Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Types of Heat Treating Equipment For Fasteners

Caricato da

evalenciaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Types of Heat Treating Equipment For Fasteners

Caricato da

evalenciaCopyright:

Formati disponibili

Types of Heat Treating

Equipment for Fasteners

by:

Daniel H. Herring The choice of heat treating equipment

“The Heat Treat Doctor”®, President

The HERRING GROUP, Inc.

varies with application. Selecting the

P.O. Box 884 right style and type of equipment will

Elmhurst, IL 60126-0884 USA

www.heat-treat-doctor.com ensure the highest quality product.

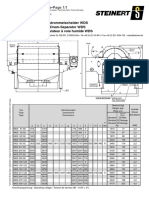

Fastener heat treatment (see Figure 1) can be performed Table 12. Classification of Furnaces.

in a wide variety of furnaces and ovens and fastener designers

should understand the choices available to them.

Heat treating equipment is normally supplied in one of

two main types: batch or continuous. The fundamental dif-

ference between these two styles is not in the materials of

construction, although there are differences due to inherent

design requirements, but instead the key difference lies in how

workloads are positioned in the units and how they interact

with the atmosphere within the furnaces.

Heat treating equipment can further be divided into (atmo-

sphere and vacuum) furnaces and ovens.

• Mechanized box furnaces (also called “sealed quench”

or “integral quench”, or “in-out” furnaces).

• Pit furnaces.

• Salt pot furnaces.

• Split or wraparound furnaces.

• Tip-up furnaces.

• Vacuum furnaces.

Of all the batch furnace types, integral quench furnaces (see

Fig. 1 — Typical production load of fasteners Figure 2) are the most common for fastener heat treatment.

entering a furnace for hardening. Continuous furnaces are characterized by the movement

Furnaces

The primary sources of energy to heat workloads in fur-

naces are (natural) gas and electricity. Alternative energy

sources such as other hydrocarbon fuels (propane, etc.) and

oil can also used. Furnaces can be classified in a number of

ways as summarized in Table 1.

Batch units tend to involve large, heavy workloads pro-

cessed for long periods of time. In a batch unit, the work

charge is typically stationary so that interaction with changes

in the furnace atmosphere are performed in near equilibrium

conditions. Batch furnace types include:

• Bell furnaces.

• Box furnaces.

• Car bottom furnaces.

• Elevating hearth furnaces.

• Fluidized bed furnaces. Fig. 2 — Batch style integral quench furnace

• Gantry furnaces. (photograph courtesy of Surface Combustion, Inc.).

xx Fastener Technology International/December 2010

Table 2. Common Applications of

Heat Treating Furnaces2.

of the workload in some manner, and the environment sur-

rounding the workload changes dramatically as a function of

the position of the work charge. Continuous furnace types

include:

• Cast link belt furnaces.

• Humpback furnaces.

• Mesh belt furnaces.

• Monorail furnaces.

• Pusher furnaces.

• Roller hearth furnace.

• Rotary drum (rotary retort) furnaces.

• Rotary hearth furnaces.

• Shaker hearth furnaces.

• Vacuum furnaces.

• Walking beam furnaces.

Of all the continuous furnace types, mesh belt conveyor

furnaces (see Figure 3) are the most common for high-volume

production demands in the fastener industry.

Fig. 3 — Mesh belt conveyor furnace for hardening

and case hardening fasteners (photograph courtesy

of Williams Industrial Furnaces).

With respect to heat treating furnaces, there are a number

of special purpose types including:

• Continuous slab and billet heating furnaces.

• Electron beam surface treatment equipment.

• Induction heating systems.

• Laser heat treating equipment.

• Quartz tube furnaces.

• Resistance heating systems.

• Rotating finger furnaces.

• Screw conveyor furnaces.

Table 2 summarizes the different processes that can be

used in each type of equipment.

Vacuum Furnaces

Vacuum furnaces can be classified, according to the mode

of loading, into horizontal (see Figure 4) and vertical furnaces

and can be batch or continuous (multi-chamber) designs.

Heat treatment in vacuum furnaces is characterized by

special conditions with regard to the design of the furnaces Fig. 4 — Batch vacuum furnace

as well as the control of temperature and vacuum level dur- (photograph courtesy of Ipsen USA).

December 2010/Fastener Technology International xx

Types of Heat Treating Equipment for Fasteners ...continued

ing the heat treatment. The design of the furnaces generally the use of special atmospheres for the processing of very

depends on the size of the load, the pressure and temperature specialized applications.

to be attained, and the medium (oil or gas) to be used in cool- The source of heat may be derived from combustion of

ing the load. The main parts of a vacuum furnace include the fuel or electricity. Heat is transferred to the work primarily

following: by natural gravity or forced convection, or by radiant sources

• Vessel. if the temperature is high enough. Today, oven construction

• Pumping system. can be used in temperature applications up to 1400ºF (760ºC)

although 1000ºF (538ºC) is a traditional upper limit. Oven

• Hot zone.

technology utilizes convection heating, that is, the circulation

• Cooling system. of air, products of combustion or an inert gas as the primary

Vacuum furnaces may be classified as hot wall or cold means to heat a workload to temperature. Oven construction

wall styles. The features of a cold-wall furnace include the also varies considerably from furnace construction.

following: Selection of the type of oven involves the careful con-

• Operating temperature in the range of 2400°F to 3000°F sideration of several variables. These variable include the

(1315°C 1650°C) or higher. following:

• Low heat losses and heat load released to the • Quantity of material to be processed.

surroundings. • Uniformity in size and shape of the product.

• Rapid heating and cooling performance. • Lot size.

• Tight (±10°F (5.5°C or better) temperature • Temperature tolerances.

uniformity control.

• Effluent evolution, if any.

Ovens Batch systems may be classified as:

Ovens may be designed for intermittent loading, that is, • Bell.

one batch at a time (see Figure 5), or for a continuous flow of • Bench top.

work using some form of conveyance through the unit. Oven • Cabinet.

equipment sizes vary dramatically, from small bench-top units • Truck.

in laboratory environments to huge industrial systems with

• Walk-in.

thousands of cubic feet (cubic meters) of capacity. Ovens

operate with air atmospheres, but may be designed to contain Continuous systems include the following:

special atmospheres such as nitrogen or argon, or incorporate • Belt.

special construction such as adaptations for retorts that allow • Drag chain.

• Monorail.

• Pusher.

• Roller hearth.

• Rotary drum (or retort).

• Screw.

• Walking beam.

There are several design criteria for oven construction

that includes:

• Operating temperature.

• Heating method.

• Thermal expansion of materials.

• Atmospheres.

• Airflow patterns.

The range of operating temperature is one of the main

determinants of oven construction. Typically, all ovens are

constructed of a double wall of sheet metal with insulation

and reinforcing members sandwiched between the sheets. The

insulation may be glass fiber, mineral wool or lightweight

fiber material. The sheet metal lining for ovens may be of

low carbon steel, galvanized steel, zinc-gripped steel, alu-

minized steel or stainless steel depending on the temperature

requirement.

Several distinct changes occur in oven construction as the

temperature increases. Problems, with expansion and sealing

the interior from heat and atmosphere, become much more

Fig. 5 — Batch oven for the heat treatment of aluminum significant at higher temperatures.

fasteners (photograph courtesy of Wisconsin For example, an oven system that is designed for opera-

Oven Corporation). tion at 400°F (205°C) will have mineral wool insulation,

xx Fastener Technology International/December 2010

4" (100 mm) thick. ing natural gas or other hydrocarbons), steam or electricity.

By contrast, for an oven with a 700°F operating tem- Infrared heating and microwave (radio frequency) can also

perature, a thickness of 7" (175 mm) is required. Thermal be used.

expansion in large oven systems is generally compensated

for by the use of telescoping panel joints in the walls, ceil- Final Thoughts

ing and floor. Door construction must incorporate similar The choice of heat treating equipment varies with appli-

expansion joints. cation. Selecting the right style and type of equipment will

The type and quantity of airflow is important. For example, ensure the highest quality product. Often times a number of

ovens designed for handling explosive volatiles such as paint furnace types can do the job, so the choices comes down to

drying or solvent extraction have special considerations economy of operation.

including large air flow volumes to dilute the volatile gases, Shops who do not operate 24 hours a day, seven days a

explosion relief hatches, purge cycles, powered exhausters, week, or who are not in a position to dedicate staff to this

airflow safety switches and fresh air dampers. endeavor may wish to consider batch equipment or vacuum

Several different patterns of air flow can be used depend- processing or look at outsourcing to qualified commercial

ing on the workload configuration. These air flow patterns heat treaters. Other shops need to evaluate which technology

include the following: is the best fit to their product mix and skill sets.

• Horizontal. To learn more about the types of heat treating systems for

• Vertical. fasteners, visit the website listed below.

www.heat-treat-doctor.com FTI

• Combination (uniflow).

The method of heating an oven often depends not only on

the availability of a particular fuel, but also on the process References:

itself. Many processes cannot tolerate products of combustion

from direct fired systems so indirect (radiant tube) firing or

1

Herring, D. H., Heat Treating Equipment,

alternate energy sources need to be considered. White Paper, 2003.

In addition, some means of heat transfer such as microwave

heating are severely limited in the type of product that can

2

Heat Treater’s Guide: Standard Practices and

be processed. Ovens are commonly heated by fuel (includ- Procedures for Steel, ASM International, 1982.

December 2010/Fastener Technology International xx

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- F2cfe613 Fjbfe613Documento518 pagineF2cfe613 Fjbfe613jvega_534120100% (3)

- Isuzu Engine Service Manual Sumitomo PT 1Documento168 pagineIsuzu Engine Service Manual Sumitomo PT 1Ronald100% (7)

- NMF Crane PDFDocumento420 pagineNMF Crane PDFCah Ndeso Klutuk75% (12)

- The Jewish Revolutionary Spirit and Its Impact On World History - E. Michael JonesDocumento46 pagineThe Jewish Revolutionary Spirit and Its Impact On World History - E. Michael JonesCristiano Ferrari67% (3)

- Baby Mait PDFDocumento2 pagineBaby Mait PDFChris LuNessuna valutazione finora

- Yamaha Engine Autralia PDFDocumento560 pagineYamaha Engine Autralia PDFLân Nguyễn100% (2)

- Methods of Chemical Analysis of FluorsparDocumento23 pagineMethods of Chemical Analysis of Fluorsparevalencia100% (1)

- Analysis of Acid-Grade Calcium Fluoride (Fluorspar) : Standard Test Methods ForDocumento14 pagineAnalysis of Acid-Grade Calcium Fluoride (Fluorspar) : Standard Test Methods ForevalenciaNessuna valutazione finora

- Minerals 09 00222Documento11 pagineMinerals 09 00222evalenciaNessuna valutazione finora

- Preparing Your LaboratoryDocumento12 paginePreparing Your LaboratoryevalenciaNessuna valutazione finora

- Sgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignDocumento10 pagineSgs Min Tp2002 04 Bench and Pilot Plant Programs For Flotation Circuit DesignevalenciaNessuna valutazione finora

- DG - AG-04 MaizeDocumento1 paginaDG - AG-04 MaizeevalenciaNessuna valutazione finora

- User Instruction Manual 9779401, Rev B, Intelli-SashDocumento11 pagineUser Instruction Manual 9779401, Rev B, Intelli-SashevalenciaNessuna valutazione finora

- Roots: Application Field: Agriculture Digestion Application Note DG-AG-08Documento1 paginaRoots: Application Field: Agriculture Digestion Application Note DG-AG-08evalenciaNessuna valutazione finora

- Beans: Application Field: Agriculture Digestion Application Note DG-AG-06Documento1 paginaBeans: Application Field: Agriculture Digestion Application Note DG-AG-06evalenciaNessuna valutazione finora

- User's Manual 9410500, Rev A, Protector PremierDocumento59 pagineUser's Manual 9410500, Rev A, Protector PremierevalenciaNessuna valutazione finora

- Ground Vegetable: Application Field: Agriculture Digestion Application Note DG-AG-03Documento1 paginaGround Vegetable: Application Field: Agriculture Digestion Application Note DG-AG-03evalenciaNessuna valutazione finora

- Tea Leaves: Application Field: Agriculture Digestion Application Note DG-AG-09Documento1 paginaTea Leaves: Application Field: Agriculture Digestion Application Note DG-AG-09evalenciaNessuna valutazione finora

- The Paste Thickener Pilot Plant Is Self-Contained and IncludesDocumento1 paginaThe Paste Thickener Pilot Plant Is Self-Contained and IncludesevalenciaNessuna valutazione finora

- And Techniques: Ethos Series Ethos SeriesDocumento55 pagineAnd Techniques: Ethos Series Ethos SeriesevalenciaNessuna valutazione finora

- Agricolture CookbookDocumento10 pagineAgricolture CookbookevalenciaNessuna valutazione finora

- DG - AG-01 Pine LeavesDocumento1 paginaDG - AG-01 Pine LeavesevalenciaNessuna valutazione finora

- DG - AG-02 Dried Plant TissueDocumento1 paginaDG - AG-02 Dried Plant TissueevalenciaNessuna valutazione finora

- 8000 Series Digital Video Recorder - Quick Start Guide V3.0 - 20181022Documento16 pagine8000 Series Digital Video Recorder - Quick Start Guide V3.0 - 20181022evalenciaNessuna valutazione finora

- Seite - Page 1/1: Nasstrommelscheider WDS Wet-Drum-Separator WDS Séparateur À Voie Humide WDSDocumento1 paginaSeite - Page 1/1: Nasstrommelscheider WDS Wet-Drum-Separator WDS Séparateur À Voie Humide WDSevalenciaNessuna valutazione finora

- Kryptonite's Car ComparisonDocumento14 pagineKryptonite's Car Comparisonhashu123Nessuna valutazione finora

- Ewura Evaluation Checklist-Revised - Feb 2017Documento6 pagineEwura Evaluation Checklist-Revised - Feb 2017cprein93Nessuna valutazione finora

- En 590Documento1 paginaEn 590anil divveNessuna valutazione finora

- Full Presentation CompressedDocumento253 pagineFull Presentation Compressedanon-940570100% (4)

- Adtic Ada216033 PDFDocumento111 pagineAdtic Ada216033 PDFYash DumaswalaNessuna valutazione finora

- 504 SNCR FLS SNCR SystemDocumento10 pagine504 SNCR FLS SNCR Systemvũ minh tâmNessuna valutazione finora

- PDFDocumento9 paginePDFkrarNessuna valutazione finora

- Total FameDocumento2 pagineTotal Fametifanifaraziska100% (1)

- T4078 Techical Sheet and Manual CAT 320E LDocumento36 pagineT4078 Techical Sheet and Manual CAT 320E Lricktmg100% (1)

- Company ProfileDocumento4 pagineCompany ProfileAnkit Verma100% (1)

- Drum Wound ArmatureDocumento3 pagineDrum Wound ArmatureidealparrotNessuna valutazione finora

- Bobcat S250 OMDocumento127 pagineBobcat S250 OMAnonymous yjK3peI7100% (1)

- Methylated Spirits: Ethyl AlcoholDocumento2 pagineMethylated Spirits: Ethyl AlcoholGianesisMiguelenaNessuna valutazione finora

- Vehicle Builders Guide v14Documento9 pagineVehicle Builders Guide v14georgemesfin@gmailNessuna valutazione finora

- CAT Programming ManualDocumento258 pagineCAT Programming ManualAnggraini Sari100% (2)

- Heui Catalog PDFDocumento6 pagineHeui Catalog PDFLuisYFer1Nessuna valutazione finora

- Craftsman 917.272065 MowerDocumento64 pagineCraftsman 917.272065 MowertjtechsterNessuna valutazione finora

- PRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Documento10 paginePRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Habibur RahamanNessuna valutazione finora

- 7 5 Kva Escorts Silent Generator Set PDFDocumento1 pagina7 5 Kva Escorts Silent Generator Set PDFmanoj_doshi_1Nessuna valutazione finora

- Maintenance: 1.2 General Maintenance Chart For Hitachi S12A2 EngineDocumento36 pagineMaintenance: 1.2 General Maintenance Chart For Hitachi S12A2 EngineKolo BenduNessuna valutazione finora

- D6R Series Ii Detailed SpecificationsDocumento4 pagineD6R Series Ii Detailed SpecificationsCJNessuna valutazione finora

- Tpd2157en-04 (08-23)Documento5 pagineTpd2157en-04 (08-23)ccssaa123Nessuna valutazione finora

- MBE - MBE900 (2007 & Newer) .MBE900 EPA07 PDFDocumento11 pagineMBE - MBE900 (2007 & Newer) .MBE900 EPA07 PDFAlfonso Robles Rubio100% (1)

- Adjusting Well Pump Pressure SwitchesDocumento1 paginaAdjusting Well Pump Pressure SwitchesD_D_76Nessuna valutazione finora