Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Piping Fabrication and Construction PDF

Caricato da

Mohamed AdelTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Piping Fabrication and Construction PDF

Caricato da

Mohamed AdelCopyright:

Formati disponibili

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Module Component Page

INTRODUCTION .................................................................................................3

01-SAMSS-010 .........................................................................................4

SAES-L-050 and SAES-L-051 ..................................................................4

DETERMINING WHETHER PIPING MEETS

FABRICATION REQUIREMENTS .......................................................................5

Material Limitations ...................................................................................5

Pipe ................................................................................................5

Material Limitations, Cont'd .......................................................................6

Pipe Nipples ...................................................................................6

Flanges...........................................................................................7

Pipe Fittings....................................................................................7

Drawings ...................................................................................................8

Fitup Tolerances .......................................................................................8

Mitered Joints ...............................................................................10

Ends for Field Welding .................................................................10

Pipe Bending...........................................................................................10

Cold Bending ................................................................................13

Hot Bending..................................................................................14

Sample Problem 1...................................................................................15

Solution ...................................................................................................17

Welding and Heat Treatment ..................................................................18

Butt-Welds....................................................................................19

Fillet Weld.....................................................................................23

Welding Steps ..............................................................................23

Inspection and Testing of Pipe Spools ....................................................26

Product Marking and Preparation for Shipment ......................................27

Identification .................................................................................27

Cleaning .......................................................................................28

Painting ........................................................................................28

Protection .....................................................................................28

DETERMINING WHETHER METALLIC PLANT PIPING

MEETS INSTALLATION REQUIREMENTS ......................................................29

Storage and Handling..............................................................................29

Saudi Aramco DeskTop Standards i

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Pipe Fitup and Tolerances ......................................................................30

Alignment of Pipe Attached to Load-Sensitive

Equipment ...............................................................................................31

Flange Joint Assembly .................................................................33

Cleaning ..................................................................................................38

Buried Installation....................................................................................38

Sample Problem 2...................................................................................39

Solution ...................................................................................................40

DETERMINING WHETHER ABOVEGROUND AND

BURIED PIPING MEET INSTALLATION

REQUIREMENTS ..............................................................................................41

Vertical Profile .........................................................................................41

Elastic Bends................................................................................42

Preformed Bends..........................................................................43

Preformed Bends for Aboveground

Pipelines.......................................................................................44

Preformed Bends for Buried Pipelines..........................................45

Storage and Handling..............................................................................46

Installation of Aboveground Pipelines .....................................................46

Installation of Buried Pipelines ................................................................48

Tie-in Temperature..................................................................................49

Cleanup and Records..............................................................................51

SUMMARY ........................................................................................................52

WORK AID 1: PROCEDURE FOR DETERMINING

WHETHER PIPING MEETS FABRICATION

REQUIREMENTS ..............................................................................................53

WORK AID 2: PROCEDURE FOR DETERMINING

WHETHER METALLIC PLANT PIPING MEETS

INSTALLATION REQUIREMENTS....................................................................58

WORK AID 3: PROCEDURE FOR DETERMINING

WHETHER ABOVEGROUND AND BURIED PIPELINES

MEET INSTALLATION REQUIREMENTS.........................................................59

GLOSSARY .......................................................................................................60

Saudi Aramco DeskTop Standards ii

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

INTRODUCTION

An engineer will often be asked to participate in the

design of a piping system by evaluating a contractor's

proposal, auditing a contractor's work, performing a

screening study for cost estimating purposes, or actually

designing and managing pieces of the project.

The previous module discussed the layout, support and

flexibility design of a piping system, one step in designing

the overall piping system. This module discusses

another step in putting the pieces of the system together:

the fabrication and construction of the piping system.

Portions of the piping system are prefabricated by

contractors. After these portions are fabricated, they are

assembled wherever the piping system will be located.

This assembly includes aligning, bolting up, and welding

pieces together. The engineer must ensure that the

fabricated portions of the piping system remain

consistent with the system design, and that they meet

Saudi Aramco requirements. If the pieces of the piping

system do not fit well together, the original design

assumptions may not be valid, and the piping system

may not meet expectations and could fail prematurely.

This module assumes Saudi Aramco Standards will be

used to audit a contractor's fabrication drawings, and field

erection standards, specifically: SAES-L-050, SAES-L-

051, and 01-SAMSS-010. This auditing ensures that the

fabrication and construction of the system meets design

requirements. These requirements, or quality control

items, include:

• Material limitations.

• Fitup tolerances.

• Pipe bending limitations.

• Welding and heat treatment requirements.

• Product marking and preparation for shipment

requirements.

• Flange bolt-up requirements.

• Alignment requirements for critical equipment.

This module discusses the quality control items set forth

by the standards and construction requirements for plant

piping systems and cross-country pipelines.

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

01-SAMSS-010

Saudi Aramco Materials System Specification 01-

SAMSS-010, Fabricated Carbon Steel Piping, is the basis

for piping fabrication requirements. This specification

covers the minimum requirements for the fabrication of

regular carbon steel pipe spools, including welding, heat

treatment, bending, and threading. It may also be used

for special steels or alloys, in which case, exceptions and

additions to this specification will be stated in the

purchase order. 01-SAMSS-010 serves as the primary

document in all purchase orders for piping fabrication.

SAES-L-050 and SAES-L-051

Saudi Aramco Engineering Standard SAES-L-050,

Construction Requirements for Metallic Plant Piping, and

SAES-L-051, Construction Requirements for Cross-

Country Pipelines, supplement fabrication requirements

that are established in the applicable ASME/ANSI B31

Codes.

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

DETERMINING WHETHER PIPING MEETS FABRICATION REQUIREMENTS

If a system is not fabricated with reasonable quality, the

design assumptions will not be met, and problems can

occur during construction and subsequent operation. For

example, forcing pieces of the system together imposes

loads that were not accounted for in the original design.

These loads could lead to system reliability and

maintenance problems, and eventual failure in extreme

cases. Saudi Aramco standards SAES-L-050, SAES-L-

051, and 01-SAMSS-010 provide the requirements that

ensure a piping system is fabricated properly. For

example, the standards give welding requirements for

fabrication that specify criteria, such as matching

diameter, angularity, and material. The Saudi Aramco

engineer must examine the contractor's work to confirm

that tolerances and other fabrication requirements meet

the standards. Work Aid 1 summarizes these fabrication

requirements.

Material Limitations

Compatible materials are essential for piping fabrication.

All materials that are used for piping elements or

structural attachments must conform to a listed

specification in accordance with ASME/ANSI B31 Codes,

and shall be traceable to mill certificates. This ensures

that basic material quality conforms to recognized

specifications, and that confirming documentation is

supplied for the materials that are actually used. 01-

SAMSS-010 provides specific additional material

requirements for fabrication. These are summarized as

follows.

Pipe

• Pipe for plant applications shall be seamless or

single-longitudinal seam submerged arc-welded

(MEX 101.02) and conform to one of the following:

- API Spec 5L, Grade B through X60.

- ASTM A53, Seamless Grade B, black (not

galvanized).

- ASTM A106, Grade B.

These specifications are all readily available and

result in pipe of comparable strength.

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Material Limitations, Cont'd

• Pipe for cross-country pipelines shall conform to one

of the following:

- Electric Resistance Welded (ERW) pipe in

accordance with 01-SAMSS-033, API 5L

Electric Welded Line Pipe.

- Spiral-welded pipe in accordance with 01-

SAMSS-035, API Line Pipe.

- If 01-SAMSS-035 pipe is not available, API 5L

or ASTM A106 pipe may be used provided it

meets the chemical composition and hardness

test requirements that are specified in 01-

SAMSS-035.

For wet, sour service, the pipe must be seamless, or

conform to 01-SAMSS-016, Sour, Wet Service Line

Pipe, for welded pipe.

Pipe Nipples

• Nipples shall conform to one of the pipe

specifications previously listed, and shall be

Schedule 80 minimum thickness. This minimum

thickness is required regardless of the design

conditions and is specified to ensure that these

small diameter nipples have adequate strength to

resist mechanical damage that could occur in the

shop or field. If threading is required, it must be a

taper pipe thread in accordance with ANSI B1.20.1,

Pipe Threads, General Purpose (inch).

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Flanges

Weld-neck flanges and blind flanges that conform to one

of the following must be used unless otherwise specified

in the purchase order.

• ASME/ANSI B16.5 using ASTM A350, Grade LF2

normalized material.

• 02-SAMSS-011.

• Saudi Aramco Standard Drawing attached to the

purchase order.

• MSS-SP-44 when not specified by either B16.5 or

Saudi Aramco Standard Drawings.

Here again, basic material strength and quality levels are

being established for standardization purposes. The

strongest flange type, i.e., a weld-neck, is being specified

to avoid any additional design consideration necessary

for slip-on or lap-joint-type flanges. However, remember

that general flange type and material selection

requirements are governed by SAES-L-009 and 02-

SAMSS-011 (as discussed in MEX 101.04), and may

differ from what is stated here for specific cases.

Pipe Fittings

• Butt-welded fittings shall be used for nominal pipe

sizes 50 mm (2 in.) and larger, and conform to 02-

SAMSS-005. Material grade and nominal wall

thickness shall be the same or equal to the

adjoining pipe.

• Forged steel threaded or socket-welded fittings shall

conform to ANSI B16.11, pressure class 3000,

ASTM A105, and unions shall conform to MSS-SP-

83. While class 2000 fittings are available, this

requirement specifies a stronger fitting as the base

case. Threaded or socket-welded fittings can only

be used for pipe sizes smaller than 50 mm (2 in.).

However, the size may include 50 mm (2 in.) NPS

for minor field repairs or maintenance.

• Forged steel welding bosses shall conform to either

Aramco Standard Drawing

AE-036175 or AE-036643 or equivalent forged steel

welding outlets, ASTM A105, pressure class 3000

minimum. These must abut the pipe wall and be

attached with a full-penetration weld. They may

only be used for NPS 50 mm (2 in.) or smaller.

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Drawings

Fabrication drawings are provided to the contractor for fabrication work. These

drawings specify piping component materials, dimensions, and specific

tolerances for piping fabrication. The Saudi Aramco engineer needs to check

that the drawings conform to all fabrication requirements, and that these are also

being followed in the field.

• The vendor shall prepare the detailed shop

fabrication drawings.

• Any details not shown on the buyer's drawings shall

be designed by the vendor in accordance with the

applicable ASME/ANSI B31 Code.

• Welded branch connections and other joints shall be

full-strength reinforced such that the MAOP of a

pipe spool shall be as limited by either the specified

pipe or the flange rating. In this way, branch

reinforcement will not be the limiting factor in setting

the piping system MAOP, and would not need to be

considered in any potential future projects to

increase system design pressure.

• Standard piping symbols that are used on Piping

Detail Sheets and Isometrics are identified on

Standard Drawing AB-036227.

Fitup Tolerances

Fitup tolerances specify the allowable limits that are

placed on mismatch between sections of piping. These

tolerances are established to limit any extra load that is

placed on the piping system or connected equipment,

and to provide greater assurance of obtaining acceptable

weld quality. Fitup tolerances apply to all pipe

fabrication.

Established tolerances control the fabrication of the pipe

spool in the shop, and ultimately the assembly of

multiple spool pieces in the field to make up a complete

piping system. Normal practice is to maximize the

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

amount of shop fabrication to bring the largest possible

spool pieces to the field for final assembly. This

minimizes the amount of work to be done in the field.

The Saudi Aramco engineer must ensure that the

specified fitup tolerances are applied to a contractor's

work. 01-SAMSS-010 provides these tolerances for

fabricated pipe sections, as summarized in Work Aid 1.

The fitup tolerances required for the installation of plant

piping are in SAES-L-050 and will be discussed later in

this module.

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Mitered Joints

• Mitered joints are changes in direction that are

obtained by welding short pipe sections together.

Mitered joints with angular offset larger than 3° are

not permitted unless specified on the buyer's

drawing.

• A welding technique shall be used which provides a

smooth, regular, and fully penetrated internal

surface. This, plus the detailed design specified for

the miter, ensures that it will be as strong as the

straight runs of connected pipe.

Ends for Field Welding

• All welding ends shall be beveled with an angle of

35°, plus or minus 5°, and a root face of 1.5 mm

(1/16 in.). The bevels shall be machine-cut bevels

or smooth, clean, slag-free flame cut. The end

plane shall be normal to the pipe axis as defined on

the piping drawing, within 0.25°. In this way, spool-

piece weld ends are already prepared for welding in

the field, when required.

Pipe Bending

A bend is a change in direction that is made by physically

bending a straight section of pipe, rather than by using a

wrought or forged elbow. Pipe bends are prefabricated,

or done by the contractor, and need to be checked by the

Saudi Aramco engineer. Bending is normally done when

a long, gradual change in direction is required, either

because of fluid flow considerations, the local terrain for

pipeline applications, or to permit pipe scraping.

• Bends shall be completely free from buckles, dents,

cracks, wrinkles, other mechanical damage or

indentations such as could be caused by the grips of

the bending machine. These could act as localized

stress-concentration points or obstructions to pipe

scrapers.

• Flat spots shall have no dimension exceeding the

value given by the following formula:

d = 2tD

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

where: d = Largest dimension of the flat spot

t = Nominal wall thickness

D = Nominal pipe diameter

Larger flat spots could cause higher local stresses

or obstruct pipe scrapers.

Pipe Bending, Cont’d

• The difference between the largest and smallest

diameter (flattening) of the cross-section shall not

exceed 5% of the nominal pipe diameter at any

point in the bend, nor 3% of the nominal pipe

diameter at the ends. A larger difference could

cause excessive local stress, make the bend more

prone to buckling, or obstruct passage of a scraper.

• The minimum wall thickness shall not be less than

the minimum allowed wall thickness of the pipe.

Some pipe thinning will occur during the bending

process. This requirement ensures that the bend

will not limit the MAOP of the system.

• Unless otherwise specified, the centerline radius of

pipe bends shall be at least five times the nominal

pipe diameter (5D). This will minimize local stresses

in the bend.

• When bends are supplied with welding ends for field

welding, a minimum straight tangent length of the

smaller of 1 1/2 times the nominal pipe diameter or

600 mm (2 ft.) shall be provided at each end. This

will provide easier access for welding at the bend.

• Bend tolerances shall be as follows (unless

otherwise specified):

- ± 0.5° on bend angle.

- ± 1% on bend radius.

These points are illustrated in Figure 1.

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

TOLERANCES AT PIPE BENDS

Notes

• (E-C) Š 0.05D at any point, 0.03D at ends

• A 5D

• B 1.5D or 600 mm (2 ft.), based on smaller value

• Bend Minimum Thickness Not Less Than Straight Pipe Minimum Allowable

Thickness

• Bend Tolerances: ±5° on angle, ±1% on radius

FIGURE 1

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Cold Bending

Cold bending is normally done on tubing and on pipe with

relatively small diameters and wall thicknesses. Proper

equipment and dies are essential to avoid wrinkling,

excessive thinning, and excessive ovality. Saudi Aramco

requires that:

• Cold bends shall be made below 649°C (1,200°F),

and seamless, Grade B pipe shall be used. The

temperature shall be below 316°C (600°F) if pipe

material that has been strengthened by cold work is

used (such as the "X" grades of the API 5L

specification). Using a higher bending temperature

with a cold-worked material will reduce the material

strength.

• For pipe that is 150 mm (6 in.) and larger in outside

diameter, cold bends shall not be used unless they

were specified in the Purchase Order, and have at

least a 10D bend radius.

• For cold bends with a radius of less the 30D, the

nominal outside diameter divided by the nominal

wall thickness shall not exceed 35.

• For wet, sour service, cold bends to a radius of 5D

or less shall be heat treated at 593-649°C (1,100-

1,200°F) for one hour per 25 mm (1 in.) nominal wall

thickness, but not less than one hour.

• For wet, sour service, a hardness measurement

shall be made on each bend at the outer radius of

the bend area. The maximum hardness is limited to

237 Brinell. Limiting the hardness level at the

maximum stress point of the bend minimizes the

probability of cracking in this service.

Saudi Aramco DeskTop Standards 13

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Hot Bending

Pipe hot bending may be done either in a furnace, or by

passing the pipe through an induction heating coil. 01-

SAMSS-010 specifies general requirements for hot

bending, and specific requirements for both the furnace

and induction methods. The following highlights several

of these requirements. Participants are referred to 01-

SAMSS-010 for additional details.

• Detailed procedures must be submitted for review

and approval by the Consulting Services

Department.

• Impact test requirements are specified for low-

temperature service [below -18°C (0°F)].

• Hardness measurements and acceptance criteria

are specified. This will ensure that the bending

procedure did not produce any locally hard areas

that would be more prone to cracking.

• Wall thickness measurements must be made along

the bend to ensure that excessive thinning did not

occur.

• Pipe material and bending temperature

requirements are specified for furnace hot bends.

• Procedural requirements are specified for induction

bends.

Saudi Aramco DeskTop Standards 14

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Sample Problem 1

This sample problem will review what has been

discussed thus far regarding fabrication and installation

of plant piping systems. Work Aid 1 may be used to help

solve this problem.

A contractor has been engaged by Saudi Aramco to

fabricate and install a piping system at a new pump.

There have been reports from the field that pipe fitup and

pump alignment have not been going smoothly. Field

personnel have expressed concern that the fabrication

and installation quality is not good. You have been asked

to begin reviewing the situation.

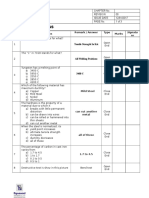

Figure 2 is a representation of a fabrication drawing for

one portion of the piping system. Your intent is to use

this as a sample to see if further review of the

contractor's work is necessary. In addition to this, flange

alignment measurements were made in the field at the P-

602 suction flange. The following misalignments were

measured:

• Vertical bolt-hole offset +1.5 mm (+ 1/16 in.)

• Horizontal bolt-hole offset -0.8 mm (- 1/32 in.)

• Rotational offset +0.4 mm (+ 1/64 in.)

• Flange-face tilt across diameter +2.4 mm (+ 3/32 in.)

• Flange-face separation +1.5 mm (+ 1/16 in.)

No deviations or additions from 01-SAMSS-010 were

permitted by the original purchase specification. Use 01-

SAMSS-010, SAES-L-050, and Work Aid 1 to assist in

your review.

Saudi Aramco DeskTop Standards 15

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

FABRICATION DRAWING

A D

B

Connect to P-602

Suction Flange

Dimensions

A = 37'6" ±1/4"

B = 13'-4" ±1/8"

C = 22'-0" ±1/8"

D = On Pipe Centerline ±3/16"

E = 96" Bend Radius

Notes

- Pipe: A106, Gr. A, 16 in., Sch 40.

- Nipples for Vents and Drains: 3/4 in., Sch 40,

A106, Gr. B.

- Weld-Neck Flanges: ASME/ANSI B16.5, Class

300, A350 LF2.

- Butt-Weld Fittings: A234, Gr. WPB.

- 3/4 in. Forged Couplings for Vents and Drains:

ANSI B16.11, Class 2000, A105

- Conform to ASME/ANSI B31.3 and 01-

SAMSS-010

FIGURE 2

Saudi Aramco DeskTop Standards 16

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Solution

1. The fabrication drawing shows the pipe material to

be A106, Gr. A. This is not an acceptable material

per 01-SAMSS-010. It should be A106, Gr. B, or

one of the other acceptable pipe material

specifications.

2. The nipples are specified to be A106, Gr. B material,

which is acceptable. However, their wall thickness

is specified as Sch. 40. They should be Sch. 80

minimum per 01-SAMSS-010.

3. The flanges are specified to be weld-neck,

ASME/ANSI B16.5, Class 300, A350 LF2 material.

This is acceptable.

4. The butt-weld fittings are specified to be A234, Gr.

WPB. This is acceptable.

5. The forged couplings are specified to be A105

material, ANSI B16.11, Class 2000. They should be

Class 3000 per 01-SAMSS-010.

6. A note indicates that the fabrication conforms to

ASME/ANSI B31.3 and 01-SAMSS-010. Based on

previous information, this is not in conformance with

at least 01-SAMSS-010 requirements.

7. The dimensional tolerances should conform to 01-

SAMSS-010 and SAES-L-050.

Dimensions B & C conform to the required 1/8 in.

tolerance.

Dimension A has a + 1/4 in. tolerance and is not

acceptable.

Dimension D indicates the flanged branch

connection can be off the pipe centerline by 3/16 in.

It should have a 1/16 in. tolerance.

The bend radius of 96 in. is acceptable since it

exceeds the minimum of five times (Nominal Pipe

Diameter) required by 01-SAMSS-010.

8. The flange alignment tolerances generally exceed

the 1/64 in. maximum misalignment tolerance

specified in SAES-L-050, since several exceed the

maximum 1/64 in. permitted.

Saudi Aramco DeskTop Standards 17

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Solution, Cont’d

In reviewing this one fabrication drawing, a large number

of relatively serious fabrication and construction

discrepancies were found. The fabrication and erection

tolerances do not conform to Saudi Aramco

requirements. Therefore, it should not be surprising that

there are problems in the field with the installation. In

addition, several material and piping component design

deficiencies were also noted. Because of all these

deficiencies, a complete design review of the contractor's

work is warranted.

It should be noted that this review was only made on the

basis of conforming to the minimum Saudi Aramco

requirements for fabrication and erection. It was not a

design review. For example, it was tacitly assumed that

Class 300 flanges and Schedule 40 thickness for the 16

in. pipe were acceptable for the design conditions. A

complete design review would at least spot check these

items, as well, at some point during project execution.

Welding and Heat Treatment

Welding is one of the primary ways of joining pipe.

Welded joints represent the ultimate in safety and

reliability. All codes call for welding to be carried out

using a qualified procedure and welders. Included in the

standard procedure are: base-metal specifications,

electrode, joint preparation, weld position, welding

process (including whether it is manual or automatic),

techniques, electrical details, preheat and interpass

temperatures, and post-weld heat treatment

requirements. The Saudi Aramco engineer needs to

check how the contractor plans to weld pipe together.

This requires knowing the primary welding types and

where they are typically employed in piping systems. 01-

SAMSS-010 and the applicable ASME/ANSI B31 Code

provide considerations for heat treatment and the two

primary weld types used: butt welds and fillet welds.

Saudi Aramco welding requirements are specified in the

following SAES's:

• SAES-W-001, Basic Welding Requirements.

• SAES-W-011, Welding Requirements for On-plot

Piping.

• SAES-W-012, Welding Requirements for Pipelines.

Saudi Aramco DeskTop Standards 18

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Butt-Welds

Butt-welds are made between two components whose

edges are in close proximity. Butt-welded joints in piping

systems are primarily of the single-V configuration and

are welded from the pipe outside surface. Larger

diameter pipes which can be accessed from the inside

will often be welded from both sides using a double-V

type of joint preparation. The joint preparation and the

procedure that is used ensure that there is complete

fusion between the edges of the components being

joined. Joint designs shown in Figure 3 or applicable

combinations of these joint design details are typically

used for ends of equal thickness. The transition between

ends of unequal thickness may be accomplished by taper

grinding the thicker pipe to match the thinner, or by using

weld metal to provide a smooth transition as shown in

Figure 4. A prefabricated thickness transition section of

not less than one-half pipe diameter in length is another

means to make the change between pipe thickness.

Butt-welds will always be used to weld pipe ends

together, to weld butt-weld-type flanges or fittings to pipe

ends, or to weld the edges of formed plate together when

plate is used to manufacture pipe.

Saudi Aramco DeskTop Standards 19

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

ACCEPTABLE BUTT-WELDED JOINT DESIGN FOR

;;;;;;;

EQUAL WALL THICKNESS

+ 5 deg. 1/16 in. + 1/32 in. 1/16 in. + 1/32 in.

30 degree- 0 deg.

37-1/2 deg.

;;;;;;;

+ 2-1/2 deg. 10 deg. + 1 deg.

Rounded

t > 7/8 in. 37 1/2 deg.

7/8 in. + 2-1/2 deg.

3/4 in.

(a) Standard End Preparation (b) Standard End Preparation

of Pipe of Butt-Welding Fittings and

Optional End Preparation of 1/16 in + 1/32 in.

Pipe 7/8 in. and Thinner

( c) Suggested End Preparation,

;;

;;

Pipe and Fittings Over

7/8 in. Thickness

+ 2-1/2 deg.

37-1/2 deg.

Standard End Preparations

+ 5 deg. 37-1/2 deg.

;;

;;;

;;;;

;;;

30 deg.

to

- 0 deg. + 2-1/2 deg.

60 deg.

- 0 deg.

+ 5 deg.

10 deg. + 1 deg.

to

+ 2-1/2 deg.

37-1/2 deg.

80 deg.

30 deg.

(d)

(e)

(f)

Acceptable Combinations of Pipe End Preparations

Source: ASME/ANSI B31.4 - 1989. With permission from American Society of Mechanical

Engineers.

FIGURE 3

Saudi Aramco DeskTop Standards 20

Engineering Encyclopedia Piping, Pipelines & Valves

; ;;;;

Piping Fabrication and Construction

; ;;;;

ACCEPTABLE BUTT-WELDED JOINT DESIGN FOR

UNEQUAL WALL THICKNESS

;; ;

t tw t tw 2 t 2

tD tw tD

1/2 t max. 30 deg. max. 1/2 t max.

3/32 in. max. 30 deg. max. to 14 deg. min. (1:4) 1

(a) (b) (c)

;; ;

t tw 2

tD

30 deg. max. 1/2 t max.

1/2 t max. 2

tw tD

; ; ;

t

30 deg. max. to 14 deg. min. (1:4) 1

(d) (e)

;; ;

1

30 deg. max. to 14 deg. min. (1:4)

30 deg. max. to 14 deg. min. (1:4) 1

30 deg. max. 1/2 t max.

2

tw tD

30 deg. max. 1/2 t max.

2 t

tD

tw

t 1

30 deg. max. to 14 deg. min. (1:4)

(f) (g)

Source: ASME/ANSI B31.4 - 1989. With permission from American Society of Mechanical

Engineers.

FIGURE 4

Saudi Aramco DeskTop Standards 21

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

FILLET WELDS

;; ;;;;;

Size of

Weld

; Surface of Perpendicular Member

Convex Fillet Weld

Size of

Surface of Weld

Horizontal

Member

Theoretical Throat

Equal Leg Fillet Weld

Concave

Fillet Weld Size

Fillet Weld

Size of

Weld

Surface of Perpendicular Member

Convex Filled Weld

Surface of

Horizontal

Member

Theoretical Throat

Unequal Leg Fillet Weld

Concave

Fillet Weld

GENRAL NOTE: GENRAL NOTE:

;;;;;;;;;;;;;;;;;;;;

;;;;

The size of An Equal Leg fillet Weld Is the Length of the Largest The size of an Unequal Leg fillet Weld Is the Lengths of the Largest

Inscribed Isosceles Right triangle (Theoretical Throat = 0.707 X Size). Right triangle Which Can Be Inscribed Within the Weld Cross Section

(e.g. 1/2 in. x 3/4 in.)

Typical Details for Double-Welded Slip-on and Socket Welding

Flange Attachment Welds

X min X min X min X min

X min X min X min X min

;;

;;

1/16 in.

Approx. Gap

The Lesser of T or 1/4 in. Before Welding

(1) Front and Back Welds (2) Face and Back Welds (3) Socket Welding Flange

xmin. = the Lesser of 1.4 T or the Thickness of the Hub

;;

t

cx

Minimum Welding Dimensions t = Pressure Design Thickness

for Socket Welding cx

Components Other Then Flanges

1/16 in. Approx. Gap

;;; ;;; ;;;

Before Welding

cx (min.) = 1-1/4 but Not

Less Than 1/8 in. (3.2mm)

;;;;; ;

;;

Typical Backing Rings and Consumable Inserts

3/16 in.

tm (c) Nonmetallic Removable

Backing Ring (Refractory

;;;;;; ;;

3/4 in. (d) Square Ring or

1/8 in. to 3/16 in. Round Wire Type

(a) Butt Joint with Bored Pipe Ends

and Solid or Split Backing Ring

3/16 in.

(e) Flat Rectangular Ring

Typical

Consumable

tm Inserts

(f) Formed Ring Type

3/4 in.

1/8 in. to 3/16 in. (g) Y-Type

(b) Butt Joint with Taper-Bored Ends

and Solid Backing Ring

Source: ASME/ANSI B31.3 - 1988. With permission from American Society of Mechanical

Engineers.

FIGURE 5

Saudi Aramco DeskTop Standards 22

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Fillet Weld

The fillet weld generally requires no special preparation

of the joints. It is an angular weld bead that joins

components positioned normally at a 90° angle to each

other. Fillet welds may be concave to slightly convex in

shape. The size of a fillet weld is stated as a leg length

of the largest inscribed right isosceles triangle as shown

in Figure 5 covering typical attachment details of slip-on

flanges. In piping systems, fillet welds are only used for

slip-on flanges, socket welds, and for welding

attachments to piping components (e.g., reinforcing pads,

supports, etc.).

Welding Steps

The following outlines the overall steps that are required

for welding.

Preparation for Welding - Procedure and Welder Qualification:

• Before any welding is done, the specific details of

how it will be carried out, i.e. the welding procedure,

must be specified and demonstrated to achieve

acceptable results. A welding procedure is as

important to the welder as a blueprint or drawing is

to a machinist. Each of the ASME/ANSI B31

Codes, plus modifications contained in SAES-W-

001 (and SAES-W-011 or SAES-W-012 as

applicable), specify welding procedure qualification

requirements.

• Welding procedure qualification demonstrates that

the approach specified for doing the weld will

achieve acceptable results when properly applied.

The next step is to qualify the particular welders and

welding equipment to carry out the specific welding

procedure. Here again, the relevant ASME/ANSI

B31 Code plus Saudi Aramco requirements must be

met.

• The end result of these two steps is that both the

welding procedure, and the individuals and

equipment executing it, have been confirmed to

produce acceptable results.

Saudi Aramco DeskTop Standards 23

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Welding and Heat Treatment, Cont’d

Cleaning:

• Internal and external surface to be thermally cut or

welded shall be clean and free from paint, oil, rust,

scale, or other material that would be detrimental to

either the weld or base metal when heat is applied.

If such items are not cleaned, they could mix with

the weld metal at elevated temperatures and result

in poor quality welds.

End Preparation:

• The ends of the components to be welded must be

set to the correct geometric shape suitable for the

materials, wall thickness, and welding process

involved.

• End preparation is acceptable only if the surface is

reasonable smooth and true, and slag from oxygen

or arc cutting is cleaned from thermally cut surfaces.

Discoloration that remains on a thermally cut

surface is not considered to be detrimental

oxidation.

• Component ends may be trimmed to allow for fitting

a backing ring, provided that the remaining net

thickness of the finished ends is not less than the

minimum required wall thickness for the service

conditions. A backing ring is often placed at the

inside surface of pipe sections to be joined by butt-

welds to assist in achieving full penetration and

fusion.

• It is permissible to size pipe ends to be of the same

nominal size to improve alignment if wall thickness

requirements are maintained.

• Where necessary, weld metal may be deposited

inside or outside the component to permit alignment

or provide for machining to ensure satisfactory

seating of rings or inserts.

Saudi Aramco DeskTop Standards 24

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Welding and Heat Treatment, Cont’d

Preheating is used, along with heat treatment, to minimize

the detrimental effects of high temperature and severe

thermal gradients that are inherent in welding. The

necessity for preheating and the temperature to be used

shall be specified in the engineering design and stated by

procedure qualification. Specific preheat temperature

requirements are specified in the appropriate

ASME/ANSI B31 Code based on the pipe material and

wall thickness that are being joined.

The following identifies specific benefits of preheating:

• Dries the metal and removes surface moisture

which could, if present, result in porosity of the weld

metal.

• Reduces the temperature difference between the

base metal and the weld to reduce the cooling rate

of the weldment, lowers the weld hardness to

reduce residual stresses, and reduces

cooling/shrinkage stresses.

• Helps maintain the weld pool molten for a longer

time to permit maximum fluxing and separation of

impurities.

• Helps drive off absorbed gases (such as hydrogen)

which could contribute to weld porosity.

Welding and Heat Treatment, Cont’d

Postweld-heat treatment is used to avert or relieve the

detrimental effects of high temperature and severe

temperature gradients that are inherent in welding, and to

relieve residual stresses that are created by bending and

forming. Specific heat treatment temperature and

procedure requirements are specified in the appropriate

ASME/ANSI B31 Code based on the pipe material and

wall thickness being joined.

Saudi Aramco DeskTop Standards 25

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

The following summarizes the principal reasons for

PWHT:

• Stress relief is the most common reason for

specifying PWHT, and is the only consideration for

the requirements that are specified in the

ASME/ANSI B31 Codes. Residual stresses will

remain in the pipe and result from shrinkage as the

weld and adjacent pipe metal cool down from

elevated welding temperatures. Residual stresses

will also remain after bending or forming processes.

If these residual stresses are too high, they can lead

to premature failure of the pipe. ASME/ANSI B31

Code requirements specify when PWHT is required

to relieve these residual stresses and bring the pipe

to an initial stress-free state. PWHT is also required

to reduce fabrication stresses to minimize the

potential for stress-corrosion cracking in certain

process environments, such as caustic, amines, and

wet H2S.

• After welding the normal grades of stainless steels

(i.e., those that are not stabilized with alloy

additions), it is necessary to heat treat the material

to restore maximum corrosion resistance.

• PWHT is required to prevent caustic embrittlement

of welded carbon steel pipe that handles alkaline

solutions. Caustic embrittlement is a form of stress

corrosion where the residual stresses due to

welding are sufficient to cause failure.

• PWHT is also sometimes necessary to reduce weld

hardness in certain materials. Minimizing weld

hardness reduces the tendency to crack, especially

in certain process environments such as caustic or

wet H2S.

Inspection and Testing of Pipe Spools

When the pipe spool piece has been completely

fabricated, it is ready for final inspection and testing. The

vendor shall give reasonably advanced notice regarding

the dates that fabrication and tests will be made. All

materials, certificates, fabrication, testing, and

examination shall be in accordance with ASME/ANSI

Saudi Aramco DeskTop Standards 26

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

B31.3, Chapter VI, and are subject to verification by the

buyer's inspector.

When all openings on a pipe spool are either flanged or

threaded, the spool shall be hydrostatically tested. When

no test pressure is indicated in the purchase order, the

hydrostatic test pressure shall be based on the flange

rating per ASME/ANSI B16.5, but in no case shall the

pipe be stressed to more than 90% of the specified

minimum yield strength based on the nominal pipe

thickness.

The vendor must provide the blind flanges, plugs and

caps that are needed to close off open spool piece ends.

This prevents the entry of dirt and debris during

transportation and subsequent storage prior to field

installation, and reduces the amount of cleaning and

flushing required in the field.

Pipe spools with welded ends shall not be pressure

tested unless specified in the purchase order. In these

cases, the spools will be tested in the field after the entire

piping system has been assembled.

Product Marking and Preparation for Shipment

In order to properly assemble the piping spools in the

field, the vendor must properly identify and prepare each

segment for shipment.

Identification

• Each spool shall be marked with the spool mark

number painted at the ends as shown on the

drawings. The numbers shall not be less than 25

mm (1 in.) in height.

• The spool number will be die-stamped on the rim of

each flange.

• Pipe bends that are delivered as separate

components must also be marked, as specified in

01-SAMSS-010.

Saudi Aramco DeskTop Standards 27

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Product Marking and Preparation for Shipment, Cont’d

Cleaning

• All loose, foreign material and weld spatter shall be

removed. The spool shall be clean and dry.

Painting

• Unless specified otherwise, spools shall not be

painted or coated.

Protection

• When spools are supplied with blind flanges, the

latter shall be bolted on with the specified gaskets

and stud bolts. Other flange faces shall be

protected by a cover that is bolted to the flange.

• Threaded pipe ends shall be provided with steel or

malleable iron pipe caps.

• Threads shall be coated with a graphite and oil

paste.

• Welding ends shall be protected by a securely

fastened bevel protector.

Saudi Aramco DeskTop Standards 28

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

DETERMINING WHETHER METALLIC PLANT PIPING MEETS

INSTALLATION REQUIREMENTS

The piping fabrication requirements that were discussed

in the previous section apply primarily to carbon steel

piping, but may be used for alloy piping as well, with

some modifications. For plant piping, there are additional

piping fabrication requirements that the engineer must be

able to identify when auditing a contractor's work. These

requirements are outlined in SAES-L-050, which

supplements ASME/ANSI Code B31.3. This section

discusses some of the requirements that are established

in ASME/ANSI B31.3 and SAES-L-050. These

requirements are highlighted in Work Aid 2.

Storage and Handling

Improper handling and storage of pipe materials and

welding filler metals can cause damage and result in poor

construction quality and failures during operation.

• Pipe shall not be stored directly on the ground, and

shall be placed on mounds or sleepers. This will

help prevent the accumulation of rainwater around

the pipe, which could result in corrosion.

• Pipe shall not be stacked so high that pipes or their

coatings may be damaged.

• Fittings and valves shall be stored in shipping crates

or on racks. This is to provide greater protection

from damage until these components are used.

• End protectors shall be firmly attached to prevent

damage to weld bevels, flange faces, threads, or

socket-weld ends.

• Lined and coated pipes and fittings shall be lifted

with wide fabric or rubber-covered slings and

padding to prevent damage. This prevents overly-

localized load application which could lead to

excessive pipe deformation and damage to the

lining or coating.

Saudi Aramco DeskTop Standards 29

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Pipe Fitup and Tolerances

Good joint fitup is essential to making a sound weld and

minimizing the loads imposed on the piping system and

connected equipment. Depending on the welding

process used, a slight mismatch may be permissible.

The applicable ASME/ANSI B31 Code specifies welding

requirements, which are supplemented by Saudi Aramco

requirements. For example, in pipe joints where the

inside diameters have not been matched up by internal

boring or tapering, fitup may become a problem,

particularly when backing rings are not used.

• Pipe fitup for welded joints shall be as required by

SAES-W-001, Section 7.

• The tolerance for axial dimensions, face-to-face,

center-to-face, and location of attachments shall be

±3 mm (±1/8 in.) maximum.

• Flattening of bends, measured as the difference

between the largest and smallest outside diameter

at any cross-section, shall not exceed 5% of the

nominal diameter of the pipe (3% at the ends).

• Lateral translation of branches and connections

from centerline of run shall not exceed ±1.5 mm

(±1/16 in.).

• Flange bolt holes shall straddle the centerlines.

Rotation of flanges, measured as the offset between

elevation of bolt holes on opposite sides of a flange

centerline, shall not exceed ±1.5 mm (±1/16 in.).

• The tilt of flange measured at the periphery across

any diameter shall not exceed 1 mm (1/32 in.) from

the square position.

Saudi Aramco DeskTop Standards 30

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Alignment of Pipe Attached to Load-Sensitive Equipment

As discussed in MEX 101.07, special care must be taken

for load-sensitive equipment, especially rotating

equipment. Specifically, in attaching pipe to rotating

equipment, the installation should avoid putting excessive

forces and moments on the machinery nozzles which

could result in misalignment. The flexibility calculations

that were discussed in MEX 101.07 do not account for

loads imposed on equipment nozzles during erection,

and tacitly assume that these will be relatively small.

Adhering to relatively small installation tolerances makes

this a valid assumption.

• Installation of piping that is connected to rotating

equipment should preferably start at the machine

nozzle flange. This will reduce the possibility of

having a large mismatch between the pipe and

machine flanges if pipe installation is begun from the

opposite end of the system. The first piping section

up to the first flange should be loosely bolted to the

machine nozzle flange. Gaskets should be used

during fabrication procedures and renewed before

final boltup. Temporary supports may be required

during installation until all pipe sections and

permanent supports are installed.

• Bolt on succeeding pipe sections as appropriate up

to the first support. Adjust this support as required

to just contact the pipe at its bearing point before

any temporary pipe supports are removed. Proceed

to any other adjacent supports which should be

similarly adjusted.

• One or more field welds are typically used to join the

piping nearest to the machine with the rest of the

system. The number and location of these field

welds are determined such that they will permit final

position adjustments to achieve acceptable flange

alignment at the machine nozzle. The piping

system should generally be freestanding on its

permanent support system without any additional

support or restraint prior to making these field welds.

If this were not the case, additional loads could be

imposed on the machine nozzle when the temporary

supports or restraints are subsequently removed

after making the field welds.

Saudi Aramco DeskTop Standards 31

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

• Spring supports should be locked in their cold

position during pipe installation.

• All spring supports will be adjusted in the locked

position just until they contact their respective

support points. If spring-support adjustment is

insufficient, modifications to associated structural

members or shimming will be required. Spring

hangers should also be locked and hanger rods

adjusted until free movement is eliminated. Vertical

flange misalignment should never be corrected by

using spring-support adjusters or spring-hanger

rods.

Alignment of Pipe Attached to Load-Sensitive Equipment, Cont’d

• Final bolt tensioning of component flanges close to

the machinery should be done after initial alignment

of nozzle flanges.

• Piping that requires any sections to be removed for

flushing after completing field welds should have

final nozzle alignment and component flange boltup

completed after replacing flushed sections.

• For piping over 75 mm (3 in.) NPS connected to

machinery, flange alignment must be within more

stringent limits than is specified for general piping

systems. More stringent limits are required to

minimize the loads that are imposed by flange

boltup. These flange alignment limits are

summarized in Work Aid 1.

• Precautions should be taken to prevent ingress of

debris into machine internals during construction of

connecting pipework.

• Spring supports are designed to support the weight

of the pipe, insulation, and contents during

operation. Flange alignment is most easily

accomplished with the spring locking stops installed,

which makes the spring a rigid support. Since

alignment is being done with the pipe empty, and

the spring support was designed for the line full,

Saudi Aramco DeskTop Standards 32

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

trying to do a pipe alignment with the spring stops

removed could be an unreasonable exercise

(especially if the springs are designed for liquid

loading during operation).

Flange Joint Assembly

Flange joint assembly procedures directly affect the

ability of the flange to be leak-tight in service. In many

low-pressure, low-temperature, and/or nonflammable

services, many rules of good flanged joint design and

makeup can and have been violated with no adverse

consequences. However, it is dangerous to break these

rules in critical, high-temperature services since the

results can be serious leakage problems with consequent

fires. The primary factors for successfully making up a

flanged joint and controlling leakage are the following:

• Proper selection and design of the flanged joint.

• Proper preparation, inspection, and installation of

the flanged joint.

• Identifying and controlling the causes of leakage.

Flanged joint assembly and leakage control are

discussed below.

Alignment of Pipe Attached to Load-Sensitive Equipment, Cont’d

Preparation, Inspection, and Installation – The following

discusses the primary steps that are required to achieve

a properly assembled flanged joint. These are

summarized in Work Aid 2.

• Redo Damaged Surfaces — Warped or badly

corroded flanges should be replaced or refaced.

Flanges with tool marks or scratches across the

gasket seating surface should be refaced, since

these form leakage paths.

• Clean Faces — All gasket and flange surfaces

should be clean. Remove all burrs, rust, and dirt

from flange faces with scrapers or wire brushes.

This step is often overlooked.

• Align flanges — Flanges at rest should be within the

Saudi Aramco DeskTop Standards 33

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

alignment tolerances previously discussed, with the

flanges practically mating before the bolts are

installed. Nonparallel flanges are sometimes

straightened by applying heat or by bending the

pipe. However, the best alignment approach usually

involves cutting off the flange and rewelding it to the

pipe.

Bringing the flanges into alignment should not leave

any residual stresses in the piping system. Residual

stresses could lead to flange leakage in service or

overload problems in systems that are connected to

load-sensitive equipment. This becomes more

important with increasing pipe diameter, as the

residual stress increases with increasing diameter

for the same amount of misalignment.

• Lubricate Threads and Nuts — Lubricate the bolt

threads and the nut faces where they will contact

the flange. An oil-graphite mixture works well. For

high temperatures, use high-temperature silicone

grease or a colloidal copper compound. Lubrication

helps increase the amount of bolt load that goes into

tightening the flange rather than into overcoming

friction. Lubrication also aids in achieving high

enough and uniform bolt tension required to achieve

a leak-free joint during operation.

Alignment of Pipe Attached to Load-Sensitive Equipment, Cont’d

• Place Gasket Properly — The gasket must be

centered on the flange faces to achieve a reliable

joint, but holding the gasket in place can be a

problem. If something must be used to hold the

gasket, a high-temperature grease may be used

sparingly in systems that operate at less than 93°C

(200°F). No grease, paste, or adhesive should be

used to hold gaskets for systems operating at 93°C

(200°F) or more. The high temperature causes

these materials to burn off, which could damage the

gasket and cause leakage.

Thin cellophane tape may be used on the outside

edges of a gasket, but never on the seating

Saudi Aramco DeskTop Standards 34

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

surfaces. Tape on the seating surfaces will deform

the gasket during joint assembly, burn out at

operating temperature, and thus provide a leakage

path. Centering rings on spiral-wound gaskets help

by allowing the gasket to be supported in the proper

position by a few bolts while the other bolts are

inserted. Sheet gaskets should be cut so that their

outside diameter corresponds to the bolt position,

again to help centering.

• Use Proper Flange Boltup Procedure — Flanges

may be made up using a wrench and hammer, an

impact wrench, a torque wrench, or a stud

tensioner. The most important aspects of a proper

boltup procedure, regardless of method, are to:

– Use a "criss-cross" pattern bolt-tightening

sequence, as is used when bolting a wheel onto

a car. Examples of such bolting patterns are

shown in Figure 6. This approach helps to

achieve a uniform bolt load around the flange.

– Use at least three rounds of tightening around

the flange, increasing the applied load in each

round, with two rounds at the maximum load.

This approach also helps achieve uniform bolt

load around the flange circumference.

– For the most critical high-temperature or high-

pressure flanges, use a method that permits

measuring the applied load (i.e., torque wrench

or stud tensioner). In this way, there is greater

assurance that uniform bolt load is achieved.

For such applications, a maximum stud stress

during boltup of 275-345 MPa (40-50,000 psi) is

the normal target.

Alignment of Pipe Attached to Load-Sensitive Equipment, Cont’d

Causes of Flange Leakage – Most of the primary causes of

flange leakage are directly related to poor inspection or

installation. These are summarized below:

Saudi Aramco DeskTop Standards 35

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

• Uneven Bolt Stress — An incorrect boltup procedure

or limited working space near one side of a flange

can leave some bolts loose while others crush the

gasket. This is especially troublesome in high-

temperature services, when the heavily loaded bolts

relax during operation.

• Improper Flange Alignment — Improper flange

alignment, especially nonparallel faces, causes

uneven gasket compression, local crushing, and

subsequent leakage.

• Improper Gasket Centering — If a gasket is off-

center compared to the flange faces, the gasket will

be unevenly compressed and more prone to

leakage.

• Dirty or Damaged Flange Faces — Dirt, scale,

scratches, protrusions, or weld spatter on gasket

seating surfaces provide leakage paths or can

cause uneven gasket compression that results in

leakage.

• Excessive Loads in the Piping System at Flange

Locations — Excessive piping system forces and

moments at flanges can distort them and cause

leaks. Common causes of this are inadequate

flexibility, using excessive force to align flanges, and

improper location of supports or restraints.

• Thermal Shock — Rapid temperature fluctuations

can cause flanges to deform temporarily, resulting in

leakage.

• Improper Gasket Size or Material. — Using the

wrong gasket size or material can result in leakage.

• Improper Flange Facing — A rougher flange-surface

finish than specified for spiral-wound gaskets can

result in leakage.

Discussing the principal methods for correcting flange

leakage problems is beyond the scope of this course.

However, several of them will be quite obvious based on

the causes of leakage highlighted above.

Saudi Aramco DeskTop Standards 36

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

TYPICAL "CRISS-CROSS" BOLT-TIGHTENING SEQUENCE

3 3

7 5

4 Bolt 8 Bolt

1 2 1 2

Flange Flange

6 8

4 4

3 13 3 11

9 7

5 7

5 11

9 15

12 Bolt 16 Bolt

1 2 1 Flange 2

Flange

16 10

12 6

8 6

8 10 12 14

4 4

13 3 17 3 1119

9 7 2115

5 7

5 11 17 23

19 15 9 14

1 20 Bolt 2 1 24 Bolt 2

16 Flange 20 13 Flange 10

12 6 24 18

8 10 8 6

20

18 4 14 12 4 16 22

FIGURE 6

Saudi Aramco DeskTop Standards 37

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Cleaning

• Prefabricated pipe spools shall be visually inspected

for cleanliness, have foreign matter removed from

the inside, and have end protectors installed.

• After assembly and installation, the piping shall be

cleaned inside to remove all material, either by

flushing or blowing with air as a minimum. Excess

debris that is left in the line could adversely impact

process operations and cause equipment damage.

• The interior of carbon steel piping for specific

services such as boiler-feed water, lube and seal oil,

must be chemically cleaned since these services

are especially sensitive to even small quantities of

dirt and corrosion products that remain in the pipe.

• Pipe cleaning must be done so that soft seats of

valves, control valves, and instruments are not

damaged. These components are typically removed

from the system prior to cleaning.

Buried Installation

• Buried metallic plant piping shall have corrosion

protection in accordance with the applicable SAES-

H and SAES-X standards. Buried installations shall

be in accordance with SAES-L-051.

• The minimum cover in paved or otherwise stabilized

areas shall be 450 mm (18 in.), or as required by

SAES-L-046. The minimum cover under paved

roads shall be 760 mm (30 in.).

Saudi Aramco DeskTop Standards 38

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Sample Problem 2

You have been assigned to review the installation of

several new piping systems being installed at Ras

Tanura. As part of your effort, you have been watching

flange installation procedures being used by the

contractor. The particular flange being installed is 600

mm (24 in.) in diameter and has 24, 38 mm (1-1/2 in.)

diameter studs. The design pressure and temperature of

the system are 3,103 kPa (450 psig) and 427°C (800°F)

respectively, and is in a dangerous, hydrocarbon service.

This is what you have observed:

• The flange make-up crew inspected the flange

surfaces and used a wire brush to clean them.

• Flange alignment was measured and compared to

the required acceptance criteria. No excessive

force was used to bring the flanges into alignment.

• They are having difficulty keeping the gasket in

place since the flange is in a horizontal pipe run.

They solved this problem by using two strips of

adhesive tape across the gasket and attached to the

flange.

• The studs are inserted and the nuts finger tightened.

Then three men take turns tightening each stud by

hammering on a stud wrench with a 5 kg (10 lb.)

hammer as hard as they can. Since the flange is

fairly large and it is a very hot day, the men are

tightening the studs in sequence around the flange

to avoid moving from one side of the pipe to the

other, and wasting time and energy.

Is this procedure acceptable?

Saudi Aramco DeskTop Standards 39

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Solution

This crew started out doing the job right, but did not finish

the job correctly. The following items are incorrect:

• Tape installed in the manner described will likely

lead to leakage during operation. If tape is needed,

it must be attached only to the edge of the gasket

and not its face. However, if the gasket is a spiral-

wound-type, there should be a centering ring to

keep the gasket in place. If the gasket is a sheet-

type, it should be cut so that its outside diameter just

contacts the bolts to help center it.

• For the service described, it would be preferable if a

torque wrench or stud tensioner was used for boltup

to help achieve more uniform bolt stress. If a

hammer and wrench is used, the highest force

should not be immediately applied to each stud. It

should be applied in increments.

• The studs should be tightened in a "criss-cross"

bolting sequence.

Saudi Aramco DeskTop Standards 40

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

DETERMINING WHETHER ABOVEGROUND AND BURIED PIPING MEET

INSTALLATION REQUIREMENTS

The piping fabrication requirements that were discussed

earlier apply primarily to all carbon steel piping systems,

but may be used for alloy piping as well, with some

modifications. For transportation piping, there are

additional piping fabrication and installation requirements

that the engineer must be able to identify when auditing a

contractor's work. These requirements are located in

SAES-L-051, which supplements ASME/ANSI B31.4 and

B31.8. This section discusses some of the requirements

that are established in ASME/ANSI B31.4 and SAES-L-

051. This information should not be used to replace the

standard for on-the-job applications. Work Aid 3

summarizes these requirements.

Vertical Profile

• A route drawing, detailed plan drawings, a piping

and instrument diagram, a hydrostatic test diagram,

and other drawings required per SAES-L-020 shall

be issued by the Prime Engineering Office (PEO)

and shall be the basis for installing the pipeline. The

end of the pipeline, Station 0 + 00, shall be stated in

the Scope of Work, and is normally the upstream

end. A metric tape shall be used for the horizontal

survey. Profile surveying shall be in meters and

decimal fractions of a meter.

• The contractor shall determine the vertical profile of

the pipeline, the amount of cover, the location and

degree of elastic and preformed bends, and the

locations of vents and drains in accordance with

SAES-L-051 and the construction drawings. The

change in slope of the pipeline at normal spacing of

30 m (100 ft.), and at intermediate stations as

required, shall be calculated. The Saudi Aramco

Construction Engineer shall approve the contractor's

design.

• Saudi Aramco will typically do without predesigned

vertical profile drawings, except at locations where

there are steep slopes, or above- to belowground

transitions that require special considerations. In all

Saudi Aramco DeskTop Standards 41

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

other cases, the required profile and required bends

are determined during construction.

• The right-of-way shall be graded to a flat or

smoothly rolling surface. Irregularities shall not

obstruct access of construction equipment. Fills and

cuts shall be made to reduce the number and/or

magnitude of overbends and sagbends in the

pipeline. Fill shall be provided to support

construction equipment in Sabkha areas as

required. The width of such fills and cuts shall not

be less than the area to be stabilized, and the

adjacent slopes shall not be steeper than one in

four.

• If the pipeline construction will change the natural

drainage pattern, either by the grading of the right-

of-way or by a bermed-over cover, provisions shall

be made to prevent washout of the pipeline cover by

rain storms.

Elastic Bends

The maximum change in slope for elastic bends (bends

that are made during installation that do not cause pipe

yielding), shall be in accordance with the Project

Specification or the Scope of Work. Larger changes of

slope shall be made with preformed bends.

The pipeline design and stress analysis specifies the

maximum permitted elastic-bend stress. If this is

exceeded, yielding might occur at points of maximum

combined stress during either the hydrotest or operations

at higher temperatures. If the pipe must be yielded in

order to conform to the required profile, it should be done

in a pipe bending machine during construction to achieve

adequate control and prevent possible ovaling, wrinkling

or buckling.

Saudi Aramco DeskTop Standards 42

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Preformed Bends

Preformed bends are made by a pipe-bending machine

which has mandrels and/or dies for each pipe size. The

machine causes a short length of the pipe to yield and

conform to the radius of the die. The result is a local

"bite" in the pipe. The required preformed bend is made

by making a series of bites at regular spacings.

• Preformed bends shall be made by welding into the

correct location of the string a length of pipe which

has been bent with a smooth stretch-bending

machine. No wrinkle bends or hot bends shall be

used. At any point along a preformed bend, the

pipe diameter shall not be reduced by more than 2-

1/2% of the nominal pipe diameter.

• Bends shall not be made closer than 600 mm (2 ft.)

from a circumferential weld unless the weld is

backwelded. The weld shall be radiographed after

the bend is made. Making a bend closer to a

nonbackwelded weld would introduce a high local

stress at the weld. Radiographing the weld after

bending will identify any weld defects caused by the

bending.

Saudi Aramco DeskTop Standards 43

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Preformed Bends for Aboveground Pipelines

The maximum permissible localized bend or "bite" at one

place on the pipe and the minimum spacing of such bites

are shown below:

Nominal Pipe Size Minimum Bite Spacing Maximum Bend per

mm (in.) mm (in.) Bite, degrees

150 (6) 300 (12) 4.5

200 (8) 300 (12) 3.8

250 (10) 300 (12) 2.8

300 (12) 300 (12) 2.3

350 (14) 300 (12) 1.7

400 (16) 300 (12) 1.5

450 (18) 300 (12) 1.2

500 (20) 450 (18) 0.9

600 (24) 450 (18) 0.75

750 (30) 450 (18) 0.6

900 and larger 450 (18) 0.5

(36 and larger)

• Vertical preformed bends shall be used when

changes of slope are required which are larger than

permissible using elastic bends. The preformed

bend shall be welded into the string so that its

center will be centered on the support at which the

change in slope occurs. Movements of the string

due to temperature changes after the location has

been first established may be neglected. The

maximum allowable angle of preformed bend per

support in a 900 to 1,200 m (3,000 to 4,000 ft.)

string shall decrease as the distance between the

bend and either free end of the string increases, as

shown below.

Distance From End of String, m Degrees Per Change in Slope

(Ft.) Support

0 to 60 (0 to 200) 10 0.1745

60 to 120 (200 to 400) 8 0.1396

120 to 180 (400 to 600) 6 0.1047

180 to 275 (600 to 900) 4 0.0698

• For aboveground restrained pipelines, the support

design shall limit the angle of vertical bend per

support to a maximum as indicated in the Project

Saudi Aramco DeskTop Standards 44

Engineering Encyclopedia Piping, Pipelines & Valves

Piping Fabrication and Construction

Drawings or Specifications. A deflection anchor

force acts at bends in restrained pipelines. The

bend angle affects the force that is transmitted to

the support, and the support is designed for a

maximum permitted force.

• For aboveground restrained pipelines, all horizontal

deflections shall be made at deflection anchors or