0.06/0.10, bai.Ti

Exhaust systems Al 2.5/3.5, V 2.0/3.0,

13 ASTM Gr.9 KS3-2.5 Ti-3Al-2.5V Bicycle frames 620 min483 15 25 105 2.5T 3T Annealing bal.Ti 0.03 0.08 0.015 0.25 0.15

Eye glass frames

Only sheets and 895 min828 10 25 105 5T Annealing Al 5.5/6.75, V 3.5/4.5, 0.05 0.08 0.015 0.40 0.20

14 ASTM Gr.5 KS6-4 Ti-6Al-4V heavy plates 4.5T

High strength Aircraft parts bal.Ti

Excellent Connecting rods

Ti-4.5Al-2Mo- Valve spring Annealing Al 4.0/5.0, Mo 1.5/2.5,

15 - alloy balance ASTM Gr.35 KSTI-9 1.6V-0.5Fe- retainers 895 min828 5 20 105 5T 5T

(Coils, Sheets) V1.1/2.1, Si 0.2/0.4, 0.05 0.08 0.015 0.20/0.80 0.25

between 0.3Si-0.03C bal.Ti

Titanium strength and Structural parts

alloy toughness Ti-4.5Al-4Cr- Golf club heads Al 4.0/5.0, Cr 3.5/4.5,

16 KS EL-F 895 min828 10 20 Annealing 0.05 0.08/0.25 0.015 0.20/0.80 0.25

0.5Fe-0.2C bal.Ti

Ti-6Al-2Sn-4Zr- L direction L direction STA Al 5.5/6.5, Zr 3.5/4.5,

17 AMS4981 KS-6-2-4-6 Jet engine parts 1172 min1103 10 T 20 T Thickness Sn 1.75/2.25, 0.04 0.04 0.015 0.15 0.15

6Mo

direction 8 direction 15 3in Mo 5.5/6.5

1.78 T 3.18 ST

Aircraft parts 703-945 689-869 12 105 T 1.78 2T 2.5T V 14.0/16.0,

AMS4914 KS15-3-3-3 Ti-15V-3Cr-3Sn- Bicycle gears Cr 2.5/3.5, 0.05 0.05 0.015 0.25 0.13

18 Cold workable 3Al Golf club heads STA

(ST) Foils 1241 min1172 5 482 , 16hr Sn 2.5/3.5, Al 2.5/3.5

alloy Super high AC

strength (STA) Implant materials

Ti-15Mo-5Zr- for orthopaedics Only sheets and STA Al 2.5/3.5, Zr 4.5/5.5,

19 KS15-5-3 3Al Erosion shields min1250 min1103 5 10 0.05 0.08 0.020 0.35 0.20

heavy plates (Forgings) Mo 14.0/16.0, bal.Ti

Golf club heads

No. Standards Nominal composition Notes No. Standards Nominal composition Notes ELI : Extra low interstitial

ST : Solution treatment

20 ASTM Gr.34 Ti-0.4Ni-0.015Pd-0.025Ru-0.14Cr KS70AKOT, Super-corrosion resistance, High strength 27 AMS4959 Ti-13V-11Cr-3Al KS13-11-3, Super-high strength STA : Solution treatment & aging

21 ASTM Gr.6 Ti-5Al-2.5Sn AMS4926, KS5-2.5, Heat resistance 28 JIS T 7401-3 Ti-6Al-2Nb-1Ta KS6-2-1, Implant materials for orthopaedics

* Drawing specifications apply to rod and forged products; bending

22 AMS4924 Ti-5Al-2.5Sn ELI KS5-2.5ELI, Heat resistance, Cryogenic property 29 KS50PDA Ti-0.15Pd Super-corrosion resistance specifications apply to plate products; values of reduction of area are

23 AMS4972 Ti-8Al-1Mo-1V KS8-1-1, Heat resistance 30 KS70PDA Ti-0.15Pd Super-corrosion resistance, High strength applied to bars and forgings.

* The letters "KS" (corresponding KOBE STEEL standard) are the initial letters

24 AMS4918 Ti-6Al-6V-2Sn AMS4971, 4978, KS6-6-2 31 KS50TA Ti-5Ta Condensed nitric acid resistance of "KOBE" and "STEEL," and the numbers 40, 50, and 70 which follow list

25 AMS4995 (Ti-17) Ti-5Al-2Sn-2Zr-4Cr-4Mo KS5-2-2-4-4, High strength at high temperature, Creep resistance 32 KS6-4-4-1-1TA Ti-5.8Al-4Sn-3.5Zn-0.5Mo-0.35Si-0.06C-1Ta Heat resistance minimum tensile strengths of 40 ksi, 50 ksi, and 70 ksi respectively. 1 ksi

is equal to 6.9 MPa.

26 AMS4983 Ti-10V-2Fe-3Al kS10-2-3, High strength, High toughness, High fatigue strength 33 KS16-4-3-3 Ti-16V-4Sn-3Al-3Nb Cold formability * The specification values listed above do not necessarily correspond to all

products manufactured by KOBE STEEL.

* The specification values of titanium alloys may be different according to

the form or dimensions of the finished product.

Developed by KOBE STEEL * We can produce materials other than those listed above.

* Please contact us for details.

Potrebbero piacerti anche

- S 45 CDocumento1 paginaS 45 CFahmi IrmanshahNessuna valutazione finora

- (Discontinued ) : ASTM A353 Alloy SteelDocumento1 pagina(Discontinued ) : ASTM A353 Alloy SteelDhanyajaNessuna valutazione finora

- ASTM A202 Low Alloy Steel PropertiesDocumento1 paginaASTM A202 Low Alloy Steel PropertiesDhanyajaNessuna valutazione finora

- ASTM A516 Carbon Steel, Grade 70 Material PropertiesDocumento1 paginaASTM A516 Carbon Steel, Grade 70 Material Propertiesdeyanshu7Nessuna valutazione finora

- ASTM A284 Steel, Grade CDocumento1 paginaASTM A284 Steel, Grade CBalaNessuna valutazione finora

- Astm A487 4 (A)Documento1 paginaAstm A487 4 (A)baladiroyaNessuna valutazione finora

- Bolts and Nuts Stainless SteelDocumento2 pagineBolts and Nuts Stainless SteelfedemochileroNessuna valutazione finora

- ISO 3506 stainless steel designation system breakdownDocumento3 pagineISO 3506 stainless steel designation system breakdownPaulo Henrique NascimentoNessuna valutazione finora

- Astm B62 C83600Documento1 paginaAstm B62 C83600hemant skNessuna valutazione finora

- ASTM A570 Steel, Grade 50Documento1 paginaASTM A570 Steel, Grade 50alejo5412}Nessuna valutazione finora

- ASTM A570 Steel Grade 50 PDFDocumento1 paginaASTM A570 Steel Grade 50 PDFranjitNessuna valutazione finora

- Idoc - Pub - Astm A570 Steel Grade 50 PDFDocumento1 paginaIdoc - Pub - Astm A570 Steel Grade 50 PDFFrancisco Javier Torres AlvaradoNessuna valutazione finora

- Idoc - Pub - Astm A570 Steel Grade 50 PDFDocumento1 paginaIdoc - Pub - Astm A570 Steel Grade 50 PDFFrancisco Javier Torres AlvaradoNessuna valutazione finora

- Cw008a Cu-Of Version1Documento1 paginaCw008a Cu-Of Version1Gaka RtaNessuna valutazione finora

- Astm A351 CF8MDocumento1 paginaAstm A351 CF8MnadeemNessuna valutazione finora

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Documento2 pagineAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadNessuna valutazione finora

- Astm A572 Steel, Grade 50 DurezaDocumento1 paginaAstm A572 Steel, Grade 50 DurezaMaikol Chino100% (1)

- Stainless Steel Data Sheet Explains Grades, Properties and ApplicationsDocumento2 pagineStainless Steel Data Sheet Explains Grades, Properties and ApplicationsGoNessuna valutazione finora

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Documento3 pagineAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNessuna valutazione finora

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Documento3 pagineAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88Nessuna valutazione finora

- ASTM A131 Grade B Steel for ShipbuildingDocumento1 paginaASTM A131 Grade B Steel for ShipbuildingEmerson IpialesNessuna valutazione finora

- AISI 1050 Steel, As RolledDocumento2 pagineAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNessuna valutazione finora

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDocumento1 paginaAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiNessuna valutazione finora

- Uns S44800Documento1 paginaUns S44800Mohammad TaherNessuna valutazione finora

- Stainless Steel 1.4462 Sheet & PlateDocumento3 pagineStainless Steel 1.4462 Sheet & PlatePaulNessuna valutazione finora

- Aisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFDocumento1 paginaAisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFfeltofsnakeNessuna valutazione finora

- Sae 1022Documento1 paginaSae 1022talebimahdi924Nessuna valutazione finora

- SULZER CastMaterials - E00510Documento5 pagineSULZER CastMaterials - E00510nhirpara1Nessuna valutazione finora

- LKM Steel Rainbow Chart 2014 UpmoldDocumento1 paginaLKM Steel Rainbow Chart 2014 UpmoldsrinivasaNessuna valutazione finora

- Sheet Coil & Plate Alloy 6061: Technical DataDocumento2 pagineSheet Coil & Plate Alloy 6061: Technical DataSarat SrinivasNessuna valutazione finora

- C95200 Aluminum BronzeDocumento1 paginaC95200 Aluminum BronzeDeepak KumarNessuna valutazione finora

- C95200 Aluminum BronzeDocumento1 paginaC95200 Aluminum BronzeDeepak KumarNessuna valutazione finora

- Bronze: LG2 - Leaded GunmetalDocumento3 pagineBronze: LG2 - Leaded GunmetalDodi SuhendraNessuna valutazione finora

- DIN 1628 ST 52.4Documento2 pagineDIN 1628 ST 52.4Anonymous m1cSnEavoNessuna valutazione finora

- Metalcor 1.4436 Aisi 316Documento1 paginaMetalcor 1.4436 Aisi 316Ahmed GhonimNessuna valutazione finora

- Guide to Low-Carbon, Medium-Carbon & High-Carbon SteelsDocumento2 pagineGuide to Low-Carbon, Medium-Carbon & High-Carbon SteelsPAKBOYS TVNessuna valutazione finora

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Documento2 pagineAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNessuna valutazione finora

- Bolt Depot - Bolt Grade Markings and Strength ChartDocumento2 pagineBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- BS 970 En8dDocumento1 paginaBS 970 En8djobseekerarulkumarNessuna valutazione finora

- Astm-A928-2005 Duplex Stailess Steel Pipe Electric Fusion WeldedDocumento6 pagineAstm-A928-2005 Duplex Stailess Steel Pipe Electric Fusion WeldedPablo PerdomoNessuna valutazione finora

- Astm A307Documento1 paginaAstm A307SAlman Khan100% (1)

- Stainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16Documento10 pagineStainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16ManuelNessuna valutazione finora

- SmppdataDocumento2 pagineSmppdataMarco NiNessuna valutazione finora

- Materials BookDocumento37 pagineMaterials BooktanNessuna valutazione finora

- QCJ1TQ 2Documento1 paginaQCJ1TQ 2JOSE CANTERONessuna valutazione finora

- Metalcor 1.4571 Aisi 316 TiDocumento1 paginaMetalcor 1.4571 Aisi 316 TirezaNessuna valutazione finora

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocumento2 pagineAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclNessuna valutazione finora

- NTPC FGD Painting SPecificationDocumento3 pagineNTPC FGD Painting SPecificationanandakumar2810Nessuna valutazione finora

- ASTM A 108 Grade 1020Documento1 paginaASTM A 108 Grade 1020juan ormacheaNessuna valutazione finora

- Carbon Steel SpecificationDocumento4 pagineCarbon Steel SpecificationSteinol SolutionsNessuna valutazione finora

- Material - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural SteelDocumento1 paginaMaterial - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural Steelaniketgupta05Nessuna valutazione finora

- Stoody Super 20Documento1 paginaStoody Super 20JUAN DAVID ESPITIANessuna valutazione finora

- Bolt Depot - Bolt Grade Markings and Strength ChartDocumento2 pagineBolt Depot - Bolt Grade Markings and Strength ChartSundar KumarNessuna valutazione finora

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionDa EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNessuna valutazione finora

- Pt. Intan Anugrah PersadaDocumento1 paginaPt. Intan Anugrah PersadacrysNessuna valutazione finora

- Pt. Intan Anugrah PersadaDocumento1 paginaPt. Intan Anugrah PersadacrysNessuna valutazione finora

- Installation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5Documento1 paginaInstallation of Stop Contact, Cable Tray and Panel Location on Level 3 & 5crysNessuna valutazione finora

- Vac 105 PDFDocumento1 paginaVac 105 PDFcrysNessuna valutazione finora

- Vac 113 PDFDocumento1 paginaVac 113 PDFcrysNessuna valutazione finora

- Pt. Intan Anugrah Persada: Void VoidDocumento1 paginaPt. Intan Anugrah Persada: Void VoidcrysNessuna valutazione finora

- 328 PDFDocumento1 pagina328 PDFcrysNessuna valutazione finora

- Sound system installation plans for Treepark City CikokolDocumento1 paginaSound system installation plans for Treepark City CikokolcrysNessuna valutazione finora

- Pt. Intan Anugrah PersadaDocumento1 paginaPt. Intan Anugrah PersadacrysNessuna valutazione finora

- Sdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadaDocumento1 paginaSdb-Atap Tower A Db-Fire Atap Tower A Pp-Lift.2A Pp-Lift.1A: Pt. Intan Anugrah PersadacrysNessuna valutazione finora

- Cipta Sukses, PT.: Pt. Intan Anugrah PersadaDocumento1 paginaCipta Sukses, PT.: Pt. Intan Anugrah PersadacrysNessuna valutazione finora

- Vac 110 PDFDocumento1 paginaVac 110 PDFcrysNessuna valutazione finora

- Asme31 3Documento1 paginaAsme31 3crysNessuna valutazione finora

- Summary Progress & Status Piping Work-Cut of Date 16 Des 2017Documento16 pagineSummary Progress & Status Piping Work-Cut of Date 16 Des 2017crysNessuna valutazione finora

- Vac 112 PDFDocumento1 paginaVac 112 PDFcrysNessuna valutazione finora

- PT Alphacon's Single V Butt Joint WPSDocumento20 paginePT Alphacon's Single V Butt Joint WPScrys0% (1)

- Lift Dan Gondola 06-11-2015Documento8 pagineLift Dan Gondola 06-11-2015crysNessuna valutazione finora

- Assembling Flanged Joints Procedure1 PDFDocumento34 pagineAssembling Flanged Joints Procedure1 PDFcrysNessuna valutazione finora

- CV FreasmanDocumento2 pagineCV FreasmancrysNessuna valutazione finora

- Indonesia LNGDocumento22 pagineIndonesia LNGcrys100% (1)

- RFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFDocumento23 pagineRFCC-T-PJ-GS-0900 Project Quality Plan (B) PDFcrysNessuna valutazione finora

- RFCC T PJ GS 0900 Project Quality Plan (B)Documento44 pagineRFCC T PJ GS 0900 Project Quality Plan (B)crysNessuna valutazione finora

- PASCAL Check Valves CatalogueDocumento19 paginePASCAL Check Valves Cataloguecrys100% (1)

- ITP Installation of Boiler - R1Documento14 pagineITP Installation of Boiler - R1crys100% (4)

- Clarification 17Documento1 paginaClarification 17crysNessuna valutazione finora

- Spark Arrestor Safety GuideDocumento6 pagineSpark Arrestor Safety GuidecrysNessuna valutazione finora

- 72957d3bb1659d7c77dbf6b6c550abeeDocumento41 pagine72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNessuna valutazione finora

- GENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTDocumento1 paginaGENERATOR SET CSTS INSTALLATION STATUS AND PROGRESS REPORTcrysNessuna valutazione finora

- Spec PDFDocumento1 paginaSpec PDFcrysNessuna valutazione finora

- Aluminium Valve FinalDocumento5 pagineAluminium Valve FinalcrysNessuna valutazione finora

- Cat - Loctite Cross ReferenceDocumento4 pagineCat - Loctite Cross ReferenceRajan MullappillyNessuna valutazione finora

- 3 Analysis and Design of Deck SlabDocumento14 pagine3 Analysis and Design of Deck SlabAshish BhoiNessuna valutazione finora

- FKG CatalogueDocumento20 pagineFKG CatalogueSyed Hassan ZulfiqarNessuna valutazione finora

- Al7050 T7451Documento16 pagineAl7050 T7451Fatih HocaogluNessuna valutazione finora

- Welding Consumables HandbookDocumento56 pagineWelding Consumables Handbookpalandev85Nessuna valutazione finora

- 85 CT McqsDocumento91 pagine85 CT McqsDishantsingh RajputNessuna valutazione finora

- Sro Psi 143 PDFDocumento5 pagineSro Psi 143 PDFmusharat_shafiqueNessuna valutazione finora

- GFRC (Glass Fiber Reinforced Concrete) - : Cast in Place Concrete StructureDocumento2 pagineGFRC (Glass Fiber Reinforced Concrete) - : Cast in Place Concrete StructureAnonymous XYAPaxjbYNessuna valutazione finora

- Q Q345 345E (China / GB) E (China / GB) : Les Propriétés Des Matériels Les Propriétés Des MatérielsDocumento2 pagineQ Q345 345E (China / GB) E (China / GB) : Les Propriétés Des Matériels Les Propriétés Des MatérielsAbdelkader DraïNessuna valutazione finora

- Design of Steel I Section BS5950Documento7 pagineDesign of Steel I Section BS5950chaNessuna valutazione finora

- NHB 700 - The Practice of Heat TreatmentDocumento75 pagineNHB 700 - The Practice of Heat TreatmentConrad Hendrik De KockNessuna valutazione finora

- 16MnCr5 IMDocumento3 pagine16MnCr5 IMeraman_meNessuna valutazione finora

- UltraTech 53 cement test certificateDocumento1 paginaUltraTech 53 cement test certificatemukesh malviyaNessuna valutazione finora

- Design and Evaluation of High Volume Flyash Concrete For Rigid Pavement Over LaysDocumento31 pagineDesign and Evaluation of High Volume Flyash Concrete For Rigid Pavement Over LaysSpchethan ChethanspNessuna valutazione finora

- Basis of DesignDocumento12 pagineBasis of DesignjayaramanrathnamNessuna valutazione finora

- AP BR 1050 Dematic RapidStore ASRS FamilyDocumento17 pagineAP BR 1050 Dematic RapidStore ASRS FamilyDeepak BansalNessuna valutazione finora

- R-Value TableDocumento4 pagineR-Value TableKKNessuna valutazione finora

- Ain Shams Engineering Journal: Yehia A. Zaher AliDocumento6 pagineAin Shams Engineering Journal: Yehia A. Zaher AliKarrar MonarchNessuna valutazione finora

- Chryso-Armourcrete 6052 4420Documento2 pagineChryso-Armourcrete 6052 4420Aquib SiddiqueNessuna valutazione finora

- Exxelor PO-1020 BrochureDocumento2 pagineExxelor PO-1020 Brochuremaheshgupte100% (1)

- Cellular Manufacturing Layout OptimizationDocumento64 pagineCellular Manufacturing Layout OptimizationMochamad AzizNessuna valutazione finora

- What Factors Causes Failure of Concrete StructuresDocumento4 pagineWhat Factors Causes Failure of Concrete StructuresNick Genese100% (1)

- Excel FileDocumento6 pagineExcel FilePravin KenNessuna valutazione finora

- Steela-'07: Duplex Stainless A Review After DSS Held in GradoDocumento11 pagineSteela-'07: Duplex Stainless A Review After DSS Held in GradoVinay MaisuriyaNessuna valutazione finora

- P&LLayout - PPT 1111111111Documento64 pagineP&LLayout - PPT 1111111111amuNessuna valutazione finora

- Optic Fiber Protection Overhead Ground Wire: Other Aluminium ProductsDocumento7 pagineOptic Fiber Protection Overhead Ground Wire: Other Aluminium ProductsburvanovNessuna valutazione finora

- Milling Speeds and FeedsDocumento1 paginaMilling Speeds and FeedsirinaNessuna valutazione finora

- Movex 2016USALDocumento332 pagineMovex 2016USALserenetaNessuna valutazione finora

- Buckling Restrained Braced FrameDocumento24 pagineBuckling Restrained Braced Framedanish khanNessuna valutazione finora

- Non Ferrous AlloysDocumento18 pagineNon Ferrous Alloysamele25Nessuna valutazione finora