Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Risk Assessment for Compressed Gas Cylinder Use

Caricato da

jeffreyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Risk Assessment for Compressed Gas Cylinder Use

Caricato da

jeffreyCopyright:

Formati disponibili

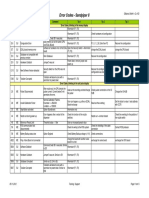

Risk Assessment Title: Use of Compressed Gas Cylinders Risk Assessment No.

: 020 Rev: 2

Associated Method Statement: N/A Next Review Date: December 2018

( * ): L: Likelihood, S: Severity

INITIAL RISK RESIDUAL RISK

ASSESSMENT ASSESSEMENT

Persons Action By

No. Task/ Process Hazard Risk(s) RISK Control Measures RISK

at risk & Timing

L* S* (R = L L* S* (R = L

x S) x S)

Transportation of cylinders must be in a purpose built

gas trolley or lifting cage and all cylinders must be se

cured by a chain

Cylinders must be adequately secured against moving

Should be in an upright position during transport (this

minimizes rate of release in a leak situation).

Secured with straps or chains connected to proper

cage.

The number of cylinders to be transported should be

limited to the absolute minimum. Drivers /

Moving load Property Workers Whenever practicable regulators or other equipment Operator

could cause damage, executing the should be separated from gas cylinders for transport. If

Transportation Site

injury or, cylinder Personnel task, Site equipment is kept attached it is absolutely essential

of gas cylinders personnel &

1. valve could be injury, High operatives 3 4 M prior to transport that the: 2 3 L

to and from Store

damaged and potential of nearby in the - cylinder valves are tightly closed;

work zones keepers

contents pressure vicinity of - The system is depressurized (vented) Daily

released. release, work station Vehicle transportation prohibited & not allowed to enter Review

in premises storage area

Restrict access by means of securing gate by padlock

and chain

Authorized personnel only handling the key for storage

gate

Proper Information, instruction and awareness training

for operatives handling the compressed gas cylinders.

Security to maintain logbook in-out going transportation

in of compressed gas cylinders

Site Make an assessment of the load to be carried Task

operatives / Introduce team handling for difficult loads or job rotation Engineer,

Manual handling Personnel

Workers 3 4 M Use mechanical aid like trolleys 2 3 L Logistics,

injury, Back Injury

executing the Cylinders are heavy and need to be handled with care. FM/

task Proper instructions must be given to workers to ensure Supervisor

Risk Assessment Title: Use of Compressed Gas Cylinders Risk Assessment No.: 020 Rev: 2

Associated Method Statement: N/A Next Review Date: December 2018

( * ): L: Likelihood, S: Severity

INITIAL RISK RESIDUAL RISK

ASSESSMENT ASSESSEMENT

Persons Action By

No. Task/ Process Hazard Risk(s) RISK Control Measures RISK

at risk & Timing

L* S* (R = L L* S* (R = L

x S) x S)

that they will be aware of the risks of manual handling. Site

Site safety officer to verify this in the toolbox talks/ pre personnel &

start briefing topic and attendance record conducted by HSE

the supervisor Daily review

Seek help.

Ensure that cylinder valves are closed and not leaking.

Never transport a cylinder inside a vehicle if a leak has

been detected. Secure in a well-ventilated area and

contact the gas supplier.

You must check that the cylinder is the correct one for

Site the intended use, is not older than15 years and has

Task

operatives, been pressure tested within the last 5 years

Engineer,

logistics Valve protection guards must remain in place at all

FM/

Fire and team times except when cylinders are secured and Supervisor

Fire or explosion damage to Supplier 3 5 H connected to the hose and are in use; 2 3 L

Site

property personnel, Cylinders must always be stored upright and personnel &

public in the segregated Driver to be briefed about emergency HSE

vicinity of

procedures and call supplier Daily review

work station

Comply and provide access to civil defense authority in

case of emergency

Proper instructions must be given to workers to ensure

that they will be aware of the risks of manual handling. Task

Site Site safety officer to verify this in the toolbox talks/ pre Engineer,

operatives, start briefing topic and attendance record conducted by FM /

Poor manual

Loading/offloadi Personnel logistics the supervisor Supervisor

2. handling 3 4 M 2 3 L

ng CGC Back Injury team Adapt good handling techniques and postures Site

technique

Supplier Gas cylinders must not be raised or lowered on the personnel &

personnel forks of a lift truck HSE

Cylinders must always be stored upright and Daily review

segregated, secured with straps or chains connected to

Risk Assessment Title: Use of Compressed Gas Cylinders Risk Assessment No.: 020 Rev: 2

Associated Method Statement: N/A Next Review Date: December 2018

( * ): L: Likelihood, S: Severity

INITIAL RISK RESIDUAL RISK

ASSESSMENT ASSESSEMENT

Persons Action By

No. Task/ Process Hazard Risk(s) RISK Control Measures RISK

at risk & Timing

L* S* (R = L L* S* (R = L

x S) x S)

a wall bracket or other fixed surface

Instructions and supervisions must be given to

operatives. Site safety officer to verify the toolbox talks

/ pre-start briefing topic and attendance record

conducted by the Supervisor

Site Ensure that the access area is clean and clear from FM /

Limited space / operatives, obstructions and well lit Supervisor

Personnel

floor conditions. logistics Ensure sufficient space around Site

Injury, slip trips 3 4 M 1 2 L

Being struck by team Employ a person to control traffic movement personnel &

and fall

object Supplier Call supplier/emergency services HSE

personnel Daily review

Visually check the cylinder to ensure there is no

damage, dents, cracks, scorch marks or corrosion.

Ensure two people are present when moving cylinders

Wear PPE “safety shoes, gloves, eye protection, etc.”

Disconnect regulators and fit protective valve caps

Ensure the chain / restraining device is in place.

Ensure the cylinder is vertical Supplier,

Site Ensure the cylinder is stored away from sources of Site

Fire, pressure operatives, ignition. personnel,

Leak due to released and logistics Restrain the cylinder to stop it falling Store /

3 4 M 2 3 L

bottles damaged damage to team Call supplier/emergency services Logistics

property Supplier Never smoke when handling gas cylinders. and HSE

personnel Daily

Never manually spin the cylinder to transport it even a Review l

short distance you may trip and fall, the cylinder may

then fall on you. Cylinders must never be dragged or

rolled.

Gas cylinders must not be raised or lowered on the

forks of a lift truck

Gas cylinders must be used in the vertical position;

Risk Assessment Title: Use of Compressed Gas Cylinders Risk Assessment No.: 020 Rev: 2

Associated Method Statement: N/A Next Review Date: December 2018

( * ): L: Likelihood, S: Severity

INITIAL RISK RESIDUAL RISK

ASSESSMENT ASSESSEMENT

Persons Action By

No. Task/ Process Hazard Risk(s) RISK Control Measures RISK

at risk & Timing

L* S* (R = L L* S* (R = L

x S) x S)

You must check that the cylinder is the correct one for

the intended use, is not older than15 years and has

been pressure tested within the last 5 years;

Visually check the cylinder to ensure there is no

damage, dents, cracks, scorch marks or corrosion.

Ensure two people are present when moving

cylinders

Wear PPE “safety shoes, gloves, eye protection,

etc.”

Disconnect regulators and fit protective valve caps

Ensure the chain / restraining device is in place.

Ensure the cylinder is vertical

Ensure the cylinder is stored away from sources of

Site

Site ignition.

Fire, pressure personnel,

operatives / Restrain the cylinder to stop it falling

Use of gas Leak due to released and storekeeper

3. Workers 3 4 M Call supplier/emergency services 2 3 L

cylinders bottles damaged damage to supervisor

executing the Never smoke when handling gas cylinders.

property and HSE

task

Never manually spin the cylinder to transport it even personnel

a short distance you may trip and fall, the cylinder

may then fall on you. Cylinders must never be

dragged or rolled.

Gas cylinders must not be raised or lowered on the

forks of a lift truck

Gas cylinders must be used in the vertical position;

You must check that the cylinder is the correct one for

the intended use, is not older than15 years and has

been pressure tested within the last 5 years;

Site Site

Fire and Transportation of cylinders must be in a purpose

operatives, personnel,

Explosion, fire damage to 3 5 H built gas trolley or lifting cage and all cylinders must 2 3 L

logistics storekeeper

property be secured by a chain

team supervisor

Risk Assessment Title: Use of Compressed Gas Cylinders Risk Assessment No.: 020 Rev: 2

Associated Method Statement: N/A Next Review Date: December 2018

( * ): L: Likelihood, S: Severity

INITIAL RISK RESIDUAL RISK

ASSESSMENT ASSESSEMENT

Persons Action By

No. Task/ Process Hazard Risk(s) RISK Control Measures RISK

at risk & Timing

L* S* (R = L L* S* (R = L

x S) x S)

Supplier On no account must a cylinder be lifted by the valve and HSE

personnel, using a web sling/chain; personnel

public in the Never manually spin the cylinder to transport it even

vicinity of a short distance.

work station Cylinders must never be dragged or rolled.

Gas cylinders must not be raised or lowered on the

forks of a lift truck

Gas cylinders must be used in the vertical position;

You must check that the cylinder is the correct one

for the intended use, is not older than15 years and

has been pressure tested within the last 5 years

Cylinders must be stored out of direct sunlight to

prevent potential rupture due to heat expansion

Ventilation must be available to keep cylinders cool.

Warning signage must be placed in prominent

positions to warn others in the vicinity.

Cylinders must always be stored upright and

segregated never store oxygen and acetylene

together and never store empty and full cylinders

together.

Cylinders must be secured with straps or chains

connected to a wall bracket or other fixed surface

Oxygen must be stored at least 3 meters away

from other flammable gases such as acetylene and

propane. Never store cylinders horizontally;

The storage area for cylinders must be at least 6

meters away from any outbuilding;

Valve protection guards must remain in place at all

times except when cylinders are secured and

connected to the hose and are in use;

Fuel hoses must be inspected for signs of cracks or

perishing and removed immediately if found. This

inspection must be carried out daily before use.

Risk Assessment Title: Use of Compressed Gas Cylinders Risk Assessment No.: 020 Rev: 2

Associated Method Statement: N/A Next Review Date: December 2018

( * ): L: Likelihood, S: Severity

INITIAL RISK RESIDUAL RISK

ASSESSMENT ASSESSEMENT

Persons Action By

No. Task/ Process Hazard Risk(s) RISK Control Measures RISK

at risk & Timing

L* S* (R = L L* S* (R = L

x S) x S)

Fuel hoses must not be used if there are no flashback

arrestors fitted at the regulator and torch end.

Regulators must be handled with care to avoid

damage to their sensitive springs, diaphragms and

valve seals.

Regulator connections must be free of damage in

particular to the thread as this give potential for gas

leaks and risk of fire/explosion.

NOTE: In an event of Emergency Situations or Casualty Evacuation - First aid cover will be provided throughout core works and ALL STAFF TO BE BRIEFED ON EMERGENCY

ARRANGEMENTS AND CASUALTY EVACUATION

Review and Approval

Prepared Checked Revision History

Approved by:

by: by: Workplace Manager / Deputy ( 6 months unless specified)

Task Supervisor / Engineer HSE

(PM or CM)

Date Date Date

Signature Signature Signature

Risk Evaluation Significance Matrix

HAZARD SEVERITY

Negligible Slight Moderate High Very High

(1) (2) (3) (4) (5)

Very Unlikely (1) LOW LOW LOW LOW MEDIUM

LIKELIHOOD OF

OCCURRENCE

Unlikely (2) LOW LOW LOW MEDIUM MEDIUM

Possible (3) LOW LOW MEDIUM MEDIUM HIGH

Likely (4) LOW MEDIUM MEDIUM HIGH HIGH

Very Likely (5) LOW MEDIUM HIGH HIGH HIGH

Potrebbero piacerti anche

- Forklift Safety Policy and ProcedureDocumento3 pagineForklift Safety Policy and ProcedureChristian Auditor Rivera100% (1)

- Jsa R B 6 ForkliftDocumento3 pagineJsa R B 6 Forkliftoscar67% (3)

- Flagman TrainingDocumento58 pagineFlagman TrainingIndermohan MehtaNessuna valutazione finora

- Flagman/ Banksman TrainingDocumento25 pagineFlagman/ Banksman TrainingAatif Patil100% (1)

- Scaffold Inspection ChecklistDocumento2 pagineScaffold Inspection Checklistjeffrey90% (10)

- Lockout Tagout TRNG GuideDocumento7 pagineLockout Tagout TRNG GuideSyed Mujtaba Ali Bukhari100% (1)

- Manual Rubbish Handling SafetyDocumento1 paginaManual Rubbish Handling SafetyScribder0% (1)

- Activity Hazard AnalysisDocumento4 pagineActivity Hazard AnalysisGerrard Singh100% (1)

- Concrete WorkDocumento1 paginaConcrete WorkChandruNessuna valutazione finora

- Risk Assessment ConcreteDocumento1 paginaRisk Assessment Concretemohamed ghaly0% (1)

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocumento168 pagineAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNessuna valutazione finora

- Risk Assessment New Site Lifting Operations 07-06-2015Documento3 pagineRisk Assessment New Site Lifting Operations 07-06-2015ANAND MLNessuna valutazione finora

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Documento15 pagineHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNessuna valutazione finora

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahDocumento14 pagineMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottNessuna valutazione finora

- Risk assessment form for forklift operationsDocumento5 pagineRisk assessment form for forklift operationsFachri HidayatNessuna valutazione finora

- Use of Hand ToolsDocumento2 pagineUse of Hand Toolsvictor100% (1)

- JHA Jack Hydraulic PalletDocumento1 paginaJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- Stop Work AuthortyDocumento8 pagineStop Work AuthortyRonald Sarillana100% (1)

- Metal Chop Saw SopDocumento2 pagineMetal Chop Saw SopkylealamangoNessuna valutazione finora

- ObservationsDocumento6 pagineObservationsjeffreyNessuna valutazione finora

- Risk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0Documento7 pagineRisk Assessment - PLCC Cable and GIB Testing 26DEC15 - Rev 0NirmalKumarSelvarajNessuna valutazione finora

- Lifting Operations Risk Assessment Crane Risk AssessmentDocumento13 pagineLifting Operations Risk Assessment Crane Risk Assessment9853318441Nessuna valutazione finora

- Risk assessment for logistics company loading and unloading vehiclesDocumento2 pagineRisk assessment for logistics company loading and unloading vehiclesDanny100% (1)

- Adverse Weather Condition HIRADocumento5 pagineAdverse Weather Condition HIRAVenkadesh PeriathambiNessuna valutazione finora

- Proper Lifting Techniques Toolbox Talk #13Documento1 paginaProper Lifting Techniques Toolbox Talk #13kimlynroseNessuna valutazione finora

- JHA Maintenance Tech HVACDocumento2 pagineJHA Maintenance Tech HVACMdavaNessuna valutazione finora

- Working at Height Rescue PlanDocumento1 paginaWorking at Height Rescue PlanAbbas AsadNessuna valutazione finora

- Safe Work at Heights ProceduresDocumento1 paginaSafe Work at Heights ProceduresOws AnishNessuna valutazione finora

- Behavior-based safety A Clear and Concise ReferenceDa EverandBehavior-based safety A Clear and Concise ReferenceNessuna valutazione finora

- HSE guidance on safety devices for rapid roller doorsDocumento11 pagineHSE guidance on safety devices for rapid roller doorsmsc920138Nessuna valutazione finora

- Confined Space Entry Program 11 2021Documento16 pagineConfined Space Entry Program 11 2021zaka ullahNessuna valutazione finora

- HSE Presentation TemplateDocumento10 pagineHSE Presentation TemplatejeffreyNessuna valutazione finora

- Monthly Ladder Inspection ChecklistDocumento1 paginaMonthly Ladder Inspection ChecklistshahidNessuna valutazione finora

- Confined Spaces Management PlanDocumento32 pagineConfined Spaces Management PlanIdris AdeniranNessuna valutazione finora

- JSA #28 - Use of Hand ToolsDocumento1 paginaJSA #28 - Use of Hand ToolsSubham SohalNessuna valutazione finora

- Rescue Confined WorkersDocumento5 pagineRescue Confined WorkersOlaniyi AdewaleNessuna valutazione finora

- Lift Accessories Lift Measure Risk Assessment Form BaseDocumento6 pagineLift Accessories Lift Measure Risk Assessment Form Basebalusandeep20Nessuna valutazione finora

- Fan InstallationDocumento2 pagineFan InstallationKrishna PatilNessuna valutazione finora

- 9 - Risk Assessment - PaintingDocumento8 pagine9 - Risk Assessment - Paintingmahmoud nadaNessuna valutazione finora

- Loading & Lifting ProcedureDocumento5 pagineLoading & Lifting Procedurekhurram shahzadNessuna valutazione finora

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocumento1 paginaScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNessuna valutazione finora

- Astm G154Documento11 pagineAstm G154jesoneliteNessuna valutazione finora

- Jsa For The Installation of I EamDocumento5 pagineJsa For The Installation of I EamMohammed MinhajNessuna valutazione finora

- Safe Unloading of Cut and BentDocumento16 pagineSafe Unloading of Cut and BentAbhinav SinhaNessuna valutazione finora

- ArresterFacts 032 The Sheath Voltage LimiterDocumento9 pagineArresterFacts 032 The Sheath Voltage Limiterdwas1314Nessuna valutazione finora

- Confine Space at Water TankDocumento7 pagineConfine Space at Water TanknaraNessuna valutazione finora

- Subject: Work at Height: Unit: Maihar Cement WorksDocumento3 pagineSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Risk AssesmentDocumento3 pagineRisk Assesmentmrogers72100% (4)

- Compressor Station MallnowDocumento8 pagineCompressor Station MallnowMANIU RADU-GEORGIANNessuna valutazione finora

- Akk Jha Installation of Diesel TankDocumento3 pagineAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Young Persons Risk Assessment V2.0 October 2021Documento2 pagineYoung Persons Risk Assessment V2.0 October 2021Lucas SantosNessuna valutazione finora

- Suspended From Man-Rider (Vertical Rescue Plan)Documento1 paginaSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- Intelligent Lithium Battery ESM 48100B1 Datasheet Draft A 01074746 010 ...Documento2 pagineIntelligent Lithium Battery ESM 48100B1 Datasheet Draft A 01074746 010 ...Eduardo Morales Ferrer100% (1)

- A002 C NightclubDocumento6 pagineA002 C NightclubBlas de LezoNessuna valutazione finora

- Heavy Lifting Safety ChecklistDocumento1 paginaHeavy Lifting Safety ChecklistMock ProjectNessuna valutazione finora

- Fire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopDocumento37 pagineFire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopTimmy CheongNessuna valutazione finora

- Suspended Loads Safety Tips (39Documento3 pagineSuspended Loads Safety Tips (39my_agautamNessuna valutazione finora

- Lifting Operations Planning Risk Assessment PDFDocumento1 paginaLifting Operations Planning Risk Assessment PDFulisses costaNessuna valutazione finora

- Banksmans responsibilitiesDocumento2 pagineBanksmans responsibilitiesAnil CNessuna valutazione finora

- Personal Protective Equipment: The Following Equipment Is Required in This Work AreaDocumento1 paginaPersonal Protective Equipment: The Following Equipment Is Required in This Work Arearmnmanila100% (1)

- Lifting Hoisting Hazard HuntDocumento1 paginaLifting Hoisting Hazard Hunt曹庆园100% (1)

- Job Hazard AssessmentDocumento26 pagineJob Hazard AssessmentGeherson AbustanNessuna valutazione finora

- General Lifting JHA SummaryDocumento1 paginaGeneral Lifting JHA Summarysujith s pNessuna valutazione finora

- Unloading of EWPs From ContainersDocumento10 pagineUnloading of EWPs From ContainersPirashanth SathananthanNessuna valutazione finora

- Safe System Of Work A Complete Guide - 2020 EditionDa EverandSafe System Of Work A Complete Guide - 2020 EditionNessuna valutazione finora

- Work Place Traffic SafetyDocumento19 pagineWork Place Traffic SafetyjeffreyNessuna valutazione finora

- Sulphur RecoveryDocumento45 pagineSulphur RecoveryjeffreyNessuna valutazione finora

- Red Oxide PrimerDocumento3 pagineRed Oxide PrimerjeffreyNessuna valutazione finora

- Red Oxide PrimerDocumento3 pagineRed Oxide PrimerjeffreyNessuna valutazione finora

- Summary Weekly Report Audi Apr 2018 WK 2Documento2 pagineSummary Weekly Report Audi Apr 2018 WK 2jeffreyNessuna valutazione finora

- Red Oxide PrimerDocumento14 pagineRed Oxide Primerjeffrey0% (1)

- Operating Instruction DX 351 01 en Operating Instruction PUB 5126242 000Documento21 pagineOperating Instruction DX 351 01 en Operating Instruction PUB 5126242 000jeffreyNessuna valutazione finora

- Guidelines DO16Documento77 pagineGuidelines DO16Marlo ChicaNessuna valutazione finora

- Food ContainerDocumento1 paginaFood ContainerjeffreyNessuna valutazione finora

- Sorry For The Inconvenience Cleaning Timing in Morning - : 6:00am To 6:30amDocumento1 paginaSorry For The Inconvenience Cleaning Timing in Morning - : 6:00am To 6:30amjeffreyNessuna valutazione finora

- Total Workforce On Site:: Team Area / Location Activity Total Track TeamDocumento1 paginaTotal Workforce On Site:: Team Area / Location Activity Total Track TeamjeffreyNessuna valutazione finora

- Maintenance Request FormDocumento1 paginaMaintenance Request FormjeffreyNessuna valutazione finora

- AD Work Zone Field GuideDocumento12 pagineAD Work Zone Field GuidejeffreyNessuna valutazione finora

- Compressed GAS CylinderDocumento2 pagineCompressed GAS CylinderjeffreyNessuna valutazione finora

- Heat Index ChartDocumento1 paginaHeat Index ChartjeffreyNessuna valutazione finora

- Google TranslateDocumento6 pagineGoogle TranslatejeffreyNessuna valutazione finora

- Turbo CompressorDocumento6 pagineTurbo Compressorrajanrane420Nessuna valutazione finora

- Hydrostatic Testing Procedure 02250-1Documento2 pagineHydrostatic Testing Procedure 02250-1RanielNessuna valutazione finora

- An overview of common vehicle indicatorsDocumento9 pagineAn overview of common vehicle indicatorsNikhitaNessuna valutazione finora

- Engine Fundamentals 1Documento3 pagineEngine Fundamentals 1anuradhaNessuna valutazione finora

- Effect of Clearance On Volumetric Efficiency in 2D Piston PumpsDocumento12 pagineEffect of Clearance On Volumetric Efficiency in 2D Piston PumpsSiddharth SinghNessuna valutazione finora

- BHELDocumento38 pagineBHELSharath Chandra100% (1)

- Karthik Krishna Resume Oct2014Documento3 pagineKarthik Krishna Resume Oct2014kkrish13Nessuna valutazione finora

- Egypowpd Module3Documento52 pagineEgypowpd Module3Jas PayaNessuna valutazione finora

- Liu JCP2019 Data Driven Intelligent Location Public Charging StationsDocumento11 pagineLiu JCP2019 Data Driven Intelligent Location Public Charging StationsRodrigoNessuna valutazione finora

- EV Technology QPDocumento3 pagineEV Technology QPvcetnaac c6Nessuna valutazione finora

- Chemistry Paper 3 TZ1 SLDocumento28 pagineChemistry Paper 3 TZ1 SLMotiani VanshikaNessuna valutazione finora

- Heat Exchangers of PolypropyleneDocumento2 pagineHeat Exchangers of PolypropyleneTan So100% (1)

- IV Report 1-1Documento11 pagineIV Report 1-1sree lekshmiNessuna valutazione finora

- Chapter 3 - Work Energy and PowerDocumento22 pagineChapter 3 - Work Energy and PowerKenny Jay LabianoNessuna valutazione finora

- Parandoush 2017Documento18 pagineParandoush 2017diego9723Nessuna valutazione finora

- 3 Goshu 3Documento18 pagine3 Goshu 3nega cheruNessuna valutazione finora

- Calibrar Slide Valve y Slid Stop en Compresor NH3Documento4 pagineCalibrar Slide Valve y Slid Stop en Compresor NH3Hector0412Nessuna valutazione finora

- Engineering Physics - G. AruldhasDocumento100 pagineEngineering Physics - G. AruldhasJaya sankarNessuna valutazione finora

- Analisis de Crudo B61Documento1 paginaAnalisis de Crudo B61Xavier DiazNessuna valutazione finora

- Cooling Tower Research PaperDocumento13 pagineCooling Tower Research PaperBhaskar KumarNessuna valutazione finora

- Catalogo Coldside MarcasDocumento93 pagineCatalogo Coldside MarcasDaniel VeraNessuna valutazione finora

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDocumento5 pagineTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNessuna valutazione finora

- Rotational Motion Engineering Mechanics IIT KanpurDocumento67 pagineRotational Motion Engineering Mechanics IIT KanpurNitin SharmaNessuna valutazione finora

- Routage GR.I 251-441 - GBDocumento6 pagineRoutage GR.I 251-441 - GBAhmad MohammadNessuna valutazione finora

- 1st PU Chemistry May 2015 PDFDocumento2 pagine1st PU Chemistry May 2015 PDFPrasad C M69% (16)

- Techniques de Commande Des Machines Electriques - Cours Et Problèmes..Documento2 pagineTechniques de Commande Des Machines Electriques - Cours Et Problèmes..Tko ToolNessuna valutazione finora