Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SOP Module Unloading & Storage

Caricato da

Rahul SahaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SOP Module Unloading & Storage

Caricato da

Rahul SahaCopyright:

Formati disponibili

SOP For Module Unloading & Storage

Park to Module Truck/Container on the flat concrete floor/road/ solid floor.

Visual check : To check lorry / Container seal before opening of lorry door match the

seal no. mentioned in the invoice. If, it is ok then break the door seal. If, there is any

decripancy then report to concerned person of supplier and mention the same in

transport documents & get the driver sign on the mentioned comments.

Visual check : To check the module boxes and pallets are visually in good condition.

If, There is any descripancy or defect then inform to concerned person and let them

know about descrepancy/defect. Take a potograph of matarial before unloading.

For unloading of pallets use Forklift /manual hydrulic pallet lifter machine.

Unloaded module box first put on solid floor and then move the same desired

location by forklift & store the module boxes on solid flat floor ( Don't stack module

boxes in double layer).

If, module box shifting in not possible upto desired with forklift then move module

pallets via Hydra with the help of Flat belt & using module protecting external box.

Module boxes will be stored in a single layer.

Provide sufficient space ( Approx. 500Mm, for a man movement) around the module

box for lifting purpose.

Ensure that nothing put over the modules/ No one sleep/sit during storage period.

Display the caution in a proper way /Manner and specify the Glass Item/ Fragile

Item.

Potrebbero piacerti anche

- SWMS - Blind IstallationDocumento12 pagineSWMS - Blind IstallationParasNessuna valutazione finora

- Quantum Field TheoryDocumento19 pagineQuantum Field TheoryRahul SahaNessuna valutazione finora

- Manual Handling ChartDocumento20 pagineManual Handling ChartTatak Bay Ahmed100% (1)

- Fault Current Calculations and Relay SettingDocumento118 pagineFault Current Calculations and Relay SettingHimdad Tahir67% (3)

- HSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesDocumento1 paginaHSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesKyaw MinNessuna valutazione finora

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocumento2 pagineRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNessuna valutazione finora

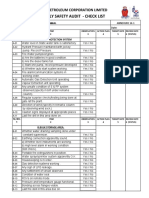

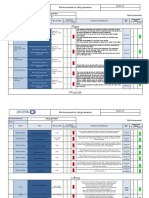

- Daily Safety ChecklistDocumento4 pagineDaily Safety ChecklistKalyan ReddyNessuna valutazione finora

- Operation and Maintenance ManualDocumento11 pagineOperation and Maintenance ManualRahul SahaNessuna valutazione finora

- Health and Safety Method Statement: SA Scaffolding LimitedDocumento8 pagineHealth and Safety Method Statement: SA Scaffolding LimitedAnonymous Wq35JtketnNessuna valutazione finora

- SWP 003 Pouring ConcreteDocumento1 paginaSWP 003 Pouring ConcreteJICKNessuna valutazione finora

- Ako AcknowledgmentDocumento1 paginaAko Acknowledgmentclaude stanton0% (1)

- Transformer Calculation Advance PDFDocumento26 pagineTransformer Calculation Advance PDFNesarkiran Bagade56% (9)

- Gas Cutting SetDocumento1 paginaGas Cutting SetProjects DepartmentNessuna valutazione finora

- Concrete Mixer Safety ChecklistDocumento1 paginaConcrete Mixer Safety ChecklistSafety Man Shop100% (1)

- Quantum MechanicsDocumento21 pagineQuantum MechanicsRahul SahaNessuna valutazione finora

- HSE guidance on safety devices for rapid roller doorsDocumento11 pagineHSE guidance on safety devices for rapid roller doorsmsc920138Nessuna valutazione finora

- Jsa Fan Coil Unites MaintenanceDocumento5 pagineJsa Fan Coil Unites MaintenanceASLAM MULANINessuna valutazione finora

- Flagman & Lookout Requirement for Vehicle ReversingDocumento1 paginaFlagman & Lookout Requirement for Vehicle ReversingarslanahmedkhawajaNessuna valutazione finora

- JSA For Erection & Dismantling of ScaffoldingDocumento4 pagineJSA For Erection & Dismantling of ScaffoldingNoe AranelNessuna valutazione finora

- Company Task Renew Main Mast Equipment: a) Navigation LightDocumento17 pagineCompany Task Renew Main Mast Equipment: a) Navigation LightAbid MujtabaNessuna valutazione finora

- SPI HSE FR 02 Tower Erection ChecklistDocumento1 paginaSPI HSE FR 02 Tower Erection ChecklistChandan KumarNessuna valutazione finora

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocumento1 paginaSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordNessuna valutazione finora

- Ms For Tele Tower ErectionDocumento12 pagineMs For Tele Tower ErectionSahabzada AamirNessuna valutazione finora

- SPI HSE FR 01 Foundation ChecklistDocumento1 paginaSPI HSE FR 01 Foundation ChecklistChandan KumarNessuna valutazione finora

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTDocumento6 pagineJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarNessuna valutazione finora

- Rigging Safety TipsDocumento2 pagineRigging Safety Tipspruncu.alianmNessuna valutazione finora

- Guidelines Flagmen - Banksmen (English)Documento1 paginaGuidelines Flagmen - Banksmen (English)Pirlo PoloNessuna valutazione finora

- JSA NO 3-Pile CapDocumento8 pagineJSA NO 3-Pile Capknabpsho50% (2)

- Risk Assessment-KioskDocumento3 pagineRisk Assessment-Kioskmubeen hassanNessuna valutazione finora

- Doka FormworkDocumento124 pagineDoka FormworkTranタオNessuna valutazione finora

- PV Layout FinalDocumento1 paginaPV Layout FinalRahul SahaNessuna valutazione finora

- Working at Height PresentationDocumento11 pagineWorking at Height PresentationAbdul Hameed OmarNessuna valutazione finora

- Ocp BatchingDocumento1 paginaOcp BatchingAarya Mishra TiwariNessuna valutazione finora

- De-Shuttering PermitDocumento1 paginaDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- ScaffoldingDocumento16 pagineScaffoldingHSENessuna valutazione finora

- Dr. Nirali Patel Pediatric Emergency MedicineDocumento31 pagineDr. Nirali Patel Pediatric Emergency Medicinemarsan12Nessuna valutazione finora

- Instructions For Using The Risk Assessment FormDocumento9 pagineInstructions For Using The Risk Assessment FormMalik Khuram ShazadNessuna valutazione finora

- HSF-PR-0063 Work at HeightDocumento32 pagineHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- Work at Heights Self Assessment SheetDocumento4 pagineWork at Heights Self Assessment SheetBalogun IsaacNessuna valutazione finora

- Plywood Material Safety Data Sheet For MR Plywood PDFDocumento4 paginePlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNessuna valutazione finora

- Asian Paints - Prem Gloss EnamelDocumento1 paginaAsian Paints - Prem Gloss EnamelwilliumstNessuna valutazione finora

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocumento2 pagineNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNessuna valutazione finora

- Pera JackhammerDocumento7 paginePera Jackhammerjumansyahamid1988Nessuna valutazione finora

- Nitoproof 230Documento2 pagineNitoproof 230Balasubramanian Ananth50% (2)

- Painting, Taping, Texturing or Epoxy CoatingsDocumento1 paginaPainting, Taping, Texturing or Epoxy CoatingsHenryOdohNessuna valutazione finora

- Hira - CivilDocumento20 pagineHira - Civilmurthy100% (1)

- Working at Height Rescue Plan: WHS-FM-008Documento2 pagineWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoNessuna valutazione finora

- JSO Cable Drum (02 Sept.'07)Documento2 pagineJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNessuna valutazione finora

- MSDS - Asada Threading Oiil Red - ENDocumento7 pagineMSDS - Asada Threading Oiil Red - ENnghiaNessuna valutazione finora

- Lifting Operations Risk AssessmentDocumento4 pagineLifting Operations Risk AssessmentIdris AdeniranNessuna valutazione finora

- Mobile Scaffold Inspection ChecklistDocumento3 pagineMobile Scaffold Inspection Checklistanthony murphyNessuna valutazione finora

- Bulldozer SOP FinalDocumento10 pagineBulldozer SOP Finaljean claude BledouNessuna valutazione finora

- General Site Safety - SignDocumento1 paginaGeneral Site Safety - SignVũ GiangNessuna valutazione finora

- Building De-Dusting JSADocumento3 pagineBuilding De-Dusting JSAJayesh J PillaiNessuna valutazione finora

- Excavation Method StatementDocumento4 pagineExcavation Method StatementAnonymous 3eHGEDbxNessuna valutazione finora

- MS Working at HeightsDocumento15 pagineMS Working at HeightsNauval FadliNessuna valutazione finora

- 02 - R.A. Working On ScaffoldsDocumento2 pagine02 - R.A. Working On ScaffoldspremNessuna valutazione finora

- Topic For TBMDocumento19 pagineTopic For TBMdauxomNessuna valutazione finora

- JSA-03 Shed DismantlingDocumento3 pagineJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Surface Exploration Drilling ChecklistDocumento5 pagineSurface Exploration Drilling ChecklistZulfiqar HyderNessuna valutazione finora

- Plant Pre Start ProcedureDocumento1 paginaPlant Pre Start Procedureheppy prastyo nugrohoNessuna valutazione finora

- Rehabilitation Project Risk ReportDocumento5 pagineRehabilitation Project Risk ReportSyed Yasir Baqar KazmiNessuna valutazione finora

- Construction Demolition HazardsDocumento2 pagineConstruction Demolition Hazardschirese2000Nessuna valutazione finora

- Summary POM 1Documento5 pagineSummary POM 1Rahul SahaNessuna valutazione finora

- String TheoryDocumento27 pagineString TheoryRahul SahaNessuna valutazione finora

- Eternal InflationDocumento4 pagineEternal InflationRahul SahaNessuna valutazione finora

- Electromagnetic FieldDocumento7 pagineElectromagnetic FieldRahul SahaNessuna valutazione finora

- Homological Mirror SymmetryDocumento3 pagineHomological Mirror SymmetryRahul SahaNessuna valutazione finora

- Gauge TheoryDocumento10 pagineGauge TheoryRahul Saha100% (1)

- Dirichlet Boundary ConditionDocumento2 pagineDirichlet Boundary ConditionRahul SahaNessuna valutazione finora

- Morphis MDocumento4 pagineMorphis MRahul SahaNessuna valutazione finora

- Vector SpaceDocumento20 pagineVector SpaceRahul SahaNessuna valutazione finora

- Ekpyrotic UniverseDocumento3 pagineEkpyrotic UniverseRahul SahaNessuna valutazione finora

- BraneDocumento3 pagineBraneRahul SahaNessuna valutazione finora

- Complex ManifoldDocumento4 pagineComplex ManifoldRahul SahaNessuna valutazione finora

- Symplectic GeometryDocumento4 pagineSymplectic GeometryRahul Saha100% (1)

- Topological String TheoryDocumento5 pagineTopological String TheoryRahul SahaNessuna valutazione finora

- DimensionDocumento8 pagineDimensionRahul SahaNessuna valutazione finora

- Quantum FluctuationDocumento4 pagineQuantum FluctuationRahul SahaNessuna valutazione finora

- Point ParticleDocumento4 paginePoint ParticleRahul SahaNessuna valutazione finora

- Voc Test Report of CREST PHQ-25KWp ProjectDocumento2 pagineVoc Test Report of CREST PHQ-25KWp ProjectRahul SahaNessuna valutazione finora

- Symplectic ManifoldDocumento5 pagineSymplectic ManifoldRahul SahaNessuna valutazione finora

- Standard ModelDocumento11 pagineStandard ModelRahul SahaNessuna valutazione finora

- Noncommutative GeometryDocumento5 pagineNoncommutative GeometryRahul SahaNessuna valutazione finora

- SupergravityDocumento6 pagineSupergravityRahul SahaNessuna valutazione finora

- String Current Measurement FormatDocumento2 pagineString Current Measurement FormatRahul SahaNessuna valutazione finora