Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

30 CR Ni Mo 8

Caricato da

Amy Griffin0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

261 visualizzazioni2 pagineMp 30CrNiMo8

Titolo originale

30CrNiMo8

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMp 30CrNiMo8

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

261 visualizzazioni2 pagine30 CR Ni Mo 8

Caricato da

Amy GriffinMp 30CrNiMo8

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

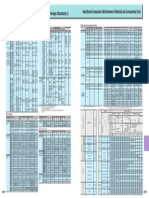

Quality 30CrNiMo8

According to standards EN 10083-3: 2006 Lucefin Group

Number 1.6580

Chemical composition

C% Si% Mn% P% S% Cr% Mo% Ni%

max max max

0,26-0,34 0,40 0,50-0,80 0,025 0,035 1,80-2,20 0,30-0,50 1,80-2,20 Permissible deviations

± 0.02 ± 0.03 ± 0.04 + 0.005 + 0.005 ± 0.05 ± 0.04 ± 0.07 on the product

Temperature °C

Hot forming Normalizing Quenching Quenching Tempering Stress relieving

1050-880 870-880 830-860 850 540-660 50 under the temperature

air oil or polymer water air of

tempering

Soft +AR natural End quench Preheating Stress relieving

annealing state hardenability test welding after welding

650-700 slowly 10 °C/h -- 850 300 550 furnace cooling

to 600 after air water AC1 AC3 MS Mf

(HB max 248) (HB max 370) 720 770 310 100

Mechanical and physical properties

Hot formed – hot rolled - rod mechan. properties for quenched and tempered condition EN 10083-3:2006

size d / t Testing at room temperature (longitudinal)

mm R Rp 0.2 A% C% Kv +20 °C HB

over to N/mm2 N/mm2 min. min. min. J min. for information

16/8 1250-1450 1050 9 40 -- 370-415

16/8 40/20 1250-1450 1050 9 40 30 370-415

40/20 100/60 1000-1300 900 10 45 35 298-380

100/60 160/100 1000-1200 800 11 50 45 298-359

160/100 250/160 900-1100 700 12 50 45 271-331

d = diameter t = thickness

Table of tempering values at room temperature for round Ø 10 mm after quenching at 850 °C in oil

HB 426 404 381 347 275 240

HRC 45 43 41 37 28 23

R N/mm2 1500 1400 1290 1150 920 800

Rp 0.2 N/mm2 1350 1250 1090 960 780 640

A % 10.0 10.0 11.0 14.0 16.0 18.0

C % 42 45 48 50 52 52

Kv J 20 50 60 75 80 92

Tempering at °C 450 500 550 600 650 700

Transition-curve LUCEFIN experience

Kv values obtained from hot-rolled round 32 mm

Quenched and tempered (induction) for R 1260 N/mm2

Rp 0.2 1110 N/mm2 – A% 11,8 – C% 59

average

°C J J Lat. Exp. mm Shear %

+20 58 – 72 - 68 66 0,62 50

0 53 – 46 - 49 49 0,42 40

-20 44 – 44 - 45 42 0,34 20

-40 31 – 32 - 35 33 0,27 10

-60 28 – 28 - 27 28 0,25 10

-80 28 – 26 - 26 27 0,16 10

E mod. of elasticity long. at +20 °C = 255700 N/mm2 G mod. of elasticità tang. at +20 °C = 98100 N/mm2

30CrNiMo8 Lucefin Group

Hot rolled quenched and tempered after Cold drawn +QT +C

size Testing at room temperature (longitudinal)

mm R Rp 0.2 A% HB

over to N/mm2 N/mm2 min min max

No indications are shown in the reference standards

Cold drawn Cold drawn Cold drawn annealing

size Testing at room temperature (longitudinal) size obtained from otherwise annealing +

mm R Rp 0.2 A% HB mm hot rolled Peeled Reeled

over to N/mm2 N/mm2 min min -- annealing HB max

No indications are shown in the reference standards

Forged quenched and tempered UNI EN 10250-3: 2001

size d / t Testing at room temperature

mm R Rp 0.2 A% L A% T A% Q Kv L Kv T Kv Q HB min.

over to N/mm2 N/mm2 min min min min J min J min J min for inform.

250/160 900 700 12 8 -- 45 22 -- 271

250/160 500/330 850 630 12 8 -- 45 22 -- 253

500/330 990/660 800 590 12 8 -- 40 20 -- 240

L = longitudinal T = tangential Q = radial

d = diameter t = thickness

EN 10083-3: 2006 Jominy test HRC grain size 5 min.

distance in mm from quenched end

1.5 3 5 7 9 11 13 15 20 25 30 35 40 45 50 -- symbol

min 48 48 48 48 47 47 47 46 46 45 45 44 44 43 43 -- H

max 56 56 56 56 55 55 55 55 55 54 54 54 54 54 54 --

min 51 51 51 51 50 50 50 49 49 48 48 47 47 47 47 -- HH

max 56 56 56 56 55 55 55 55 55 54 54 54 54 54 54 --

min 48 48 48 48 47 47 47 46 46 45 45 44 44 43 43 -- HL

max 53 53 53 53 52 52 52 52 52 51 51 51 51 50 50 --

Temperature Mod. of elasticity Thermal Specific heat Specific electric Thermal

E long. expansion capacity resistivity conductivity

Testing at °C N/mm2 [(m/m●K) ●10-6 °C-1 ] J/(Kg●K) Ohm●mm2/m W/(m●K)

-100 217000 10.5 423 -- --

0 213000 11.4 456 -- --

20 212000 11.5 461 0.309 33.7

100 207000 12.1 479 0.354 36.2

200 199000 12.7 499 0.418 37.8

300 192000 13.2 517 0.505 37.2

400 184000 13.6 536 0.609 35.7

500 175000 14.0 558 0.727 34.0

600 164000 14.4 587 0.867 32.0

Density +20 °C

Kg/dm3 DIN SEW 310 (08/1992) Physical properties

7.80

EUROPE EN ITALY UNI CHINA GERMANY DIN FRANCE AFNOR U.K. B.S. RUSSIA USA AISI/SAE

30CrNiMo8 30CrNiMo8 -- 30CrNiMo8 30NCD8 823M30 -- A320L43

Potrebbero piacerti anche

- Astm A537-A537m-95-2000Documento4 pagineAstm A537-A537m-95-2000NadhiraNessuna valutazione finora

- 42 CR Mo 4Documento2 pagine42 CR Mo 4niladriprasadrNessuna valutazione finora

- Cromax 42CrMo4Documento3 pagineCromax 42CrMo4ElMacheteDelHuesoNessuna valutazione finora

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocumento2 pagineSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Aisi 1008Documento2 pagineAisi 1008GANESH GNessuna valutazione finora

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocumento8 pagineWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNessuna valutazione finora

- Measuring Quench Time as a Process Control ToolDocumento4 pagineMeasuring Quench Time as a Process Control ToolCh PrasadNessuna valutazione finora

- Ansteel Product CatalogueDocumento13 pagineAnsteel Product Cataloguerashid isaarNessuna valutazione finora

- ASTM A633 GR E Data Sheet 2012 04 01Documento2 pagineASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- BOC Purging While Welding Brochure351 - 68116 PDFDocumento16 pagineBOC Purging While Welding Brochure351 - 68116 PDFAl0611981Nessuna valutazione finora

- 14H, 22H DetailsDocumento1 pagina14H, 22H DetailsmshNessuna valutazione finora

- S For Quenching D Tentpering-: SteelDocumento28 pagineS For Quenching D Tentpering-: SteelDidier LZNessuna valutazione finora

- Manufacturing procedure for recommended filler materials and preheat temperaturesDocumento5 pagineManufacturing procedure for recommended filler materials and preheat temperaturesMiguel Rodriguez100% (1)

- d10 6-d10 6mPVDocumento6 pagined10 6-d10 6mPVDhanush Nair0% (1)

- Ams4943l 2020Documento8 pagineAms4943l 2020BauyrzhanNessuna valutazione finora

- High-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessDocumento3 pagineHigh-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessMarcelo BarretosNessuna valutazione finora

- Copper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification ForDocumento8 pagineCopper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification Foralucard375Nessuna valutazione finora

- Hardness Conversion TableDocumento3 pagineHardness Conversion TableRavindra KirangeNessuna valutazione finora

- A493 00 PDFDocumento3 pagineA493 00 PDFJohano AraújoNessuna valutazione finora

- AluminizedDocumento4 pagineAluminizedmarkengineerNessuna valutazione finora

- X20Cr13, 1.4021, AISI 420 - Stainless Steel PDFDocumento7 pagineX20Cr13, 1.4021, AISI 420 - Stainless Steel PDFCBM Production100% (1)

- Cast Carbon Steels in AWS D1.1 PDFDocumento3 pagineCast Carbon Steels in AWS D1.1 PDFIndra NainggolanNessuna valutazione finora

- SAE-J995 Steel NutsDocumento9 pagineSAE-J995 Steel Nutsgaso99Nessuna valutazione finora

- Isothermal Heat Treatment PDFDocumento6 pagineIsothermal Heat Treatment PDFsmani170Nessuna valutazione finora

- ASTM A242 and A588 Steel Grade Comparison (39 charactersDocumento3 pagineASTM A242 and A588 Steel Grade Comparison (39 charactersIsaac ZTNessuna valutazione finora

- Tata Steel - YMPRESS S500MC - Data SheetDocumento2 pagineTata Steel - YMPRESS S500MC - Data SheetpnagarajjNessuna valutazione finora

- Domex 100 XF hot rolled steel data sheetDocumento2 pagineDomex 100 XF hot rolled steel data sheetzubblwump5063Nessuna valutazione finora

- ASTM A 514 - A 514-00. Standard Specification For High-YieldDocumento3 pagineASTM A 514 - A 514-00. Standard Specification For High-YieldHo Le QuangNessuna valutazione finora

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocumento4 pagineSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuNessuna valutazione finora

- B729Documento3 pagineB729LambertWayneNessuna valutazione finora

- Astm A106 1999Documento13 pagineAstm A106 1999Rolando CastilloNessuna valutazione finora

- Tigweldarc Alloys: Certification of TestsDocumento1 paginaTigweldarc Alloys: Certification of TestsArunNessuna valutazione finora

- HY100 PropertiesDocumento21 pagineHY100 PropertiesSungJun ParkNessuna valutazione finora

- Thermanit MTS 3 - GTAWDocumento1 paginaThermanit MTS 3 - GTAWdnageshm4n244Nessuna valutazione finora

- Rescue Carabiners: Standard Specification ForDocumento6 pagineRescue Carabiners: Standard Specification Forastewayb_964354182Nessuna valutazione finora

- Aws A4.4m 01Documento30 pagineAws A4.4m 01Martin Urriza VelazquezNessuna valutazione finora

- Mil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322Documento2 pagineMil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322FlavioNessuna valutazione finora

- 304 DDQ SpecificationDocumento1 pagina304 DDQ Specificationdac_angelovNessuna valutazione finora

- Iso 2553Documento8 pagineIso 2553Eduardo TeixeiraNessuna valutazione finora

- AISI 1018 Carbon Steel (UNS G10180) : Topics CoveredDocumento4 pagineAISI 1018 Carbon Steel (UNS G10180) : Topics CoveredPablo MenendezNessuna valutazione finora

- 440C DS CarpenterDocumento5 pagine440C DS CarpenterdaymonNessuna valutazione finora

- AISI 4340 Alloy Steel Properties and ApplicationsDocumento4 pagineAISI 4340 Alloy Steel Properties and ApplicationsLamhotFernandoSihombingNessuna valutazione finora

- C45 STD PDFDocumento2 pagineC45 STD PDFJeetu GosaiNessuna valutazione finora

- Jis G3101 1995Documento14 pagineJis G3101 1995TUAN NGUYEN VANNessuna valutazione finora

- Astm A27 (2010) PDFDocumento4 pagineAstm A27 (2010) PDFStuar TencioNessuna valutazione finora

- AWS A5-8 2004 Filler Metals For BrazingDocumento47 pagineAWS A5-8 2004 Filler Metals For BrazingEmelda JulianNessuna valutazione finora

- Aluminium AloyDocumento2 pagineAluminium AloyGian GiovaniNessuna valutazione finora

- Astm E7Documento30 pagineAstm E7Akki SaudiNessuna valutazione finora

- SB 271Documento4 pagineSB 271AnilNessuna valutazione finora

- Aerospace Material SpecificationDocumento6 pagineAerospace Material Specificationvsraju2Nessuna valutazione finora

- Inconel 625 Alloy Guide: Composition, Properties & UsesDocumento3 pagineInconel 625 Alloy Guide: Composition, Properties & UsesalokbdasNessuna valutazione finora

- ASTM A572 Steel - Grade 50Documento1 paginaASTM A572 Steel - Grade 50FWICIP100% (1)

- Sa 325 PDFDocumento12 pagineSa 325 PDFMo'men Abu-SmaihaNessuna valutazione finora

- A434Documento3 pagineA434alirioNessuna valutazione finora

- Sa 213Documento11 pagineSa 213gst ajahNessuna valutazione finora

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDa EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNessuna valutazione finora

- 36NiCrMo16 PDFDocumento2 pagine36NiCrMo16 PDFAmy GriffinNessuna valutazione finora

- 34 CR Ni Mo 6Documento2 pagine34 CR Ni Mo 6hp_vijaykNessuna valutazione finora

- Perkins 1104cDocumento140 paginePerkins 1104cGilvan Junior82% (11)

- Perkins 1104cDocumento140 paginePerkins 1104cGilvan Junior82% (11)

- QuickFlex DMG Mori Seiki - enDocumento24 pagineQuickFlex DMG Mori Seiki - enAmy GriffinNessuna valutazione finora

- Steel-HardnessDocumento1 paginaSteel-HardnessNoir HamannNessuna valutazione finora

- Catalogo MITUTOYO INGLÊSDocumento1 paginaCatalogo MITUTOYO INGLÊSAmy GriffinNessuna valutazione finora

- A6-A6M 02b Rolled Steel PDFDocumento64 pagineA6-A6M 02b Rolled Steel PDFJoflNessuna valutazione finora

- Cincom Evolution Line: Sliding Headstock Type Automatic CNC LatheDocumento8 pagineCincom Evolution Line: Sliding Headstock Type Automatic CNC LatheAmy GriffinNessuna valutazione finora

- AÇOS VILLARES VF800-AT - InglesDocumento2 pagineAÇOS VILLARES VF800-AT - InglesAmy Griffin100% (1)

- Steel-HardnessDocumento1 paginaSteel-HardnessNoir HamannNessuna valutazione finora

- 36NiCrMo16 PDFDocumento2 pagine36NiCrMo16 PDFAmy GriffinNessuna valutazione finora

- Prog Eia-Iso MP 6200y PDFDocumento356 pagineProg Eia-Iso MP 6200y PDFAmy GriffinNessuna valutazione finora

- Mazak Programing Class BookDocumento510 pagineMazak Programing Class BookBriciu Teofil Mihail100% (7)

- 40NiCrMo7 PDFDocumento2 pagine40NiCrMo7 PDFAmy GriffinNessuna valutazione finora

- 39NiCrMo3 PDFDocumento2 pagine39NiCrMo3 PDFAmy GriffinNessuna valutazione finora

- 34 CR Ni Mo 6Documento2 pagine34 CR Ni Mo 6hp_vijaykNessuna valutazione finora

- 40NiCrMo3 PDFDocumento1 pagina40NiCrMo3 PDFAmy GriffinNessuna valutazione finora

- Milk - Run Volkswagen PDFDocumento34 pagineMilk - Run Volkswagen PDFAmy GriffinNessuna valutazione finora

- Astm A350 LF2Documento1 paginaAstm A350 LF2anjangandak2932100% (1)

- Astma105 PDFDocumento1 paginaAstma105 PDFAmy GriffinNessuna valutazione finora

- Parker Fluid Power Seal Design Guide 5370Documento300 pagineParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- AutoCAD 2013Documento264 pagineAutoCAD 2013panosscribd100% (1)

- Rockwell Hardness of Metallic Materials: Standard Test Methods ForDocumento38 pagineRockwell Hardness of Metallic Materials: Standard Test Methods ForochableNessuna valutazione finora

- Manual Fresa Dora Ha AsDocumento143 pagineManual Fresa Dora Ha AsAmy GriffinNessuna valutazione finora

- Reebol: High Performance Environmental Friendly Mould Release AgentDocumento2 pagineReebol: High Performance Environmental Friendly Mould Release AgentKrishna PrakashNessuna valutazione finora

- Application Methodology - ShaliEnamelDocumento5 pagineApplication Methodology - ShaliEnamelPradeep SinghNessuna valutazione finora

- Technical English For Electrical Engineering (Continuing Course) 2020-2021semester 1 Final TestDocumento2 pagineTechnical English For Electrical Engineering (Continuing Course) 2020-2021semester 1 Final TestsanNessuna valutazione finora

- Handbook-V 1 2Documento4 pagineHandbook-V 1 2Sebastiän Äbrigo GömezNessuna valutazione finora

- Matabi BookDocumento71 pagineMatabi BookAndrésNessuna valutazione finora

- Cement Air Slide DesignDocumento4 pagineCement Air Slide DesignAhmedRizkNessuna valutazione finora

- Material Product Data Sheet Masking Tapes For Thermal Spray: Quick FactsDocumento3 pagineMaterial Product Data Sheet Masking Tapes For Thermal Spray: Quick FactsPatingas PatingasNessuna valutazione finora

- The Manufacturing Process of LeadDocumento10 pagineThe Manufacturing Process of LeadJACKULIN DAFNEENessuna valutazione finora

- Api 510 Open 1Documento4 pagineApi 510 Open 1ty tNessuna valutazione finora

- Flowcom - Ranurada y BridadaDocumento1 paginaFlowcom - Ranurada y BridadaErickNessuna valutazione finora

- Redox Reaction PDFDocumento12 pagineRedox Reaction PDFErsan ResurreccionNessuna valutazione finora

- CASE STUDY 1 - Catalytic Oxidation of SO2Documento15 pagineCASE STUDY 1 - Catalytic Oxidation of SO2LuthandoNessuna valutazione finora

- Experimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFDocumento7 pagineExperimental Investigation For Welding Aspects of Stainless Steel 310 For The Process of TIG Welding PDFfaisalNessuna valutazione finora

- Desanding HydrocycloneDocumento2 pagineDesanding HydrocycloneKapwell LimitedNessuna valutazione finora

- Inthe1 Converter Occurs Twice A Gas Cooling Through The Two Heat Exchanger Interbed Cooler and Process Gas CoolerDocumento2 pagineInthe1 Converter Occurs Twice A Gas Cooling Through The Two Heat Exchanger Interbed Cooler and Process Gas Coolerrudy_423522658Nessuna valutazione finora

- Cu Ni 18 ZN 19 PB 1Documento1 paginaCu Ni 18 ZN 19 PB 1Isa CatNessuna valutazione finora

- The Welding Procedure and Its QualificationDocumento51 pagineThe Welding Procedure and Its QualificationMohd Faya100% (8)

- EnDOtec Welding Cored WireDocumento12 pagineEnDOtec Welding Cored WirecriuvosNessuna valutazione finora

- Metal Sealing Gate Valve PN40Documento4 pagineMetal Sealing Gate Valve PN40Emran HaniniNessuna valutazione finora

- Foam Extinguishes Fires by Smothering and CoolingDocumento2 pagineFoam Extinguishes Fires by Smothering and CoolingCkaal74Nessuna valutazione finora

- 18ee2128 Waste To EnergyDocumento1 pagina18ee2128 Waste To Energys sNessuna valutazione finora

- Cameron MBO Multi-Bowl Wellhead SystemDocumento6 pagineCameron MBO Multi-Bowl Wellhead SystemiswantmachooNessuna valutazione finora

- Sheet Metal Forming PDFDocumento8 pagineSheet Metal Forming PDFAlpha WolfNessuna valutazione finora

- Manufacture Plastic Crates FacilityDocumento1 paginaManufacture Plastic Crates FacilityVikas Awdhesh DubeyNessuna valutazione finora

- L8 Thermochemistry V21 ST August 2023Documento4 pagineL8 Thermochemistry V21 ST August 2023krishanuNessuna valutazione finora

- Post Test 3rd QTRDocumento11 paginePost Test 3rd QTRPamela AltarejosNessuna valutazione finora

- Vacuum Carburizing Using Acetylene GasDocumento6 pagineVacuum Carburizing Using Acetylene GasRamesh JakkanagoudarNessuna valutazione finora

- Din 580Documento13 pagineDin 580rajeskumarNessuna valutazione finora

- WSC2015 TP06 at M2Documento1 paginaWSC2015 TP06 at M2CAO FAO CNC عربيNessuna valutazione finora

- CMCI Aliphatic PU coating applicationDocumento3 pagineCMCI Aliphatic PU coating applicationPageduesca RouelNessuna valutazione finora