Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SanRO HS PDF

Caricato da

john_paisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SanRO HS PDF

Caricato da

john_paisCopyright:

Formati disponibili

SanRO-HS

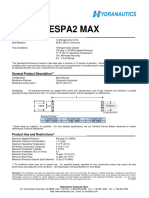

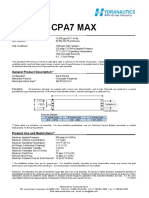

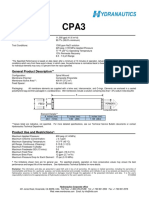

SanRO-HS Heat Sanitizable, High Rejection RO Composite Membrane Elements are designed

specifically for High Performance in USP and other high purity water systems. Elements with Sanitary,

Full-fit outer-wraps eliminate “dead flow” areas for maximum bacteria control. SanRO-HS components

conform to FDA regulation CFR Title 21.

Products:

Element Performance* System

Membrane Performance**

Description Permeate Flow and Rejection

Type Applied Permeate

GPD (m3/day) Pressure TDS,

% Rej psig (MPa) PPM

8040 4040

SanRO-HS Heat Sanitizable, High Rejection 8800 (33.3) 2200 (8.4) 99.7 180 (1.24) 6.6

Composite SANRO HS-8 SANRO HS-4

Heat Sanitizable, High Flux, 14,000 (53) 3000 (11.4)

SanRO-HS2 99.6 129 (0.89) 12.5

High Rejection Composite SANRO HS2-8 SANRO HS2-4

* Element Performance is at 225 psig (1.55 MPa), 1500 mg/L NaCl, 15% Recovery, 77F (25 C).

** Applied Pressure and Permeate TDS are projected values for a 2:2:1 array system operating at 15 GFD (26 LMH) average

flux with 500 mg/L TDS feed (NaCl), 80% Recovery, pH 7, 77F (25 C).

Type Configuration: Sanitary (Full-Fit) Spiral Wound

Membrane Polymer: Composite Polyamide

Application Data† Maximum Applied Pressure 600 psig (4.14 MPa)

Maximum Chlorine Concentration < 0.1 PPM

Maximum Operating Temperature 131 F (55 C)

Sanitizing Temperature/Pressure Max. 185/25 F/psig (85/0.17 C/MPa)

Operating pH Range: 2.0 - 10.0

Cleaning pH Range: 1.0 - 12.0

Maximum Pressure Drop for a vessel 60 psig (0.41 MPa)

†

The limitations shown here are for general use. The values may be more conservative for specific projects to

ensure the best performance and longest life of the membrane. See Hydranautics Technical Bulletins for more detail

on operation limits, cleaning pH, and cleaning temperatures.

4040 8040

Size A B C Area

2 2

in (cm) in (cm) in (cm) ft (m )

4040 40.0 (102) 3.98 (10.1) 0.750 (1.9) O.D. 90 (8.3)

8040 40.0 (102) 7.90 (20.1) 1.125 (2.9) I.D. 380 (35.2)

Notice: Elements are enclosed in a sealed polyethylene bag containing less than 1.0% sodium meta-bisulfite solution, and then packaged in a cardboard box. All SanROHS

elements are heat set at the factory with a one hour vacuum rinse at 85 C. Elements include interconnector assembly, ATDs, and one brine seal. Hydranautics believes the

information and data contained herein to be accurate and useful. The information and data are offered in good faith, but without guarantee, as conditions and methods of use of

our products are beyond our control. Hydranautics assumes no liability for results obtained or damages incurred through the appli cation of the presented information and data.

It is the user's responsibility to determine the appropriateness of Hydranautics' products for the user's specific end uses. 5/13/14

Hydranautics Corporate: 401 Jones Road, Oceanside, CA 92058

1-800-CPA-PURE Phone: 760-901-2500 Fax: 760-901-2578 info@Hydranautics.com

Potrebbero piacerti anche

- Gas Sweetening and Processing Field ManualDa EverandGas Sweetening and Processing Field ManualValutazione: 4 su 5 stelle4/5 (7)

- Nano SW MaxDocumento1 paginaNano SW Maxfelipe RezendeNessuna valutazione finora

- Hydranautics ESPA1 8040Documento1 paginaHydranautics ESPA1 8040hazim.houssemNessuna valutazione finora

- Hydranautics ESPA2-Max RO Membrane Spec SheetDocumento1 paginaHydranautics ESPA2-Max RO Membrane Spec SheetScribberNessuna valutazione finora

- Membrane Element SWC - 2540: PerformanceDocumento1 paginaMembrane Element SWC - 2540: PerformanceAshish GulrandheNessuna valutazione finora

- Esna1 LF2 LD 4040Documento1 paginaEsna1 LF2 LD 4040Soledad OrtegaNessuna valutazione finora

- Hydranautics CPA2 4040Documento1 paginaHydranautics CPA2 4040jdk18Nessuna valutazione finora

- Hydranautics ESPA2 LD 4040Documento1 paginaHydranautics ESPA2 LD 4040zerocool86Nessuna valutazione finora

- Membrane Element Cpa2: Application DataDocumento1 paginaMembrane Element Cpa2: Application DataMilton Jiménez NaveaNessuna valutazione finora

- CPA2 4040 SpecificationDocumento1 paginaCPA2 4040 SpecificationasdasNessuna valutazione finora

- Membrane Specs: High-Flow RO ElementDocumento1 paginaMembrane Specs: High-Flow RO ElementsadNessuna valutazione finora

- Cpa2 4040 PDFDocumento1 paginaCpa2 4040 PDFcarlos pachecoNessuna valutazione finora

- Membrane Element CPA2-4040: PerformanceDocumento1 paginaMembrane Element CPA2-4040: Performancecarlos pachecoNessuna valutazione finora

- ESPA2-LD-4040 membrane specificationsDocumento1 paginaESPA2-LD-4040 membrane specificationsJesus SelasorNessuna valutazione finora

- ESPA2-Membrane Element 4040: Performance: TypeDocumento1 paginaESPA2-Membrane Element 4040: Performance: Typepo bangkokNessuna valutazione finora

- Hydranautics SWC5 LD LDocumento1 paginaHydranautics SWC5 LD LAlexis Jara VidalNessuna valutazione finora

- Cpa5 LD PDFDocumento1 paginaCpa5 LD PDFNarin InverterNessuna valutazione finora

- Membrane Element Cpa5-Ld: (Low Fouling Technology) PerformanceDocumento1 paginaMembrane Element Cpa5-Ld: (Low Fouling Technology) PerformanceAbid HaroonNessuna valutazione finora

- CPA5-LD Membrane Element Performance SpecsDocumento1 paginaCPA5-LD Membrane Element Performance SpecsBassemNessuna valutazione finora

- Cpa5 LDDocumento1 paginaCpa5 LDHolliver Michael Estredo Ch.Nessuna valutazione finora

- HYDRACoRe10 and 50 LD SeriesDocumento1 paginaHYDRACoRe10 and 50 LD SeriesSathishNessuna valutazione finora

- SWC4 LDDocumento1 paginaSWC4 LDJUANNessuna valutazione finora

- Espa1: Specified PerformanceDocumento1 paginaEspa1: Specified PerformanceBerlin TirtaNessuna valutazione finora

- Hydranautics CPA2 L PDFDocumento1 paginaHydranautics CPA2 L PDFMilton Jiménez NaveaNessuna valutazione finora

- Lenntech: Membrane Element Cpa2Documento1 paginaLenntech: Membrane Element Cpa2Daniel LagosNessuna valutazione finora

- High-Performance Membrane Element CPA5 MAXDocumento1 paginaHigh-Performance Membrane Element CPA5 MAXlordsethdarknessNessuna valutazione finora

- ESPA2-LD MAX membrane element spec sheetDocumento1 paginaESPA2-LD MAX membrane element spec sheetHaseebNessuna valutazione finora

- Membrane Element Cpa3: PerformanceDocumento1 paginaMembrane Element Cpa3: PerformanceMuhammad Iqbal Khan ChandioNessuna valutazione finora

- CPA3 DatasheetDocumento1 paginaCPA3 DatasheetkhuramNessuna valutazione finora

- TM 800 ADocumento2 pagineTM 800 Ama_princess7840Nessuna valutazione finora

- Hydranautics SWC5-LD (PW)Documento1 paginaHydranautics SWC5-LD (PW)mahdi rasoulianNessuna valutazione finora

- Swro TM800KDocumento2 pagineSwro TM800KthanhhuyenNessuna valutazione finora

- SWC5-LD Membrane Spec SheetDocumento1 paginaSWC5-LD Membrane Spec SheetBenjamin MillerNessuna valutazione finora

- SWC5 LDDocumento1 paginaSWC5 LDAhmed AzabNessuna valutazione finora

- ESPA2-MAXDocumento1 paginaESPA2-MAXoussama bvbNessuna valutazione finora

- Sea2 4040 PDFDocumento1 paginaSea2 4040 PDFMd. Suruz ZamanNessuna valutazione finora

- Мембрана TM810 SpecDocumento2 pagineМембрана TM810 SpecAlexanderNessuna valutazione finora

- Hydranautics ESPA2 LD LDocumento1 paginaHydranautics ESPA2 LD LZi Wei LeongNessuna valutazione finora

- Hydranautics ESPA2 LD Low Fouling Membrane Element LenntechDocumento1 paginaHydranautics ESPA2 LD Low Fouling Membrane Element Lenntechzerocool86Nessuna valutazione finora

- CPA6-LD Membrane Spec SheetDocumento1 paginaCPA6-LD Membrane Spec Sheetmahdi rasoulianNessuna valutazione finora

- Lfc3-Ld: Specified PerformanceDocumento1 paginaLfc3-Ld: Specified PerformanceLuqmanNessuna valutazione finora

- System ManualDocumento14 pagineSystem ManualCareers SSPNessuna valutazione finora

- Datasheet LG BW 400 R Dura ENGDocumento1 paginaDatasheet LG BW 400 R Dura ENGSaul RosalesNessuna valutazione finora

- OltremareDocumento1 paginaOltremareAfraz ShaikhNessuna valutazione finora

- Datasheet LG SW 400 SR G2 ENGDocumento1 paginaDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNessuna valutazione finora

- Data Sheet: LG SW 4040 RDocumento1 paginaData Sheet: LG SW 4040 RAcquetech AcquetechNessuna valutazione finora

- Pro XP1Documento2 paginePro XP1sunil patelNessuna valutazione finora

- Toray TM820M 440 - Spec - SheetDocumento2 pagineToray TM820M 440 - Spec - SheetJoselito CortesNessuna valutazione finora

- Cpa2 PDFDocumento1 paginaCpa2 PDFaniket royNessuna valutazione finora

- CPA7 MAX PerformanceDocumento1 paginaCPA7 MAX Performance문종철Nessuna valutazione finora

- Sea Water RO Elements: DimensionsDocumento2 pagineSea Water RO Elements: Dimensionswahyu raharjoNessuna valutazione finora

- Data Sheet: LG BW 4040 EsDocumento1 paginaData Sheet: LG BW 4040 EsAcquetech AcquetechNessuna valutazione finora

- RE3012-800_v2.0(22)_1Documento1 paginaRE3012-800_v2.0(22)_1Lam PhiNessuna valutazione finora

- Hydranautics ESPA2 LD MAX LDocumento1 paginaHydranautics ESPA2 LD MAX Lzerocool86Nessuna valutazione finora

- MembranesDocumento1 paginaMembranesalkasbi952Nessuna valutazione finora

- CPA3 RO Element Spec SheetDocumento1 paginaCPA3 RO Element Spec SheetImran Ahmed KhanNessuna valutazione finora

- VONTRON LP21-4040T RO Element IntroductionDocumento2 pagineVONTRON LP21-4040T RO Element Introductionsukiraj RasalingamNessuna valutazione finora

- Data Sheet: LG BW 400 EsDocumento1 paginaData Sheet: LG BW 400 EsZi Wei LeongNessuna valutazione finora

- LG Chem LG BW 4040 ES L PDFDocumento1 paginaLG Chem LG BW 4040 ES L PDFhonoviw115Nessuna valutazione finora

- Membrane Element SWC3+: PerformanceDocumento1 paginaMembrane Element SWC3+: PerformanceAshraf BayomiNessuna valutazione finora

- E2 Series 60 HZ: Reverse Osmosis Machine 375 To 2535 Gallons Per DayDocumento2 pagineE2 Series 60 HZ: Reverse Osmosis Machine 375 To 2535 Gallons Per Dayjohn_paisNessuna valutazione finora

- Water Quality & Conditioning ProductsDocumento2 pagineWater Quality & Conditioning Productsjohn_paisNessuna valutazione finora

- Water Specialist 2.0 Motorized Alternating ValveDocumento2 pagineWater Specialist 2.0 Motorized Alternating Valvejohn_paisNessuna valutazione finora

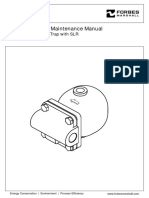

- I&M SOFT31-O - Single Orifice Float Trap With SLRDocumento16 pagineI&M SOFT31-O - Single Orifice Float Trap With SLRjohn_paisNessuna valutazione finora

- SanRO HS PDFDocumento1 paginaSanRO HS PDFjohn_paisNessuna valutazione finora

- Industry FilterDocumento0 pagineIndustry Filterjohn_paisNessuna valutazione finora

- GFSDMEDocumento12 pagineGFSDMEjohn_paisNessuna valutazione finora

- 2130 TURBIDITY : 1. Sources and SignificanceDocumento4 pagine2130 TURBIDITY : 1. Sources and SignificanceNguyen Hien Duc HienNessuna valutazione finora

- 2013 Rubinos D.A. Environ. Sci. Pollut. Res. Fractionation and Mobility of Metals in Bauxite Red Mud Journal Volume 1 16Documento17 pagine2013 Rubinos D.A. Environ. Sci. Pollut. Res. Fractionation and Mobility of Metals in Bauxite Red Mud Journal Volume 1 16Ayashkant sahooNessuna valutazione finora

- How Do Sails WorkDocumento13 pagineHow Do Sails WorkStephen J Chandler100% (1)

- 9zero Liquid Discharge Plant - Multiple Effect Evaporator-Khatav PDFDocumento29 pagine9zero Liquid Discharge Plant - Multiple Effect Evaporator-Khatav PDFहरिओम हरी100% (2)

- CHP 2b Water ReticulationDocumento26 pagineCHP 2b Water ReticulationMuhammad AmirNessuna valutazione finora

- CE405-EE-I MOD.3 - ProblemsDocumento37 pagineCE405-EE-I MOD.3 - ProblemsShanihaKK100% (2)

- Dairy Wastewater Treatment MethodsDocumento20 pagineDairy Wastewater Treatment MethodsRASHEED YUSUFNessuna valutazione finora

- Smeg Manual GW1060Documento44 pagineSmeg Manual GW1060shtempelNessuna valutazione finora

- Fosroc Chemical Breaker PDFDocumento2 pagineFosroc Chemical Breaker PDFrkvaitlaNessuna valutazione finora

- Architecture Civil Engineering 2014Documento44 pagineArchitecture Civil Engineering 2014Nicholas ThompsonNessuna valutazione finora

- Powerpoint 101Documento9 paginePowerpoint 101Shyra Dela CruzNessuna valutazione finora

- Aircraft Hangar Construction StandardsDocumento6 pagineAircraft Hangar Construction StandardsShara Mae de MesaNessuna valutazione finora

- NM Hydrology ManualDocumento157 pagineNM Hydrology ManualOktayNessuna valutazione finora

- Alfalfa CultivationDocumento4 pagineAlfalfa CultivationEdwin Jose SNessuna valutazione finora

- Acknowledgement and Abstract of a Textile Industry Effluent Treatment ProjectDocumento2 pagineAcknowledgement and Abstract of a Textile Industry Effluent Treatment ProjectAkram aliNessuna valutazione finora

- Remove Oil Grease Water 40Documento6 pagineRemove Oil Grease Water 40Sai PrasathNessuna valutazione finora

- So2 Emission Control and Finding A Way Out To Produce Sulphuric Acidfrom Industrial So2 Emission 2157 7048 1000230Documento7 pagineSo2 Emission Control and Finding A Way Out To Produce Sulphuric Acidfrom Industrial So2 Emission 2157 7048 1000230Bernie_Garcia__9886Nessuna valutazione finora

- FAO Training Manual PDFDocumento235 pagineFAO Training Manual PDFByakatonda JimmyNessuna valutazione finora

- Report On Sundarban Mangrove ForestDocumento44 pagineReport On Sundarban Mangrove ForestTAREQ AL HOSSAINNessuna valutazione finora

- MiniVecLoader50 MiniVecLoaderDocumento2 pagineMiniVecLoader50 MiniVecLoaderr_anzarNessuna valutazione finora

- MSDS Paprica OleoresinDocumento7 pagineMSDS Paprica OleoresinIndra triganesaNessuna valutazione finora

- Guidelines in The Evaluation of Comprehensive Land Use PlanDocumento8 pagineGuidelines in The Evaluation of Comprehensive Land Use PlanPa Rian Rho DoraNessuna valutazione finora

- 5b. STP Weekly Log BookDocumento1 pagina5b. STP Weekly Log BookNISHANTH GANESHNessuna valutazione finora

- "Triplex Diaphragm" 3426 / 3526 / 3626 SERIES Automatic Water System PumpDocumento4 pagine"Triplex Diaphragm" 3426 / 3526 / 3626 SERIES Automatic Water System PumpCinthia RojasNessuna valutazione finora

- HI8410 Hanna Manual Do ControladorDocumento20 pagineHI8410 Hanna Manual Do ControladoroumgueNessuna valutazione finora

- Storm Water Drainage ManualDocumento397 pagineStorm Water Drainage ManualAKASH FERAGNessuna valutazione finora

- Biodegradable Plastic Bottles Case StudyDocumento1 paginaBiodegradable Plastic Bottles Case StudyENSO Plastics, LLC100% (1)

- UNIFYING THEMES OF LIFEDocumento32 pagineUNIFYING THEMES OF LIFEZay SalazarNessuna valutazione finora

- HVAC RequirementsDocumento112 pagineHVAC Requirementsaruiloba99Nessuna valutazione finora

- Final PDFDocumento16 pagineFinal PDFpratiksha ghayalNessuna valutazione finora