Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Piston and Piston Ring

Caricato da

N Dhanunjaya Rao BorraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Piston and Piston Ring

Caricato da

N Dhanunjaya Rao BorraCopyright:

Formati disponibili

The International Journal Of Engineering And Science (IJES)

|| Volume || 4 || Issue || 10 || Pages || PP -29-35|| 2015 ||

ISSN (e): 2319 – 1813 ISSN (p): 2319 – 1805

Analysis of engine piston and piston ring using CATIA and

ANSYS for attaining higher Efficiency

SANDEEP JAIN1,NAVNEET KHARE3, DEEPAK SAHU3

Mtech Scholar SIRT Bhopal (MP)

--------------------------------------------------------ABSTRACT--------------------------------------------------

In this present work a piston and piston ring are designed for a single cylinder four stroke

petrolengineusingCATIAV5R20software. Complete design is imported to ANSYS14.5 software and then analysis

is performed. Three different materials have been selected for structural and thermal analysis of piston. For

piston ring two different materials are selected and structural and thermal analysis is performed using

ANSYS14.5software. Results are shown and a comparison is made to find the most suited design.

----------------------------------------------------------------------------------------------------------------------------- ----------

Date of Submission: 11 September 2015 Date of Accepted: 10 October 2015

----------------------------------------------------------------------------------------------------------------------------- ---------

I. Introduction

The modern trend is to develop IC Engine of increased power capacity. One of the design criteria is the

endeavor to reduce the structures weight and thus to reduce fuel consumption. This has been made possible by

improvedenginedesign.Theseimprovementsincludeincreaseduseoflight- weight materials, such as advanced

ultra-high tensile strength steels, aluminum and magnesium alloys, polymers, and carbon-fiber reinforced

composite materials. The integration of lighter weight

materialsisespeciallyimportantifmorecomplexpartscanbemanufacturedasasingleunit.Inthe next 10–20 years,

anadditional 20–40% reduction inoverall weight, without sacrificing safety, seemstobepossible.Cuddyetal

(1997)havereportedthatforevery10%weightreductionofthe vehicle,animprovementin fuelconsumptionof6–8%is

expected.Improvedenginedesignrequires optimized engine components. Therefore sophisticated tools are

needed to a n a l y z e engine components.Enginepistonisoneof

themostanalyzedcomponentsamongallautomotiveor other

industryfieldcomponents.Theenginecanbecalledtheheartofanautomobileandthepistonmaybe considered themost

importantpartofanengine. Many sophisticated Aluminumpistonanalysis methods have beenreported

inthepastyears. Silva2006hasanalyzed fatiguedamagedpiston. Damagesinitiatedat the

crown,ringgrooves,pinholesandskirtare assessed.An analysisofboth

thermalfatigueandmechanicalfatiguedamagesispresentedandanalyzedinthiswork.Alinear

staticstressanalysis,using„„cosmosworks‟‟,is usedtodeterminethestressdistributionduringthe

combustion.Stressesatthepistoncrownandpinholes,aswellasstressesatthegroovesandskirtas a function

oflandclearancesarealsopresented. Buyukkaya et al (2007)

hasinvestigatedaconventional(uncoated)dieselpiston,madeofaluminumsiliconalloyandsteel.Hehas performed

thermalanalysesonpistons,coatedwithMgO–ZrO2 materialbymeansofusingacommercialcode, namelyANSYS.

Finally,theresultsoffourdifferentpistonsarecompared witheachother.The effectsof

coatingsonthethermalbehaviorsofthepistonsareinvestigated.Ithasbeenshownthatthe

maximumsurfacetemperatureofthecoatedpistonwithmaterialwhichhaslowthermalconductivity

isimprovedapproximately48%fortheAlSialloyand35%forthesteel.Saadetal.(2008) has donenumericalanalysis

toanalyzethestressesduetothermalcyclewithdifferentaluminumalloy

ofpiston.Finiteelementmethodwasusedtoevaluatethecouplingfield(thermal–stress)onthe

piston.ANSYS5.4Finiteelementcodeisusedto carryoutthemodelingprocesstodeterminethe

couplingstress.Twomodelswiththreedimensions arecreated. The firstisused to evaluate the temperature

distribution through the pistonvolume, and these co disused to evaluate the thermal

stressdistributionduetoheatgradientanddifferentmaterials.Theresultshowthemaximumrange

oftemperaturesis4.3°Candincreaseswithdecreasingofmaterialthermalconductivity.Thermal

stressisconcentratedonthepistonedges and depends on the material types. Gudimetaletal. (2009) hasreported

a CADmodelofadamagedinternalcombustion(IC)enginepistonandthenhasused thestate-of-the-

artANSYSfiniteelementanalysispackagetoperformalinearstaticanda coupled thermal-structural a n a l y s i s of the

component. Further, a parametric evaluationofthematerialpropertiesvis-à-

visoperatingconditionsiscarriedouttogeneratearelational database for the piston to arriveat

optimaldesignsolutionsunderdifferentoperatingconditions. Wanget al.(2010)has

www.theijes.com The IJES Page 29

Analysis of engine piston and piston ring using…

reportedasolidmodelincludingpistonandpistonpinofanewdesignedpistonbyPro/Esoftware,

andthefiniteelementanalysismodelwasalsoestablishedby usingANSYSsoftware.Thethermo-

mechanicalcouplingstressdistributionandthe deformationwerefirstlycalculated.Consideringthe nonlinear material

properties ofpistonandpistonpin,theNewton-Raphson equilibriumiterativemethodis

applied.Calculatingresultsindicatesthatthemaximumstressconcentrationis attheupper

endofpistonpinbossinnerhole,andismainlycausedbythepeakpressureofthefuelgas.Zenget

al.(2010)hassetupageometrymodelofadieselenginespistoninUGgraphics.Thetemperature

fieldsofthepistonforburningdieselandDMEseparatelyarecalculatedusingANSYS10.0.The

resultshowsthatthevariationofthethermalloadby substitutingdieselwithDMEis stillwithinthe

thermalstrengthofthematerial.ThetemperatureoftheDMEfueleddieselenginedecreasesalong

thepistonaxisfromtoptobottom.ThetemperatureofthepistonofDMEfueledengineincreaseas a

wholecomparingwithburningdiesel.However,thetemperaturefielddistributionhas no significant

changedecreasesandthenincreasesfromthecombustionchambercenterto theedge,anddecreases again tothe edge of

the piston top. Durat. et al (2012) a steady-state thermal analysis was performedto

evaluatethetemperaturegradientsinthestandardandtwodifferentpartiallystabilized ceramiccoatedpistonsbyusing

Abaqus©finiteelement(FE)software.Asharpincreaseinthe temperature of the coated area of the piston was

observed as a result of FE simulations. Itis concluded that the annulus Y-PSZ coating may contribute better,

as compared to Mg-PSZ, to

decreasethecoldstartandsteadystateHCemissionswithoutautoignition,sincethetemperaturein

theareashowsalocalsharpincrease.Junjuetal.(2012)hastriedtoreducetheintensityofthermal

andstructuralstressesbyusingtheceramicmaterialSiliconNitrideasthematerialforpistoncrown

(thetopportionofthepiston).Asthecrownmaterialis brittleinnatureandskirtmaterialis ductilein

nature.AceramicreinforcedfiberstripwasintroducedinbetweenceramiccrownandAlalloyskirt

toavoidfailureoftheceramiccrownduetoitsbrittlenaturewhenitissubjectedtoimpactloadsthat areresultofexplosionof

combustiongases.InthisworkEutecticAlAlloy(Si11-13%)wastakenas

pistonmaterial.Initiallythermalandstructuralanalysiswasperformedon Al Alloypistonwithout

siliconnitridecrownandthenwith siliconnitridecrownusingthesoftwareANSYS.Thentheresults

obtainedarecompared. Thecomparisonofresultsindicatedthatthepistonwhichisarrangedby

siliconnitridecrownisbettertowithstandhighthermalandstructuralstressesthanthepistonwhich isnot arrangedby

siliconnitridecrown.Thepresentworkhasbeenundertakenwiththefollowing objective.

1- T o designanICengine(pistonandpistonring)byusingCATIAV5R20software

2- T o performthestructuralandthermalanalysis(ofpistonandpistonring)usingANSYS14.5 software.

Threedifferentmaterialshavebeenselectedforpistonandtwodifferentmaterialsforpistonrings.

1.1 Materials and their properties

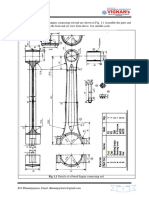

.Dimensionsare calculatedandtheseareused formodelingthe pistonandpistonringin

CATIAV5R20asshowninFig1andFig2.

www.theijes.com The IJES Page 30

Analysis of engine piston and piston ring using…

Fig.1PistonDrawingandDimensions

Fig.2ThreeDpistonring

These were thenimported toANSYS 14.5forstructural andthermalanalysis. Structural

analysisofpistonisperformedonANSYS14.5mechanicalAPDLandthermalanalysisisperformed onANSYS 14.5

workbench. Structural andthermal analysisofpistonringisperformed onthe ANSYS14.5workbench.

2. Boundary Conditions for Structural Analysis of Piston

Combustionofgasesinthecombustionchamberexertspressureontheheadofthepiston duringpowerstroke.

Thepressureforcewillbetakenasboundaryconditioninstructuralanalysis usingANSYSmechanicalAPDL.

Fixedsupporthasgivenatsurfaceof pinhole.Becausethepiston

willmovefromTDCtoBDCwiththehelpoffixedsupportatpinhole.Sowhatevertheloadis

applyingonpistonduetogasexplosionthatforcecausestofailureofpistonpin(inducingbendingstresses).Pressureacting

2

onpiston=3.3N/mm asshowninFig.3.

3. Boundary Condition for Thermal Analysis of Piston

Thethermalboundaryconditionsconsistofapplyingaconvectionheattransfercoefficient

andthebulktemperature,andtheyareappliedtothepistoncrown,landsides,pistonskirtshownin

0 0

Fig.4. Maximumonpistonheadtemperature= 859.7 C, Bulktemperature= 25 C,Heattransfer

2 0

coefficientonpistonsurface=3200W/m K,Maximumtemperatureat edgespiston=482.7 C,Heat transfer

2

coefficient on edge piston = 2400 W/m K, Heat transfer coefficient

2 2

onlandsrings=1600W/m K,Heattransfercoefficientonpistonskirt=1000W/m K

Fig.3boundaryconditionofstructuralanalysis Fig.4boundaryconditionforthermalanalysis

www.theijes.com The IJES Page 31

Analysis of engine piston and piston ring using…

4. BoundaryConditionforStructuralandThermalAnalysisofPistonRing

Fig.5boundaryconditionforstructuralanalysis Fig.6boundaryconditionforthermal

Fig.7DisplacementvectorsumforAlAlloy4032 Fig .8StressintensityforAlAlloy4032

Fig.9DisplacementvectorsumforAlloySteel4340 Fig.10StressintensityforAlloySteel4340

Fig.11Displacementvectorsumfor TitaniumTi-6Al-4V Fig.12StressintensityforTitaniumTi-6Al-4V

www.theijes.com The IJES Page 32

Analysis of engine piston and piston ring using…

Fig.15temperatureforAISIAlloySteel4340 Fig.16 HeatfluxforAISIAlloySteel4340

Fig.17temperatureforTitaniumTi-6Al-4V Fig.18Heatfluxfor TitaniumTi-6Al-4V

Fig.19 totaldeformationforNodular Fig.20StressintensityforNodular

Spheroidal c a s t iron Spheroidal c a s t iron

Fig.21totaldeformationforgreycastiron Fig.22Stressintensityforgreycastiron

Fig.23TemperatureforNodular Fig.24TotalheatfluxforNodular

Spheroidal castiron Spheroidal castiron

www.theijes.com The IJES Page 33

Analysis of engine piston and piston ring using…

Fig.25Temperature forgreycastiron Fig.26Totalheatfluxforgreycastiron

V. Results and di scussi on

Itisclearfromfigure7,9and11thatthemaximumdisplacementisobservedinthepiston made of Al alloy 4032

and minimum in AlSl 4340 alloy steel. As itis expected

maximumdisplacementisobservedatthetopofthecentreofthepiston.Itisshowninthefigure8,10&12

thatthemaximumstressintensityisobservedinAlSl4340with301.903MPaandminimumin

Alalloy4032with295.69MPa.Itis observedthatthe maximumstressintensityisonthebottom surfaceof

theallpistoncrownandalongtheedges.Againin pistonmadeoftitaniumalloymoderate

stressintensityisfound.WhereastheyieldstrengthofthepistonisveryhighinTitaniumalloy

pistonfollowedbyAISI4340steelandAlalloy4032.

Thermalanalysisofpistonshowsthatthevalueofmaximumtemperatureis sameforallthe

materialsatthetopsurfaceofthepistoncrown,butminimumvalueoftemperatureinthepiston

madeoftitaniumalloy.Thehighestvalueof minimumtemperatureis foundinthepistonofAlalloy.

Thisisduetothermalconductivity ofthematerials. Minimum temperatureisintheskirtofthe

pistonisobservedasshowninfigure13,15&17.

Figure14,16&18showsthatmaxtotalheatfluxisobservedinpistonofAlalloyandpiston

oftitaniumalloyshowsthelowestvalueofmaxtotalheatfluxalongtheedges.

PistonringsaremadeofNodularSpheroidalCastIron&GreyCastIron.GCIPistonRings

showmoredeformationthaninNSCI.Stressintensityisequalinboth.Maximumtemperature isequalinbothmaterials,

o

whereminimum temperatureishigherinGCI,whichis222.8 C. Here,

MaximumtotalheatfluxisobservedinGCIpistonrings&minimumvalueinNSCIpistonrings.

VI. Conclusion

Itisconcludedfromthe abovestudythatusingCATIAV5R20softwaredesignandmodeling become easier.

Only few stepsareneededtomake drawinginthree dimensions. Same canbe

importedtoANSYSforanalysis.PistonmadeofthreedifferentmaterialsAlalloy4032,AISI4340.

AlloysteelandTitaniumTi-6Al-4V(Grade5) areanalyzed.Theirstructuralanalysisshowsthatthe

maximumstressintensityisonthebottomsurfaceofthepistoncrownin all the materials,butstress

intensityisclosetotheyieldstrengthofAlalloypiston.Maximumtemperatureisfoundatthecenter

ofthetopsurfaceofthepistoncrown.Thisisequalforallmaterials. Dependingonthethermal

conductivityofthematerials,heattransferrateisfoundmaximuminAlalloypistonandminimumin

Tialloypiston.Forthegivenloadingconditions,Alalloypistonisfoundmostsuitable.Butwhen

theloadingpatternchanges,othermaterialsmaybe considered.Withtheadvancementinmaterial

science,verylightweightmaterialswithgoodthermalandmechanicalpropertiescanbe usedfor fail

safedesignoftheI.C.engine.Thiswillreducethefuelconsumptionandprotecttheenvironment.

References

Chapters in book

[1] Cuddy,M.R.&Wipke,K.B.(1997),Analysis ofFuelEconomyBenefitofDrivetrain

Hybridization.http://www.nrel.gov/vehiclesandfuels/vsa/pdfs/22309.pdf(NationalRenewableEnergylaboratory).

[2] F.S.Silva(2006)Fatigueonenginepistons–Acompendiumofcasestudies.EngineeringFailureAnalysis,13pp (480–492).

[3] EkremBuyukkaya,MuhammetCerit(2007)Thermalanalysisofa ceramiccoatingdiesel enginepistonusing 3 -

Dfiniteelementmethod.SurfaceandCoatingsTechnology 2 0 2 ,2pp (398–402).

[4] Dr.NajimA.Saad,Dr.HaithamR. AbedAli,Dr. HayderShakirAbudalla,(2008),numerical analysisofthethermal–stressesof

apetrolenginepistonwithdifferentmaterials,TheIraqi JournalforMechanicalandMaterialEngineering,8,3pp(249-256).

[5]

GudimetalP,GopinathC.V,(2009)FiniteElementAnalysisofReverseEngineeredInternalCombustionEnginePiston,AIJST

PME,2,4pp(85-92).

www.theijes.com The IJES Page 34

Analysis of engine piston and piston ring using…

[6] YanxiaWang,YongqiLiu, Haiyan(2 0 1 0 ),SimulationandAnalysisofThermo-

MechanicalCouplingLoadandMechanicalDynamicLoadforaPiston;IEEE,pp(106-110).

[7] Wu,YiZeng, Dongjian Feng, Zhiyuan, (2010)FiniteElement Analysis

fortheThermalLoadofPistoninDimethylEtherFueledDieselEngine,IEEE.

[8] MesutDurat,MuratKapsiz,ErgunNart,FeritFicici&AdnanParlak,(2012),Theeffectsof

coatingmaterialsinsparkignitionenginedesign;Materials&Design,36PP(540-545).

[9] VinodJunju, M.V.Mallikarjun andVenkataRameshMamilla,(2012),Thermomechanical analysis

ofdieselenginepistonusingceramic crown;International Journal ofEmerging trendsinEngineeringandDevelopment5,2, pp(22-29).

Books

th

[10] R .S.Khurmi,J.K.Gupta(2005);MachineDesign;14 ed.;EurasiaPublishingHouse(Pvt.) Ltd.,Ramnagar,NewDelhi.

Papers/ Theses

[11] AjeetKumarRaiandAshishKumar,“AReviewon PhaseChangeMaterials&Their Applications”, International Journal ofAdvanced

Research inEngineering &Technology (IJARET),Volume3,Issue2,2012,pp.214-225,ISSNPrint:0976-6480,ISSNOnline:0976-

6499.

[12] AjeetKumarRai,RichaDubey,ShaliniYadavand VivekSachan,“TurningParameters Optimization for Surface Roughness by

Taguchi Method”, International Journal of MechanicalEngineering&Technology(IJMET),Volume4,Issue3,2013,pp.203-211,

ISSNPrint:0976–6340,ISSNOnline:0976–6359.

[13] Yuvaraj P.Ballal, ManjitM. Khade andAjitR. Mane, “Comparison ofPerformance ofCoated Carbide Inserts with Uncoated

Carbide Inserts in Turning Gray Cast Iron”,

InternationalJournalofMechanicalEngineering&Technology(IJMET),Volume4,Issue2,2013,pp.392-400,ISSNPrint:0976–

6340,ISSNOnline:0976–6359.

[14] HaiderShahadWahad,AjeetKumarRaiandPrabhatKumarSinha,“ModelingandAnalysis of

InvoluteHelicalGearusingCatia5andAnsysSoftwares”,InternationalJournalof

MechanicalEngineering&Technology(IJMET),Volume4,Issue5,2013,pp.182-190, ISSNPrint:0976–6340,ISSNOnline:0976–

6359.

www.theijes.com The IJES Page 35

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Unit-1: Fundamentals of MachiningDocumento2 pagineUnit-1: Fundamentals of MachiningN Dhanunjaya Rao BorraNessuna valutazione finora

- MCMT Mid-2 Mech 3-1 R13Documento1 paginaMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNessuna valutazione finora

- MCMT Mid-2 Mech 3-1 R13Documento1 paginaMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNessuna valutazione finora

- MCMT Mid-1 Mech 3-1 R13Documento1 paginaMCMT Mid-1 Mech 3-1 R13N Dhanunjaya Rao BorraNessuna valutazione finora

- MCMT Mid-1 P-QusDocumento5 pagineMCMT Mid-1 P-QusN Dhanunjaya Rao BorraNessuna valutazione finora

- Mid 2Documento6 pagineMid 2N Dhanunjaya Rao BorraNessuna valutazione finora

- MCMT Unit-2 PPQDocumento2 pagineMCMT Unit-2 PPQN Dhanunjaya Rao BorraNessuna valutazione finora

- Mid 2Documento6 pagineMid 2N Dhanunjaya Rao BorraNessuna valutazione finora

- Unit 1Documento5 pagineUnit 1N Dhanunjaya Rao BorraNessuna valutazione finora

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocumento1 paginaStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNessuna valutazione finora

- MCMT Mid-1 P-QusDocumento5 pagineMCMT Mid-1 P-QusN Dhanunjaya Rao BorraNessuna valutazione finora

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocumento1 paginaStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNessuna valutazione finora

- Ucmp QBDocumento1 paginaUcmp QBN Dhanunjaya Rao BorraNessuna valutazione finora

- New Text DocumentDocumento1 paginaNew Text DocumentN Dhanunjaya Rao BorraNessuna valutazione finora

- Part A5 Cotter JointsDocumento8 paginePart A5 Cotter JointsN Dhanunjaya Rao BorraNessuna valutazione finora

- New Text DocumentDocumento1 paginaNew Text DocumentN Dhanunjaya Rao BorraNessuna valutazione finora

- Composite Materials QuotationDocumento1 paginaComposite Materials QuotationN Dhanunjaya Rao BorraNessuna valutazione finora

- CAMD QuestionsDocumento3 pagineCAMD QuestionsN Dhanunjaya Rao Borra100% (1)

- Part A5 Cotter JointsDocumento8 paginePart A5 Cotter JointsN Dhanunjaya Rao BorraNessuna valutazione finora

- New Microsoft Excel WorksheetDocumento3 pagineNew Microsoft Excel WorksheetN Dhanunjaya Rao BorraNessuna valutazione finora

- Assembly DrawingsDocumento15 pagineAssembly DrawingsN Dhanunjaya Rao BorraNessuna valutazione finora

- Part A4 Keyed JointsDocumento8 paginePart A4 Keyed JointsN Dhanunjaya Rao BorraNessuna valutazione finora

- Assembly DrawingsDocumento15 pagineAssembly DrawingsN Dhanunjaya Rao BorraNessuna valutazione finora

- Part A4 Keyed JointsDocumento8 paginePart A4 Keyed JointsN Dhanunjaya Rao BorraNessuna valutazione finora

- Part-B1-Petrol Engine Connecting RodDocumento5 paginePart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraNessuna valutazione finora

- Advanced NDE Lesson 1Documento190 pagineAdvanced NDE Lesson 1N Dhanunjaya Rao BorraNessuna valutazione finora

- Part-B-Topic AB 1 CAMD Petrol Engine Connecting - RodDocumento8 paginePart-B-Topic AB 1 CAMD Petrol Engine Connecting - RodN Dhanunjaya Rao BorraNessuna valutazione finora

- Part-A5-Cotter Joints PDFDocumento6 paginePart-A5-Cotter Joints PDFN Dhanunjaya Rao BorraNessuna valutazione finora

- Part A5 Cotter JointsDocumento6 paginePart A5 Cotter JointsN Dhanunjaya Rao BorraNessuna valutazione finora

- Intro To NDTDocumento34 pagineIntro To NDTkbldamNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 498 Plate Girder CombinedDocumento12 pagine498 Plate Girder CombinedovikbasuNessuna valutazione finora

- d4n Ds e 10 1 csm1248Documento20 pagined4n Ds e 10 1 csm1248Letícia Perassoli De MeoNessuna valutazione finora

- 1 - TN1 Cold and Hot Weather Construction PDFDocumento9 pagine1 - TN1 Cold and Hot Weather Construction PDFMyra Chemyra LuvabyNessuna valutazione finora

- T7335A BCDE SeriesDocumento18 pagineT7335A BCDE SeriesCosmin RoboNessuna valutazione finora

- Ashtech QuotationDocumento13 pagineAshtech Quotationmehul dholakiyaNessuna valutazione finora

- KGN BIO TECH EIA Report PDFDocumento275 pagineKGN BIO TECH EIA Report PDFjyothi0% (1)

- Gek105060 File0060Documento12 pagineGek105060 File0060Mauricio GuanellaNessuna valutazione finora

- Indicator Norme Deviz Sanitare SDocumento484 pagineIndicator Norme Deviz Sanitare SPavel SergiuNessuna valutazione finora

- Senior Engineer SW AutosarDocumento2 pagineSenior Engineer SW AutosarDeepak Kumar RautNessuna valutazione finora

- Detailed Estimate For The Construction of A Residential BuildingDocumento8 pagineDetailed Estimate For The Construction of A Residential BuildingSukhendra SinghNessuna valutazione finora

- Blank Copy of PHE - Estimate For BLOCK 4Documento34 pagineBlank Copy of PHE - Estimate For BLOCK 4basantadrreddys100% (2)

- Product List Additives For Liquid Coatings MARCH 2013Documento12 pagineProduct List Additives For Liquid Coatings MARCH 2013Pongthip PesachpinankulNessuna valutazione finora

- Rotary Spoa7-9 Spo9 400 Series Install PDFDocumento16 pagineRotary Spoa7-9 Spo9 400 Series Install PDFFranck RoyerNessuna valutazione finora

- Design of SewerDocumento115 pagineDesign of SewerRonak KamdarNessuna valutazione finora

- Ab Brass IveDocumento4 pagineAb Brass IvejengandxbNessuna valutazione finora

- Pi GEA Omni en-US 1.1 tcm25-27710Documento62 paginePi GEA Omni en-US 1.1 tcm25-27710Edgar Joel Torres OlórteguiNessuna valutazione finora

- Module 2 Planning 3 Lecture Fundamentals Urban Planning PDF LECTUREDocumento44 pagineModule 2 Planning 3 Lecture Fundamentals Urban Planning PDF LECTUREGrace PabicoNessuna valutazione finora

- Art NouveauDocumento22 pagineArt Nouveauadefesc100% (3)

- Zero Defect Strategy at System Level For Multistage Manufacturing in Paint ShopDocumento12 pagineZero Defect Strategy at System Level For Multistage Manufacturing in Paint ShopMahendra GandhaleNessuna valutazione finora

- Exhibition Space Guidelines PDFDocumento36 pagineExhibition Space Guidelines PDFSophieNessuna valutazione finora

- Linden Comansa Tower Cranes Spec Bfbc0aDocumento8 pagineLinden Comansa Tower Cranes Spec Bfbc0aMarco RodriguezNessuna valutazione finora

- OSST Know Your Steel Guide January 2010Documento61 pagineOSST Know Your Steel Guide January 2010vikzefgNessuna valutazione finora

- Honeywell On SystemDocumento2 pagineHoneywell On SystemVishnu Vardhan . CNessuna valutazione finora

- SHC AluminiumDocumento2 pagineSHC Aluminiumsylent gohNessuna valutazione finora

- Transistor As A SwitchDocumento5 pagineTransistor As A SwitchTENS DeviceNessuna valutazione finora

- EARTHWORK (Embankment-Cleaning, Grubbing, Cutting, Filling, Leveling and FDD) (REACH 3 TO 6)Documento4 pagineEARTHWORK (Embankment-Cleaning, Grubbing, Cutting, Filling, Leveling and FDD) (REACH 3 TO 6)Ankur BarsainyaNessuna valutazione finora

- GN046Documento20 pagineGN046Jacky_LEOLEONessuna valutazione finora

- Catalogo Rotofluid Eng SONDocumento40 pagineCatalogo Rotofluid Eng SONtunaNessuna valutazione finora

- Ba TP17-TPM-Multi en PDFDocumento44 pagineBa TP17-TPM-Multi en PDFHINANessuna valutazione finora

- Embedded System Lecture Notes by Prof. Dr. Surendra Shrestha SirDocumento698 pagineEmbedded System Lecture Notes by Prof. Dr. Surendra Shrestha SirAakura Pyakura50% (2)