Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Prinect Prepress Interface

Caricato da

Zoran ProkicCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Prinect Prepress Interface

Caricato da

Zoran ProkicCopyright:

Formati disponibili

Prinect Prepress Interface

Prinect

abcde

Information

Prinect Prepress Interface 2011

Version 2011

Installation and User’s Guide

Revision 1.0

Order No. SZ.111.1706

ABC

Copyright © 2011 Heidelberger Druckmaschinen AG

Heidelberger Druckmaschinen AG.Kurfuersten-Anlage 52–60

No part of this book may be 69115 Heidelberg

reproduced without prior written

Germany

permission. Phone +49 6221 92-00

Fax +49 6221 92-6999

www.heidelberg.com

. ......................................................................................

Important notice: The information contained in this Order No. SZ.111.1706

We are dedicated to improving and manual about performance and Version 2011

enhancing our products. speed as well as technical data Printed in Germany

Consequently, the information in concerning application of our

this manual is subject to technical products is not legally binding as it

modifications and other changes does not constitute a written

without notice. contract of features.

Heidelberger Druckmaschinen AG If any problems occur with the

assumes no responsibility for product described in this manual,

information and description as far please contact the Heidelberg

as third-party products are agency which is responsible for

concerned. you.

Overall chapter overview

Overall chapter overview

Before you start................................................... 1

1 About this documentation.............................. 1

1.1 General information............................... 1

1.2 What you should already know.............. 1

1.3 Other documentation............................. 1

1.4 Links and conventions in the

documentation....................................... 1

1.5 Important text sections........................... 2

2 Heidelberg online........................................... 3

Introduction......................................................... 5

1 Prinect Prepress Interface............................. 5

2 What is the task of Prinect Prepress

Interface?....................................................... 5

2.1 Ink zone presetting on the printing press 5

2.2 Connection to Prinect Image Control..... 6

2.3 Position information for Prinect Auto

Register................................................. 6

2.4 Position marks for postpress ................ 6

3 What are the functions of Prinect Prepress

Interface?....................................................... 7

4 Basic concept................................................. 8

4.1 Server-client architecture....................... 8

4.1.1 Prepress Interface Cockpit as a

client........................................... 10

4.1.2 Prinect License Server............... 10

4.2 Supported languages............................. 11

5 Components................................................... 11

5.1 Prinect Prepress Interface..................... 11

5.2 Prepress Interface Cockpit.................... 12

5.3 Services................................................. 12

, Prinect Prepress Interface 2011, Operating manual III

Overall chapter overview

5.4 File formats............................................ 13

5.5 Master data store................................... 13

Hardware and software requirements................. 15

1 System requirements and limits..................... 15

1.1 Prinect Prepress Interface Server.......... 15

1.1.1 Comments on the virus scanner. 17

1.2 Prinect Prepress Interface Client

(Cockpit)................................................ 18

1.3 Operating system variants..................... 19

2 System limits.................................................. 20

2.1 Jobs....................................................... 20

3 Prinect Press Center with "Wallscreen"......... 20

3.1 Note on thumbnail images..................... 21

4 Backup device................................................ 21

5 Facts relevant for trouble-free communication

in a networked system environment.............. 22

5.1 Notes..................................................... 22

5.2 System environment.............................. 22

5.3 Server access to network drives............ 23

5.4 Browsing the network............................ 23

Installation........................................................... 25

1 Installation...................................................... 25

1.1 Overview................................................ 25

1.2 Delivered parts....................................... 25

1.3 Installation requirements........................ 25

1.3.1 Necessary rights......................... 25

1.4 Installation process................................ 26

1.5 Server installation.................................. 26

1.5.1 General information.................... 26

1.5.2 Performing the server installation 27

1.6 Steps after the server installation.......... 36

1.7 Upgrading a server................................ 37

IV , Prinect Prepress Interface 2011, Operating manual

Overall chapter overview

1.7.1 General information.................... 37

1.7.2 Performing a server upgrade...... 37

1.8 Client installation.................................... 43

1.8.1 General information.................... 43

1.8.2 Performing the client installation. 43

1.9 Upgrading a client.................................. 46

1.9.1 General information.................... 46

1.9.2 Performing a client upgrade....... 46

1.10 Installing the Job Memory Card drive.... 47

1.10.1 Structure of the Job Memory

Card drive................................... 47

1.10.2 Installation process..................... 47

1.10.3 Installing the USB driver............. 48

1.11 Connecting the Job Memory Card drive 49

1.12 Setting up monitor workstations............. 50

1.12.1 Safety and health protection....... 50

Uninstalling......................................................... 51

1 Uninstalling.................................................... 51

1.1 General information............................... 51

1.2 The uninstallation process..................... 51

Licensing............................................................. 53

1 General information....................................... 53

1.1 Which basic licenses are available?...... 53

1.2 Task of the license server...................... 53

1.3 Dongle................................................... 53

1.4 After the installation............................... 54

2 Licensing for the first time.............................. 54

2.1 Licensing for the first time...................... 54

3 Frequently asked questions........................... 59

3.1 What happens the first time I start the

application?............................................ 59

3.2 What happens if the license server is not

available?............................................... 60

, Prinect Prepress Interface 2011, Operating manual V

Overall chapter overview

3.3 How do I define a new license server?. . 60

3.4 How can I protect myself from the

license server failing?............................ 61

3.5 Can I fix a defective LDS?..................... 62

3.6 When should I repair an LDS?............... 62

3.7 What does "time tampering" mean?...... 63

Configuration....................................................... 65

1 Administration................................................ 65

2 Master data.................................................... 65

2.1 Master data store................................... 65

2.1.1 Symbols...................................... 66

2.2 Color tables............................................ 67

2.2.1 Defining a new color (special

color)........................................... 69

2.3 Printing press catalog............................ 70

2.3.1 Defining a new press

configuration............................... 70

3 Configuration.................................................. 71

3.1 General information............................... 71

3.2 Overview of the configuration................ 72

3.2.1 Recommended procedure.......... 73

3.2.2 Explanatory notes on "Devices". 74

3.2.3 Explanatory notes on "Attribution

rules".......................................... 77

3.2.4 Explanatory notes on "Transfer

graphs"....................................... 77

3.2.5 Explanatory notes on

"Processes"................................ 77

3.2.6 Configuration options.................. 78

3.3 Defining the general process setting..... 79

3.3.1 Procedure................................... 79

3.3.2 "Server" section.......................... 80

3.3.3 "Default values" section.............. 80

VI , Prinect Prepress Interface 2011, Operating manual

Overall chapter overview

3.4 Quick configuration................................ 82

3.4.1 Which directories are

automatically generated?........... 83

3.4.2 The Quick configuration

procedure................................... 83

3.5 Devices.................................................. 90

3.5.1 Defining a device........................ 90

3.5.2 Deleting a device........................ 98

3.6 Creating the process.............................. 98

3.6.1 The "Basic configuration" section 101

3.6.2 The "Available devices" section.. 104

3.6.3 The "Transformations" section. . . 107

3.6.4 Selecting the "Transfer curve

(characteristic curve)" section.... 109

3.6.5 The "Backup directory for

defective PPF files" section........ 109

3.6.6 The "Backup directory for correct

PPF files" section....................... 111

3.6.7 The "Automatic

combiner"section........................ 111

4 Attribution rules (filtering information from the

PPF/CIP file).................................................. 114

4.1 What can I use the attribution rules for? 114

4.2 Which steps have to be taken?.............. 115

4.3 Create new attribution rule..................... 117

4.3.1 Example...................................... 118

4.4 Preview of the attribution rules.............. 130

4.4.1 The "Examples" section.............. 133

4.5 Delimiter................................................. 133

4.5.1 Inserting separation characters. . 134

4.6 Defining an attribution rule for the output

file name................................................ 135

4.7 Editing an attribution rule....................... 136

4.8 Copying attribution rules........................ 137

, Prinect Prepress Interface 2011, Operating manual VII

Overall chapter overview

4.9 Deleting an attribution rule..................... 137

5 Transfer curves (characteristic printing curve) 137

5.1 General information............................... 137

5.2 Creating a transfer curve....................... 138

5.3 Editing a transfer curve.......................... 140

5.4 Copying transfer graphs........................ 140

5.5 Deleting a transfer graph....................... 141

6 Calculating area coverage values and ink

consumption for paper only............................ 141

6.1 Activating the function............................ 142

7 Log files.......................................................... 144

8 DTV service................................................... 144

9 Opening the log file with the DTV Debug

Viewer............................................................ 144

9.1 Procedure.............................................. 144

Starting and terminating Prinect Prepress

Interface........................................................... 145

1 Starting Prinect Prepress Interface................ 145

1.1 Starting automatically............................ 145

1.2 Starting manually................................... 145

2 Exiting Prinect Prepress Interface.................. 145

The Heidelberg user interface............................. 147

1 The Heidelberg user interface........................ 147

1.1 The user interface concept.................... 147

1.2 Arrangement of the user interface......... 147

1.3 The menu bar........................................ 149

1.4 The tool bar............................................ 149

1.5 The dynamic window............................. 151

1.5.1 Adjusting the window size.......... 151

1.5.2 Context menu............................. 152

1.5.3 Buttons in the dynamic window. . 153

VIII , Prinect Prepress Interface 2011, Operating manual

Overall chapter overview

1.6 The dynamic status panel...................... 153

2 Control elements............................................ 154

2.1 Folder..................................................... 154

2.2 Status displays....................................... 154

2.3 Your choice............................................ 157

2.4 Detailed sections................................... 157

2.5 Choice.................................................... 157

2.6 Input fields............................................. 157

2.7 Add/Delete............................................. 158

2.8 Help....................................................... 158

2.8.1 Hyperlinks................................... 159

2.8.2 Table of contents/full text search 159

2.8.3 Forward/backward...................... 159

2.8.4 Previous/Next............................. 160

2.8.5 Help menu.................................. 160

2.9 Key combinations.................................. 160

3 Table/tree structure and filter......................... 161

3.1 General information............................... 161

3.2 Table view.............................................. 162

3.3 Tree structure........................................ 162

3.4 Switching between the table view and

tree structure.......................................... 163

3.5 The Adjust table configuration symbol... 164

3.6 How do I create my personal table

configuration?........................................ 164

3.6.1 What to consider before creating

a table configuration................... 164

3.6.2 Creating a new table

configuration............................... 165

3.7 Selecting the table configuration............ 171

3.8 Delete Column Set................................. 171

3.9 Changing the sequence of the columns 172

3.10 Changing the width of the columns........ 174

3.11 Filter function......................................... 174

, Prinect Prepress Interface 2011, Operating manual IX

Overall chapter overview

3.11.1 prefiltering on the Prinect

Prepress Interface server;.......... 175

3.11.2 Filter options on a Prinect

Prepress Interface Cockpit......... 179

3.11.3 Filter not set................................ 180

3.11.4 Filter set...................................... 180

3.11.5 Filter job from the queue/sheet

list............................................... 180

Working with jobs................................................ 185

1 Working with jobs........................................... 185

1.1 General information............................... 185

1.2 Brief description of the Jobs menu........ 185

1.3 How do I open a job?............................. 187

1.4 Functions with a "closed" sheet/job....... 187

1.4.1 How can I process a new job/

sheet again?............................... 187

1.4.2 How can I delete the output files? 188

1.4.3 How can I delete the job list?...... 188

1.4.4 How can I combine sheets/jobs? 188

1.4.5 How can I save a job on the Job

Memory Card?............................ 188

1.4.6 How can I define a special color

for a sheet?................................. 188

1.4.7 How can I print out the job data? 188

1.5 Functions with an opened sheet/job...... 189

1.5.1 The color separation section...... 192

1.5.2 Show geometry........................... 194

1.5.3 Zoom function............................. 196

1.6 Processing straight printing and

perfecting jobs and "pure" perfecting

jobs an a press without perfector........... 197

1.7 The Details tab....................................... 199

1.7.1 Overview..................................... 199

1.8 The Queue tab....................................... 200

X , Prinect Prepress Interface 2011, Operating manual

Overall chapter overview

1.8.1 Overview..................................... 200

1.9 The Messages tab................................. 200

1.9.1 Overview..................................... 200

1.10 Process monitoring (Status tab)............ 201

1.10.1 Process monitoring..................... 201

1.11 The Waiting queue menu....................... 203

1.11.1 Overview..................................... 203

2 Deletion rules................................................. 204

2.1 Deleting the output files......................... 205

2.1.1 How are the output files deleted? 205

2.1.2 Are the output files of other

presses also deleted?................. 206

2.1.3 How can I recognize that an

output file has been deleted?..... 208

2.2 Deleting the jobs/sheets from the job list/

sheet list................................................. 209

Working with special colors................................. 211

1 Working with special colors............................ 211

1.1 Local special colors............................... 211

1.1.1 Example...................................... 211

1.2 Special colors in the MDS (color table in

the Master Data Store).......................... 212

1.3 Define special color............................... 213

1.4 Is the defined special color transferred

into the Master Data Store?................... 218

Working with the combiner.................................. 219

1 Working with the combiner............................. 219

1.1 General information............................... 219

1.2 What do I need to be aware of when

combining?............................................ 219

1.3 Which cases of use can be realized

manually/automatically?........................ 220

1.4 How do I go to the combiner?................ 221

, Prinect Prepress Interface 2011, Operating manual XI

Overall chapter overview

1.5 Explanation of the combiner user

interface................................................. 222

1.6 General approach for manual

combination........................................... 223

1.6.1 What do you need to be aware of

when saving a newly combined

sheet?......................................... 223

1.7 Combine n-separations to one sheet..... 224

1.8 Combining two separate sheets (front/

reverse) to one sheet............................. 231

1.9 Combine two front sides to one sheet

with front and reverse sides................... 237

1.10 Swapping separations of a sheet from

the front side <-> reverse side............... 243

1.11 Separating sheets with front and reverse

sides to two sheets with only front sides 250

1.12 Adding an individual varnish separation

to a sheet later on.................................. 258

1.13 Semiautomatic combination of sheets... 264

1.13.1 Example "Combining separated

front and reverse side"............... 264

Working with the Job Memory Card/USB memory 269

1 Flashcard....................................................... 269

1.1 Function................................................. 269

1.2 Supported formats................................. 269

1.3 Comparison of the D1 and D2 formats. . 269

1.4 How do I activate the Job Memory Card

drive?..................................................... 270

1.5 How do I open the "Job Memory Card

drive" dialog window?............................ 270

1.6 Brief description of the "Jobs on Job

Memory Card" dialog window................ 271

1.6.1 The "Jobs on Job Memory Card"

section........................................ 272

XII , Prinect Prepress Interface 2011, Operating manual

Overall chapter overview

1.7 Configuration of the Job Memory Card

output..................................................... 274

1.7.1 Manual printing unit/color

allocation (color code allocation

on CPC 1-02/03)......................... 274

1.7.2 CPC 1-02/03 settings................. 278

1.7.3 Setting the date format............... 281

1.8 How do I work with the Job Memory

Card?..................................................... 282

1.8.1 Saving data to the Job Memory

Card............................................ 282

1.8.2 Saving several sheets on the Job

Memory Card.............................. 285

1.8.3 How do I move jobs from one

position to another?.................... 286

1.8.4 How do I delete the jobs of a

position on the Job Memory

Card?.......................................... 288

1.8.5 How can I format the Job Memory

Card?.......................................... 289

1.8.6 Checking the contents and the

available disk space................... 291

1.8.7 Copying jobs onto a USB storage

medium....................................... 291

2 USB storage medium..................................... 293

2.1 Function................................................. 293

2.2 How do I configure (activate) the USB

storage medium?................................... 293

2.2.1 Carrying out the configuration.... 293

2.3 Which data is saved?............................. 296

2.4 How do I work with the USB storage

medium?................................................ 297

2.4.1 Saving data on the USB storage

medium....................................... 297

, Prinect Prepress Interface 2011, Operating manual XIII

Overall chapter overview

2.4.2 Saving several sheets at the

same time on the USB storage

medium....................................... 301

2.4.3 Copying jobs onto the Job

Memory Card.............................. 302

2.4.4 Deleting jobs............................... 304

Backup and Restore........................................... 307

1 Backup and Restore...................................... 307

1.1 General information............................... 307

1.2 How can I carry out a "Backup" or

"Restore"?.............................................. 307

1.3 Performing a backup.............................. 307

1.4 Performing a restore.............................. 308

PPI importer........................................................ 311

1 Importer.......................................................... 311

1.1 Note....................................................... 311

1.2 Previous versions supported................. 311

1.3 There are 2 sources for the import:....... 311

1.4 Procedure.............................................. 311

1.5 Starting the importer.............................. 312

1.6 Assigning import files............................. 312

2 Importing the configuration............................ 313

2.1 General information............................... 313

2.2 Description of the individual process

attributes................................................ 315

2.2.1 Name.......................................... 315

2.2.2 Description.................................. 316

2.2.3 PPF directory.............................. 316

2.2.4 File extension............................. 316

2.2.5 FileStableTime............................ 316

2.2.6 Printing press.............................. 316

2.2.7 Printing press configuration........ 317

2.3 Defining and transferring the devices.... 318

XIV , Prinect Prepress Interface 2011, Operating manual

Overall chapter overview

2.4 Description of the individual device

attributes:............................................... 319

2.4.1 Name.......................................... 319

2.4.2 Description.................................. 320

2.4.3 Path............................................ 320

2.4.4 Maximum number of files........... 321

2.4.5 Maximum size............................. 321

2.4.6 Maximum age............................. 321

2.4.7 Overwrite output file.................... 321

2.4.8 Defining the process................... 321

2.5 Automatically transferred process

attributes................................................ 322

2.5.1 Transfer graph............................ 322

2.5.2 Attribution rules........................... 323

2.5.3 The remaining geometry data..... 323

2.6 Transferring customer-specific press

configurations........................................ 324

2.7 Transferring processes without

terminals/devices................................... 326

2.8 Transferring devices which are

connected via the CDK interface........... 329

2.9 Overview of the imported processes..... 332

3 Transferring the inking unit settings to the

press.............................................................. 332

3.1 Transferring the inking unit settings to

the press................................................ 332

4 Providing import files...................................... 335

4.1 The PPI 3.* database............................. 335

4.2 The PPI 3.* registry entries.................... 336

4.2.1 For versions 3.2 and 3.3............. 336

4.2.2 For old versions < 3.2................. 337

Connecting sheetfed presses from other

manufacturers.................................................. 341

, Prinect Prepress Interface 2011, Operating manual XV

Overall chapter overview

1 Connecting sheetfed offset presses from

other manufacturers....................................... 341

1.1 General information............................... 341

1.2 Function................................................. 341

1.3 Prerequisites.......................................... 341

1.4 Overview of the configuration................ 342

2 Defining a new device.................................... 343

2.1 Defining a new device............................ 343

3 Sets of characteristic curves.......................... 349

3.1 Overview................................................ 349

3.2 General information on sets of

characteristic curves.............................. 349

3.3 Defining a new set of characteristic

curves.................................................... 351

3.4 Defining a new characteristic curve for a

special color........................................... 352

3.5 Modifying a characteristic curve............ 354

3.6 Assigning a new set of characteristic

curves to an existing device................... 356

4 Offline connection.......................................... 358

4.1 Prerequisites.......................................... 358

4.2 Copying sheets to a floppy disk............. 358

Web presses....................................................... 361

1 Connection of web presses............................ 361

XVI , Prinect Prepress Interface 2011, Operating manual

Before you start

1 About this documentation

start

you

Before

1.1 General information

This documentation is valid for the Prinect Prepress

Interface 2010. This manual contains all the

information you require to operate the Prinect Prepress

Interface.

Note

Please note that the printed documentation may differ

in its content from the online documentation (PDF,

online help), since for printing-related reasons it is not

always possible to include the most current changes

in the printed manuals. The online documentation

always contains the most up-to-date information.

1.2 What you should already know

We require that you are familiar with the basic functions

of Windows 2000®/Windows Server 2003®/Windows

XP® and Windows Vista®.

We also assume that you have experience in

connecting PCs and other hardware components and

integrating them in networks.

1.3 Other documentation

You can find more information in the following

documentation:

• Heidelberg Prinect Licensing - operation

1.4 Links and conventions in the documentation

The following conventions are used in this manual:

, Prinect Prepress Interface 2011, Operating manual 1

Before you start

• References to other chapters and sections appear

blue (on the screen) and are underlined.

Example: See section "Links and conventions in the

documentation (Page 1)"

• Menus, folders, functions, hardware descriptions,

switch positions, system messages are displayed

in bold.

Example: Turn the switch to Off.

• Menus, functions and sub-functions are separated

by ">".

Example: Select File > Open.

• Keys and buttons are displayed in italics.

• Buttons which you should hold down

simultaneously are connected with a plus

character.

Example: Press Alt+A.

1.5 Important text sections

Important sections of text are accompanied by

symbols at the edge of the page. The symbols are used

as follows:

Warning - Warning text...

Contains information that must be observed to protect

the operator from potential hazards or damage.

Caution - Text...

Contains information that must be observed to prevent

damage to hardware or software.

2 , Prinect Prepress Interface 2011, Operating manual

Before you start

Note

Contains important general or additional information

on a specific topic.

Prerequisite: Lists prerequisites that must be met to

allow the following steps to be performed.

2 Heidelberg online

(1.) Do you have questions about our products?

(2.) Do you want to improve your workflows?

(3.) Then pay us a visit on the internet. You can find us

at:

Homepage of Heidelberger Druckmaschinen AG

, Prinect Prepress Interface 2011, Operating manual 3

Before you start

4 , Prinect Prepress Interface 2011, Operating manual

Introduction

1 Prinect Prepress Interface

Introduction

Prinect Prepress Interface is the digital interface

between prepress, press and postpress.

The printing presses from Heidelberg are directly

linked to Prepress workflow systems via Prinect

Prepress Interface. It considerably simplifies ink and

register presettings for Speedmaster printing presses

equipped with CPC 102/03, CPC 104, Prinect CP2000

Center, Prinect Print Center and Prinect Press Center.

In addition MiniSpots and color strip information can be

provided for Prinect Image Control and position marks

can be made available to postpress systems. Data

exchange takes place in PPF format.

The Print Production Format (PPF) is a standardized

interface. It enables the exchange of production or

presetting data between the digital prepress, press and

postpress, regardless of manufacturer and press. The

Print Production Format was defined by the

international consortium "The International

Cooperation for the Integration of Processes in

Prepress, Press and Postpress" (CIPPPP => CIP4)

(www.cip4.org).

2 What is the task of Prinect Prepress Interface?

2.1 Ink zone presetting on the printing press

Based on the CIP4-PPF standard, the correct

presetting of ink zones is calculated using the digital

data from the imposition station and RIP and then

transferred to the printing press. This ensures that the

exact amount of ink that is needed on the print sheet

is made available in the respective ink zones. With

Prinect Prepress Interface it is also possible to provide

, Prinect Prepress Interface 2011, Operating manual 5

Introduction

the printing press with parameters such as paper

category, ink type and L*a*b* values. Special colors

are displayed true-to-color on the Prinect CP2000

Center, Prinect Print Center and Prinect Press Center

and characteristic curves are selected automatically.

2.2 Connection to Prinect Image Control

The integration of Prinect Image Control - the high-end

color measuring system - into the workflow adds

additional process reliability. The digital data from

prepress is read by the Prinect Prepress Interface and

transmitted to Prinect Image Control (MiniSpot and

color strip information).

2.3 Position information for Prinect Auto Register

If the digital prepress data also includes information for

Prinect Auto Register, this is received by Prinect

Prepress Interface and made available online to

printing presses with Prinect CP2000 Center / Prinect

Press Center. Prinect Auto Register will then

automatically set the ink zones in which the register

marks have been positioned, thus ensuring more

reliability during makeready. The online transmission

of position data takes place via the Prinect CP2000

Center module Preset Link or Prinect Instant Gate (as

of V.44 and Prinect Press Center).

2.4 Position marks for postpress

In addition to the interface to the printing press, Prinect

Prepress Interface is also able to transfer the position

marks for postpress processes, such as for folding and

cutting systems. A prerequisite here is that the relevant

information has been included in the PPF file in the

digital prepress area.

6 , Prinect Prepress Interface 2011, Operating manual

Introduction

3 What are the functions of Prinect Prepress Interface?

The following functions are realized in the Prinect

Prepress Interface:

• Automatic conversion of PPF data from an area

coverage of the entire sheet into the

percentagewise area coverage per ink zone

• Representation of the calculated area coverage

values for a selected print sheet

• Representation of ink consumption for a selected

print sheet

• Color representation of the complete sheet and

area coverage values per ink fountain zone in per

cent. For straight printing and perfecting jobs, the

front and reverse side of the sheet can be

displayed.

• Tabular presentation of area coverage values of the

ink fountain zones in percent with printout option.

• Option to switch from sheet view to job view

• Option for changing the job or sheet designation

• Automatic allocation of the job to the respective

printing press format.

• Accepting and processing transformations.

• Accepting and processing transfer curves.

• Editable transfer characteristic curves for the

process area "Copy to Plate".

• Adjustable printing press parameters.

• Option for adapting print jobs (Combiner function)

• For example combining, assigning color

separations for perfecting jobs.

, Prinect Prepress Interface 2011, Operating manual 7

Introduction

• Individual separations can be displayed in black

and white. The separations are displayed in the

corresponding color.

• Option for defining special colors.

• Automatic transfer of area coverage values to the

printing press.

• When using Prinect Online Kit for CPTronic/

CPC 1-04 presses, Classic Center presses or

Printmaster presses.

• When using Prinect CP2000 Center / Prinect

Press Center with the optional software module

"CP2000 Preset Link" or Prinect Instant Gate

(as of V.44 and Prinect Press Center).

• Automatic transfer to postpress systems.

• Each output device can provide process-

dependent data in the form of a PPF+ file via an

interface protocol. This means that the various

processing stages only receive data which is

relevant for the particular process. For example,

the PPF+ file which is forwarded to the

Compucut software of PolarMohr only contains

cutting data.

• For the new printing presses with Press Center,

the data is saved in an expanded format.

4 Basic concept

4.1 Server-client architecture

Prinect Prepress Interface is a "multiple" client/server

and a "multiple" user application. The Prinect Prepress

Interface server is installed as a Windows service and

thus runs permanently. The actual calculation

8 , Prinect Prepress Interface 2011, Operating manual

Introduction

processes and data management take place on this

server.

PT.000.0016-000GRAENU_01

Fig. 1

The Prepress Interface Cockpit works as a "client" in

the system environment. A basic installation of the

Prepress Interface Cockpit is installed on the server by

default. You can also install and use the Prepress

Interface Cockpit software on one or more other

computers.

The number of users who can operate a Prepress

Interface Cockpit application at any given time

depends on the number of Prepress Interface Cockpit

licenses available.

Thanks to this architecture several users can access

the same data (on the server) at the same time. Thus

it is possible to connect several job memory card

drives.

, Prinect Prepress Interface 2011, Operating manual 9

Introduction

4.1.1 Prepress Interface Cockpit as a client

The Prepress Interface Cockpit is the "switching point"

for managing and controlling the processing of jobs. As

it does not always make sense to control the Prinect

Prepress Interface just from a central location, i.e. the

Prinect Prepress Interface "server", the Prepress

Interface Cockpit has been designed as a "Java client"

software.

You can therefore install the Prinect Prepress Interface

server in a server room, while the system is controlled

and managed from a workstation. All that needs to be

done to use this setup is to install the Prepress

Interface Cockpit software on a workstation computer.

The Prepress Interface Cockpit user interface offers

you direct access to all resources and jobs managed

there as well as access to the local file system (not to

the entire file system) of the server. This means that

the display of data and all operator actions (editing

data, using the job memory card) take place on the

Prepress Interface Cockpit.

4.1.2 Prinect License Server

The "Heidelberg Prinect Licensing" software is used

for managing licenses. It comprises the following

modules:

• Prinect License Server

• Prinect License Manager

The Prinect License Server has the task of managing

all product licenses on a central server (computer). The

Prinect License Server can be installed on the Prinect

Prepress Interface server, or an already existing

Prinect License Server (for example from Prinect

Signa Station) can be used.

10 , Prinect Prepress Interface 2011, Operating manual

Introduction

The possible products no longer have a dedicated

product dongle each, but rather send a license request

to the Prinect License Server, which is secured with a

single dongle. The licenses are implemented by a

dongle (hardware) and a license option file (software).

4.2 Supported languages

The user interface supports the following languages:

• German

• English

• Spanish

• French

• Korean

• Japanese (Kanji)

• Italian

• Chinese

A change of the language setting during runtime is not

possible. Therefore you need to restart the Prinect

Prepress Interface Cockpit when you have changed

the language.

5 Components

5.1 Prinect Prepress Interface

The Prinect Prepress Interface consists of two parts:

The desktop tools such as the Prepress Interface

Cockpits with which you can control and process jobs

interactively, and a service (Tomcat service) which

runs on the server.

, Prinect Prepress Interface 2011, Operating manual 11

Introduction

5.2 Prepress Interface Cockpit

With the Prepress Interface Cockpit you can check

your jobs and manage your configuration and master

data. You can edit jobs and can manually save jobs on

the Job Memory Card . You can install your Prepress

Interface Cockpit applications on many workstations

since the licenses are not computer-dependent

(floating).

5.3 Services

The Prinect Prepress Interface server is implemented

as a "Windows service" ("Tomcat service") and thus

"runs" permanently in the background.

"Windows services" are applications that can be

started and terminated under Windows without

needing their own user interface. You can control the

services under the Windows computer management.

The "Tomcat service" contains the following services:

• MDS (master data service)

• PPI service

• Event service

The "Tomcat service" transfers the incoming PPF files

into the PPF job model and saves the data in a

database. Depending on the configuration, expanded

PPF files will then be provided to the defined devices

in an output directory. These functions are carried out

by the "Tomcat service" without any operator action.

Thus Prinect Prepress Interface can "run" in the

background.

12 , Prinect Prepress Interface 2011, Operating manual

Introduction

5.4 File formats

Prepress generates data in the Print Production

Format (PPF) defined by the CIP4 group

(www.cip4.org). This PPF file is imported into the

Prinect Prepress Interface via a PPF import interface.

After processing, a device-specific file is generated

and forwarded to the postpress equipment via an

export interface.

5.5 Master data store

The master data memory enables the central

management of information (so-called master data

and configuration data) which can by used by several

Prinect products. The following master data is

available in Prinect Prepress Interface after the

installation:

• Printing press catalog

• Color tables

You can find further information in the "Administration

> Master Data Store (Page 65)" chapter.

, Prinect Prepress Interface 2011, Operating manual 13

Introduction

14 , Prinect Prepress Interface 2011, Operating manual

Hardware and software requirements

1 System requirements and limits

requirements

software

and

Hardware

1.1 Prinect Prepress Interface Server

The computer must fulfill the following requirements for

the installation of the Prinect Prepress Interface server

(incl. license server):

Hardware and software Minimum requirement Recommendations

Processor Desktop CPU, for Dual CPU, Intel Pentium

example Intel Pentium IV IV >= 2.4 GHz Xeon

>= 2.8 GHz, CPU, Hyper threading

Hyperthreading enabled enabled

Main memory 1 GB GB RAM (for Microsoft

Windows Vista)

Hard disk 40 GB or more 80 GB

Network board 100 Mbit/s Ethernet, See minimum

(depending on the requirements

network in place either:

• Coax/BNC

• Twisted Pair

Graphics board Minimum 1280x1024, 16 Commercial standard,

Bit color depth 1280x1024 or higher

Monitor 17’’, min. resolution 19’’ or larger, Min.

1280x1024 pixels resolution 1280 x 1024

pixels

Interfaces One USB interface for See minimum

connecting the USB requirements

dongle SCSI controller

for the backup drive (e.g.

Adaptec 29160N or

equivalent)

, Prinect Prepress Interface 2011, Operating manual 15

Hardware and software requirements

Hardware and software Minimum requirement Recommendations

DVD ROM drive DVD read speed 16x or See minimum

faster requirements

Operating system • Microsoft Windows • Microsoft Windows

Server 2003 SP2 Server 2003 SP2

• Microsoft Windows Note: The following is not

Server 2003 R2 supported:

• Microsoft Windows Microsoft Windows Small

XP Professional Business Server 2003

• Microsoft Windows

Vista Business or

Ultimate (requires a

minimum main

memory of 1 GB)

• Microsoft Windows 7

(requires a minimum

main memory of 1 GB)

Note: The following is not

supported:

Microsoft Windows Small

Business Server 2003

Virus scanner Only the default See minimum

Heidelberg virus scanner requirements

McAfee 8 has been

tested (see also the

following section

"Comments on the virus

scanner").

Tab. b. 1

16 , Prinect Prepress Interface 2011, Operating manual

Hardware and software requirements

1.1.1 Comments on the virus scanner

All information relating to the virus scanner is

described below.

Maximum virus protection versus optimum system

performance

Using virus protection software with "on access" virus

protection (checks for computer viruses when writing

and/or reading files and directories) can reduce the

processing speed and interaction behavior of software

applications more or less significantly on every

computer.

This also applies to Heidelberg applications such as

Prinect Prepress Interface.

To prevent a reduction in performance through "on

access" virus scans you can remove certain file types

or directories from the "on access" virus scan, if the

virus software supports it. However, you must be

aware that this causes a higher risk of the computer

possibly becoming infected with computer viruses. If

you decide to use this approach, it is important that you

limit this risk by setting up a daily automatic virus scan

of all local volumes of the computer concerned,

including all file types and directories. Only the

customer can make the decision for greater system

performance while accepting a security risk!

Which file types and/or directories may lead to a

reduction in throughput with "on-access" virus scans?

• File types (extensions)

Jar, xml, jdf, pdf and file type definitions which

contain these file types (for example pdf).

, Prinect Prepress Interface 2011, Operating manual 17

Hardware and software requirements

1.2 Prinect Prepress Interface Client (Cockpit)

The following requirements apply to the computers for

the separate installation of the Prepress Interface

Client (with Job Memory Card drive if necessary) on

one or more computers:

Hardware and software Minimum requirement Recommendations

Processor Desktop CPU, for Desktop CPU, for

example Intel Pentium IV example Intel Pentium IV

>= 2.4 GHz >= 2.8 GHz

Main memory 500 MB RAM 1 GB (for Microsoft

Hard disk 40 GB 80 GB

Network board 100 Mbit/s Ethernet, 1GBit/s network

(depending on the recommended

network in place either:

• Coax/BNC

• Twisted Pair

Graphics board Minimum 1280x1024, 16 Commercial standard,

Bit color depth 1280x1024 or higher

Monitor 17’’, min. resolution 19’’ or larger, Min.

1280x1024 pixels resolution 1280 x 1024

pixels

Interfaces One USB interface for See minimum

connecting the external requirements

Job Memory Card drive

or the USB storage

medium

DVD ROM drive DVD read speed 16x or See minimum

faster requirements

Operating system • Microsoft Windows • Microsoft Windows

Server 2003 SP2 XP Professional

18 , Prinect Prepress Interface 2011, Operating manual

Hardware and software requirements

Hardware and software Minimum requirement Recommendations

• Microsoft Windows • Microsoft Windows

XP Professional Vista (requires a

minimum main

• Microsoft Windows

memory of 1 GB)

Vista (requires a

minimum main

memory of 1 GB)

• Microsoft Windows 7

(requires a minimum

main memory of 1 GB)

Virus scanner Only the default See minimum

Heidelberg virus scanner requirements

McAfee 8 has been

tested (see also the

previous section

"Comments on the virus

scanner").

Tab. 2

We recommend that common market standards are

applied.

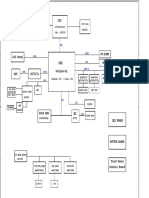

1.3 Operating system variants

Prinect Prepress Interface can be efficiently operated

on various operating systems. The illustration below

shows the operating systems used for server and

client.

, Prinect Prepress Interface 2011, Operating manual 19

Hardware and software requirements

PT.000.2407-000GRAUND_00

Fig. 1

2 System limits

2.1 Jobs

The following table lists the currently applicable system

limits.

Function Number

Maximum quantity of 25000

saved jobs

Tab. 3

3 Prinect Press Center with "Wallscreen"

Prinect Prepress Interface 4.5 cannot be installed on

the control station computer.

Thus there are two options:

20 , Prinect Prepress Interface 2011, Operating manual

Hardware and software requirements

• To start the Prinect Prepress Interface Client on

another computer via a remote desktop connection.

However, a remote desktop connection is only

possible with the Microsoft Windows Server 2003

operating system.

• To install a Prinect Prepress Interface Client on a

computer with the Microsoft Windows XP or Vista

operating system. The remote desktop connection

can then be started on this computer. In this case,

however, only the remote desktop connection can

"run" on this computer.

3.1 Note on thumbnail images

In order to view the individual color separations on the

Wallscreen of the Prinect Press Center, the data

volume from Prinect Prepress Interface to the Prinect

Press Center has been extended.

The separation files are saved in a shared directory in

"PNG" format. The Wallscreen must be able to access

this directory.

4 Backup device

Tape drives of the following types are best suited for

data backups:

• DLT

• For example, a DLT80 from HP: C5725A

• SDLT

• For example an SDLT 160/320GB SCSI from

HP

, Prinect Prepress Interface 2011, Operating manual 21

Hardware and software requirements

DAT tape drives are also suitable. They cost a lot less,

however, their data throughput is much slower. This

means that backups will take much longer.

For the backup itself, the backup software of the

operating system is used.

The backup hardware used should not be a device

integrated in the file system of the Prinect Prepress

Interface Server and which can be written on by it. For

example:

• all external hard disks

• DVD burner (not supported)

• Due to the low reliability of the media (DVD-RW)

and its limited capacity at present.

5 Facts relevant for trouble-free communication in a

networked system environment

5.1 Notes

• The following information is intended for system

administrators and is less relevant to Prinect

Prepress Interface users.

• We assume that the reader of this document is

familiar with managing Windows 2000/2003

systems (and, if applicable, also with UNIX systems

and Samba software).

5.2 System environment

Prinect Prepress Interface server and Prinect Prepress

Interface clients can be operated both in Windows

workgroups and in Windows domains. They can also

22 , Prinect Prepress Interface 2011, Operating manual

Hardware and software requirements

be linked to other computers in a networked system

environment.

Please ensure that all Windows computers involved in

the Prinect Prepress Interface workflow (Prinect

Prepress Interface server and client stations) are in

either

• a Windows workgroup

or

• a Windows domain.

Try and avoid a mixed system with both domains and

workgroups.

5.3 Server access to network drives

The processes on the Prinect Prepress Interface

server run with the permissions of a Windows user set

up during the installation. To ensure trouble-free

access to resources in a networked system

environment it is necessary to set up this user:

• As a domain user if the Prinect Prepress Interface

computers are in a Windows domain. Please be

aware that this user must have local Administrator

permissions (local group of Administrators).

• As a local user on all computers which are

accessed by the Prinect Prepress Interface

processes if the Prinect Prepress Interface

computers are in a Windows workgroup.

5.4 Browsing the network

Note

Please note the following limitations:

, Prinect Prepress Interface 2011, Operating manual 23

Hardware and software requirements

• Prinect Prepress Interface can only display names

of shared directories with no more than 12

characters.

• Shared directories whose name is longer than 12

characters are not listed.

24 , Prinect Prepress Interface 2011, Operating manual

Installation

1 Installation

Installation

1.1 Overview

This chapter contains a step-by-step instruction of how

to install the Prinect Prepress Interface software

modules and how to connect the Job Memory Card

drive.

Note

For the operation of Prinect Prepress Interface we

highly recommend that you set up at least two

partitions:

• System partition C:\

• File partition D:\

1.2 Delivered parts

The scope of delivery of Prinect Prepress Interface

depends on the "Media Kit" ordered.

1.3 Installation requirements

The prerequisites for the installation are computers

(servers and, if applicable, clients) which fulfill the

requirements described in the chapter "Hardware and

software requirements (Page 15)". Read the

requirements carefully before starting the installation

process.

1.3.1 Necessary rights

Note

For the installation you need to be logged on as a user

with administrator permissions.

, Prinect Prepress Interface 2011, Operating manual 25

Installation

1.4 Installation process

Perform the installation steps in the following

sequence:

• Check the scope of delivery

• Apply for the license key

• Verify the installation requirements

• Switch on the computer and log on

• Install the Prinect Prepress Interface Server (a

Prepress Interface Cockpit is always installed with

it)

• Restart the computer

• License Prinect Prepress Interface via the

Heidelberg Prinect License Manager.

• If necessary: Install the Prepress Interface Cockpit

on one or more clients.

• If necessary: Install the USB driver for the Job

Memory Card drive on one or more clients

(Prepress Interface Cockpits).

1.5 Server installation

1.5.1 General information

Together with the Prinect Prepress Interface server a

Prepress Interface Cockpit is also installed as

standard. You simply need to perform licensing as

described in and you can then work at this workstation

with the Prinect Prepress Interface.

If you also want to work with Prinect Prepress Interface

from other workstations you need to install Prepress

26 , Prinect Prepress Interface 2011, Operating manual

Installation

Interface Cockpit at this workstation too (see "Client

installation (Page 43)")

1.5.2 Performing the server installation

1. Insert the installation DVD into the corresponding

drive.

• The installation starts automatically. If this does

not happen, check whether you have

deactivated the "Autorun" function. Otherwise

run the "PPIServerSetup.exe" file in the main

directory of the DVD.

• The installation program is started.

2. Click on Next.

• The window with the license terms appears.

3. Read the license terms carefully and then click on

Yes.

• You need to agree to the license terms to

proceed with the installation.

• The following window appears.

, Prinect Prepress Interface 2011, Operating manual 27

Installation

PT.000.0231-000GRAUND_01

Fig. 1

4. Activate the PPI Server option.

• With this option the server and a Prepress

Interface Cockpit application are installed and

all necessary directories are created.

5. Click on Next.

• The following window appears.

28 , Prinect Prepress Interface 2011, Operating manual

Installation

PT.000.0233-000GRAUND_00

Fig. 2

6. Here you should enter the directory in which you

wish to install the Prinect Prepress Interface client.

• We recommend using the default directory C:

\Program Files\Heidelberg\Prinect Prepress

Interface\.

• The Prinect Prepress Interface client is then

installed in the directory C:\Program Files

\Heidelberg\Prinect Prepress Interface

\PPIClient.

7. Click on Next.

• The following window appears.

, Prinect Prepress Interface 2011, Operating manual 29

Installation

PT.000.0234-000GRAUND_00

Fig. 3

• Starting the Prinect Prepress Interface "PPI

Service" requires a user account. The default user

name is:

• User: prinect

• Password: prinect

• The user "prinect" is defined in the local user

administration of the Windows operating system.

8. Activate the option Yes, I will create a new local

user account.

9. In the "User" input field enter the name "prinect".

10.In the "Password" input field enter the password

"prinect".

11.In the "Confirm Password" input field reenter the

password "prinect".

12.Click on Next.

• The following window appears.

30 , Prinect Prepress Interface 2011, Operating manual

Installation

PT.000.0238-000GRAUND_00

Fig. 4

Note

On the Prinect Prepress Interface server two

directories required for the work are always created.

They are the directories "PPIConfig" and "PPIJobs".

Both directories are automatically released in the

network. The directory "PPIConfig" contains all the

configuration files. "PPIJobs" contains all the job

structures.

13.Enter the directory for the configuration files

("PPIConfig").

• The default is always the directory C:

\PPIConfig.

• We recommend using the directory D:

\PPIConfig.

14.Click on Next.

• The following window appears.

, Prinect Prepress Interface 2011, Operating manual 31

Installation

PT.000.0239-000GRAUND_00

Fig. 5

15.Enter the share name for the configuration

directory.

As previously described, the configuration directory

"PPIConfig" is shared in the network. This means

you must enter a share name for it in the network.

The default name is "PPIConfig". We recommend

that you do not change this, as the documentation

refers to it in many places and this will make it easier

to understand the instructions.

16.Click on Next.

• The following window appears.

32 , Prinect Prepress Interface 2011, Operating manual

Installation

PT.000.0240-000GRAUND_00

Fig. 6

17.Enter the directory for the job files ("PPIJobs").

• The default is always the directory C:\PPIJobs.

• We recommend using the directory D:\PPIJobs.

18.Click on Next.

• The following window appears.

, Prinect Prepress Interface 2011, Operating manual 33

Installation

PT.000.0232-000GRAUND_00

Fig. 7

19.As previously described, the configuration directory

"PPIJobs" is shared in the network. This means you

must enter a share name for it in the network. The

default name is "PPIJobs". We recommend that you

do not change this, as the documentation refers to

it in many places and this will make it easier to

understand the instructions.

20.Click on Next.

21.Enter the name of the license server here. The

license server manages all product licenses at a

central point.

• You need to enter the computer's host name

here. Either the host name of the computer on

which you want to install the Prinect Prepress

Interface server or the host name of the already

existing license server.

22.Click on Next.

34 , Prinect Prepress Interface 2011, Operating manual

Installation

23.Check again whether you have entered the correct

paths/directories for the installation.

• If you select Back, you can move back in the

installation process to make changes.

24.Click on Next.

• The installation of the Prinect Prepress Interface

server and the Prepress Interface Cockpit

begins.

25.Click on Finish.

• The installation of the Prinect Prepress Interface

server and the Prepress Interface Cockpit has

been completed successfully.

• The PPI Cockpit icon is created on the desktop.

26.Restart the computer.

If you have used all the directories listed in the

installation instructions, the directory structure should

be identical to the one shown in the following

illustration.

, Prinect Prepress Interface 2011, Operating manual 35

Installation

PT.000.0237-000GRAUND_00

Fig. 8

1.6 Steps after the server installation

1. Log off Microsoft Windows and then log back on

again.

36 , Prinect Prepress Interface 2011, Operating manual

Installation

2. Plug the USB dongle supplied into a free USB

socket. Make sure you plug the dongle into the

computer which you defined as the license server.

3. License the Prinect Prepress Interface software via

the Prinect License Manager.

• Menu: Start > Programs >Heidelberg Prinect

Licensing > License Manager.

• You can find a detailed description in .

4. Now you can start the Prepress Interface Cockpit

application via the PPI Cockpit icon on the desktop.

1.7 Upgrading a server

1.7.1 General information

Together with the Prinect Prepress Interface server a

Prepress Interface Cockpit is also installed as

standard. If you have installed other workplaces

(clients), you also have to carry out the upgrade on

these workplaces. Otherwise, after starting the

Prepress Interface Cockpit on these workplaces, you

receive the message that the client version currently

installed does not match the server version.

1.7.2 Performing a server upgrade

1. Insert the installation DVD into the corresponding

drive.

• The upgrade installation starts automatically. If

this does not happen, check whether you have

deactivated the "Autorun" function. Otherwise

run the "PPIServerSetup.exe" file in the main

directory of the DVD.

, Prinect Prepress Interface 2011, Operating manual 37

Installation

• The installation program is started. After a short

time the following window appears.

PT.000.1369-000GRAUND_01

Fig. 9

2. Click on Next.

• The following window appears.

38 , Prinect Prepress Interface 2011, Operating manual

Installation

PT.000.1370-000GRAUND_01

Fig. 10

3. Here you should enter the directory in which you

wish to save the backup data.

4. Click on Next.

• The following window appears.

, Prinect Prepress Interface 2011, Operating manual 39

Installation

PT.000.1371-000GRAUND_01

Fig. 11

5. Enter the password for the "prinect" user here.

• When installing the Prinect Prepress Interface

you defined this user account with a password.

The default settings were:

User: prinect

Password: prinect

6. Click on Next.

• The following window appears.

40 , Prinect Prepress Interface 2011, Operating manual

Installation

PT.000.1372-000GRAUND_01

Fig. 12

7. Check again whether the data backup directory

was selected correctly.

8. Click on Next.

• The upgrade is started.

, Prinect Prepress Interface 2011, Operating manual 41

Installation

PT.000.1373-000GRAUND_01

Fig. 13

9. Wait until the upgrade has been completed and the

following window appears.

PT.000.1374-000GRAUND_01

Fig. 14

10.Click on Finish.

42 , Prinect Prepress Interface 2011, Operating manual

Installation

• The upgrade was carried out successfully.

Now perform the upgrade on all other workplaces

(clients).

1.8 Client installation

1.8.1 General information

To be able to work with the Prinect Prepress Interface,

you need the Prepress Interface Cockpit application on

the clients. With the help of Prepress Interface Cockpit,

users can process jobs on the Prinect Prepress

Interface server.

1.8.2 Performing the client installation

Note

You can always find the installation file for the Prinect

Prepress Interface Cockpit on the Prinect Prepress

Interface server in the directory D:\PPIConfig\PPI

Cockpit Installer. This is the directory that you defined

during the server installation ().

1. Go to the workstation where you wish to install the

Prepress Interface Cockpit.

2. Log in as a user.

• Remember, you need to have the necessary

permissions.

3. Open Microsoft Explorer.

4. Map the Server name\PPIConfig directory of the

Prinect Prepress Interface server.

• To do this, you need the computer name of the

Prinect Prepress Interface server. For example:

\\ServerPPI\PPIConfig

, Prinect Prepress Interface 2011, Operating manual 43

Installation

• The "PPIConfig" directory is always shared and

accessible on the Prinect Prepress Interface

server.

5. Open the "PPIConfig\PPI Cockpit Installer" folder.

PT.000.0236-000GRAUND_00

Fig. 15

6. Double-click on the "PPIClientSetup.exe" file.

• The client installation program is started.

7. Click on Next.

• The window with the license terms appears.

8. Read the license terms carefully and then click on

Yes.

• You need to agree to the license terms to

proceed with the installation.

• The following window appears.

44 , Prinect Prepress Interface 2011, Operating manual

Installation

PT.000.0235-000GRAUND_00

Fig. 16

9. Here you should enter the directory in which you

wish to install the Prinect Prepress Interface client.

• We recommend using the default directory C:

\Program Files\Heidelberg\Prinect Prepress

Interface\.

• The Prinect Prepress Interface client is then

installed in the directory C:\Program Files

\Heidelberg\Prinect Prepress Interface

\PPIClient.

10.Click on Next.

• The window with the directory structure

appears.

11.Click on Next.

• The Prepress Interface Cockpit is being

installed. After this the "Complete" dialog

window appears.

12.Click on Finish.

, Prinect Prepress Interface 2011, Operating manual 45

Installation

• The PPI Cockpit icon is created on the desktop.

1.9 Upgrading a client

1.9.1 General information

If you have performed an upgrade on the server, you

also have to carry out an upgrade on all other

workplaces (clients). Otherwise, after starting the

Prepress Interface Cockpit on these workplaces, you

receive the message that the client version currently

installed does not match the server version.

1.9.2 Performing a client upgrade

1. Firstly, uninstall the Prinect Prepress Interface

Cockpit on all workstations (clients).

2. Then install the client, as described in "Performing

the client installation (Page 43)"

Note

You can always find the installation file for the Prinect

Prepress Interface Cockpit upgrade on the Prinect

Prepress Interface server in the directory D:\PPIConfig

\PPI Cockpit Installer. This is the directory that you

defined during the server installation ().

46 , Prinect Prepress Interface 2011, Operating manual

Installation

1.10 Installing the Job Memory Card drive

1.10.1 Structure of the Job Memory Card drive

The Job Memory Card unit has the following

connections and control functions:

• USB port for connecting the Prepress Interface

Cockpit (to the Prinect Prepress Interface server or

to the clients)

• Eject button (for ejecting the Job Memory Card)

• Green signal lamp (lights up when the power supply

has been established via the USB port and the drive

is ready to operate)

• Red signal lamp (lights up when the device is

currently accessing the Job Memory Card for a read

or write process. The red signal lamp also lights up

briefly when you insert the Job Memory Card into

the drive).

Caution - When the red LED lights up

Never try to remove the Job Memory Card while the

red LED is lit up.

1.10.2 Installation process

• Close the Prepress Interface Cockpit application.

• Install the USB driver on the Prepress Interface

Cockpits (server/clients) on which you want to use

the Job Memory Card drive.

, Prinect Prepress Interface 2011, Operating manual 47

Installation

• Using the supplied connection cable (USB plug),

plug the Job Memory Card drive into a free USB

port on the respective Prepress Interface Cockpit.

• Start the Prinect Prepress Interface Cockpit and

insert the Job Memory Card.

1.10.3 Installing the USB driver

1. Go to the workstation where you want to use the

Job Memory Card drive.

2. Insert the installation DVD into the corresponding

DVD drive.

3. Open Microsoft Explorer and go to the directory

Service\Drivers\OmniDrive_USB on the DVD.

4. Double-click on the "Setup.exe" file.

• Confirm any "Security Warnings" that might pop

up with run.

• The "Setup" window appears.

5. Click on the Continue button.

• The window with the license terms appears.

6. Read the license terms carefully and then click on

Yes.

• You need to agree to the license terms to

proceed with the installation.

• A window appears advising you to read the

product information.

7. Activate the No option.

8. Click on the Continue button.

• In the next window that appears you are asked

to define the target folder.

48 , Prinect Prepress Interface 2011, Operating manual

Installation

• C:\Program Files\OmniDrive USB Pro is set by

default. This target folder must not be changed.

9. Click on Next.

• In the next window that appears you are asked

to select the program folder.

• "OmniDrive USB Pro" is set by default. The

name must not be altered.

10.Click on the Continue button.

• The USB driver is being installed. After the

installation, the "Setup complete" window

appears.

11.Click on the Finish button.

• The window is closed.

1.11 Connecting the Job Memory Card drive

1. Plug the USB plug of the supplied connection cable

into an unused USB port of the Prepress Interface

Cockpit.

• The power is supplied via the USB interface.

2. Plug the other plug of the supplied connection cable

into the socket on the back of the Job Memory Card

drive.

• The green signal lamp on the drive must light up.

3. Now start Prepress Interface Cockpit.

4. Insert the Job Memory Card into the drive.

• The Jobs menu now contains the dialog section

"Jobs on the Job Memory Card".

, Prinect Prepress Interface 2011, Operating manual 49

Installation

1.12 Setting up monitor workstations

1.12.1 Safety and health protection

When you set up a screen workplace you must duly

observe the requirements of the EEC Directive 90/270/

EWG, Directive on the Minimum Requirements with

Respect to Safety and Health Protection During Work

on Visual Display Units, and the individual national

implementations of this Directive.

50 , Prinect Prepress Interface 2011, Operating manual

Uninstalling

1 Uninstalling

Uninstalling

1.1 General information

Use the function for removing programs in the

Microsoft Windows Control Panel to uninstall the

Prinect Prepress Interface application.

Note

Close all open programs before the uninstallation.

1.2 The uninstallation process

1. Open the menu Start > Settings > Control Panel >

Software in the Windows Control Panel.

2. Select the software you want to remove.

• In the case of Prinect Prepress Interface Server,

the "Heidelberg Prinect PPI Service" program.

• In the case of Prinect Prepress Interface Cockpit

(Clients), the "Heidelberg Prinect Prepress

Interface Cockpit" program.

3. Highlight the entry and click on the Change/

Remove button.

• The window shown below appears.

, Prinect Prepress Interface 2011, Operating manual 51

Uninstalling

PT.000.0224-000GRAUND_00

Fig. 1

4. Activate the Remove option.

5. Click on Next.

• The uninstallation starts. The program including

all its components is deleted. While the program

is being uninstalled, you can follow the process

on a progress bar. The dialog window

"Complete" then appears.

6. Click on Finish.

• The dialog box is closed.

52 , Prinect Prepress Interface 2011, Operating manual

Licensing

1 General information

Licensing

The use of the Prinect Prepress Interface is controlled

by licenses. The licenses are managed centrally on a

server. The Heidelberg License Server is used to

manage the licenses. The licenses are implemented

by a dongle (hardware) and a license option file

(software).

As there is already a detailed description of

"Heidelberg Prinect Licensing", at this point we would

just like to describe how to license the product for the

first time and answer a few frequently asked questions.

This description should help you to license the Prinect

Pressroom Interface that has just been installed

quickly and easily.

1.1 Which basic licenses are available?

• Basic version "Prinect Prepress Interface 52"

• Basic version "Prinect Prepress Interface 75"

• Basic version "Prinect Prepress Interface 105"

• Basic version "Prinect Prepress Interface 145+"

1.2 Task of the license server

The license server has the task of managing all product

licenses on a central server (PC). The possible

products no longer have a dedicated product dongle

each, but rather send a license request to the license

server, which is secured with a single dongle.

1.3 Dongle