Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Guardsman G and Guardsman L Series: Smith Meter Turbine Meters

Caricato da

Anonymous 1ykzuaxWgYTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Guardsman G and Guardsman L Series: Smith Meter Turbine Meters

Caricato da

Anonymous 1ykzuaxWgYCopyright:

Formati disponibili

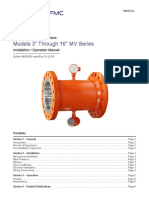

Smith Meter ® Turbine Meters

Guardsman G™ and

Guardsman L™ Series

Installation/Operation/Service

Issue/Rev. 0.7 (11/10) Bulletin MN02002

Installation and Service for:

• Guardsman (G) Series

• Guardsman L Ball Bearing (LB) Series

• Guardsman L Journal Bearing (LJ & LSJ) Series

Note: Meters shipped after September 1991 have the Catalog Code (formerly termed “Model Code”) on the

nameplate. Consult the respective specification bulletin or the factory for code descriptions.

Contents

Section 1 – General....................................................................................................................................... Page 2

Introduction...................................................................................................................................................... Page 2

Receipt of Equipment...................................................................................................................................... Page 2

Pre-Installation Inspection............................................................................................................................... Page 2

Section 2 – Installation.................................................................................................................................. Page 3

Mechanical...................................................................................................................................................... Page 3

Electrical.......................................................................................................................................................... Page 4

Section 3 – Repair Guide.............................................................................................................................. Page 6

Section 4 – Operation.................................................................................................................................. Page 10

Section 5 – Troubleshooting Guide............................................................................................................ Page 11

Section 6 – Related Publications............................................................................................................... Page 12

The Most Trusted Name In Measurement

Section 1 — General

Introduction Receipt of Equipment

The Smith Meter® Guardsman™ and Guardsman L™ When the equipment is received, the outside packing

Series Turbine Meters are volumetric flow measuring case should be checked immediately for any shipping

transducers with a frequency output that is directly damage. If the packing case has been damaged, the

proportional to flow rate. local carrier should be notified at once regarding his

The turbine meter consists of a rotor which senses the liability. Carefully remove the unit from its packing case

linear velocity of a flow stream. The moving liquid imparts and inspect for damaged or missing parts.

a rotation velocity to the rotor which is detected electri- If damage has occurred during shipment or parts are

cally by a variable reluctance-type pickup coil. As the missing, a written report should be submitted to the

equally-spaced, ferromagnetic rotor blades pass through Customer Service Department, FMC Technologies Mea-

the magnetic field created by the pickup coil, a sinusoi- surement Solutions, Inc., Erie, Pennsylvania 16514-0428.

dal voltage is generated. The peak-to-peak voltage of Prior to installation, the unit should be stored in its

this signal is directly proportional to the rotor speed and original packing case and protected from adverse weather

each positive peak-to-peak voltage pulse represents an conditions and abuse.

increment of volume throughput.

The output per unit volume is termed K-Factor (pulses/

unit volume). For a specific meter, the K-Factor, as Pre-Installation Inspection

determined through a factory performance test, is listed

on a “Turbine Meter Test Data Card” which is supplied Visually inspect the meter and meter nameplate to

with the meter. For maximum accuracy, the actual ensure the proper size, model number, flange rating,

K-Factor must be established for a given product from and flow range. Note the direction of flow (described by

on-site proving at the actual operating conditions. an arrow) in which the unit was calibrated and should

be installed.

The Smith Meter Guardsman and Guardsman L Series

Turbine Meters are precise measuring instruments and

should be treated as such. Install carefully.

2 • MN02002 Issue/Rev. 0.7 (11/10)

Section 2 – Installation

Mechanical Installation To Swing-Joint

Loading Arm

Warning: Care must be taken in the installation of

turbine meters. The installer must comply with all

national, regional, and local codes. Block

Valve

It is recommended that turbine meters be installed in the 5 Dia.

section of piping where the pressure is highest, down- Straightening

To Swing-Joint

Section

stream from pumps and upstream from valves (see figure Loading Arm

3). When it is expected that flow will be intermittent, the

Turbine

turbine meter should not be mounted at or near a low Meter Meter

Block

point in the piping. Solids or water which settle in a low 10 Dia.

Run

Valve

point can freeze or damage the metering element. Straightener

The piping arrangements herein described are intended Strate

Plate

Turbine

Meter

to be general recommendations and, therefore, may

require modification top fit your specific applications. Flow

Block Block

Valve

Back-Pressure Strainer

Reducer as

Required

Valve

Strainer

Reducer as

Required

A positive back-pressure is required to prevent cavitation

and inaccurate output. Recommended back-pressure Figure 2 – Typical Guardsman L Series Turbine Meter

= 2 x pressure drop + 1.25 x absolute vapor pressure. Installation (Vertical or Horizontal, Conventional and Strate

(Reference Section 5 – Appendix, Pressure Drop Chart.) Plate Flow Conditioners)

Example: 3" turbine meter, flow rate 600 gpm, vapor

pressure 10 psia. Flow Conditioning

Back-pressure = 2 x 3 + 1.25 x 10 = 18.5 psig. The standard rule of 20 to 25 pipe diameters upstream

of the meter (where a flow straightener is not used)

Strainer and 5 pipe diameters downstream of the meter may be

A strainer should be installed to protect the flow meter adequate for some installations. However, variables of

and extend service life. For most installations, a 20- or viscosity, pipe size, and upstream configuration (fittings)

40-mesh screen is suitable. should be considered. Therefore, reference should be

made to the API Manual of Petroleum Measurement

WARNING! Standards, Chapter 5, Section 3 – Turbine Meters.

Thermal Pressure

Thermal expansion of liquid in this equipment can

cause high pressure damage. A Thermal Pressure

Relief Valve may be necessary in the system.

Reduced as Flow Straightener

Block Valve

Required (Tube Bundle)

Strainer Meter Run Proving

Connections

10 Pipe

as Required

Diameters or

20-25 5

Pipe Diameters* Pipe

Diameters

Flow

Block Turbine Block and

Valves Meter Bleed Valve

Block and

Bleed Valve Indicates Smith-Supplied

Upstream Straightening Downstream Straightening Equipment

Section Section

* 10 pipe diameters with tube bundle or 20-25 pipe diameters without tube bundle.

Figure 1 – Typical Guardsman Series Turbine Meter Installation (Horizontal Only)

Issue/Rev. 0.7 (11/10) MN02002 • 3

Section 2 – Installation (continued)

Strate Plate Electrical Installation

When a Strate Plate is supplied with a meter, it is matched

marked at the factory. When installing the Strate Plate, the Turbine meters are supplied with a signal pickup coil mounted

arrows on the housing and the Strate Plate should be aligned. in an explosion-proof housing attached to the meter. Where the

For cases where the Strate Plate is not matched marked transmission distance from the meter to an electronic readout

(field retrofits), the Strate Plate should be installed so that is less than 2,000 feet (609.6m), no special amplification is

holes forming a straight line are aligned with the number required if Smith electronic readout is less than 2,000 feet

1 boss. (609.6m), no special amplification is required if Smith elec-

Note: The strate plate has a cutout on the bottom of the plate to align

tronic instruments having "Common Mode Rejection" are

with the number 1 pick-up boss. employed. The signal input, direct from the pickup coil,

enters the readout device through a common mode

noise rejection circuit. The circuit is sensitive to low-level

meter signals, but highly insensitive to unwanted noise

interference.

In cases where the signal transmission distance is greater than

2,000 feet (609.6m) and Smith instruments are being used,

or if the receiving instruments accept only pulse inputs, then a

preamplifier (Model PA-6) is recommended.

The PA-6 Preamplifier is designed to fit in the standard

explosion-proof coil housing as shown in Figures 4 through 7.

When using the Turbine Meter Preamplifier, Model PA-6, refer

to the Preamplifier Specification Bulletin.

Recommended Signal Transmission Cable

Distance Wire Size Type Cable (or Equal)

Figure 3 – Strate Plate for the Guardsman LJ (Vertical and 2 Conductor - Belden 8762

Horizontal) Turbine Meter Up to 2,000 ft

#20 AWG 3 Conductor - Belden 8772

(610 metres)

4 Conductor - Alpha 2414

2 Conductor - Belden 8760

Up to 3,000 ft

#18 AWG 3 Conductor - Belden 8770

(915 metres)

4 Conductor - Alpha 2424

2 Conductor - Belden 8719

Up to 5,000 ft

#16 AWG 3 Conductor - Belden 8618

(1,525 metres)

4 Conductor - Alpha 3248

Note: For distances greater than 5,000 ft, a trial run should be made

employing the best available engineering techniques.

Important: All cable shields must be terminated only at

the instruments.

Electrical Installations (General)

The maximum ambient temperature for the GP Junction

box w/PA-x amplifier and or UPCC/ID-2000 instrument is

Figure 3A – Strate Plate for the Guardsman LSJ (Vertical and 70°C; if the process temperature of the Turbine meter is

Horizontal) Turbine Meter expected to exceed this value then the enclosure(s) shall

be remotely mounted to guarantee the 70°C ambient is

not exceeded.

Note: For meters manufacutured prior to October, 2002 the strate plate

has two (2) mounting screws on the outer diameter of the plate.

For meters manufactured after October, 2002 the strate plate has Note: Electrical installations should only be performed by qualified

one (1) mounting screw located in the middle of the strate plate. technicians / electricians that are trained in the techniques that apply

to hazardous locations electrical equipment.

Meter Bypass

Where possible, such as in a new system, it is advisable Caution: To prevent ignition of hazardous atmospheres,

to include a valved bypass around the metering section. disconnect from supply circuit before opening, keep

This allows inspection of the meter without stopping the enclosure tightly closed when circuits are in operation.

system flow. The bypass connections, however, should Warning: Enclosure may contain batteries and or capaci-

not be placed within the “meter run” (see Figure 1). tors, to prevent ignition of hazardous atmospheres, do not

open unless area is known to be non-hazardous.

4 • MN02002 Issue/Rev. 0.7 (11/10)

Section 2 – Installation (continued)

Electrical Installations Utilizing ATEX and IEC Ex Electrical Connections

Certifications Due to the variety of electronic totalizers used with

All electrical installations shall be in accordance with EN/ turbine meters, only general information is provided

IEC 60079-14 “Explosive atmospheres – Part 14: Electri- in this manual. The installation manual for a particular

cal installations design, selection and erection” totalizer should be consulted.

Cable entry must be in accordance to EN/IEC 60079-1 Refer to Figures 4 through 7 for suggested wiring for

section 13. “Explosive atmospheres – Part 1: Equipment pickup coil and preamplifier.

protection by flameproof enclosures "d" When installing conduit, a union should be installed for

For systems utilizing cable glands, the gland and or ease of meter removal for servicing.

thread adaptor must be Ex certified. The cable end must

be securely installed and depending on the cable type be Coil Use 2-Conductor

properly protected from mechanical damage. Housing Shielded Cable

For systems utilizing conduit, an Ex certified sealing

device must be used immediately at the entrance of the

enclosure. Any unused entry must be suitably blocked

with an Ex certified plug.

Installations Following North American Electrical

Codes Union

All electrical installations shall be in accordance with ap-

propriate electrical codes or with the rules provided by Figure 4 – 1 Coil - No Preamplifier

the regulatory authority having jurisdiction.

USA – NEC code, NFPA 70 Articles 500 – 515 as appropriate

Canada – CEC Code, CSA 22.1 as appropriate

Issue/Rev. 0.7 (11/10) MN02002 • 5

Section 3 – Repair Guide

Use 3-Conductor

Coil Shielded Cable

Housing

1 2 3 4 5

10 9 8 7 6

1 - Logic Common

Signal Output

2 - X 0.5 Out

Union 3 - X1 Out

4 - X2 Out

5 - 8-29 Vdc

Figure 8 – Pickup Coil Removal

Figure 5 – 1 Coil and 1 PA-6 Preamplifier

Unscrew the pickup coil and lift it out (see Figure 8).

Use an ohmmeter to check the resistance of the coil

Coil Housing Use 4-Conductor (1,200 Ω). Also check the resistance between one lead

Typical (3) Shielded Cable of the coil and the metal coil housing. This resistance

should be greater than 20 kΩ. If not, replace the pickup

coil.

Pickup Coil

Inductance: 400 mH, maximum at 1 kHz.

DC Coil Resistance: 1,200 Ω.

Junction

Box

Temperature Range: -40°F TO 225°F (-73°C to 107°C).

Union

Should it be suspected that the preamplifier is not

functioning properly, remove it from the conduit box. Its

Figure 6 – 2 Coils - No Preamplifier output should be checked in accordance with the output

signal shown under specifications in the “Turbine Meter

Preamplifier Installation Guide.”

Use 4-Conductor

Coil Housing Shielded Cable Internal Parts Removal and Disassembly Procedure

Typical (3)

Use a screwdriver to pry the end of the stator retainer

6 7 8 9 10 1 2 3 4 5 ring up and out (see Figure 9). Once the end of the

5 4 3 2 1 10 9 8 7 6

retainer ring is clear of its slot, pull it until the entire ring

is clear of the turbine meter housing.

*1 - Logic Common

Some Guardsman and Guardsman L Series Meters

Signal Output have a slotted stator fin with an Allen head set screw.

2 - X 0.5 Out

Union 3 - X1 Out The set screw must be loosened before the internal parts

4 - X2 Out Junction assembly can be removed.

5 - 8-29 Vdc Box

Remove the internal parts assembly.

*Common for both preamps.

Figure 7 – 2 Coils and 2 PA-6 Preamplifiers

The Smith Meter ® Turbine Meter is field-serviceable. How-

ever, being a precision instrument, this manual must be

followed to ensure that proper repair procedures are used.

Pickup Coil Removal

Important: Disconnect all electrical power.

Unscrew the cover from the conduit box and disconnect

all cable leads. Easier access to the pickup coil occurs

when the conduit box is completely removed. When

using the turbine meter Preamplifier Model PA-6, refer to

“Turbine Meter Preamplifier Installation Guide.” Figure 9 – Retainer Ring Removal

6 • MN02002 Issue/Rev. 0.7 (11/10)

Section 3 – Repair Guide (continued)

Figure 10 – Guardsman L & LB (1-1/2" and 2") Turbine Meter Internals

After

October

2002

Figure 11 – Guardsman and Guardsman J Series (2", 3" & 4") Turbine Meter Internals

Prior to

October 2002

After

October 2002

After

October 2002

Figure 11A – Guardsman LSJ Series Horizontal and Vertical (3" & 4") Turbine Meter Internals

Issue/Rev. 0.7 (11/10) MN02002 • 7

Section 3 – Repair Guide (continued)

Remove the cotter pin and castle nut (old style) or the selection of the tool and fixture to ensure a “straight

lock hex nut (new style) from the downstream end of line” or axial press only. Push the bearing out with

the shaft. The remaining components (see Figures 10 a smooth, steady motion.

and 11) will be free to slide off the shaft.

Ball Bearing Replacement –

Guardsman LB Series Only

For Guardsman LB Series Turbine Meters, flanged

ball bearings are used. To replace the ball bearings as

they become worn, the following procedure should be

followed:

Slide the downstream cone onto the shaft with the bear-

ing inner race support first (see Figure 12). Next slide

the ball bearing, flanged-side first, onto the shaft. Center

Figure 13 – Tungsten Carbide Rotor Bearing Removal

B. The new bearing may be installed with the same

equipment used to remove the old bearing. Press

the chamfered end of the bearing into the hub first.

Center the hub bore before pressing. The bearing

material has been selected for its hardness and

wear characteristics, but may be chipped or broken

if mistreated. Press the bearing into the rotor hub to

Figure 12 achieve equal protrusion from both faces.

Clean bearing surfaces and lubricate with light ma-

the upstream-side of the rotor (marked “IN”) on the bear- chine oil. Guide the rotor onto the platform bearing

ing. Use the downstream cone to guide the rotor onto and check for freedom of rotation.

the bearing as shown (push evenly across the cone).

Remove the downstream cone from the shaft and place Internal Parts Reassembly Procedure –

the inner race spacer on the shaft followed by the ball Guardsman and Guardsman L Series

bearing with the flanged-side last. As was done for the Reassembly is accomplished by reversing the order

upstream bearing, use the downstream cone to guide of the disassembly steps. The retaining nut should be

the bearing into the rotor hub. Carefully remove the ro- properly tightened and where used (3" and 4"), secured

tor and bearings from the shaft and place the upstream with the cotter pin (old style). See Table 1 for proper

cone in the proper orientation. Next install the rotor onto torque values.

the shaft with the “IN” side first. Install the downstream

cone and the lock hex nut or castle nut (old style). Torque Table 1 – Retaining Nut Torque Values

the nut to the value given in Table 1. If meter is old style Meter Meter Thread Torque Required

(prior to 1997), install the cotter pin to ensure the nut Size Series Size (Lubricated)

does not loosen (1.5" and 2" Guardsman L Meters do 1.5" Guardsman 2-56 UNC-2 29-33 in-oz

not have cotter keys). 1.5" Guardsman L 2-56 UNC-2 29-33 in-oz

Rotor Bearing Replacement – 2" Guardsman 6-32 UNC-2 7-9 in-lb

Guardsman and Guardsman LJ Series Only 2" Guardsman L 6-32 UNC-2 70-79 in-oz

Should the tungsten carbide bearing in the rotor ever 3", 4" Guardsman 10-32 UNF-2 24-28 in-lb

require replacing, it is recommended that the rotor

3", 4" Guardsman L 10-32 UNF-2 24-28 in-lb

assembly be returned to the factory. If it becomes

necessary to replace the rotor bearing in the field, the hese torque values will be approximated by tightening the nut an

T

following repair procedure should be followed: additional 1/4 turn (60 to 70 degrees) after all the parts have been

put together “snug” tight.

A. With the proper tool and fixture (see Figure 13),

To be sure that the stator shaft nut is locked securely

the old rotor bearing may be forced out of the rotor

in place on 0.75" and 1" models, apply Loctite “Thread

hub with an arbor press. Care must be taken in the

Locker” 242 adhesive/sealant. Application must be

8 • MN02002 Issue/Rev. 0.7 (11/10)

Section 3 – Repair Guide (continued)

made to clean parts: Loctite primer is optional. Use ex- After reassembly, the meter internal parts assembly can

tra care to prevent Loctite from entering moving parts, be inserted in the upstream-side of the turbine meter

such as journal and rotor bearings. Allow the parts to housing. Make certain that the slotted stator fin is in-

set undisturbed for twenty minutes to allow full curing serted between the two rotational stops (see Figure 14).

of the Loctite. This will prevent any rotational movement of the stator

during product flow.

For meters with slotted stator fins, after inserting the

internal parts assembly, the set screw is adjusted so

that there is no free play.

If the meter is equipped with a strate plate reinsert the

strate plate with screw(s). Loctite "Thread Locker" 242

should be used to prevent loosening.

Reinsert the stator retainer ring into the slot provided at

the upstream-end of the meter housing. Make certain

the retainer ring is seated correctly. Any protruding edge

may alter the product flow profile, which can affect meter

performance.

Figure 14 – Stator Rotational Stops

Issue/Rev. 0.7 (11/10) MN02002 • 9

Section 4 – Operation

Typical Hook-Up If, during the proving, suitable repeatability of runs is not

obtained and the prover is functioning properly, verify

The signal leads are connected to the meter coil at that the pickup coil is tightly in place and that there is no

one end and the appropriate readout device at the electrical “noise” on the pulse circuit. If proper repeat-

other, Figure 15. The shielding is connected to the ability continues, check for adequate back pressure as

instrument ground only, not at the meter and not described in Section 2.

to any earth ground. Because neither signal lead is It may be necessary to remove the meter and inspect

grounded there is no polarity and, hence, either signal it for damage to the rotor, thrust bearings, or platform

lead may be connected to either coil terminal. bearing.

Shield Not Signal Input Maintenance

Connected

} Maintenance is normally required when proving shows

a dramatic shift in the K-Factor or suitable repeatability

cannot be obtained.

Turbine Shield Connected

Meter to Instrument Ground In some cases, the internals may have to be cleaned

Electronic Totalizer of buildup or deposits. Always check that the ports on

the stator fins are free and clean of any debris. When

draining the turbine meter installation for inspection, the

Figure 15 line should be opened downstream of the meter so that

fine debris that may be attached to the leading edges

Proving of the blades remains affixed. Draining from upstream

creates a backflow that may remove this debris.

Once the meter has been installed into the line, it should Notes:

be proved. This is normally accomplished using a 1. When a meter is removed from the line, particularly if it has been

disassembled and reassembled, it should be recalibrated for opti-

displacement type prover of cer tified volume. mum accuracy.

Recommended procedures are covered in the API 2. These products have been designed for petroleum applications,

Manual of Petroleum Measurement Standards, Chapters where corrosion/erosion is normally minimum. The design has

adequate material allowance for typical petroleum applications.

4 and 12. It is very important that the proving be done Consult the factory for other applications or for the actual material

under conditions (flow rate, pressure, temperature, and allowances.

liquid characteristics) that are as close to those of normal

operation as possible.

Verify that there are no leaks (internal or external) and

that all liquid going into the prover has passed through

the meter.

10 • MN02002 Issue/Rev. 0.7 (11/10)

Section 5 – Troubleshooting Guide

For maximum accuracy, the meter must be recalibrated after each repair.

Problem Probable Cause Corrective Action

Overdelivery Dirty or fouled bearings. Clean.

(or under registration)

Corrosion, erosion. Minor: Reprove meter. Extreme: Replace damaged parts.

Bent blades. Replace rotor.

Missing rotor blade. Replace rotor.

Underdelivery Deposits (wax, for example). Clean.

(or over registration)

Clogging of tube bundles. Remove and clean.

Bent blades Replace rotor.

Cavitation. Higher back-pressure.

Entrained air or gas. Eliminate source or add air eliminator.

Noise or transmission line. Add or check shielded cable.

Eliminate source.

Check that shield is grounded at

instrument end only.

Decrease sensitivity on instrument

front end.

Add suppression circuit to preamplifier.

Non-Repeatability Dirty bearings. Clean.

Missing blade. Replace rotor.

Electrical noise interference. See “Underdelivery.”

Meter Factor Shift Refer to Probable Cause of Overde- Refer to action to be taken for overdelivery and

livery, Underdelivery. underdelivery.

Output Without Flow Noise. See “Underdelivery.”

Line vibration transmission through Eliminate source of vibration.

pickup coil. With pickup coil only, desensitize coil by inserting a non-ferrous

spacer(s) (0.030" increments) in pickup coil boss. With preamp,

refer to preamplifier bulletin to desensitize.

Issue/Rev. 0.7 (11/10) MN02002 • 11

Revisions included in MN02002 Issue/Rev. 0.7 (11/10):

Electrical Installations (General) and installation utilizing ATEX and IEC Ex certifications added.

The specifications contained herein are subject to change without notice and any user of said specifications should verify from the manufacturer that the specifications are currently

in effect. Otherwise, the manufacturer assumes no responsibility for the use of specifications which may have been changed and are no longer in effect.

Contact information is subject to change. For the most current contact information, visit our website at www.fmctechnologies.com/measurementsolutions and click on the

“Contact Us” link in the left-hand column.

Headquarters:

500 North Sam Houston Parkway West, Suite 100, Houston, TX 77067 USA, Phone: +1 (281) 260 2190, Fax: +1 (281) 260 2191

Measurement Products and Equipment: Integrated Measurement Systems:

Erie, PA USA +1 (814) 898 5000 Dubai, United Arab Emirates +971 (4) 883 0303 Corpus Christi, TX USA +1 (361) 289 3400

Ellerbek, Germany +49 (4101) 3040 Los Angeles, CA USA +1 (310) 328 1236 Kongsberg, Norway +47 (32) 286700

Barcelona, Spain +34 (93) 201 0989 Melbourne, Australia +61 (3) 9807 2818 Dubai, United Arab Emirates +971 (4) 883 0303

Beijing, China +86 (10) 6500 2251 Moscow, Russia +7 (495) 5648705

Buenos Aires, Argentina +54 (11) 4312 4736 Singapore, +65 6861 3011

Burnham, England +44 (1628) 603205 Thetford, England +44 (1842) 822900

Visit our website at www.fmctechnologies.com/measurementsolutions

Printed

12 in U.S.A. © 11/10 FMC Technologies Measurement Solutions, Inc. All rights reserved. MN02002 Issue/Rev. 0.7 (11/10)

• MN02002 Issue/Rev. 0.7 (11/10)

Potrebbero piacerti anche

- MN 02009Documento6 pagineMN 02009Ahmad Delfhin AnantaNessuna valutazione finora

- AAliant Target Meter IOM PDFDocumento24 pagineAAliant Target Meter IOM PDFza3am100% (1)

- gdm-5410 Sun Chassis g1 PDFDocumento63 paginegdm-5410 Sun Chassis g1 PDFbarrilonNessuna valutazione finora

- Nuflo Turbine Meter Manual PDFDocumento16 pagineNuflo Turbine Meter Manual PDFfatsfinderNessuna valutazione finora

- Model Mx25 1'' Oval Gear Flowmeter: Instruction ManualDocumento20 pagineModel Mx25 1'' Oval Gear Flowmeter: Instruction ManualRómulo Zevallos GutiérrezNessuna valutazione finora

- Factory Alarm Tvss - IvdDocumento39 pagineFactory Alarm Tvss - IvdRohn J JacksonNessuna valutazione finora

- Rohr, Inc.: CHULA VOSTA GALIFORNIA 91910-2098 (B19) 891-4111 ' TELEX: 89-5038Documento13 pagineRohr, Inc.: CHULA VOSTA GALIFORNIA 91910-2098 (B19) 891-4111 ' TELEX: 89-5038jordiNessuna valutazione finora

- Flow Transmitter (SIEMENS) PDFDocumento10 pagineFlow Transmitter (SIEMENS) PDFjuliunNessuna valutazione finora

- Plasma TV: Service ManualDocumento38 paginePlasma TV: Service ManualRafael GarridoNessuna valutazione finora

- G Series Industrial and Chemical Owners ManualDocumento20 pagineG Series Industrial and Chemical Owners ManualbayuNessuna valutazione finora

- Transmission Pressures - Test (SENR9159-10)Documento3 pagineTransmission Pressures - Test (SENR9159-10)Anderson Oliveira SilvaNessuna valutazione finora

- Plasma TV: Service ManualDocumento36 paginePlasma TV: Service ManualAnnon201Nessuna valutazione finora

- Recommended Procedure For Cutting Brake Chamber Push-Rod: Service BulletinDocumento2 pagineRecommended Procedure For Cutting Brake Chamber Push-Rod: Service BulletinFernando PadillaNessuna valutazione finora

- Toshiba 42wh18 - 50wh18 c01pDocumento107 pagineToshiba 42wh18 - 50wh18 c01pΓιωργοςNessuna valutazione finora

- Series LFM In-Line and Panel Mount Flowmeter: Specifications - Installation and Operating InstructionsDocumento2 pagineSeries LFM In-Line and Panel Mount Flowmeter: Specifications - Installation and Operating InstructionsKarasu LakeNessuna valutazione finora

- IM200-20 (LC Mag Insertion) PDFDocumento8 pagineIM200-20 (LC Mag Insertion) PDFLazzarus Az GunawanNessuna valutazione finora

- SQM4 Synchro Models LiteratureDocumento29 pagineSQM4 Synchro Models LiteratureĐất RồngNessuna valutazione finora

- Service Manual: 13VT-N100 13VT-N150 13VT-CN10Documento90 pagineService Manual: 13VT-N100 13VT-N150 13VT-CN10Isidro CamposNessuna valutazione finora

- Mark V Target Strain Gage Flowmeter Installation, Operation and Maintenance ManualDocumento24 pagineMark V Target Strain Gage Flowmeter Installation, Operation and Maintenance Manualابزار دقیقNessuna valutazione finora

- IM Rime 4000 CompleteDocumento37 pagineIM Rime 4000 CompleteVivi Puspita SariNessuna valutazione finora

- Sony GDM-F500 F500T9 N3P Revised @Documento60 pagineSony GDM-F500 F500T9 N3P Revised @StefanNessuna valutazione finora

- Dart Valves - Operating & MaintenanceDocumento6 pagineDart Valves - Operating & MaintenanceGenard Sabenacio GarciaNessuna valutazione finora

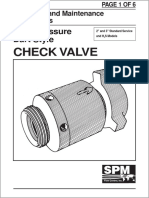

- Check Valve: High Pressure Dart StyleDocumento6 pagineCheck Valve: High Pressure Dart StyleGenard Sabenacio GarciaNessuna valutazione finora

- Engine Removal and InstallationDocumento8 pagineEngine Removal and InstallationEj GonzalezNessuna valutazione finora

- MN 01034Documento16 pagineMN 01034jose-fumeroNessuna valutazione finora

- Tyco Water Motor AlarmDocumento6 pagineTyco Water Motor AlarmhendrobamaNessuna valutazione finora

- R230 Manual Macfarlane GeneratorsDocumento7 pagineR230 Manual Macfarlane Generatorsshutter1001Nessuna valutazione finora

- Installation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"Documento2 pagineInstallation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"heartofdixieNessuna valutazione finora

- Color Television: Service ManualDocumento59 pagineColor Television: Service Manuala1electronicsNessuna valutazione finora

- Plasma TV: Service ManualDocumento39 paginePlasma TV: Service ManualAdriano OliveiraNessuna valutazione finora

- 42lc2rr PDFDocumento49 pagine42lc2rr PDFHanif Rathore PrinceNessuna valutazione finora

- INVERTERvacon NXSPIN-07Documento24 pagineINVERTERvacon NXSPIN-07Mohd Abu AjajNessuna valutazione finora

- Armored Purgemeter: Instruction Bulletin D184B003U33 Rev. 01 / 01.2001Documento20 pagineArmored Purgemeter: Instruction Bulletin D184B003U33 Rev. 01 / 01.2001HUNGNessuna valutazione finora

- CVO Instruction ManualDocumento16 pagineCVO Instruction ManualJonathas KovaskiNessuna valutazione finora

- Warman Pumps: Assembly, Operating and Maintenance InstructionsDocumento19 pagineWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia RanaivoarimananaNessuna valutazione finora

- GDM 5403Documento59 pagineGDM 5403Flaviano SaccàNessuna valutazione finora

- 48T 6SI ManualDocumento82 pagine48T 6SI ManualGene Williams Jr.Nessuna valutazione finora

- Iom Biffi Morin Series A B C S en en Us 6089118Documento37 pagineIom Biffi Morin Series A B C S en en Us 6089118Anonymous Wu6FDjbNessuna valutazione finora

- Amd 230 TransmitterDocumento26 pagineAmd 230 TransmitterAgustantoNessuna valutazione finora

- Instruction Manual BR33 enDocumento20 pagineInstruction Manual BR33 enHimozaesNessuna valutazione finora

- Surge Arresters: MOV Storm Trapper Secondary Class Surge Arrester Installation InstructionsDocumento4 pagineSurge Arresters: MOV Storm Trapper Secondary Class Surge Arrester Installation InstructionscrcruzpNessuna valutazione finora

- Energy Losses in Bends and Fittings - F1-22Documento1 paginaEnergy Losses in Bends and Fittings - F1-22MohammadNessuna valutazione finora

- MN 02004Documento12 pagineMN 02004hyarub9Nessuna valutazione finora

- Sony Kdl-55w805a Chasis Rb1g Ver.1.0 Segm - MW RMDocumento28 pagineSony Kdl-55w805a Chasis Rb1g Ver.1.0 Segm - MW RMLuis Fernando AraujoNessuna valutazione finora

- AC 665-39005, 665-1180-038 - en (Main Boom Extension)Documento94 pagineAC 665-39005, 665-1180-038 - en (Main Boom Extension)arslanahmedkhawajaNessuna valutazione finora

- Frame and Underbody: Section 9NDocumento6 pagineFrame and Underbody: Section 9NJarry PotterNessuna valutazione finora

- Oversized 3/5/reverse & Underdrive Pressure Control Valve KitDocumento2 pagineOversized 3/5/reverse & Underdrive Pressure Control Valve KithidraulicNessuna valutazione finora

- Panasonic Service Manual g80Documento119 paginePanasonic Service Manual g80Vojtěch ProcházkaNessuna valutazione finora

- 1553-19 Automated Rotary Actuator - StockDocumento12 pagine1553-19 Automated Rotary Actuator - StockjmiselemNessuna valutazione finora

- Amb24 3 SDocumento5 pagineAmb24 3 SWagner OliveiraNessuna valutazione finora

- Lumix Dmcgm5kpDocumento62 pagineLumix Dmcgm5kpArif SriwidodoNessuna valutazione finora

- JFR Instruction Manual AVRDocumento28 pagineJFR Instruction Manual AVRSugar RayNessuna valutazione finora

- LG Ru-42pz61 42PZ71Documento43 pagineLG Ru-42pz61 42PZ71BElectric100% (1)

- CB-142 English Manual Mb-070102-1e-Cb&drwgDocumento31 pagineCB-142 English Manual Mb-070102-1e-Cb&drwgTaufiq Omar HasanNessuna valutazione finora

- Manual Varec Series 180 181 Double Port Regulator Varec en en 5197388Documento4 pagineManual Varec Series 180 181 Double Port Regulator Varec en en 5197388reneNessuna valutazione finora

- Section 26 - Oilgear PV Liquid MeterDocumento18 pagineSection 26 - Oilgear PV Liquid MeterhammamiNessuna valutazione finora

- D-357557 ManualDocumento65 pagineD-357557 ManualAnh NguyenNessuna valutazione finora

- Econominder Remote Reset Meters: 2750RM, 2850RM, 3100RM & 3900RMDocumento32 pagineEconominder Remote Reset Meters: 2750RM, 2850RM, 3100RM & 3900RMGreg ReynekeNessuna valutazione finora

- RCM - M1 Rev H (IOM) 8 PageDocumento8 pagineRCM - M1 Rev H (IOM) 8 PageRoger GimenesNessuna valutazione finora

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDa EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNessuna valutazione finora

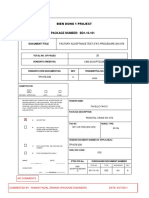

- 4 - Drawing &datasheet 20-10kDocumento131 pagine4 - Drawing &datasheet 20-10kAnonymous 1ykzuaxWgYNessuna valutazione finora

- 4 Year MaintenanceDocumento4 pagine4 Year MaintenanceAnonymous 1ykzuaxWgYNessuna valutazione finora

- FWD Favco Crane Boom Drawings Data SheetsDocumento27 pagineFWD Favco Crane Boom Drawings Data SheetsAnonymous 1ykzuaxWgYNessuna valutazione finora

- 6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Documento256 pagine6 10K Favco Operating Maintenance Parts Manual Book 1 of 3Anonymous 1ykzuaxWgY100% (1)

- Crane Inspection Checklist MigasDocumento7 pagineCrane Inspection Checklist MigasAnonymous 1ykzuaxWgYNessuna valutazione finora

- PC1000 Favco Other CraneDocumento1.449 paginePC1000 Favco Other CraneAnonymous 1ykzuaxWgY100% (2)

- SLI ManualDocumento142 pagineSLI ManualAnonymous 1ykzuaxWgY100% (1)

- Mpmy-El-Spc-1005 - 2.0-Specification For Electrical Power, Control and Earthing CablesDocumento24 pagineMpmy-El-Spc-1005 - 2.0-Specification For Electrical Power, Control and Earthing CablesAnonymous 1ykzuaxWgYNessuna valutazione finora

- 3 - Function SystemDocumento70 pagine3 - Function SystemAnonymous 1ykzuaxWgYNessuna valutazione finora

- Q22-Fat Procedure SN 1676 Mt1-Cr-7350 - BDocumento29 pagineQ22-Fat Procedure SN 1676 Mt1-Cr-7350 - BAnonymous 1ykzuaxWgYNessuna valutazione finora

- 6 - Torque Test, MPIDocumento63 pagine6 - Torque Test, MPIAnonymous 1ykzuaxWgYNessuna valutazione finora

- QA QC ReferDocumento26 pagineQA QC ReferAnonymous 1ykzuaxWgYNessuna valutazione finora

- Mpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureDocumento21 pagineMpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureAnonymous 1ykzuaxWgYNessuna valutazione finora

- Mpmy PM PRC 0001 - 2.0 Document Numbering ProcedureDocumento18 pagineMpmy PM PRC 0001 - 2.0 Document Numbering ProcedureAnonymous 1ykzuaxWgYNessuna valutazione finora

- Q & A About SUEZ Membrane Element StorageDocumento2 pagineQ & A About SUEZ Membrane Element StorageAnonymous 1ykzuaxWgYNessuna valutazione finora

- Is Iso 10474 1991Documento12 pagineIs Iso 10474 1991Anonymous 1ykzuaxWgY100% (2)

- Astm G48Documento11 pagineAstm G48thedreampower100% (4)

- BS en Iso 11114-1 1998Documento50 pagineBS en Iso 11114-1 1998Anonymous 1ykzuaxWgYNessuna valutazione finora

- MOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsDocumento20 pagineMOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsAnonymous 1ykzuaxWgYNessuna valutazione finora

- MOM-MUR-10-PC-SP-0001!00!1 Process Piping Fabricaton, Inspection and Testing SpecificationDocumento52 pagineMOM-MUR-10-PC-SP-0001!00!1 Process Piping Fabricaton, Inspection and Testing SpecificationAnonymous 1ykzuaxWgY100% (1)

- Astm d2022Documento107 pagineAstm d2022Anonymous 1ykzuaxWgYNessuna valutazione finora

- MOM SK311 91 IC SP 0010-00-0 - SAPA Spec For Package Equipment InstrumentationDocumento171 pagineMOM SK311 91 IC SP 0010-00-0 - SAPA Spec For Package Equipment InstrumentationAnonymous 1ykzuaxWgYNessuna valutazione finora

- The Ultimate Bass Guide PDFDocumento164 pagineThe Ultimate Bass Guide PDFPauloValverdeSobarzo85% (20)

- S2 StudioDocumento1 paginaS2 StudioΟρεστης ΝαλμπαντηςNessuna valutazione finora

- Wireless Receiver - Sennheiser EW100G2 Product SheetDocumento50 pagineWireless Receiver - Sennheiser EW100G2 Product SheetCory LeggNessuna valutazione finora

- Electronic Systems in Yamaha GuitarsDocumento4 pagineElectronic Systems in Yamaha GuitarsQuique BonzonNessuna valutazione finora

- Torsional Modal ShopDocumento6 pagineTorsional Modal ShopEwdes HernandezNessuna valutazione finora

- Fuji Manual HG10Documento18 pagineFuji Manual HG10Jéssi TDNessuna valutazione finora

- Guardsman G and Guardsman L Series: Smith Meter Turbine MetersDocumento12 pagineGuardsman G and Guardsman L Series: Smith Meter Turbine MetersAnonymous 1ykzuaxWgYNessuna valutazione finora

- SCAMPER WorksheetDocumento2 pagineSCAMPER Worksheetryle34Nessuna valutazione finora

- YamahaBB604m 511084Documento9 pagineYamahaBB604m 511084rufusdexterNessuna valutazione finora

- Huddersfield Jazz Guitar Society: Celebrating The Art and Craft of Jazz GuitarDocumento25 pagineHuddersfield Jazz Guitar Society: Celebrating The Art and Craft of Jazz GuitarDarren Dutson-BromleyNessuna valutazione finora

- Effects Pedals - AdviceDocumento4 pagineEffects Pedals - Advicedorje@blueyonder.co.ukNessuna valutazione finora

- Profibus Troubleshooting & MaintenanceDocumento92 pagineProfibus Troubleshooting & Maintenancemsohaibkhalid100% (3)

- Magnetic Flux Leakage Testing: HapterDocumento19 pagineMagnetic Flux Leakage Testing: HapterkingstonNessuna valutazione finora

- Ee 1989 12extraDocumento80 pagineEe 1989 12extraAdrian_Andrei_4433100% (2)

- Modern Recording Techniques Audio Engineering Society Presents 9th EditionDocumento62 pagineModern Recording Techniques Audio Engineering Society Presents 9th Editionbill.owens447100% (46)

- Zoom A3 Manual 475877 PDFDocumento44 pagineZoom A3 Manual 475877 PDFNPUIUNessuna valutazione finora

- Asco ControlerDocumento40 pagineAsco ControlerjulNessuna valutazione finora

- Digiq 9Documento3 pagineDigiq 9Wahyu KurniawanNessuna valutazione finora

- How To Mic A SitarDocumento10 pagineHow To Mic A Sitartekaltian100% (4)

- 7SR11 and 7SR12 Argus Catalogue Sheet PDFDocumento24 pagine7SR11 and 7SR12 Argus Catalogue Sheet PDFSudipta ChatterjeeNessuna valutazione finora

- Advanced Magnetic MaterialsDocumento240 pagineAdvanced Magnetic MaterialsMiodrag AndrijasevicNessuna valutazione finora

- PD081GB10 13Documento16 paginePD081GB10 13Kaiser IqbalNessuna valutazione finora

- Bouncy SensorDocumento137 pagineBouncy SensorJagadesh BabuNessuna valutazione finora

- Steel GuitarDocumento5 pagineSteel GuitarangelroninNessuna valutazione finora

- Read Me First!: Resophonic and National Biscuit Installation GuideDocumento3 pagineRead Me First!: Resophonic and National Biscuit Installation GuideJohn BrombaNessuna valutazione finora

- MTH 103e050719revisedDocumento2 pagineMTH 103e050719revisedAchmad Jauhar EfendiNessuna valutazione finora

- Turbine Speed MeasurementDocumento26 pagineTurbine Speed MeasurementAyyar Kandasamy100% (4)

- Windrock 6310-PA Hoerbiger CompressedDocumento64 pagineWindrock 6310-PA Hoerbiger CompressedManuel Otero Alza100% (3)

- US5831196 Sensor Assembly For Stringed Musical Instruments PDFDocumento10 pagineUS5831196 Sensor Assembly For Stringed Musical Instruments PDFZalNessuna valutazione finora

- Godin ManualDocumento5 pagineGodin ManualElektra KatNessuna valutazione finora