Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Water Mist Calculation

Caricato da

Manjunath HrmCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Water Mist Calculation

Caricato da

Manjunath HrmCopyright:

Formati disponibili

System description for RAMSIS PROJECT

ETEA SICUREZZA S.r.l.

INDEX

0 SYSTEM CRITERIA ......................................................................................... 3

1 SYSTEM DESCRIPTION.................................................................................. 4

1.1 Pump system ........................................................................................................................................ 5

1.1.1 Pump unit.......................................................................................................................................... 7

1.1.2 Water supply ..................................................................................................................................... 8

1.1.3 Control Panel .................................................................................................................................... 8

1.1.4 Pressure relief valve........................................................................................................................ 10

1.1.5 Water mist nozzles.......................................................................................................................... 10

1.1.6 Flow detection valves ..................................................................................................................... 12

2 PIPE NETWORK DESIGN ............................................................................. 13

2.1 Pipe dimensions ................................................................................................................................. 13

2.2 Pipes and fittings ............................................................................................................................... 13

3 BILL OF MATERIALS .................................................................................... 16

4 DATA SHEETS .............................................................................................. 17

ETEA SICUREZZA S.r.l.

0 System criteria

System is a high pressure water mist system designed to discharge a fine Class 1 water mist fog

in the protected area and to provide excellent fire protection to goods and persons. System is

design to operate automatically.

System is a wet pipe system complemented with closed type nozzles. These systems maintain a

low pressure (between 15 to 30 bar) at pipe network in normal conditions (no fire). When a fire is developed,

heat from the fire will activate the thermal detectors (bulb glass type) of the nozzles that are located in the fire

vicinity. Pressure drop will be detected and a fine water mist will be discharge through all nozzles activated by

the fire.

System includes one flow detection valve per each floor. Flow detection valve will give a signal

indicating at which floor have closed nozzle been activated.

System is designed for protection of Ordinary Hazard Class 1 with an operational area of 90 m2.

Pipe network as been designed to provide a minimum water pressure of 80 bar at nozzle. The system provides

a water density of at least 1.1 mm/min in the activated areas.

System shall be connected directly to water town main supply. Water supply shall be enough to

provide a minimum of 122 lpm. Water quality should ensure filtrage of any particles above 10 µm.

ETEA SICUREZZA S.r.l.

1 System description

System consists of the following main parts:

• One electrical pump system.

• One jockey pump (1.1 lpm).

• One pump system control panel.

• 888 closed nozzles type with 57ºC or 68ºC bulbs.

• 9 Accomodation valves with Flow control.

System is designed to operate automatically and can be activated manually at pump control panel or by

remote activation.

Under normal condition (no fire) pipe network is constantly pressurized between 20 and 30 bar. Pressure is

continuously monitored. In case of pressure drop due to leakage jockey pump will reestablish the pressure.

Pump control panel includes means to verify how many times jockey pump has been activated for

maintenance purposes.

In case of fire detection through any closed nozzle type jockey pump will not be able to reestablish pressure

and main pumps will activate. Pumps will activate sequentially depending on water demand. In case of excess

of water flow provided by the pumps pressure relief valves will derive excess of water to drainage.

In case of water flow trough any of the nine sections, signal will be given from the flow control valve installed in

the section being involved.

Discharge can be stopped at any time by shutting section valves or by manually stopping pumps through

pumps control panel.

ETEA SICUREZZA S.r.l.

1.1 Pump system

The water mist pumping systems from consist of the water supply and feed system, the pressure gear,

the distribution system and the control and protection system. Following are some general information of the

system which comprises most standard flow rates.

5

3

4 15

16 13

12

11 1

150

100 200

14

S

50 250

0 300

315

bar

Kl.1.0

16 6

10

2 8

17

7

9

DETALLE VISTA PERFIL Y COLECTORES VISTA ALZADO SISTEMA

18

VISTA EN PLANTA DEL SISTEMA

Fig. 2.1: Example of the water mist pumping system for a one-pump flood system

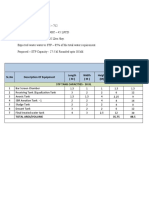

Item Description components

01 Vertical cylindrical tank PPH 3000 l

02 Detector of the correct water level or low water level. To be connected to the control panel

03 Filter 2”

04 Float valve 1¼”

05 Vent with elbow and grid 1”

06 Suction outlet 2” with ball drip valve, PVC 1½”, and reduction 2”x1½”

ETEA SICUREZZA S.r.l.

07 Plaited flexible hose 1½”

08 Electro-motor gear with coupling socket for the following configurations:

- 1 Pump 122 lpm each with electric motor 30 kw each connected in parallel

The system can be installed with a jockey pump 1.1 lpm and electric motor 0.18 kw in the case of a wet pipe system. A

special support on the bed-plate is required.

09 Non-return valve ¾” in the impeller pump

10 Suction manifold 1½” stainless steel

11 Impeller manifold ¾” stainless steel

12 Glycerin pressure gauge 0-315 bar

13 Pressure transducer 0-250 bar to be connected to the control panel

14 Relief valve of 60 lpm for configurations of 44 lpm and 120 lpm for configurations of 86, 112 and 224 lpm

15 Control panel, specific to each process. It includes electrical protections, programmable automation and touch screen

terminal. To be connected to the general distribution panel

16 Ball drip valve ¾” PN300

17 Hose 2¾” impeller pump outlet to manifold ¾”

18 Outlet for drainage 1” with ball drip valve PVC 1”

ETEA SICUREZZA S.r.l.

1.1.1 Pump unit

This comprises a high pressure 9-piston volumetric pump (max. pressure 160 bar) of fixed movement, driven

by a three-phase electric squirrel cage motor made of aluminum, totally closed and with D-Y start-up at

380/220 V. It includes a device for coupling it to the pump (hood) fixed to the bed-plate, universal, of

appropriate dimensions in accordance with the configuration of the system. The supports are movable, in L-

shape laminated profile, fixed to the main electro-motor / pump gear. The base plate has four anti-vibration

feet, if a system with a jockey pump is installed (wet pipe system) with assembly to the left or right,

irrespectively. The suction manifold and impeller manifold equipped with the control instrumentation and

system hydraulic safety elements are located in the support bays of the bed-plate. The minimum suction

pressure is 0.9–5 bar abs.

The motor / pump gear are:

- 1 PAH 63 pumps with unitary flow of 122 lpm and one 30 Kw ABB power motors of

1,500 rpm

- A PAH 2 pump with unitary flow of 1.1 lpm and 0.18 Kw power motor (jockey pump)

of 750 rpm

INLET

OUTLET

PUMP BELL MOTOR

Fig. 2.1.2.1.1: Pump - motor gear

ETEA SICUREZZA S.r.l.

Flow Power (kw)/rpm ∅ inlet ∅ outlet Dimensions Weight Obs.

rate. (mm) (kg)

(lpm)

1.1 0.18/750 ½” ¼” 200 x 200 Jockey

pump

122 30/1500 2 x 1 ½” 2 x 1 ¼” 1445 x 1660 x 1500

660

1.1.2 Water supply

Vertical cylindrical tank made of polypropylene (PPH) with a conical shape at the bottom, equipped with a fitted

lid, outlet sleeve H-2”, vent with elbow 1” with grid and drainage sleeve H-1”.

Description of main components

Water filter with centrifuge pre-filtration for particles of 10 microns and over, ensuring the

purity of the water and allowing filtration without accumulation, high and constant flow with

only a slight loss of the pressure, high degree of self-cleaning and easy regeneration. It is

delivered with a pack of 5 spare filtering units. As the glass is transparent, it is possible to

control visually the degree of dirt of the filtering element.

Float valve made of stainless steel with nominal pressure PN-16. Through a mechanical

system the valve allows the mains water to enter (full on) and closure (progressive) When

the water level falls below the correct level probe, the float valve opens, letting the mains

water in. When the water level is optimum, the valve shuts off the supply of water.

The tank is equipped with two level detectors of polypropylene, one installed in the top part of

the tank (at the height of the float valve) indicating the correct level of the water and the other

installed in the bottom part of the tank indicating the minimum water level. The two detectors

send a 24V electric signal to the control panel.

1.1.3 Control Panel

Complete panel designed to fully automatically operate the pump units. Both the electro-motor and the control

and operation panel have the corresponding seal of compliance with electrical safety and electro-magnetic

compatibility.

The control and operation panel include the following services:

• Protection by fuses or magnetic circuit breakers (not thermal ones)

• Main switch of suitable power

• Contacts for star/triangle start-up of three-phase 380V motors

• Detector of phase failure for each pump

• Transformer

• Indicators of the status of the system

ETEA SICUREZZA S.r.l.

• Alarms for:

• Tank water level: indicates minimum water level.

• Start-up failure.

• Electric/non-automatic failure: When the system is started up manually or when there is an electrical

fault (inverted phases, no voltage)

• Start-up command: When the system receives an external start-up command

• Overpressure: Indicates that the outlet valve is closed

• Pump start-up and stoppage buttons

• Programmable logic control unit: Programmable automation and panel operator terminal.

Interaction between the user and the system by means of:

• Touch screen terminal (it shows the general status of the system and also of its elements; it shows

the system alarms: it keeps records of alarms and warnings; it allows commands to be given to the

system and for it to be configured).

• Pilot lamps (which show the general status of the system: READY, BREAKDOWN and NON-

OPERATIONAL).

• Horn (which warns of the alarms and of the system start-up).

• STOP button (for the pumping station when it has started up).

• START-.UP PUMP 1 button (which starts up main pump 1 without any kind of control).

• START-.UP PUMP 2 button (which starts up main pump 2 without any kind of control).

• START-.UP PUMP 3 button (which starts up main pump 3 without any kind of control).

• START-.UP PUMP 4 button (which starts up main pump 4 without any kind of control).

Control panel includes 3 pilot lamps located on the door of the electricity cabinet and control panel.

Pilot lamp Colour Meaning

READY / PREPARADO Green The system is ready to run.

If this pilot lamp is off, the INOPERATIVE / NON-

OPERATIONAL pilot lamp will be alight.

FAULT / AVERÍA Orange The System has some kind of alarm Check which alarm it is

via the touch screen terminal.

It may happen that the alarm has already turned itself off, but

a record will remain and the pilot lamp will be alight.

INOPERATIVE / NON- Red The system is non-operational and cannot work in the event

OPERATIONAL of a fire.

Whenever an alarm is produced, making the system NON-OPERATIONAL or otherwise, the horn will sound:

Acoustic signal Meaning

intermittent slow An alarm has been produced

(Sounds for 0.5 second and pauses for 1 second)

intermittent fast Low pressure has been detected and the

ETEA SICUREZZA S.r.l.

(Sounds for 1 second and pauses for 0.5 second) system will start up after the number of

seconds configured at the touch screen

terminal has elapsed.

This acoustic signal applies only to stations

with an auxiliary pump.

Continuous The system has started up

Control panel is connected to outlet manifold pressure transducer. The pressure transducer is the element that

makes it possible to control and monitor at all times the state of pressurisation of the system, sending an

analogue signal to the Programmable Logic Control Unit of the control panel. The transducer allows the

system to carry out the pump start-up operations, to control any overpressure in the system or indications of

pumps in service or triggered extinguishing.

1.1.4 Pressure relief valve

Each pump unit is complemented with a Danfoss pressure relief valve in order to prevent over pressure and to

divert excess flow rate to drainage. Pressure relief valves will derive complete flow rate at a pressure between

140 and 160 bar.

1.1.5 Water mist nozzles

mist offers a wide range of water mist nozzles to suit to different applications with a mean drop side of the

water mist is about 50 microns. Water Mist nozzles can provide with k-factors rating from 0.025 l/

(min·bar0.5) up to 5.000 l/ (min·bar0.5). Other k-factors can be manufactured under demand. All water mist

nozzles are equipped with FB 85 filters to avoid blockage of the nozzles. Nozzles heads can be complemented

with an internal check-valve for maintenance porpurses.

Mechanical glass bulb closed type nozzle:

AISI 303 Stainless steel open nozzle for total flooding systems with ring fitting connection

equipped with FB 85 filter. Nozzle can hold up to 4 micro-nozzles. Maximum working

pressure 300 bar. This nozzle includes a fast response time (RTI=36) frangible glass bulb to

operate at 57ºC or 68ºC.

ETEA SICUREZZA S.r.l.

Nozzle Selection accordingly to manufacturer recomendations:

Ordinary Hazard Class 1:

Reference 82405760

k-factor 1.1 l/ (min·bar0.5)

Maximum Height 5m

Spacing 3.0 m

Minimum/Maximum 1.0 m / 2.0 m

distance to Wall

Minimum Pressure 80 bar

Density 1.1 lpm/m2

ETEA SICUREZZA S.r.l.

1.1.6 Flow detection valves

flow valve will provide an electrical signal when flow through it has been detected. System is

complemented with a shutting valve, test valve, check valve and pressure gauge:

Technical characteristics

Flow valve

Maximum Maximum Response Protection. Consumption Voltage

Flow working time

velocity pressure.

(cm/s) (bar)

300 300 1 a 10 s IP 67 400 mA 20 a 36

Vdc

ETEA SICUREZZA S.r.l.

2 Pipe network design

2.1 Pipe dimensions

Water mist systems’ pipe network shall be dimensioned accordingly to engineering needs. In order to fulfill these

requirements has developed their own software FireNet®. This software assures required pressure and flow

rate at the nozzles.

Software calculations are based on Darcy-Weibach equations described at NFPA 750.

2.2 Pipes and fittings

⇒ Pipes shall be installed in accordance with the isometric drawing accompanying the project. Measures,

dimensions and pipe quality indicated in the drawing shall be respected, as any modifications related to

pipe dimensions or measures would impair system operation. In case of requiring any modifications, the

engineering department responsible for the system design shall be notified as appropriate.

Pipe should be non-welded stainless steel AISI 316L DIN-2462.

Pipes can be bend up to 90º.

Fittings have to be ring fittings PN315.

Installation shall be earthed.

Pipe painting shall be red (RAL 3002).

Pipe can be bent taking into account that minimum radius has to be 5 times pipe diameter.

Supports will be Stauff Standard Series Aluminium AISI 12

Every pipe network must have at least two supports.

ETEA SICUREZZA S.r.l.

Maximum distance between supports will be never be higher than:

Nominal Diameter Nominal Diameter Maximum distance

(mm) (inches) (m)

10 3/8 1.0

15 ½ 1.5

20 ¾ 1.8

25 1 2.1

32 1¼ 2.4

40 1½ 2.7

50 2 3.4

70 2½ 3.5

80 3 3.7

100 4 4.3

Whenever the pipe is more than 2 inches (DN 50) and table spacing cannot be adhered to for building

design reasons, the distance may be raised to 6 m, if the pipe is provided with double supports.

Pipe supports shall be located near joints in the pipe.

Supports shall connect pipe system directly to the building structure and shall not be used to support other

objects. The sides of the building where supports are fixed shall be strong enough to take the load (see

table for design charge). Otherwise, additional straps shall be fixed to other resistant elements. Only pipes

with nominal diameters less than or equal to 5 mm may be attached to metallic structures in the shape of

trusses or concrete slabs (the design shall be approved by the authorities). Fastening plugs in concrete

slabs shall be located at least 150 mm away from the edge of the slab.

The distance between the nozzle and its support shall be the shortest possible:

- For pipes with a smaller or equal diameter to 25 mm, maximum distance from support to nozzle

shall be 0.1 m.

- For pipes more than 25 mm diameter, maximum distance from support to nozzle shall be 0.25 m.

Supports type hangers or manifold "U" fixation are recommended. Pipe clips and other fittings for holding

the pipe, shall completely surround the pipe and be closed.

Supports shall comply with the following minimum requirements for sectional areas and depth of

anchoring:

ETEA SICUREZZA S.r.l.

Pipe Nominal Diameter Design charge Thread size Minimum depth of anchoring

(N) (metric) for fastening plugs in

concrete (mm)

Up to DN 50 (2”) 2000 8 30

Between DN 50 (2”)

3500 10 40

and DN 100 (4”)

Between DN 100 (4”)

5000 12 40

and DN 150 (6”)

Between DN 150 (6”)

8500 16 50

and DN 200 (8”)

Supports shall be installed following installation plans. Those supports installed inside the hazard area

have to be aluminum designed to withstand high temperatures.

ETEA SICUREZZA S.r.l.

3 Bill of materials

Item Description Quantity

1 Complete 122 lpm type piston pump system with 1

ABB type M2AA225S-4 30 kW 1475 rpm electric motor mounted

on a steel galvanized frame. Includes jockey pump (electrical or

pneumatic), over pressure valves, pressure transducer and

pressure gauge and CE mark control panel. 3000 l break tank

with filter, float valve, drainage valve and level switches is

included. Completed with all accessories.

2 Water Mist Nozzle for Ordinary Hazard Class 1. 888

K=1.1. 57ºC.

3 Accomodation valve with Flow indicator 9

ETEA SICUREZZA S.r.l.

4 Data Sheets

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Water Mist Project

LPG Técnicas en extinción de Incendios S.A. Departamento Técnico Comercial

Potrebbero piacerti anche

- Foam CalculationsDocumento8 pagineFoam CalculationsdheerajdorlikarNessuna valutazione finora

- Fire Pumps CalculationDocumento31 pagineFire Pumps CalculationArun DMK0% (1)

- Design of Hose Reel System: - Nozzle: P 200 Kpa 0.4 L/SDocumento36 pagineDesign of Hose Reel System: - Nozzle: P 200 Kpa 0.4 L/Sمحمد القدومي100% (1)

- Corridor Pressurization Calculation 20170310Documento1 paginaCorridor Pressurization Calculation 20170310wow proNessuna valutazione finora

- Calculation of Fire Water Tank CapacityDocumento2 pagineCalculation of Fire Water Tank Capacitymunim87100% (1)

- 04-Sprinkler SystemDocumento32 pagine04-Sprinkler SystemRavi100% (1)

- Manual HC For in Rack Sprinklers Reference NFPA 13 - 2013, Chapter 23 (PLANS AND CALCULATIONS) (Mehboob Shaikh)Documento16 pagineManual HC For in Rack Sprinklers Reference NFPA 13 - 2013, Chapter 23 (PLANS AND CALCULATIONS) (Mehboob Shaikh)Jerry TomNessuna valutazione finora

- Stair Pressurization CalculationDocumento9 pagineStair Pressurization CalculationHaymanot BaynesagnNessuna valutazione finora

- Fire Drencher System - Base-Engineer PDFDocumento2 pagineFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- Fire Sprinkler Hydraulic Calculation SheetDocumento2 pagineFire Sprinkler Hydraulic Calculation SheetSameera Lakmal50% (2)

- Inergen Sizing CalculationDocumento3 pagineInergen Sizing CalculationStephanie Webb0% (1)

- Fire Pump Head CalculationsDocumento2 pagineFire Pump Head Calculationsendu100% (1)

- Hydraulic Calculations Adjusted FlowDocumento9 pagineHydraulic Calculations Adjusted FlowMd Shaidur Rahman100% (1)

- Hose Reel CalculationDocumento2 pagineHose Reel Calculationjonnel100% (1)

- How FPE Determines Sprinkler Flow for BuildingsDocumento12 pagineHow FPE Determines Sprinkler Flow for BuildingsArt James100% (1)

- Hose Reel Friction Loss CalculationDocumento2 pagineHose Reel Friction Loss CalculationNethajiNessuna valutazione finora

- Tank Calculation TemplateDocumento4 pagineTank Calculation TemplateKazehaya AliNessuna valutazione finora

- Stair Pressurization CalculationDocumento2 pagineStair Pressurization Calculationnaruto256100% (1)

- Guide For Fire Protection and Detection SystemDocumento50 pagineGuide For Fire Protection and Detection SystemGreenbuild ZM-JV100% (1)

- Hydraulic Calculations ExplainedDocumento38 pagineHydraulic Calculations ExplainedJovani G. Ballon100% (4)

- Piping Lay Out For Fire Sprinkler System - An OverviewDocumento6 paginePiping Lay Out For Fire Sprinkler System - An OverviewFitsum BulloNessuna valutazione finora

- Water Mist Nozzle GW M5 PDFDocumento6 pagineWater Mist Nozzle GW M5 PDFZulfi Andrie ZulkiarNessuna valutazione finora

- 02 - Automatic Sprinkler System Design CalculationsDocumento2 pagine02 - Automatic Sprinkler System Design CalculationsFebous WambuaNessuna valutazione finora

- Template Wet Riser CalculationDocumento4 pagineTemplate Wet Riser CalculationMFaiz RHamira100% (1)

- Foam CalculationsDocumento8 pagineFoam Calculationsahmed salemNessuna valutazione finora

- Stair Case PressurisationDocumento5 pagineStair Case Pressurisationsardarmkhan100% (1)

- 3-Gaseous Systems Calculations.Documento3 pagine3-Gaseous Systems Calculations.AyaEzzNessuna valutazione finora

- Fire Pump Pressure SettingsDocumento2 pagineFire Pump Pressure SettingsJhe Inibam100% (1)

- Design Fire Fighting Systems CO2 CalculationDocumento3 pagineDesign Fire Fighting Systems CO2 Calculationantonalmeida100% (1)

- Smoke Spill 2Documento2 pagineSmoke Spill 2Briana JenkinsNessuna valutazione finora

- Smoke Extraction - TECDocumento1 paginaSmoke Extraction - TECdasmechNessuna valutazione finora

- Selection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of PracticeDocumento21 pagineSelection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of Practiceabhirami91Nessuna valutazione finora

- Hidraulic Calculation For Hotel PDFDocumento8 pagineHidraulic Calculation For Hotel PDFangel dario100% (1)

- Hydraulic Calculation For FFDocumento2 pagineHydraulic Calculation For FFosama alabsi100% (1)

- A Tutorial To Getting Started With FHC: Hydraulic Calculation Software For Water Based Fire Protection SystemsDocumento7 pagineA Tutorial To Getting Started With FHC: Hydraulic Calculation Software For Water Based Fire Protection SystemsZaw Moe Khine100% (1)

- Mechanical Smoke Ventilation Calculations For Basement (Car Park)Documento7 pagineMechanical Smoke Ventilation Calculations For Basement (Car Park)Mahmoud Abd El-KaderNessuna valutazione finora

- Fike - Water Mist Design Machinery SpacesDocumento6 pagineFike - Water Mist Design Machinery SpacesminiongskyNessuna valutazione finora

- Smoke & Ventilation CalculationsDocumento7 pagineSmoke & Ventilation CalculationsZine ModelsNessuna valutazione finora

- Relationships for Smoke Control CalculationsDocumento148 pagineRelationships for Smoke Control CalculationsArgile-assholeNessuna valutazione finora

- Fire protection design briefDocumento10 pagineFire protection design briefRK PROJECT CONSULTANTS100% (1)

- Sprinklers Coverage Area Calculation:: Areaof Coverage S LDocumento9 pagineSprinklers Coverage Area Calculation:: Areaof Coverage S LMuhammad Raza Rafiq100% (1)

- Sprinkler Sizing en v1Documento12 pagineSprinkler Sizing en v1CristianDumitru0% (1)

- Wet Riser Stage 2 (Above)Documento1 paginaWet Riser Stage 2 (Above)ZamzuriNessuna valutazione finora

- Sustainability & Smoke ControlDocumento11 pagineSustainability & Smoke ControlmpwasaNessuna valutazione finora

- Sprinkler Design ChecklistDocumento3 pagineSprinkler Design ChecklistVigneshNessuna valutazione finora

- System Design: Total Flooding Extinguishing SystemDocumento45 pagineSystem Design: Total Flooding Extinguishing SystemsureshkanuboyinaNessuna valutazione finora

- Sprinkler Sloped - Ceilings - 2010 PDFDocumento7 pagineSprinkler Sloped - Ceilings - 2010 PDFnrodinis7Nessuna valutazione finora

- Viking Residential Sprinkler Installation GuideDocumento18 pagineViking Residential Sprinkler Installation Guidesina_84Nessuna valutazione finora

- Fire TankDocumento30 pagineFire TankPraveen Kumar100% (1)

- Is 13039 External Fire HydrantDocumento10 pagineIs 13039 External Fire HydrantNanu PatelNessuna valutazione finora

- Linde - HPV Data and SpecificationsDocumento33 pagineLinde - HPV Data and SpecificationsxxshNessuna valutazione finora

- Preaction System With Model DV-5 Deluge Valve Double Interlock - Electric/Pneumatic Actuation 1-1/2 Thru 8 Inch (DN40 and DN200)Documento16 paginePreaction System With Model DV-5 Deluge Valve Double Interlock - Electric/Pneumatic Actuation 1-1/2 Thru 8 Inch (DN40 and DN200)PhuNguyenHoangNessuna valutazione finora

- Bul 36115 Servo Valve OperationDocumento12 pagineBul 36115 Servo Valve Operationrikkitech100% (1)

- Bomba Desplazamiento Variables FuncionamientoDocumento10 pagineBomba Desplazamiento Variables FuncionamientoAndré MaldonadoNessuna valutazione finora

- Acv Automatic Control Valves PDFDocumento20 pagineAcv Automatic Control Valves PDFabdallah391Nessuna valutazione finora

- Self-Operated Pressure Regulators ANSI Version: T 2513 EN Type 41-23 Universal Pressure Reducing ValveDocumento6 pagineSelf-Operated Pressure Regulators ANSI Version: T 2513 EN Type 41-23 Universal Pressure Reducing ValveagrovadoNessuna valutazione finora

- Pc210 (LC) - 10m0 Sen06701-C0 Hydraulic SystemDocumento98 paginePc210 (LC) - 10m0 Sen06701-C0 Hydraulic Systemdatphuong100% (2)

- Spesifikasi Booster PumpDocumento5 pagineSpesifikasi Booster PumpagieyogaswaraNessuna valutazione finora

- Instalacion Bombas de Presion CatDocumento2 pagineInstalacion Bombas de Presion CatTito Zenon100% (1)

- Manual de PropietarioDocumento22 pagineManual de PropietarioSergioPortillaLastarria100% (2)

- CFM Ir SizDocumento1 paginaCFM Ir SizManjunath HrmNessuna valutazione finora

- Statistics: 10.1 Mean and Standard Deviation - Single DataDocumento20 pagineStatistics: 10.1 Mean and Standard Deviation - Single DataManjunath HrmNessuna valutazione finora

- Design calculations for swimming pool pumps filtersDocumento2 pagineDesign calculations for swimming pool pumps filtersManjunath Hrm100% (2)

- Grundfosliterature 3081295Documento7 pagineGrundfosliterature 3081295Manjunath HrmNessuna valutazione finora

- Stairwell & Lift Pressurization CalculationsDocumento31 pagineStairwell & Lift Pressurization CalculationsAneng2890% (10)

- Freeware PDF UnlockerDocumento116 pagineFreeware PDF UnlockerManjunath HrmNessuna valutazione finora

- Manual On Artificial Recharge of Ground WaterDocumento198 pagineManual On Artificial Recharge of Ground WaterShyam BudhwarNessuna valutazione finora

- Design of Smoke Control Systems For Areas of Refuge 1993Documento25 pagineDesign of Smoke Control Systems For Areas of Refuge 1993mingming1Nessuna valutazione finora

- Quick Guide To M: PlasticsDocumento2 pagineQuick Guide To M: PlasticsManjunath Hrm100% (1)

- Gas CalculationDocumento1 paginaGas CalculationManjunath HrmNessuna valutazione finora

- Plant CapacityDocumento1 paginaPlant CapacityManjunath HrmNessuna valutazione finora

- Dimensions of A Series Paper SizesDocumento3 pagineDimensions of A Series Paper SizesRaja KathiravanNessuna valutazione finora

- Typical Classroom Layout and Contents 25-08-2018Documento1 paginaTypical Classroom Layout and Contents 25-08-2018Manjunath HrmNessuna valutazione finora

- New PricelistDocumento1 paginaNew PricelistManjunath HrmNessuna valutazione finora

- BellDocumento30 pagineBellsas999333Nessuna valutazione finora

- A Pump Is A Device That Moves FluidsDocumento19 pagineA Pump Is A Device That Moves FluidsManjunath HrmNessuna valutazione finora

- Is SP 20 1991 PDFDocumento167 pagineIs SP 20 1991 PDFAnonymous 0ABCZ1bINessuna valutazione finora

- Hi FogDocumento36 pagineHi FogManjunath HrmNessuna valutazione finora

- Interview TipsDocumento26 pagineInterview TipsManjunath HrmNessuna valutazione finora

- CAD For High Embankments-IITDocumento29 pagineCAD For High Embankments-IITNAUTILUS87Nessuna valutazione finora

- Fire Requirement As Per NBCDocumento1 paginaFire Requirement As Per NBCManjunath HrmNessuna valutazione finora

- The Design of Concrete Highway Bridges and Structures With External and Unbonded PrestressingDocumento12 pagineThe Design of Concrete Highway Bridges and Structures With External and Unbonded PrestressingManjunath HrmNessuna valutazione finora

- Discrimination Report for Wipro Coimbatore Electrical ServiceDocumento30 pagineDiscrimination Report for Wipro Coimbatore Electrical ServiceManjunath HrmNessuna valutazione finora

- British Standard: A Single Copy of This British Standard Is Licensed ToDocumento13 pagineBritish Standard: A Single Copy of This British Standard Is Licensed ToManjunath HrmNessuna valutazione finora

- Revenue by Quarters: Q1 Q2 Q3 Q4Documento4 pagineRevenue by Quarters: Q1 Q2 Q3 Q4Manjunath HrmNessuna valutazione finora

- Novec VentingoutDocumento2 pagineNovec VentingoutManjunath HrmNessuna valutazione finora

- Uniform Mechanical CodeDocumento185 pagineUniform Mechanical CodeCostas Sar100% (2)

- Discrimination Report for Wipro Coimbatore Electrical ServiceDocumento30 pagineDiscrimination Report for Wipro Coimbatore Electrical ServiceManjunath HrmNessuna valutazione finora

- IEC 62305-2010 Tieu Chuan Chong SetDocumento489 pagineIEC 62305-2010 Tieu Chuan Chong SetThuậnHồ80% (5)

- Cavagna CatalogueDocumento95 pagineCavagna CatalogueALONSONessuna valutazione finora

- 80 14 Handling Gas Container EmergenciesDocumento28 pagine80 14 Handling Gas Container Emergencies오일중동Nessuna valutazione finora

- USA Bell & Gossett 116506 - D120 (68GAL)Documento6 pagineUSA Bell & Gossett 116506 - D120 (68GAL)1092 hanna (primary soul)Nessuna valutazione finora

- Ptreliefvalves 0418Documento2 paginePtreliefvalves 0418choopoNessuna valutazione finora

- Low Pressure Pumps: Installation and Start-Up InstructionDocumento12 pagineLow Pressure Pumps: Installation and Start-Up InstructionsmithworkNessuna valutazione finora

- PIP PCCCV002-2018 Pressure Regulators Selection CriteriaDocumento7 paginePIP PCCCV002-2018 Pressure Regulators Selection Criteria刘旭Nessuna valutazione finora

- Introduction To Double Block and BleedDocumento7 pagineIntroduction To Double Block and BleedDefenceDogNessuna valutazione finora

- Saep 318Documento28 pagineSaep 318brecht1980Nessuna valutazione finora

- In-Line Hydraulic TesterDocumento5 pagineIn-Line Hydraulic TesterMasterrNessuna valutazione finora

- Manual IrDocumento292 pagineManual IrSISOYDANNYNessuna valutazione finora

- Saudi-Arabian-Engineering-Standardssaes-J-001 PDFDocumento11 pagineSaudi-Arabian-Engineering-Standardssaes-J-001 PDFsalasineNessuna valutazione finora

- Process Safety Beacon - LPG TragedyDocumento1 paginaProcess Safety Beacon - LPG TragedyRodrigo RattoNessuna valutazione finora

- New LNG Train Skikda Project LNG Expander Operating ManualDocumento18 pagineNew LNG Train Skikda Project LNG Expander Operating ManualRabah AmidiNessuna valutazione finora

- Pressure Control ValvesDocumento40 paginePressure Control ValvesVivek VardhanNessuna valutazione finora

- Axial Piston Variable Pump A4VG Series 32: EuropeDocumento94 pagineAxial Piston Variable Pump A4VG Series 32: Europemuhammed atnNessuna valutazione finora

- Failure Analysis - Case StudyDocumento43 pagineFailure Analysis - Case StudySyed HaiderNessuna valutazione finora

- Safety Valve PDFDocumento4 pagineSafety Valve PDFTARIQ IQBALNessuna valutazione finora

- Dataheet - SimSci VISUAL FLARE PDFDocumento5 pagineDataheet - SimSci VISUAL FLARE PDFFarid BerrahouNessuna valutazione finora

- Installation and Operation Manual: VSRT SeriesDocumento68 pagineInstallation and Operation Manual: VSRT SeriesedgardoNessuna valutazione finora

- Design and Analysis of Rams Bottom Spring Loaded Safety ValveDocumento42 pagineDesign and Analysis of Rams Bottom Spring Loaded Safety ValveMayur GardeNessuna valutazione finora

- Pilot Pressure Proportional Control (PPC)Documento16 paginePilot Pressure Proportional Control (PPC)EkoNessuna valutazione finora

- MNL036Documento22 pagineMNL036husni1031Nessuna valutazione finora

- PSV PDFDocumento3 paginePSV PDFKasnowo DiponegoroNessuna valutazione finora

- RVP-RVS Series Relief Valve CatalogDocumento4 pagineRVP-RVS Series Relief Valve CataloglorenzoNessuna valutazione finora

- General Installation and Maintenance InstructionsDocumento12 pagineGeneral Installation and Maintenance Instructionshipnofenix0% (1)

- 7-Ottawa County Farms CP 7-Vi Pipe-Stress-Calculations 530131 7Documento91 pagine7-Ottawa County Farms CP 7-Vi Pipe-Stress-Calculations 530131 7Juan Carlos RiveraNessuna valutazione finora

- Process Pressure Vessels and Piping SystemsDocumento5 pagineProcess Pressure Vessels and Piping SystemsEn NdyNessuna valutazione finora

- 2011 Relief-Devices Shattering ConsiderationsDocumento13 pagine2011 Relief-Devices Shattering ConsiderationskglorstadNessuna valutazione finora

- Safety Relief Valves Operation ManualDocumento21 pagineSafety Relief Valves Operation ManualSumit JadhavNessuna valutazione finora

- Pressure Relief Pitfalls PDFDocumento8 paginePressure Relief Pitfalls PDFsara25dec689288Nessuna valutazione finora