Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Air Slide Conveyor Systems for Powdered Materials

Caricato da

joe_kudoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Air Slide Conveyor Systems for Powdered Materials

Caricato da

joe_kudoCopyright:

Formati disponibili

Air Slide Conveyor Systems

W.G. Benjey’s air slide conveyor systems will quickly and effi-

ciently convey materials such as raw and finished cement, fly

ash, and precipitator dust. The simple combination of air

pressure and gravity allows powdered materials to flow like a

fluid. Air slide conveyors are very efficient and quiet. And

with no moving parts, these conveyors are also extremely

cost effective and require very little maintenance.

W G Benjey inc. www.benjey.com 800-269-9006

SPECIFICATIONS AND FEATURES:

Upper and lower bodies are formed from 10 gage

steel, with 1/4” steel end flanges. Maximum sec-

tion length is 12’. Each section is independently

pressurized and requires only a single air inlet.

• Flow regulation through air pressure regulation

• Extremely quiet operation

• Low maintenance, no moving parts

• Minimal wear from abrasion

• Low pressure requirements, 0.5—5.0 psi

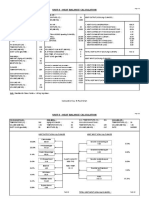

Type Maximum “A” “B” “C”

Capacity (in.) (in.) (in.)

WGB-AS6 1200 cu.ft./hr. 6 7-7/8 4-5/8

WGB-AS12 7620 cu.ft./hr. 12 15-3/4 4-5/8

WGB-AS24 56000 cu.ft./hr. 24 23-5/8 4-5/8

2293 WERTH ROAD

ALPENA, MI 49707

PHONE: (989) 356-1433

FAX: (989) 356-6446

SYSTEM DESIGN:

Air slide conveyors can be used in a single

straight run, but are equally as effective

when used in large systems. Through the

use of turn boxes, conveyors can easily

change directions, merge, or split without the

need for powered conveyors or diverters.

Manual or powered shut off gates can be inte-

grated into any point of the system to control

flow.

The maximum range of the conveyors are lim-

ited only by the height of the source. Con-

veyors require a minimum of a 5 degree drop

angle to function properly. A 10 degree angle

is recommended for most applications.

Air slide conveyors also utilize traditional conveyor components such as diverter gates, flow

controls, shut-off gates, and discharge chutes. Air slide technology can also be applied to your

existing or newly manufactured storage bins.

2293 WERTH ROAD

ALPENA, MI 49707

PHONE: (989) 356-1433

FAX: (989) 356-6446

Potrebbero piacerti anche

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Air Slide Working ManualDocumento20 pagineAir Slide Working ManualKrishnadas Gopalakrishnan100% (3)

- Pneumatic Conveying: Technology You Can TrustDocumento16 paginePneumatic Conveying: Technology You Can TrustSyed Rameez MohiuddinNessuna valutazione finora

- AUMUND Pan Conveyors Fd0a10Documento24 pagineAUMUND Pan Conveyors Fd0a10Bruno100% (1)

- Long Filter BagDocumento1 paginaLong Filter BagAlbar BudimanNessuna valutazione finora

- Polytrack Clinker Cooler.: PolysiusDocumento3 paginePolytrack Clinker Cooler.: PolysiushathamphanNessuna valutazione finora

- Atox 20 Coal Mill Critical Interlock SheetDocumento6 pagineAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunNessuna valutazione finora

- Fons Technology PDFDocumento28 pagineFons Technology PDFBulent BULUTNessuna valutazione finora

- Sturt Air ClassifierDocumento6 pagineSturt Air ClassifierHenry Vladimir VianchaNessuna valutazione finora

- Kiln Shell Specification SummaryDocumento20 pagineKiln Shell Specification SummaryAnonymous p4GdtQpNessuna valutazione finora

- Seperator Efficiency CM1 May 2015Documento9 pagineSeperator Efficiency CM1 May 2015Junaid MazharNessuna valutazione finora

- Example of Cement Mill QuestionnaireDocumento5 pagineExample of Cement Mill QuestionnaireIrfan AhmedNessuna valutazione finora

- Cfi SiloDocumento4 pagineCfi SiloSyed KhalilNessuna valutazione finora

- Bag House Differential Pressure: Key Indicator of Operation and TroubleshootingDocumento8 pagineBag House Differential Pressure: Key Indicator of Operation and TroubleshootingZegera Mgendi100% (2)

- PFC - The Great CoolerDocumento47 paginePFC - The Great CoolerM.IBRAHEEM100% (1)

- FLS Cooling of ClinkerDocumento30 pagineFLS Cooling of Clinkersaber ghodbaneNessuna valutazione finora

- Air SeperatorDocumento45 pagineAir Seperatorsameh ibrahemNessuna valutazione finora

- Monitoring, Inspection & Evaluation of Ball Cement MillsDocumento6 pagineMonitoring, Inspection & Evaluation of Ball Cement MillsMin MCLNessuna valutazione finora

- How To Measure False Air PDFDocumento3 pagineHow To Measure False Air PDFPrashant Kumar mishraNessuna valutazione finora

- FivesFCB Brochure Horomill GBDocumento6 pagineFivesFCB Brochure Horomill GBpeymanNessuna valutazione finora

- 15th NCB Technical PaperDocumento10 pagine15th NCB Technical PaperSalah RomdaniNessuna valutazione finora

- MHR21924 CMC Chapter CCDocumento48 pagineMHR21924 CMC Chapter CCDede KaladriNessuna valutazione finora

- Raw Meal Suspension in CalcinerDocumento48 pagineRaw Meal Suspension in CalcineremadsabriNessuna valutazione finora

- Storage and Aeration System in SiloDocumento2 pagineStorage and Aeration System in Siloibnuwibowo1990Nessuna valutazione finora

- Energy Efficiency with IKN Pendulum CoolerDocumento28 pagineEnergy Efficiency with IKN Pendulum CoolerJunaid MazharNessuna valutazione finora

- AirslidesDocumento3 pagineAirslidesVisnu SankarNessuna valutazione finora

- BEUMER Bucket ElevatorsDocumento12 pagineBEUMER Bucket ElevatorsIsmailNessuna valutazione finora

- Hydraulic Cylinder Maintenance ChecklistDocumento10 pagineHydraulic Cylinder Maintenance Checklisthaziq100% (1)

- Vertical Roller Mill State of The Art Raw GrindingDocumento4 pagineVertical Roller Mill State of The Art Raw GrindingzementheadNessuna valutazione finora

- R A R F U: % Passing Size, M Feed Coarse FinesDocumento3 pagineR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütNessuna valutazione finora

- Loesche Grinding Plants for Coal GasificationDocumento45 pagineLoesche Grinding Plants for Coal GasificationMaxim Polevoy100% (1)

- FLSmidth Highlights by Shahid HussainDocumento38 pagineFLSmidth Highlights by Shahid HussainShahid HussainNessuna valutazione finora

- Jaypee Cement Project ReportDocumento29 pagineJaypee Cement Project ReportPurnendu MishraNessuna valutazione finora

- Technical Specification of VSK PDFDocumento28 pagineTechnical Specification of VSK PDFmaran.suguNessuna valutazione finora

- FK PumpDocumento29 pagineFK PumpPP2 Common ID/OperationNessuna valutazione finora

- QUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYDocumento8 pagineQUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYVijay BhanNessuna valutazione finora

- 154 Loesche Mills For Cement Raw Material E 2016Documento28 pagine154 Loesche Mills For Cement Raw Material E 2016faheemqcNessuna valutazione finora

- Collaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurDocumento4 pagineCollaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurjmpbarrosNessuna valutazione finora

- Wear Rate Calculator MonoDocumento2 pagineWear Rate Calculator MonoBùi Hắc HảiNessuna valutazione finora

- Modern Cement Grinding Systems ComparedDocumento14 pagineModern Cement Grinding Systems ComparedCao Ngoc AnhNessuna valutazione finora

- A4-P 1.0 enDocumento21 pagineA4-P 1.0 enmkpqNessuna valutazione finora

- Gear and equipment specification summaryDocumento4 pagineGear and equipment specification summaryprashant mishraNessuna valutazione finora

- Heat correction of kiln cranks is cost effectiveDocumento4 pagineHeat correction of kiln cranks is cost effectiveMohamed Shehata100% (2)

- Fuller-Kinyon Kompact Pumps Pneumatic ConveyingDocumento4 pagineFuller-Kinyon Kompact Pumps Pneumatic ConveyingAnoop Tiwari0% (1)

- Ball Mill Systems Grinding and Separating EfficiencyDocumento64 pagineBall Mill Systems Grinding and Separating EfficiencyPaulo VidasNessuna valutazione finora

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Documento19 pagineKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNessuna valutazione finora

- Presentation-Hydraulic System in VRPMDocumento24 paginePresentation-Hydraulic System in VRPMmsvprasadNessuna valutazione finora

- Rotary Kiln Process Training: Krupp Polysius CorpDocumento15 pagineRotary Kiln Process Training: Krupp Polysius CorpbabarNessuna valutazione finora

- ESPDocumento15 pagineESPlrpatraNessuna valutazione finora

- Bag Filters For Cement IndustryDocumento9 pagineBag Filters For Cement Industrymahreza189Nessuna valutazione finora

- Bag Filter ComponentsDocumento6 pagineBag Filter ComponentsAhmad Dagamseh100% (2)

- Nelson Machinery Int'l Equipment Highlights 2019-04Documento64 pagineNelson Machinery Int'l Equipment Highlights 2019-04Andy GNessuna valutazione finora

- Mini Plant Training Material: Air SlidesDocumento28 pagineMini Plant Training Material: Air Slidesbulentbulut100% (2)

- FLSPfister IB05000 I GBTRWSD0216 MailDocumento26 pagineFLSPfister IB05000 I GBTRWSD0216 MailLuis Angel BusturiaNessuna valutazione finora

- Dokumen - Tips - Atox Raw Mill 55844e0e63329Documento13 pagineDokumen - Tips - Atox Raw Mill 55844e0e63329pipit agusNessuna valutazione finora

- Air SlideDocumento3 pagineAir SlideMuhamad FadzirNessuna valutazione finora

- Air Slide Conveyor Systems for Powdered MaterialsDocumento3 pagineAir Slide Conveyor Systems for Powdered MaterialsAbrar CheemaNessuna valutazione finora

- Catalog Page 1.6 PDFDocumento1 paginaCatalog Page 1.6 PDFGustavo BimNessuna valutazione finora

- Superior Pipeline EquipmentsDocumento68 pagineSuperior Pipeline Equipmentsaliyildizx17730Nessuna valutazione finora

- Material TransportsDocumento4 pagineMaterial TransportshfjfjfjNessuna valutazione finora

- Business Model Design WorkbookGuideDocumento22 pagineBusiness Model Design WorkbookGuideAdrian LererNessuna valutazione finora

- Aasr 2012 3 2 1162 1174Documento13 pagineAasr 2012 3 2 1162 1174Mohammed AbdoNessuna valutazione finora

- Basic principles of particle sizing: Understanding size distributions and statisticsDocumento37 pagineBasic principles of particle sizing: Understanding size distributions and statisticsjoe_kudoNessuna valutazione finora

- ZKG IndiaDocumento36 pagineZKG Indiajoe_kudo0% (1)

- User Guide PDFDocumento27 pagineUser Guide PDFbulentbulut100% (1)

- Combustion CalculationDocumento22 pagineCombustion CalculationTejas T S TejasNessuna valutazione finora

- Does Shape MatterDocumento56 pagineDoes Shape Matterjoe_kudoNessuna valutazione finora

- Introduction of Low-Temperature Waste Heat Recovery Power Generator (WHRPG) Technology PDFDocumento25 pagineIntroduction of Low-Temperature Waste Heat Recovery Power Generator (WHRPG) Technology PDFjoe_kudoNessuna valutazione finora

- ACT Cement-Based MaterialsDocumento13 pagineACT Cement-Based Materialsjoe_kudoNessuna valutazione finora

- Thermo and Mechanical Stress Modelling Kiln Outlet DesignDocumento5 pagineThermo and Mechanical Stress Modelling Kiln Outlet Designjoe_kudoNessuna valutazione finora

- Chemistry Page on Clinker Moduli CalculationsDocumento1 paginaChemistry Page on Clinker Moduli Calculationsjoe_kudoNessuna valutazione finora

- Vertical Roller Mill Process DetailsDocumento49 pagineVertical Roller Mill Process Detailsrecai100% (3)

- Aasr 2012 3 2 1162 1174Documento13 pagineAasr 2012 3 2 1162 1174Mohammed AbdoNessuna valutazione finora

- Major Comp. (A-1)Documento1 paginaMajor Comp. (A-1)joe_kudoNessuna valutazione finora

- Laboratory FurnacesDocumento47 pagineLaboratory Furnacesjoe_kudoNessuna valutazione finora

- User Guide PDFDocumento27 pagineUser Guide PDFbulentbulut100% (1)

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocumento2 pagineUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTjoe_kudoNessuna valutazione finora

- Data Driven Decision MakingDocumento59 pagineData Driven Decision Makingjoe_kudoNessuna valutazione finora

- User Guide PDFDocumento27 pagineUser Guide PDFbulentbulut100% (1)

- Simulasi Kenaikan Heat Consumption Akibat Kenaikan LSFDocumento3 pagineSimulasi Kenaikan Heat Consumption Akibat Kenaikan LSFjoe_kudoNessuna valutazione finora

- Grate cooler precast bullnose designDocumento16 pagineGrate cooler precast bullnose designjoe_kudo100% (1)

- Cement manufacturing technologies for energy efficiency and emission reductionDocumento22 pagineCement manufacturing technologies for energy efficiency and emission reductionnecdetdalgicNessuna valutazione finora

- FiatDocumento56 pagineFiatOmkar ParkarNessuna valutazione finora

- Milenium BypassDocumento1 paginaMilenium BypassdinotecNessuna valutazione finora

- Manual Instalaciones Electricas para Centros de ComputoDocumento65 pagineManual Instalaciones Electricas para Centros de ComputoJorge Estrada0% (3)

- Suparco+ KRL Test Ques For Electrical EngrzDocumento5 pagineSuparco+ KRL Test Ques For Electrical Engrzمحمد فصیح آفتابNessuna valutazione finora

- 176Documento3 pagine176Karthik AmigoNessuna valutazione finora

- Man Power PlanningDocumento5 pagineMan Power PlanningKarthik AchinNessuna valutazione finora

- PERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedDocumento4 paginePERFAPPRAISAL Research proposal on performance appraisal practices at National Bank of Pakistan and United Bank LimitedNadia KhanNessuna valutazione finora

- SANY SSR180C 8 OM EN PreviewDocumento31 pagineSANY SSR180C 8 OM EN Previewzaploc.admNessuna valutazione finora

- Roof Slab of Guard RoomDocumento3 pagineRoof Slab of Guard RoomAditya KumarNessuna valutazione finora

- JonWeisseBUS450 04 HPDocumento3 pagineJonWeisseBUS450 04 HPJonathan WeisseNessuna valutazione finora

- Questionnaire For Future BLICZerDocumento1 paginaQuestionnaire For Future BLICZerAlejandra GheorghiuNessuna valutazione finora

- bbk-lt2614-lt3214 Service Manual PDFDocumento42 paginebbk-lt2614-lt3214 Service Manual PDFrj arcinasNessuna valutazione finora

- HoltacDocumento8 pagineHoltacdargil66Nessuna valutazione finora

- Programmability in SPSS 16 & 17, Jon PeckDocumento36 pagineProgrammability in SPSS 16 & 17, Jon PeckJasmin MaricNessuna valutazione finora

- Multi-Stage Centrifugal Blower Design Pressure ConsiderationsDocumento5 pagineMulti-Stage Centrifugal Blower Design Pressure ConsiderationsSATYA20091100% (1)

- 4c - Expanded - RevisedDocumento132 pagine4c - Expanded - RevisedMartín Serena75% (4)

- Model Railroad Plans and DrawingsDocumento7 pagineModel Railroad Plans and DrawingsBán ZoltánNessuna valutazione finora

- QUICK GUIDE ON WRITING PATENT SPECIFICATION v1Documento37 pagineQUICK GUIDE ON WRITING PATENT SPECIFICATION v1Muhammad Azuan TukiarNessuna valutazione finora

- General Purpose Relay SpecsDocumento2 pagineGeneral Purpose Relay SpecsAndres DiazNessuna valutazione finora

- Rob Thomas Digital Booklet - Cradle SongDocumento15 pagineRob Thomas Digital Booklet - Cradle SongAgnieszka ŁukowskaNessuna valutazione finora

- F1FR80 Series Quick-Response SprinklersDocumento6 pagineF1FR80 Series Quick-Response SprinklersAtila AmayaNessuna valutazione finora

- Aluminium GMAW GuideDocumento32 pagineAluminium GMAW GuideDaniel Salinas100% (2)

- RS-485 2X227 AWG SFUTP PVC - 9FY7F1V129 - V - 1 - R - 1Documento2 pagineRS-485 2X227 AWG SFUTP PVC - 9FY7F1V129 - V - 1 - R - 1jeffv65Nessuna valutazione finora

- Nazneen Wahab CVDocumento5 pagineNazneen Wahab CVRavi MittalNessuna valutazione finora

- Degx1 Dggx1 Us PartsDocumento24 pagineDegx1 Dggx1 Us PartsJeff RussoNessuna valutazione finora

- Excel Dashboard WidgetsDocumento47 pagineExcel Dashboard WidgetskhincowNessuna valutazione finora

- Template Icme 13 PosterDocumento1 paginaTemplate Icme 13 PosterZulma Xiomara Rueda GarciaNessuna valutazione finora

- Abstracts Book Nanotech 2013Documento151 pagineAbstracts Book Nanotech 2013felipe de jesus juarez torresNessuna valutazione finora

- List of Title-01Documento30 pagineList of Title-01najwaNessuna valutazione finora

- Advances in Remediation-eBookDocumento88 pagineAdvances in Remediation-eBookalinerlfNessuna valutazione finora