Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

s110-244 Rev 524

Caricato da

vipinkala1Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

s110-244 Rev 524

Caricato da

vipinkala1Copyright:

Formati disponibili

PS4-MT3/15-H

SPECIFICATIONS

PS4-MT Series Hydrogen Gas Purifier, 30 and 50 slpm

General Description

The MonoTorr® Hydrogen Purifier is a getter-based purifier designed specifically to provide ultra-

high purity (UHP) gas for semiconductor applications. Outlet impurity levels for O2, H2O, CO, CO2

and N2 are reduced to low parts per billion (ppb) levels or below.

The patented getter alloy operated at elevated temperatures, removes impurities by forming

irreversible chemical bonds. Impurities will not be released under any circumstances when the

purifier is operated within specification.

The purifier will continuously supply ultra pure gas at rated flows provided that inlet impurities are

within specified levels, until getter cartridge replacement is necessary.

PS4 Phase II Controller Features

• Heater indicates status of heater.

• Temperature display heater mode while maintaining getter material at preset operating

temperature.

• Valves indicate status of purifier as controlled by pneumatic valves.

• Alarms Pneumatic alarm caused by loss of adequate pressure for valves. Power alarm

indicates that extended power failure has caused purifier to go into Standby condition.

Temperature alarm indicates a high or low temperature condition in the purifier cartridge. High

impurity levels (air) in the gas stream could cause the high temperature alarm. Alarm causes

the purifier to go to Bypass mode. Additional error codes provide alarms for exhaust fan, heater

or solid state relay failure.

• Heater On/Off activates heater only when no alarms exist.

• Valve Control positions valve to Purifier or Bypass mode.

• LED Check assures proper functioning of all LEDs and alarm buzzer.

• Acknowledge Silence audible alarm and restores operation if certain alarm conditions have

been corrected.

• Over Pressure Vent automatically vents hydrogen, which will reduce system pressure.

PS4-MT3/15-H 1 S110-244, Rev. -, DCN 1978, 22 January, 2002

Process Gas Specifications

Specification SPG Standard

Maximum Flow Rate: (maximum purified gas MT3: 30 slpm

delivered)

MT15: 50 slpm

Nominal Flow Rate: MT3: 5 slpm

MT15: 15 slpm

Minimum Flow Rate: (for purity measurement) MT3: 1 slpm

MT15: 1 slpm

Maximum Inlet Pressure 10.3 bar (~150 psig)

Maximum Pressure Drop @ 7 bar inlet pressure < 1 bar (~14.5 psid)

and maximum rated flow

Inlet Gas Temperature Range 0o – 35o C (32 o – 95o F)

Outlet Gas Temperature (maximum) < 50o C ( 122 o F)

Facilities Requirements – Electrical

Specification SPG Standard

Installed Power Optional 120 VAC – MT3: 235W, MT15: 450W

(customer to specify voltage at time of order)

Optional 220 VAC – MT3: 220W, MT15:500W

Note: The purifier is designed to operate with a 30mA GFI that will trip when a 30mA leakage current

occurs.

Facilities Requirements – General

Specification SPG Standard

Instrument Air Pressure: 5.5 bar (80 psig) - 6.9 bar (100 psig)

(clean dry air or nitrogen filtered to 10 μm)

Ambient Temperature Range 5o / 35o C (41o / 95o F)

PS4-MT3/15-H 2 S110-244, Rev. -, DCN 1978, 22 January, 2002

Analytical Specifications (based on 99.999% pure inlet gas)

SPG Standard Outlets - Phase II 3000 SPG Standard Outlets – Phase II 15000

Outlet Impurity 0-20 slpm 20-30 slpm Outlet Impurity 0-30 slpm 30-50 slpm

O2 < 1 ppb < 1 ppb O2 < 1 ppb < 1 ppb

H2O < 1 ppb < 1 ppb H2O < 1 ppb < 1 ppb

CO < 1 ppb < 1 ppb CO < 1 ppb < 1 ppb

CO2 < 1 ppb < 1 ppb CO2 < 1 ppb < 1 ppb

N2 < 1 ppb < 10 ppb N2 < 1 ppb < 10 ppb

General Purifier Specifications

Purifier Height (envelope) 86.4 cm (~34 inches)

Purifier Width (envelope) 20.3 cm (~8 inches)

Purifier Depth (envelope) 22.7 cm (~8.94 inches)

Purifier Weight MT3: 23 kg (50 pounds)

MT15: 28 kg (61 pounds)

Feed Gas Inlet ¼ inch VCR Female

Purified Gas Outlet ¼ inch VCR Male

Getter Bed Operating Temperature 300o C (572o F)

Heater Power Consumption MT3: 125 / <235

(watt) Nominal/Maximum MT15: 187 / <500

Outlet Particle Filter 0.003 μm absolute all metal type

Instrument Air Inlet ¼ inch FNPT

Pressure Relief (Vent connection) ¼ inch VCR Male

Valves Four, ¼ inch diaphragm type, Air actuated

Thermocouple Two, ungrounded, K type

Standard power cord length 2 m (80 inches)

PS4-MT3/15-H 3 S110-244, Rev. -, DCN 1978, 22 January, 2002

Gas Wetted Surface Finish Up and Downstream of Getter Vessels = 316L SST,

Electropolished, 12 Ra Maximum, 10 Ra Average for

tubing and tube fittings

Control System Discrete analog temperature controller with alarm and

shut-down features

Accessories 2EA ¼ inch VCR gaskets

MT3: 1EA 3 A fuse (120V), 1EA 2 A fuse (220V)

MT15: 1EA 5 A fuse (120V), 1EA 4 A fuse (220V)

Applicable Codes & Standards CE Marking

PS4-MT3/15-H 4 S110-244, Rev. -, DCN 1978, 22 January, 2002

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- SPEC. FOR ELECTRICAL REQUIREMENTS FOR PACKAGE EQUIPMENT rg6s911380002 - 001Documento20 pagineSPEC. FOR ELECTRICAL REQUIREMENTS FOR PACKAGE EQUIPMENT rg6s911380002 - 001Muthiah MuruganNessuna valutazione finora

- 10 CodesDocumento4 pagine10 CodesPerzi ValNessuna valutazione finora

- Learn Practise and Profit From InvestingDocumento43 pagineLearn Practise and Profit From Investingvipinkala1Nessuna valutazione finora

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Case 1 MH&ADocumento5 pagineCase 1 MH&Avipinkala1Nessuna valutazione finora

- Practice Problems2Documento48 paginePractice Problems2vipinkala1100% (1)

- Case 1 MH&ADocumento5 pagineCase 1 MH&Avipinkala1Nessuna valutazione finora

- Case 1 MH&ADocumento5 pagineCase 1 MH&Avipinkala1Nessuna valutazione finora

- Case 1 MH&ADocumento5 pagineCase 1 MH&Avipinkala1Nessuna valutazione finora

- Case 1 MH&ADocumento5 pagineCase 1 MH&Avipinkala1Nessuna valutazione finora

- Case 1 MH&ADocumento5 pagineCase 1 MH&Avipinkala1Nessuna valutazione finora

- Case 1 MH&ADocumento5 pagineCase 1 MH&Avipinkala1Nessuna valutazione finora

- Ch2 - Cost Accounting - Horngren'sDocumento16 pagineCh2 - Cost Accounting - Horngren'svipinkala1Nessuna valutazione finora

- Ch2 - Cost Accounting - Horngren'sDocumento16 pagineCh2 - Cost Accounting - Horngren'svipinkala1Nessuna valutazione finora

- Ch2 - Cost Accounting - Horngren'sDocumento16 pagineCh2 - Cost Accounting - Horngren'svipinkala1Nessuna valutazione finora

- Unilever To Cut Emissions To Zero by 2039, Adopt Carbon Labeling - BloombergDocumento4 pagineUnilever To Cut Emissions To Zero by 2039, Adopt Carbon Labeling - Bloombergvipinkala1Nessuna valutazione finora

- Agricultural Tractors, CEV & Combine HarvesterDocumento4 pagineAgricultural Tractors, CEV & Combine Harvestervipinkala1Nessuna valutazione finora

- Cost of Goods Sold 9,100,000.00 Gross Margin 4,500,000.00Documento2 pagineCost of Goods Sold 9,100,000.00 Gross Margin 4,500,000.00vipinkala1Nessuna valutazione finora

- Draft ExplanatoryMemorandum - Solar Power Projects - 30jun09Documento1 paginaDraft ExplanatoryMemorandum - Solar Power Projects - 30jun09vipinkala1Nessuna valutazione finora

- Unilever To Cut Emissions To Zero by 2039, Adopt Carbon Labeling - BloombergDocumento4 pagineUnilever To Cut Emissions To Zero by 2039, Adopt Carbon Labeling - Bloombergvipinkala1Nessuna valutazione finora

- Category M and N 3500KgDocumento2 pagineCategory M and N 3500Kgvipinkala1Nessuna valutazione finora

- DE102005056101A1 - Air Bag Filling Meth... Nitrogen and Hydrogen - Google PatentsDocumento3 pagineDE102005056101A1 - Air Bag Filling Meth... Nitrogen and Hydrogen - Google Patentsvipinkala1Nessuna valutazione finora

- Parameter DeclarationsDocumento1.338 pagineParameter DeclarationsAbqary Property MamminasataNessuna valutazione finora

- Product End-of-Life Disassembly InstructionsDocumento8 pagineProduct End-of-Life Disassembly InstructionsinkblueNessuna valutazione finora

- Journal of Crystal Growth: S. Dhanuskodi, T.C. Sabari GirisunDocumento6 pagineJournal of Crystal Growth: S. Dhanuskodi, T.C. Sabari GirisunRama GaurNessuna valutazione finora

- EMI Reduction and PCB Layout TechniquesDocumento3 pagineEMI Reduction and PCB Layout Techniquesfelixrajesh0% (1)

- TDR & FMCW Radar Level Transmitters Principle Instrumentation ToolsDocumento3 pagineTDR & FMCW Radar Level Transmitters Principle Instrumentation Toolskali bangonNessuna valutazione finora

- Sky Star 2 PciDocumento2 pagineSky Star 2 PciSor Dela FlorNessuna valutazione finora

- Tutorial OverviewDocumento44 pagineTutorial OverviewBharavi K SNessuna valutazione finora

- STB 11 NK 50 ZDocumento16 pagineSTB 11 NK 50 ZLEB 280Nessuna valutazione finora

- Khurram Shahzad New Cv.Documento3 pagineKhurram Shahzad New Cv.TajMuhammadAbbasiNessuna valutazione finora

- Nima Contact List: SR - No Contact Person Company TypeDocumento6 pagineNima Contact List: SR - No Contact Person Company TypeSunny Mahajan100% (1)

- The IOT Based Automatic Toll Gate System Using Raspberry PiDocumento8 pagineThe IOT Based Automatic Toll Gate System Using Raspberry PiShubham BhardwajNessuna valutazione finora

- Manual Sony HCD-SH2000 (88 Páginas)Documento2 pagineManual Sony HCD-SH2000 (88 Páginas)Alberto CaseroNessuna valutazione finora

- 4440 4540 4545Documento2 pagine4440 4540 4545coolwatersNessuna valutazione finora

- RB941-2nD-TC Product Details 2018-08-08 0104Documento2 pagineRB941-2nD-TC Product Details 2018-08-08 0104AliviaNovitaAndariNessuna valutazione finora

- FSL100 Series Flame Detector Quick Start Guide: Wiring To A 4-20 Ma Current Sourcing PLCDocumento2 pagineFSL100 Series Flame Detector Quick Start Guide: Wiring To A 4-20 Ma Current Sourcing PLCeng_elbarbaryNessuna valutazione finora

- BOOK 2, CHAPTER 8 - Directional Control Valves - Other Technologies Content From Hydraulics & PneumaticsDocumento21 pagineBOOK 2, CHAPTER 8 - Directional Control Valves - Other Technologies Content From Hydraulics & PneumaticssriramNessuna valutazione finora

- ACG StarterDocumento9 pagineACG StarterAnggi RustandiNessuna valutazione finora

- Hspice UseDocumento28 pagineHspice Useprasanna810243Nessuna valutazione finora

- 5990 4245en PDFDocumento9 pagine5990 4245en PDFumts12345Nessuna valutazione finora

- Kenwood RC-2000 Instructions ManualDocumento60 pagineKenwood RC-2000 Instructions Manualgus289Nessuna valutazione finora

- Luminus SST-20-WxS DatasheetDocumento15 pagineLuminus SST-20-WxS Datasheetunder attack (UnderAttack69)Nessuna valutazione finora

- Starting SystemDocumento34 pagineStarting SystemGetachew Tikue100% (2)

- Sens Battery ChargerDocumento17 pagineSens Battery ChargervjNessuna valutazione finora

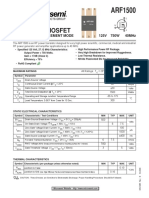

- Arf1500 PDFDocumento4 pagineArf1500 PDFbookreader1968Nessuna valutazione finora

- M3BADocumento17 pagineM3BAROBIN RAJPUROHITNessuna valutazione finora

- SAFT Primary Lithium Selector Guide - 2010-07Documento14 pagineSAFT Primary Lithium Selector Guide - 2010-07MedSparkNessuna valutazione finora

- User Instruction Manual and License Agreement: Drums of War - 1 of 5Documento5 pagineUser Instruction Manual and License Agreement: Drums of War - 1 of 5umbralNessuna valutazione finora

- The Thermoelectric GeneratorDocumento8 pagineThe Thermoelectric GeneratorSayed MesallamyNessuna valutazione finora