Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ACMV DESIGN: Sample Heat Load Calculation For General Office Meeting Room PDF

Caricato da

Venkates AdhinarayananTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ACMV DESIGN: Sample Heat Load Calculation For General Office Meeting Room PDF

Caricato da

Venkates AdhinarayananCopyright:

Formati disponibili

15 More Next Blog»

ACMV DESIGN

“Share your knowledge. It is a way to achieve immortality.” ― Dalai Lama XIV

+21 Recommend this on Google

Blog Archive 21 January 2013 About Me Th

► 2014 (1) Wel

▼ 2013 (3) Sample Heat Load Calculation for General for m

misu

► April (1) Office Meeting Room anyt

to m

▼ January (2)

Sample Heat Load Calculation for General Office Meeting Room zaw

Zaw Moe Khine

Sample Heat Load om

Calculation for Follow 174

General Office

Me... View my complete Tha

profile Zaw

HEAT LOAD

CALCULATION

Popular Posts

► 2012 (3)

Sample Heat Load C

General Office Meet

Sample Heat Load C

General Office Meet

Calculation - -Coolin

upply Air V olume (

PRECOOLED AHU

Just start with preco

Calculation!! When

precooled AHU, you

air volume and temp

Heat Load Calculation -

-Cooling Capacity (kW) , Design Supply Air T

-Supply Air Volume (CMH), When we design the

specifies how much

-Supply Fresh Air Volume (CMH),

volume is. If we need

-Chilled Water Flow Rate (l/s) if CHW System is used. supply air volume, w

HEAT LOAD CALCU

When we calculate t

When we calculate the heat load,

to know the location

We need some information for space. (Country,City) And t

1-Location of space information such as

(Ambient Temp for out door air )

ACMV DESIGN COURSE

(Singapore -Summer Ambient Temp - 32.8C/26.1C (DB/WB)

ACMV DESIGN COURSE ACMV D

2- Room/ Space Datas & Orientation (Facade Orientation) E-20(Hourly Analysis Program-HA

(Area-50 m2 & Room is located at North Side of Building) ACMV DESIGN COURSE (SATUR

YOU WA...

3-Room Construction Materials

(Such as Window Glass (U-value & Sc-Value) ,Wall, Partition & Floor.) (no title)

4-No of Occupancy & Room Usage http://www.scribd.com/doc/11156

(20-Persons & Meeting Room) Calculation-Spreadsheets-Quick-A

Relying-on-Rules-of-Thumb?

secret_password=1lkzrbj8jn...

I-Internal Heat Gain

i-Heat Gain from Lighting နi ုင%&တက) အဆင့္မ/ Building Ser

စ္ေယ)က္ အ3ဖစ္ ရပ7ည္ ခ:င;<မ:ာ

(Based on SS-530-Office Lighting Power - 15 W/m2) င္းေက)င္း

Lighting Load = 50 x 15 = 750 W နi ုင%&တက) အဆင့္မ/ Building Ser

ii-Heat Gain from Human (20-person) စ္ေယ)က္ အ3ဖစ္ ရပ7ည္ ခ:င;<မ:ာ

င္းေက)င္း RSED Engineering

(Based on ASHRAE Office Human Sensible -75 W/person & Latent 55 W/person) M&a...

Human Load (S) 75 x 20 = 1500 W ,(L) 55 x 20 = 1100 W

iii-Electrical Equipments Load ( General Office 25 W/m2)

Laptop-55 W x 20 & Projector-300 W.

Electrical Equipments Load= 30 x 50 = 1500 W

II-External Heat Gain

i-Heat Gain from Wall (Conduction Heat Gain)

(Q= A x U x ∆T)

Wall Area = 10 m x 1m = 10m2

Wall U-value(200mm brick wall = 2.254 W/m2)

∆T for North side facing 200mm brick wall = 14

So, Q= 10 x 2.254 x 14 = 315.56 W

ii- Heat Gain from Glass Window. (Conduction + Radiation Heat Gain)

Glass Area = 10 m x 3 m = 30m2

Glass U-value = 1.7 W/m2

Glass Sc-Value = 0.3

CF = 0.8

(Q= (3.4 x A x U ) + (211 x A x Sc x CF)

Q = (3.4 x 30 x 1.7 ) + (211 x 30 x 0.3 x 0.8 ) = 1692.6 W

iii- Heat Gain from Partition Wall ( Conduction Heat Gain)

(Q= A x U x ∆T)

Partition Area = 20 x 4 = 80 m2

Partition Wall U-Value = 0.573 W/m2

∆T (30-24) = 6

Q = 80 x 0.573 x 6 = 275 .04 W

iv- Heat Gain from Floor ( Conduction Heat Gain)

(Q= A x U x ∆T)

Floor Area = 50 m2

Floor U-Value = 2.452 W/m2

∆T (30-24) = 6

Q = 50 x 2.452 x 6 = 735.6 W

After adding out the total heat load-

Sensible Heat Load is 6746.8 W (10% SF) 7421.53 W = 7.421 kW.

Latent Heat Load is 1100 W (10% SF)-1210 W =1.21 kW

SHR = SH/(SH+LH) = 7.421/(7.421+1.21) = 0.86

That's mean 86% is Sensible and 14 % is Latent heat.

Once we get the total sensible heat load, we can get the supply air volume.

Qs = m c ∆T

Qs = 7.421 kW (kJ/s)

c = 1.004 kJ/kg

If supply air temp is 14 C, ∆T = 24-14 = 10.

m = Qs / (c x ∆T) - (kg/s)

m = 7.421 / (1.004 x 10 ) = 0.73919 kg/s

V,Air Volume (m3/s) = m x v (Humid Volume-m3/kg)

If supply air temp is 14 C, v is about 0.825 m3/kg.

So, Air Volume , V = 0.73919 (kg/s) x 0.825 (m3/kg)

V = 0.6098 m3/s = 2195 CMH.

So, Supply Air Volume is 2195 CMH.

Next step is Fresh Air Volume Supply, If the space type is under office,

Minimum FA Requirement is based on 62.1 ASHRAE

(2.5 l/s/person + 0.3 l/s/m2)= (2.5x20) + (0.3x50)=65 l/s

Minimum FA Requirement based on local code (SS-553).

5.5 l/s/person or 0.6 l/s/m2 (Choose higher volume)

5.5 x 20 = 110 l/s.

So, We have to choose 110 l/s for this meeting room.

Fresh Air Supply will be 110 l/s (396 CMH).

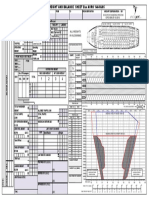

Air Con Sketch

So,supply air volume 2195 cmh &

fresh air volume-396 cmh for this

meeting room.

Layout will be as per air con sketch. Just need to calculate how much capacity we need.

For Cooling Load Capacity ,

Q = m ∆h

m = mass of air (kg/s) (we already calculated)

∆h = enthalpy differential of entering air and leaving air (kJ/kg)

For ∆h = h1-h2

h1= enthalpy of entering air into coil (maxing air)

h2= enthalpy of leaving air from coil (supply air)

So that we need to calculate maxing air temp.

Mixing air volume is same as supply air volume. See Air con Sketch dwg.

In our design condition,

Supply Air Temp is 14 C & Room Operation Temp is 24C(maxi) & RH is 50~55 %.

Fresh air temp is Singapore Summer Temp , 32.8 C (DB) & 26.1 C (WB).

So that we can calculate maxing air temp (entering air temp/on coil air temp).

Supply air volume (maxing air volume) is addition of return air volume and fresh air volume. So,

maxing air temp is depended on ratio of return and fresh air volume.

Equation will be -

Tm x Mixing Air Volume = (Tr x Return Air Volume) + (Tf x Fresh Air Volume)

Other way is

Tm x 100% = (Tr x Return Air % of Supply Air) + (Tf x Fresh Air % of Supply)

So we just calculate fresh air volume % of supply air volume = 396 / 2195 x 100 = 18%

Fresh air volume is 18%, return air volume will be 100-18= 82%.

Tm x 100 = ( Tr x 82) + (Tf x 18)

Tr = Room Operation Temp (24 C)

(It should add 1 or 2 C for duct heat gain and plenum heat gain)

Tf = Fresh Air Temp (32.8 C).

Tm x 100 = (24x82) + (32.8 x 18)

Tm = 25.58 C

Mixing Air Temp (DB) is 25.58 C.

Next step is maxing air temp (WB ) or Humidity Ratio (∆g)

Same as maxing air temp (DB)-

equation will be

gm x Mixing Air Volume = (gr x Return Air Volume) + (gf x Fresh Air Volume)

gm x 100 = ( gr x 82) + (gf x 18)

gr = Return Air Humidity Ratio

Read from Psychrometric Chart by Room Operation Temp ( 24 C & RH-54%)

gr=9.8 g/kg = 0.0098 kg/kg

gf = Fresh Air Humidity Ratio.

Read from Psychrometric Chart by Singapore Summer Temp ( 32.8 C & 26.1 C)

gf = 18.6 g/kg = 0.0186 kg/kg.

So gmx100 = (0.0098 x 82)+(0.0186x18)

gm = 11.83 g/kg = 0.01183 kg/kg

By Maxing Air Temp (DB) Tm,25.58C & Mixing Air Humidity Ratio (gm) 11.83 g/kg,

h1=55 kJ/kg (From Psychrometric Chart)

For h2, Read from Psychrometric Chart

Based on supply air temp,coil ADP,Space SHR & intersection line.

Supply Air temp is 14 C.

Space SHR = 0.86

Coil ADP = 12.71 C (By coil bypass factor is 0.1)

h2= 37.2 kJ/kg.

So, Cooling Capacity is

Q = m ∆h

m = 7.421 / (1.004 x 10 ) = 0.73919 kg/s

∆h = h1-h2 = 55- 37.2 = 17.8 kJ/kg

Q = 0.73919 x 17.8

Q = 13.15 kJ/s (kW)

Fan Coil Unit minimum cooling capacity is 13.15 kW.

Cooling Rate is 13.15/50x100 = 263 W/m2.

Supply Air Volume is 2195 CMH

Fresh Air Volume is 396 CMH.

If FCU is chilled water system and CHW ∆T is 5.5,

Chilled Water Flow rate ?

Q = m c ∆T

Q = V ℓ c ΔT

Q = Cooling Capacity (kJ/s) (kW)

V = Water Flow (m3/s)

ℓ = Density of water (kg/m3) (1000 kg/m3 for water)

c = Specific Heat Capacity of Water (4.19 kJ/kg)

m= mass of water (kg/s)

∆T = 5.5

V = Q / ℓ c ∆T = 13.15 / (1000x4.19 x 5.5)

V = 0.00057 m3/s

(1m3/s = 1000 l/s)

So, V = 0.57 l/s.

So Chilled Water Flow Rate is 0.57 l/s.

So that for CHW System, m = V = .... (Unit is l/s)

Q = m c ∆T

m = Q / (c x ∆T) ... (l/s)

Thanks,

zaw moe khine

Posted by Zaw Moe Khine at 01:18

+15 Recommend this on Google

Labels: Sample Heat Load Calculation

5 comments

Add a comment as venkates A

Top comments

JAICE JOY SKARIA 6 months ago - Shared publicly

Thanks a lot for such an elaborated detailing of the cooling load calculations.. i could

easily clear many doubts in heat load calculation process.

1 · Reply

Ram Kaushik 11 months ago - Shared publicly

Thanks for sharing everything very clearly and step by step

1 · Reply

Manjunath Hr 1 year ago - Shared publicly

I AM SO THANK FULL FOR YOU YOUR RIGHT KNOWLEDGE SHARING IS POWER

THROUGH WHICH WE CAN DO WONDERES THANKS FOR THE INFO.

I WISH IF I CAN POST ANY OF THSE KIND OF ENGINERRING INFO.

CAN YOU PLEASE LET ME KNOW HOW TO ADD THESE DETAILS INTO INTO SO THAT

OTHERS CAN GO THROUGH AND CAN COMMENTS ON THE SAME

+1 1 · Reply

2

1

godwin igot 4 months ago - Shared publicly

thank you very much for this step by step detailing of the cooling load calculation. Great

Help!!!

1 · Reply

Raz K 11 months ago - Shared publicly

Hi,

I'm struggling to understand h2 calculation.

tha data and the lines on the Psychrometric Chart does not meet.

The SHR & humidity ratio lines seems not in place.......

could you check and re-explain.

Many thanks, Raz.

+3 1 · Reply

4

3

Newer Post Home Older Post

Subscribe to: Post Comments (Atom)

Watermark template. Template images by wingmar. Powered by Blogger.

Potrebbero piacerti anche

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocumento5 pagineGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaNessuna valutazione finora

- Fuel Pump Design Calculation SheetDocumento1 paginaFuel Pump Design Calculation SheetIslam SolimanNessuna valutazione finora

- Technical Handbook Air CurtainsDocumento13 pagineTechnical Handbook Air Curtainsaca111111Nessuna valutazione finora

- PRICE - Air Distribution GuideDocumento5 paginePRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Documento1 paginaPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNessuna valutazione finora

- Krueger Fan Coil EngineeringDocumento15 pagineKrueger Fan Coil EngineeringYutt WattNessuna valutazione finora

- Comparison VRF Vs Aircooled Chiller: Rec-Unitech Philippines Design Review and Proposal From: Engr Beng Rosales, MsmeDocumento6 pagineComparison VRF Vs Aircooled Chiller: Rec-Unitech Philippines Design Review and Proposal From: Engr Beng Rosales, MsmeBeng RosalesNessuna valutazione finora

- Step-by-Step Cooling Load Calculation GuideDocumento28 pagineStep-by-Step Cooling Load Calculation GuideEngr Lanre MajekNessuna valutazione finora

- ASHRAE62.1 and FAQsDocumento18 pagineASHRAE62.1 and FAQsols3dNessuna valutazione finora

- Water Cooled Centrifugal Chiller Technology FeaturesDocumento16 pagineWater Cooled Centrifugal Chiller Technology Featuresthu hangNessuna valutazione finora

- Acmv DesignDocumento10 pagineAcmv DesignLuís AbreuNessuna valutazione finora

- Machinery Room Ventilation Analysis ToolDocumento48 pagineMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaNessuna valutazione finora

- EC Fan Application Note - EMERSONDocumento8 pagineEC Fan Application Note - EMERSONlouie mabiniNessuna valutazione finora

- Drain Pipe Work of Indoor UnitDocumento24 pagineDrain Pipe Work of Indoor UnitMiguel AbuegNessuna valutazione finora

- Staircase Pressurization Calculation SheetDocumento4 pagineStaircase Pressurization Calculation SheetTariq AsgharNessuna valutazione finora

- Assessment of CompresorsDocumento14 pagineAssessment of CompresorsranveerNessuna valutazione finora

- HVAC Thermal Load EstimatingDocumento28 pagineHVAC Thermal Load EstimatingIntisar Ali SajjadNessuna valutazione finora

- Central Cooling and Heating Plants: Design Considerations and AdvantagesDocumento21 pagineCentral Cooling and Heating Plants: Design Considerations and AdvantagesRolando Valdez GutierrezNessuna valutazione finora

- Sizing The Dehumidifier - Bry Air PDFDocumento16 pagineSizing The Dehumidifier - Bry Air PDFprabhanshu241991100% (1)

- SPF Stair Case FanDocumento2 pagineSPF Stair Case FanAla ShakerNessuna valutazione finora

- Stand Alone Restaurant's Kitchen Ventilation PDFDocumento1 paginaStand Alone Restaurant's Kitchen Ventilation PDFSudhir KulkarniNessuna valutazione finora

- Fire Safety Requirements for General WarehousesDocumento6 pagineFire Safety Requirements for General Warehousesecruz_yhwhNessuna valutazione finora

- Determine cooling coil and reheater outputs for office AC systemDocumento4 pagineDetermine cooling coil and reheater outputs for office AC systemRashel Hasan100% (1)

- Cooling LoadDocumento16 pagineCooling LoadAbdul Razzak100% (1)

- HVAC Long Year Maintenance Plan - Status - 12 March 2013Documento12 pagineHVAC Long Year Maintenance Plan - Status - 12 March 2013haskenNessuna valutazione finora

- Psych Rome TricsDocumento46 paginePsych Rome TricsDenitta D'RoseNessuna valutazione finora

- Dehumidification Calcs AshraeDocumento7 pagineDehumidification Calcs AshraeSujit RajanNessuna valutazione finora

- 02 Cooling Load Calculation - HAPDocumento2 pagine02 Cooling Load Calculation - HAPU DEEPAKNessuna valutazione finora

- Nicotra (Backward Curve)Documento95 pagineNicotra (Backward Curve)Archityrema Surya100% (1)

- Training DuctingDocumento20 pagineTraining Ductingpanji uteNessuna valutazione finora

- Refrigeration Heat Load EstimatingDocumento17 pagineRefrigeration Heat Load EstimatingAnonymous 1gbsuaafddNessuna valutazione finora

- Glass Unit V Air-Conditioning Load CalculationDocumento26 pagineGlass Unit V Air-Conditioning Load CalculationASWIN KUMAR N SNessuna valutazione finora

- Case Against Balancing ValvesDocumento4 pagineCase Against Balancing Valvesa_salehiNessuna valutazione finora

- Plenum Box Sizing For Air Handling UnitDocumento2 paginePlenum Box Sizing For Air Handling UnitMohanad SulimanNessuna valutazione finora

- Calculating cooling load for a battery roomDocumento2 pagineCalculating cooling load for a battery roomMohammed IqbalNessuna valutazione finora

- Humidification Load Calculation Armstrong PDFDocumento3 pagineHumidification Load Calculation Armstrong PDFsyedNessuna valutazione finora

- HVAC 101: The Basics of Heating, Ventilation and Air ConditioningDocumento33 pagineHVAC 101: The Basics of Heating, Ventilation and Air ConditioningChan SeanNessuna valutazione finora

- Comparison of VRF Over ChillersDocumento2 pagineComparison of VRF Over ChillersAdil MohdNessuna valutazione finora

- Im j1 Personnel Cooling Load Estimation 2014Documento40 pagineIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezNessuna valutazione finora

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Documento8 pagineADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansNessuna valutazione finora

- Average Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Documento7 pagineAverage Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Alexandre HugenNessuna valutazione finora

- Prinston Smart Engineers InternshipDocumento33 paginePrinston Smart Engineers InternshipCalvin bNessuna valutazione finora

- CO2 Sensor RoomDocumento8 pagineCO2 Sensor RoomTrần Khắc ĐộNessuna valutazione finora

- 78 Return Grille LocationsDocumento2 pagine78 Return Grille LocationsKyaw San OoNessuna valutazione finora

- Chvac Software Tutorial PDFDocumento55 pagineChvac Software Tutorial PDFPhelan Roque100% (1)

- Air Changes Per HourDocumento4 pagineAir Changes Per HourKg Chit ZawNessuna valutazione finora

- Shop Drawing: Welcome Air-Tech (M) SDN BHDDocumento1 paginaShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanNessuna valutazione finora

- Thermal Ice Storage Application & Design GuideDocumento68 pagineThermal Ice Storage Application & Design GuideJosh Garcia100% (1)

- Design Briefs Advanced VAV SystemsDocumento27 pagineDesign Briefs Advanced VAV SystemsHESuarezNessuna valutazione finora

- HVAC & Refrigeration SystemDocumento22 pagineHVAC & Refrigeration SystemSivakumar NadarajaNessuna valutazione finora

- 1Documento3 pagine1ntt_121987Nessuna valutazione finora

- Central Air Conditioning Systems ReviewDocumento23 pagineCentral Air Conditioning Systems ReviewlalaNessuna valutazione finora

- KRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODocumento4 pagineKRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODo MinhNessuna valutazione finora

- Proposal for AC and HW system using thermal energyDocumento1 paginaProposal for AC and HW system using thermal energyTEMESGENNessuna valutazione finora

- L & T 737-800 186Y Rev 1 Incr MTOWDocumento1 paginaL & T 737-800 186Y Rev 1 Incr MTOWPaolo TWIXNessuna valutazione finora

- Balancesheet B737-300 InstruccionDocumento1 paginaBalancesheet B737-300 InstruccionCarlos JaldinNessuna valutazione finora

- Daily Log SheetDocumento1 paginaDaily Log SheetYousuf AliNessuna valutazione finora

- Clearance Bae AVRO-146-RJ85 - V.3 (October 25, 2013)Documento1 paginaClearance Bae AVRO-146-RJ85 - V.3 (October 25, 2013)Rodrigo ArgoteNessuna valutazione finora

- Engine Cooling SystemDocumento3 pagineEngine Cooling SystemNabil ChowdhuryNessuna valutazione finora

- RHF Log Books-New (10494)Documento2 pagineRHF Log Books-New (10494)sourajpatelNessuna valutazione finora

- WBFT400927CP - Manual Urinal Flush ValveDocumento1 paginaWBFT400927CP - Manual Urinal Flush ValveVenkates AdhinarayananNessuna valutazione finora

- Omron SSG 2015 2016 EN X302E307 201503 FULL PDFDocumento532 pagineOmron SSG 2015 2016 EN X302E307 201503 FULL PDFGanjar SopyanaNessuna valutazione finora

- Adobe PageMaker Tutorial for BeginnersDocumento11 pagineAdobe PageMaker Tutorial for Beginnersarenguna100% (2)

- The Common Cooling Water Problem SolverDocumento59 pagineThe Common Cooling Water Problem SolverVenkates AdhinarayananNessuna valutazione finora

- Bus BarDocumento32 pagineBus BarVenkates AdhinarayananNessuna valutazione finora

- ACMV CPS Separator ManualDocumento6 pagineACMV CPS Separator ManualVenkates AdhinarayananNessuna valutazione finora

- ACMV DESIGN: Sample Heat Load Calculation For General Office Meeting RoomDocumento5 pagineACMV DESIGN: Sample Heat Load Calculation For General Office Meeting RoomVenkates Adhinarayanan50% (2)

- TransformerDocumento5 pagineTransformerVenkates AdhinarayananNessuna valutazione finora

- 5S (Methodology)Documento4 pagine5S (Methodology)Venkates AdhinarayananNessuna valutazione finora

- Viscosity and Normal Stress Differences in Molten PlasticsDocumento30 pagineViscosity and Normal Stress Differences in Molten PlasticsAzizol WahabNessuna valutazione finora

- Practice PLSQL SEC 4Documento19 paginePractice PLSQL SEC 4annonymous100% (1)

- 2 Hinged ArchDocumento19 pagine2 Hinged ArchSaeed_HassaniurscorpNessuna valutazione finora

- 150-4059 - Rockbreaker Installation Manual PDFDocumento26 pagine150-4059 - Rockbreaker Installation Manual PDFDanny Joel Espinoza CastañedaNessuna valutazione finora

- Lourdes San Isidro Telacsan Road Program RevisedDocumento36 pagineLourdes San Isidro Telacsan Road Program RevisedCent TorresNessuna valutazione finora

- AF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsDocumento5 pagineAF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsTheo Pozo JNessuna valutazione finora

- Foundation Practice Exam Questions 5Documento11 pagineFoundation Practice Exam Questions 5Dr CoolzNessuna valutazione finora

- Kitchen DetailsDocumento12 pagineKitchen DetailsAJ PAJENessuna valutazione finora

- API 5l Grade l245 PipesDocumento1 paginaAPI 5l Grade l245 PipesMitul MehtaNessuna valutazione finora

- API 6D Valves Bonney Forge PDFDocumento12 pagineAPI 6D Valves Bonney Forge PDFSQUALO_122Nessuna valutazione finora

- Quantifying Life Safety Part II - Quantification of Fire Protection SystemsDocumento6 pagineQuantifying Life Safety Part II - Quantification of Fire Protection SystemskusumawardatiNessuna valutazione finora

- Central Changing of Triggers in WinCC V6.2 Images (PDL)Documento10 pagineCentral Changing of Triggers in WinCC V6.2 Images (PDL)www.otomasyonegitimi.comNessuna valutazione finora

- UOP046-85 Wax Content in Petroleum OilsDocumento6 pagineUOP046-85 Wax Content in Petroleum OilsZiauddeen Noor100% (1)

- Propeller Pin Crack InspectionDocumento4 paginePropeller Pin Crack InspectionNicolás PiratovaNessuna valutazione finora

- Volvo FMX: Product Guide - Euro 3-5Documento24 pagineVolvo FMX: Product Guide - Euro 3-5HiT Dayat100% (2)

- Reaffirmed Indian Standards for Water Resources DepartmentDocumento2 pagineReaffirmed Indian Standards for Water Resources Departmentjamjam75Nessuna valutazione finora

- Aoc Le32w136 TVDocumento82 pagineAoc Le32w136 TVMarcos Jara100% (4)

- Eductor AgitationDocumento2 pagineEductor AgitationNicolás Solano CondeNessuna valutazione finora

- AutoCAD CommandsDocumento59 pagineAutoCAD Commandsamalendu_biswas_1Nessuna valutazione finora

- Canon Ir3245 Series-PcDocumento154 pagineCanon Ir3245 Series-PcPetrescu CezarNessuna valutazione finora

- THE William Francis Galvin, Secretary of The Commonwealth State Publications and RegulationsDocumento54 pagineTHE William Francis Galvin, Secretary of The Commonwealth State Publications and Regulationsbubbo07Nessuna valutazione finora

- Ducha EmpotradaDocumento1 paginaDucha Empotradagilmar melendresNessuna valutazione finora

- Reliable Ni-Cd batteries keep railroads running smoothlyDocumento8 pagineReliable Ni-Cd batteries keep railroads running smoothlyJesus LandaetaNessuna valutazione finora

- Seller DashboardDocumento8 pagineSeller DashboardAditya KumarNessuna valutazione finora

- BTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)Documento160 pagineBTS3900 GSM Site Maintenance Terminal User Guide - (V300R008 - 06)engrvinzzNessuna valutazione finora

- Siemens Technical FlyerDocumento2 pagineSiemens Technical FlyerThiagoPinheiroNessuna valutazione finora

- FESCO Consumer Service Manual OverviewDocumento60 pagineFESCO Consumer Service Manual OverviewMus'ab FarouqNessuna valutazione finora

- Cisco IOS XR Configuration Guide Master IndexDocumento66 pagineCisco IOS XR Configuration Guide Master IndexvictorpetriniNessuna valutazione finora

- Engineering Data Ip5-3600Documento2 pagineEngineering Data Ip5-3600CESAR SEGURANessuna valutazione finora

- Ca2 ZDocumento105 pagineCa2 ZAde RachmanNessuna valutazione finora