Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Data Sheet For Control Valve

Caricato da

alinor_tnTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Data Sheet For Control Valve

Caricato da

alinor_tnCopyright:

Formati disponibili

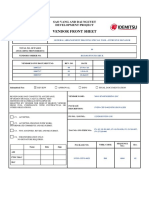

Contractor: Engineering: Project: Client:

NAWARA PROJECT

(PIPELINE)

Contract n°: OTP/PP/189 OMV/BIMS EPCC PPL

Job n° : P13IT02472

Contractor doc. n°: Engineering doc. n°: Sheet Class Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 1 of 5 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

TECHNICAL DATA SHEET FOR CONTROL VALVE

000 17/03/2015 Issue for Use/Construction FPA MBO BFU

C02 02/03/2015 Issue for Approval FPA MBO BFU D

C01 19/12/2014 Issue for Review FPA MBO BFU C

Rev. Date REVISION TITLE PREPARED CHECKED APPROVED Rev. Status

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File Name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 2 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

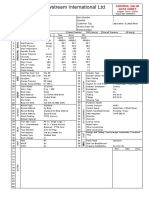

INDEX FOR SHEETS AND REVISIONS

SHEET

DENOMINATION DATE OF LAST REV. REVISION

N°

1 Cover 02/03/2015 C01 C02

2 Index 02/03/2015 C01 C02

3 General Notes 02/03/2015 C01 C02

4 NG0-324-PCV-0621 - Pressure control valve at Propane metering skid outlet 02/03/2015 C01 C02

5 NG0-323-PCV-0721 - Pressure control valve at Butane metering skid outlet 02/03/2015 C01 C02

6

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 3 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

GENERAL NOTES

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 4 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

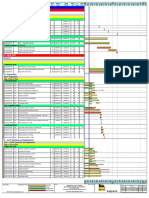

CONTROL VALVE

VALVE TAG NUMBER : NG0-324-PCV-0621 REFERENCE SPEC. NO.: NAWPPL-BIMS-NPPL-000-CI-SPE-00005

1 Location/P&ID NAWPPL-BIMS-0F04-324-PR-PID-00003 63 MFR. (*) Model (*)

2 Service pressure control at propane metering skid outlet 64 Pneumatic diaphragm piston others

3 Haz. area class. Zone 2, Gas Group IIB, Temperature Class T3 65 Style sprg. opposed double act. air spr.

4 Ambient temp. -0.2°C min. 46.2°C max. 66 Area (*)

5 Allowable sound pressure level 85 dB(A) 67 Reqd. Travel (mm) / angle (°) (*) / (*)

6 Pipe identification No. NG0-6"-LP-324-0019-B51-V 68 Supply press. (*) min. (*) max.

ACTUATOR (*)

PROCESS DATA RELEVANT FOR CONTROL VALVE SELECTION

7 DN /Rating 6" / 300# (In) 6" / 300# (Out) 69 Bench range (*)

8 Pipe wall thickness (Out) 7.11 mm 70 Action modulating on-off others

9 Pipe material ASTM A 333 Gr. 6 71 Air connection size and thread (*)

10 Pipe insulation thermal acoustic 72 Case material/finish/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002

11 Pipe corrosion allow. 1 mm 73 Actuator orientation Vertical

12 Pipe connection (note 3) 4" 74 Other actuator elect. hydraulic manual

13 Pipe design pressure/temperature 44 barg / 85 °C 75

14 Process fluid Propane 76 Handwheel

15 Upstream condition liquid vapour gas 77

16 Min. Norm. Max. Unit 78 Tag. No. MFR. (*) Model (*)

17 Flow rate 20023 20030 58000 kg/h 79 Input signal pneumatic (0.2-1 barg) electric (4-20 mA)

18 Inlet pressure P1 33.91 33.91 25 barg 80 Action direct reverse

19 Outlet pressure P2 10 (note 4) 23 23 barg 81 Style single act. double act.

POSITIONER (*)

20 Temperature T1 12.4 12.4 50 °C 82 Characteristic linear MFR.STD.

21 Inlet density ρ or M 517.4 516.5 452.8 kg/m3 83 Digital comunication HART

22 Specific gravity 0.52 0.52 0.45 84 Electric connection ISO M20 Air connection (*)

23 Viscosity 0.11 0.11 0.08 cP 85 Enclosure material low copper aluminium, epoxy coated

24 Vapour pressure Pv 7.1 7.1 17.6 bara 86 Enclosure mechanical protection IP 66

25 Critical pressure Pc 42.82 bara 87 Accessories bypass gauges

26 Ratio of specific heats k 1.6 88 Reduction of haz. Ex-ia explos.-proof

27 Compressibility factor Z 0.11 89 Tag. No. MFR. Model

28 Max. Shutoff ΔP 34 bar 90 Switch type mech. proximity pneumatic

POS. IND. SWITCH (*)

29 Air supply 4.5 barg min. 10.5 barg max. 91 Contact type SPST SPDT DPDT Namur

30 Power failure pos. open closed hold 92 Switching pos. closed % travel open

31 Calculations MFR data 93 Switching acting make break

32 Min. Norm. Max. 94 Contact rating Contact material

SUPPLIER (note (1) , (*))

33 CV 6.57 9.74 71.21 CV= 95 Reduction of haz. intrin. safe explos.-proof

34 % travel 10.2 14.6 63 96 Enclosure mechanical protection Enclosure material

35 FLP FLP= 97 Electric conn. (n°/size)

36 FD FD= 98 Integral indicator

37 σ σMR= 99 Tag. No. MFR. Model

38 xT 100 Valve style two way three way four way

39 Mach n°/ outlet velocity (m/s) 1.32 m/s 1.32 m/s 4.4 m/s 101 Coil de-energ.: ctrl. valve open closed hold

SOLENOID VALVE (*)

40 Sound pressure level (dB(A)) 82 < 70 < 70 102 Air connection Port size

41 MFR (*) Model (*) 103 Reset automatic manual

42 Body type single seat globe 104 Body/Trim material

43 Flow direction to close 105 Mechanical protection Electric connection

44 Pressure rating 300# 106 Reduction of haz. intrin. safe explos.-proof

45 Nominal size 4" 107 Coil supply nominal voltage (U) UMIN : UMAX :

46 End conn. flg. flgless welded thd. 108 Coil insulation class / max consumption /

47 Flange face finish RF 125Ra 109

VALVE BODY ASSEMBLY (*)

48 Valve face to face dimension (*) 110 Air set MFR. (*) Model (*) connect:¼" NPT-F

49 End extensions required (xx mm) not required 111 with filter with gauge

50 Bonnet style std. ext bellows 112 Transducer MFR. Model

51 Body/bonnet matl. CS ASTM A350 LF2 / ASTM A352 LCB 113

52 Trim standard low noise anti cavitation (*) 114

53 Characteristic linear eq. percent 115 Booster MFR. Model

OTHERS (*)

54 Plug / ball / disc matl. AISI 316 + STELLITE 116

55 Guide / seat matl. AISI 316 / AISI 316 + STELLITE 117 Lockup MFR. Model

56 Stem matl. AISI 316 118

57 Seat style metal soft seat 119 Position transmitter MFR. Model

58 Trim coating 120

59 Leakage specification/ class ANSI FCI 70-2 / IV 121 Stem travel indicator

60 Packing type low emission normal 122 Tubing & fittings 10 mm OD Matl. SS

61 Packing matl. PTFE 123

62 External coat painting/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002 124

NOTES

(*) Information to be supplied or to be confirmed by Manufacturer

(1) Manufacturer is required to provide his valve calculation sheet according to ISA S 75-01 (engineering calculation sheet is attached for preliminary valve sizing purpose)

(2) Valve shall be supplied completely assembled with actuator and all the accessories requested on this data sheet.

(3) Pipe provided with concentric reductions and connections to suit valve body/size connection

(4) Minimum operating pressure to be confirmed by SNDP

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR CONTROL VALVE

Contractor doc. n°: Engineering doc. n°: Rev: C01 C02 000 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00010 P13IT02472-ICT-DS-000-0047 Sheet: 5 of 5 Class: 2 NAWPPL-BIMS-NPPL-000-CI-DAT-00010

CONTROL VALVE

VALVE TAG NUMBER : NG0-323-PCV-0721 REFERENCE SPEC. NO.: NAWPPL-BIMS-NPPL-000-CI-SPE-00005

1 Location/P&ID NAWPPL-BIMS-0F05-323-PR-PID-00003 63 MFR. (*) Model (*)

2 Service pressure control at butane metering skid outlet 64 Pneumatic diaphragm piston others

3 Haz. area class. Zone 2, Gas Group IIB, Temperature Class T3 65 Style sprg. opposed double act. air spr.

4 Ambient temp. -0.2°C min. 46.2°C max. 66 Area (*)

5 Allowable sound pressure level 85 dB(A) 67 Reqd. Travel (mm) / angle (°) (*) / (*)

6 Pipe identification No. NG0-4"-LB-323-0019-B41-V 68 Supply press. (*) min. (*) max.

ACTUATOR (*)

PROCESS DATA RELEVANT FOR CONTROL VALVE SELECTION

7 DN /Rating 4" / 300# (In) 4" / 300# (Out) 69 Bench range (*)

8 Pipe wall thickness (Out) 6.02 mm 70 Action modulating on-off others

9 Pipe material ASTM A 106 Gr. B 71 Air connection size and thread (*)

10 Pipe insulation thermal acoustic 72 Case material/finish/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002

11 Pipe corrosion allow. 1 mm 73 Actuator orientation Vertical

12 Pipe connection (note 3) 3" 74 Other actuator elect. hydraulic manual

13 Pipe design pressure/temperature 44 barg / 85 °C 75

14 Process fluid Butane 76 Handwheel

15 Upstream condition liquid vapour gas 77

16 Min. Norm. Max. Unit 78 Tag. No. MFR. (*) Model (*)

17 Flow rate 20023 20057 28000 kg/h 79 Input signal pneumatic (0.2-1 barg) electric (4-20 mA)

18 Inlet pressure P1 33.74 33.74 16.5 barg 80 Action direct reverse

19 Outlet pressure P2 7.8 (note 4) 14.5 14.5 barg 81 Style single act. double act.

POSITIONER (*)

20 Temperature T1 11.7 11.7 50 °C 82 Characteristic linear MFR.STD.

21 Inlet density ρ or M 583.5 581.4 533.6 kg/m3 83 Digital comunication HART

22 Specific gravity 0.58 0.58 0.53 84 Electric connection ISO M20 Air connection (*)

23 Viscosity 0.19 0.19 0.13 cP 85 Enclosure material low copper aluminium, epoxy coated

24 Vapour pressure Pv 1.94 1.94 5.87 bara 86 Enclosure mechanical protection IP 66

25 Critical pressure Pc 37.52 bara 87 Accessories bypass gauges

26 Ratio of specific heats k 1.4 88 Reduction of haz. Ex-ia explos.-proof

27 Compressibility factor Z 0.1 89 Tag. No. MFR. Model

28 Max. Shutoff ΔP 36.2 bar 90 Switch type mech. proximity pneumatic

POS. IND. SWITCH (*)

29 Air supply 4.5 barg min. 10.5 barg max. 91 Contact type SPST SPDT DPDT Namur

30 Power failure pos. open closed hold 92 Switching pos. closed % travel open

31 Calculations MFR data 93 Switching acting make break

32 Min. Norm. Max. 94 Contact rating Contact material

SUPPLIER (note (1) , (*))

33 CV 5.98 6.95 31.54 CV= 95 Reduction of haz. intrin. safe explos.-proof

34 % travel 17.9 20.4 59.4 96 Enclosure mechanical protection Enclosure material

35 FLP FLP= 97 Electric conn. (n°/size)

36 FD FD= 98 Integral indicator

37 σ σMR= 99 Tag. No. MFR. Model

38 xT 100 Valve style two way three way four way

39 Mach n°/ outlet velocity (m/s) 2.1 m/s 2.1 m/s 3.2 m/s 101 Coil de-energ.: ctrl. valve open closed hold

SOLENOID VALVE (*)

40 Sound pressure level (dB(A)) 81 73 < 70 102 Air connection Port size

41 MFR (*) Model (*) 103 Reset automatic manual

42 Body type single seat globe 104 Body/Trim material

43 Flow direction to close 105 Mechanical protection Electric connection

44 Pressure rating 300# 106 Reduction of haz. intrin. safe explos.-proof

45 Nominal size 3" 107 Coil supply nominal voltage (U) UMIN : UMAX :

46 End conn. flg. flgless welded thd. 108 Coil insulation class / max consumption /

47 Flange face finish RF 125Ra 109

VALVE BODY ASSEMBLY (*)

48 Valve face to face dimension (*) 110 Air set MFR. (*) Model (*) connect:¼" NPT-F

49 End extensions required (xx mm) not required 111 with filter with gauge

50 Bonnet style std. ext bellows 112 Transducer MFR. Model

51 Body/bonnet matl. CS ASTM A216 WCB 113

52 Trim standard low noise anti cavitation (*) 114

53 Characteristic linear eq. percent 115 Booster MFR. Model

OTHERS (*)

54 Plug / ball / disc matl. AISI 316 + STELLITE 116

55 Guide / seat matl. AISI 316 / AISI 316 + STELLITE 117 Lockup MFR. Model

56 Stem matl. AISI 316 118

57 Seat style metal soft seat 119 Position transmitter MFR. Model

58 Trim coating 120

59 Leakage specification/ class ANSI FCI 70-2 / IV 121 Stem travel indicator

60 Packing type low emission normal 122 Tubing & fittings 10 mm OD Matl. SS

61 Packing matl. PTFE 123

62 External coat painting/colour NAWPPL-BIMS-NPPL-000-MC-SPE-00002 124

NOTES

(*) Information to be supplied or to be confirmed by Manufacturer

(1) Manufacturer is required to provide his valve calculation sheet according to ISA S 75-01 (engineering calculation sheet is attached for preliminary valve sizing purpose)

(2) Valve shall be supplied completely assembled with actuator and all the accessories requested on this data sheet.

(3) Pipe provided with concentric reductions and connections to suit valve body/size connection

(4) Minimum operating pressure to be confirmed by SNDP

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00010-000.xlsx

Potrebbero piacerti anche

- API 675 Positive Displacement Pumps - Controlled VolumeDocumento41 pagineAPI 675 Positive Displacement Pumps - Controlled VolumeFrancisco Pérez ChaniqueNessuna valutazione finora

- Datasheet PSV PDPDEDocumento8 pagineDatasheet PSV PDPDERicardo NapitupuluNessuna valutazione finora

- VDS (Valve Data Sheet)Documento1 paginaVDS (Valve Data Sheet)Shandi Hasnul Farizal0% (1)

- PVRVDocumento4 paginePVRVbkkbrazil100% (1)

- Globe Valve1 DatasheetDocumento1 paginaGlobe Valve1 DatasheetobumuyaemesiNessuna valutazione finora

- Choke Valve DetailsDocumento4 pagineChoke Valve DetailspagloosndgNessuna valutazione finora

- 112-EP4-PE-IsS-0404 - Datasheet For Control Valve (High Pressure Letdown)Documento135 pagine112-EP4-PE-IsS-0404 - Datasheet For Control Valve (High Pressure Letdown)cre1982Nessuna valutazione finora

- Offshore Design Section Functional Specification For Level TransmitterDocumento10 pagineOffshore Design Section Functional Specification For Level TransmitterGerman ToledoNessuna valutazione finora

- PZ D CS Pi SP 015 02Documento60 paginePZ D CS Pi SP 015 02epbamdadNessuna valutazione finora

- TB2-SDC-00100-P-G1-CAL-0002 RevB PDFDocumento1.210 pagineTB2-SDC-00100-P-G1-CAL-0002 RevB PDFHanLe DuyNessuna valutazione finora

- Thermowell Calculation Guide V1.3Documento19 pagineThermowell Calculation Guide V1.3Sriram SridaranNessuna valutazione finora

- DataSheet For Carbon Steel LinepipesDocumento17 pagineDataSheet For Carbon Steel LinepipesDaniel Dambo0% (1)

- Dye Injection Skid Process DatasheetDocumento7 pagineDye Injection Skid Process Datasheetjibran42Nessuna valutazione finora

- Datasheet Anchor FlangeDocumento1 paginaDatasheet Anchor FlangeHafiz Ashadi100% (1)

- Pipe Supports DesignDocumento29 paginePipe Supports DesignkarunaNessuna valutazione finora

- Datasheets For Bucket Type StrainerDocumento2 pagineDatasheets For Bucket Type StrainerbecpavanNessuna valutazione finora

- 10P87-D0003-046-R0-WHRU by TEPLDocumento23 pagine10P87-D0003-046-R0-WHRU by TEPLjigarNessuna valutazione finora

- PSV Force Rev0bDocumento1 paginaPSV Force Rev0bdumbledoreaaaaNessuna valutazione finora

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocumento4 pagineVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNessuna valutazione finora

- Control Valve Data SheetDocumento6 pagineControl Valve Data SheetsisesetNessuna valutazione finora

- Pipe Size Flange Rating Operating Condition: E F SFDocumento4 paginePipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- TDS For Y-StrainerDocumento2 pagineTDS For Y-StrainerRAGHVENDRA PRATAP SINGHNessuna valutazione finora

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocumento1 paginaPY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Nessuna valutazione finora

- Data Sheet For Ball ValveDocumento6 pagineData Sheet For Ball ValveTauqueerAhmadNessuna valutazione finora

- Material Requisition For Expansion Joint - Rev1Documento4 pagineMaterial Requisition For Expansion Joint - Rev1altipatlarNessuna valutazione finora

- BE-WI-248-01-F19 Datasheet Breather ValveDocumento3 pagineBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNessuna valutazione finora

- Compiled Vol IIDocumento69 pagineCompiled Vol IIashish.mathur1Nessuna valutazione finora

- Pressure RELIEF VALVE DATA SHEETDocumento4 paginePressure RELIEF VALVE DATA SHEETAlvin SmithNessuna valutazione finora

- Pt. Bahana Karya Mandiri: Data SheetDocumento8 paginePt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoNessuna valutazione finora

- MSRODocumento1 paginaMSROAjay ChodankarNessuna valutazione finora

- Hydraulic Report Lifting Station R0Documento12 pagineHydraulic Report Lifting Station R0Unni CyriacNessuna valutazione finora

- TR0038-3 - Valve-ActuatorsDocumento49 pagineTR0038-3 - Valve-ActuatorsMaffone NumerounoNessuna valutazione finora

- Ane Spinms PVV Mto 300031 PDFDocumento17 pagineAne Spinms PVV Mto 300031 PDFAtty AttyNessuna valutazione finora

- Ball Valve Data Sheet: Item Requirement NotesDocumento1 paginaBall Valve Data Sheet: Item Requirement NotesVivi OktaviantiNessuna valutazione finora

- Calculation of Steel Piping SupportsDocumento21 pagineCalculation of Steel Piping Supportsalinor_tnNessuna valutazione finora

- INDEX AND GENERAL NOTES FOR CONTROL VALVE DATASHEETDocumento5 pagineINDEX AND GENERAL NOTES FOR CONTROL VALVE DATASHEETveenaNessuna valutazione finora

- NTF in DS LG 001 Data Sheet Level GaugeDocumento4 pagineNTF in DS LG 001 Data Sheet Level GaugeRicardo NapitupuluNessuna valutazione finora

- Piping Material Specification RatingsDocumento4 paginePiping Material Specification RatingsPrasanta Kumar BeheraNessuna valutazione finora

- Spring Hanger Support Design-StepsDocumento19 pagineSpring Hanger Support Design-StepsrgopalanNessuna valutazione finora

- Utility Gate Valve Data SheetsDocumento9 pagineUtility Gate Valve Data SheetsArunkumarNessuna valutazione finora

- 2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisDocumento23 pagine2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisSachin ShindeNessuna valutazione finora

- A11Documento1 paginaA11liviu_dovaNessuna valutazione finora

- WIKA Thermowell Wake FrequencyDS IN0015 en Co 1353Documento7 pagineWIKA Thermowell Wake FrequencyDS IN0015 en Co 1353Shameer MajeedNessuna valutazione finora

- Isolation Philosophy - SampleDocumento24 pagineIsolation Philosophy - SampleOlalekan IgeNessuna valutazione finora

- GF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Documento60 pagineGF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Rami KsidaNessuna valutazione finora

- 6208734-I-Rfq-001 PLC RFQ R1Documento26 pagine6208734-I-Rfq-001 PLC RFQ R1KarthikeyanNessuna valutazione finora

- Orifice Plate Flow Meter Data SheetDocumento4 pagineOrifice Plate Flow Meter Data SheetTaimoor KhanNessuna valutazione finora

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Documento4 pagineENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronNessuna valutazione finora

- Intools Software Free Download Crack For Windows PDFDocumento4 pagineIntools Software Free Download Crack For Windows PDFJasonNessuna valutazione finora

- Piping Specification for Darquain Oil Field Development ProjectDocumento13 paginePiping Specification for Darquain Oil Field Development ProjectJorge Castro CucurellaNessuna valutazione finora

- Actuated Ball Valve 357 D - BDKDocumento5 pagineActuated Ball Valve 357 D - BDKfarhanakhtar ansariNessuna valutazione finora

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocumento7 pagine13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNessuna valutazione finora

- Vessel Data SheetDocumento1 paginaVessel Data SheetMichael HaiseNessuna valutazione finora

- RR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction OrificeDocumento16 pagineRR-02-PT-100-IN-DT-0063 Data Sheet For Orifice Plate Restriction Orificemohsen ranjbar100% (1)

- Ongc 2004a Rev 7Documento78 pagineOngc 2004a Rev 7dzardoniNessuna valutazione finora

- Technical Data Sheet For Temperature TransmitterDocumento38 pagineTechnical Data Sheet For Temperature Transmitteralinor_tnNessuna valutazione finora

- Nawppl Bims NPPL 000 Co MST 00004 000 Wms For Slit TrenchesDocumento18 pagineNawppl Bims NPPL 000 Co MST 00004 000 Wms For Slit TrenchesWalid KhelfaNessuna valutazione finora

- NAWPPL-BIMS-NPPL-000-HS-PRO-00009 - C01 - Tagging & Isolation ProcedureDocumento8 pagineNAWPPL-BIMS-NPPL-000-HS-PRO-00009 - C01 - Tagging & Isolation ProcedureMoaatazz NouisriNessuna valutazione finora

- Nawppl-Bims-Nppl-000-Co-Mst-00001-000 - Method of Statement For Pipeline Route Site VisitDocumento34 pagineNawppl-Bims-Nppl-000-Co-Mst-00001-000 - Method of Statement For Pipeline Route Site VisitWalid KhelfaNessuna valutazione finora

- Nawppl-Bims-Nppl-000-Yl-Spe-00002-004 - Pipeline Hydrostatic Pressure Test SpecificationDocumento44 pagineNawppl-Bims-Nppl-000-Yl-Spe-00002-004 - Pipeline Hydrostatic Pressure Test Specificationradhwen chammakhi100% (1)

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDocumento32 pagineHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- Pipeline Welding Visual Inspection ReportDocumento8 paginePipeline Welding Visual Inspection Reportalinor_tn0% (1)

- IDS For Fiber Optic CableDocumento5 pagineIDS For Fiber Optic Cablealinor_tnNessuna valutazione finora

- 000-Za-E-09303 - 0 Packing and Marking ProcedureDocumento251 pagine000-Za-E-09303 - 0 Packing and Marking Procedurealinor_tnNessuna valutazione finora

- 000 ZA E 09411 Punch List ProcedureDocumento17 pagine000 ZA E 09411 Punch List Procedurealinor_tn100% (1)

- Technical Data Sheet For Temperature TransmitterDocumento38 pagineTechnical Data Sheet For Temperature Transmitteralinor_tnNessuna valutazione finora

- Calculation of Steel Piping SupportsDocumento21 pagineCalculation of Steel Piping Supportsalinor_tnNessuna valutazione finora

- Pipeline Hydrotest ProcedureDocumento78 paginePipeline Hydrotest Procedurealinor_tn100% (1)

- Walkways Steel Structure and R.C. Foundations DrawingsDocumento3 pagineWalkways Steel Structure and R.C. Foundations Drawingsalinor_tnNessuna valutazione finora

- Work Method Statement For De-Watering Drying and Purging After HydrotestDocumento12 pagineWork Method Statement For De-Watering Drying and Purging After Hydrotestalinor_tnNessuna valutazione finora

- Site Nonconformity Management ProcedureDocumento11 pagineSite Nonconformity Management Procedurealinor_tn100% (1)

- 000-ZA-E-09413 Construction Progress Meas ProcDocumento12 pagine000-ZA-E-09413 Construction Progress Meas Procalinor_tnNessuna valutazione finora

- Welders MatrixDocumento1 paginaWelders Matrixalinor_tn100% (1)

- Flowlines NDT RequestDocumento4 pagineFlowlines NDT Requestalinor_tnNessuna valutazione finora

- Sample Test Pack - Piping HydrotestDocumento96 pagineSample Test Pack - Piping Hydrotestalinor_tn75% (4)

- ITP-000 Piping Fabrication (Exemple)Documento5 pagineITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Reports Approval Status - 11.12.2017Documento4 pagineReports Approval Status - 11.12.2017alinor_tnNessuna valutazione finora

- MLE System SubSystem SheduleDocumento29 pagineMLE System SubSystem Shedulealinor_tnNessuna valutazione finora

- Mechanical Test Specimens PlanDocumento3 pagineMechanical Test Specimens Planalinor_tn100% (1)

- Tie-In StatusDocumento22 pagineTie-In Statusalinor_tnNessuna valutazione finora

- Piezometer Marker Installation GuideDocumento1 paginaPiezometer Marker Installation Guidealinor_tn100% (1)

- WPS MS 01C Rev. 0Documento1 paginaWPS MS 01C Rev. 0alinor_tnNessuna valutazione finora

- RT Permit To WorkDocumento1 paginaRT Permit To Workalinor_tnNessuna valutazione finora

- ESAB - PipelinesDocumento65 pagineESAB - PipelinesLigia114100% (2)

- Comparison of API 1104 Appendix A and BS 7910 Procedures For The Assessment of Girth Weld FlawsDocumento10 pagineComparison of API 1104 Appendix A and BS 7910 Procedures For The Assessment of Girth Weld Flawsalinor_tnNessuna valutazione finora

- Omniscan Techniques For Crack SizingDocumento31 pagineOmniscan Techniques For Crack Sizingalinor_tnNessuna valutazione finora

- General Procedure For AUTDocumento19 pagineGeneral Procedure For AUTalinor_tn100% (2)

- Recommandation TodfDocumento14 pagineRecommandation Todfalinor_tnNessuna valutazione finora

- Ch16 Fss CodeDocumento7 pagineCh16 Fss Codeerudite_0206Nessuna valutazione finora

- ES1 Work Panel DatasheetDocumento3 pagineES1 Work Panel DatasheetGerardo Alberto Navarro LopezNessuna valutazione finora

- (Nima Naghibi) Rethinking Global Sisterhood Weste PDFDocumento220 pagine(Nima Naghibi) Rethinking Global Sisterhood Weste PDFEdson Neves Jr.100% (1)

- Vivaldi - Genuis of BaroqueDocumento279 pagineVivaldi - Genuis of Baroqueilcanto100% (4)

- The Ideal Structure of ZZ (Alwis)Documento8 pagineThe Ideal Structure of ZZ (Alwis)yacp16761Nessuna valutazione finora

- HIS 101 Home Work 2Documento10 pagineHIS 101 Home Work 2Nabil HussainNessuna valutazione finora

- Johnson 1999Documento20 pagineJohnson 1999Linh Hoàng PhươngNessuna valutazione finora

- Pump IntakeDocumento6 paginePump IntakeAnonymous CMS3dL1T100% (1)

- ccpc15 Supportive and Preventive WorkbookDocumento30 pagineccpc15 Supportive and Preventive WorkbookJeremy HamptonNessuna valutazione finora

- PEB Requirment by ClientDocumento4 paginePEB Requirment by ClientViraj ModiNessuna valutazione finora

- Chapter-5 Contract ManagementDocumento43 pagineChapter-5 Contract Managementprem kumarNessuna valutazione finora

- Chicago TemplateDocumento4 pagineChicago TemplateJt MetcalfNessuna valutazione finora

- Sukkur IBA University Aptitude Test Candidates ListDocumento306 pagineSukkur IBA University Aptitude Test Candidates ListFurkan memonNessuna valutazione finora

- Money MBA 1Documento4 pagineMoney MBA 1neaman_ahmed0% (1)

- Component 2 Learner Statement Y2Documento6 pagineComponent 2 Learner Statement Y2api-426152133Nessuna valutazione finora

- July 4th G11 AssignmentDocumento5 pagineJuly 4th G11 Assignmentmargo.nicole.schwartzNessuna valutazione finora

- Transistor Amplifier Operating ParametersDocumento21 pagineTransistor Amplifier Operating ParametersReddyvari VenugopalNessuna valutazione finora

- Anticipate Problems Before They Emerge: White PaperDocumento7 pagineAnticipate Problems Before They Emerge: White PaperYotsapol KantaratNessuna valutazione finora

- 3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2Documento24 pagine3 - 6consctructing Probability Distributions CG A - 4 - 6 Lesson 2CHARLYN JOY SUMALINOGNessuna valutazione finora

- Ubc 2015 May Sharpe JillianDocumento65 pagineUbc 2015 May Sharpe JillianherzogNessuna valutazione finora

- Timoshenko Beam TheoryDocumento8 pagineTimoshenko Beam Theoryksheikh777Nessuna valutazione finora

- Media LiteracyDocumento33 pagineMedia LiteracyDo KyungsooNessuna valutazione finora

- TiONA 592 PDS - ENDocumento1 paginaTiONA 592 PDS - ENQuang VANessuna valutazione finora

- LaQshya Labour Room Quality Improvement InitiativeDocumento2 pagineLaQshya Labour Room Quality Improvement InitiativeHimanshu SharmaNessuna valutazione finora

- Questions 32 - 34: Sunny English MqaDocumento9 pagineQuestions 32 - 34: Sunny English MqaHạnh NguyễnNessuna valutazione finora

- MATH Concepts PDFDocumento2 pagineMATH Concepts PDFs bNessuna valutazione finora

- PoiconverterDocumento2 paginePoiconvertertaco6541Nessuna valutazione finora

- Hong Kong A-Level Chemistry Book 3ADocumento69 pagineHong Kong A-Level Chemistry Book 3AMARENG BERNABENessuna valutazione finora

- Liugong 938 Wheel Loader Parts ManualDocumento20 pagineLiugong 938 Wheel Loader Parts Manualjonathan100% (49)

- Safety Data Sheet for Instant AdhesiveDocumento6 pagineSafety Data Sheet for Instant AdhesiveDiego S. FreitasNessuna valutazione finora

- Mpce 24Documento39 pagineMpce 24Sachin Mehla0% (1)