Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SKL WP2 - Product Data Sheet - English PDF

Caricato da

anon_2398345380 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni2 pagineTitolo originale

SKL-WP2_Product-Data-Sheet_English.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni2 pagineSKL WP2 - Product Data Sheet - English PDF

Caricato da

anon_239834538Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

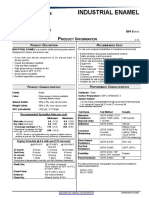

Product Data Sheet

SKL-WP2

Water Washable Visible Dye Penetrant

Designed for large surface areas and rough surfaces where excess penetrant is difficult to remove with

a solvent removable cleaner or emulsifier, SKL-WP2 can be removed with a water spray, either manually

or with an automated step. It produces a visible red color contrast for discontinuity identification, and it

also has outstanding penetrating characteristics. It is normally used on welds, forgings, pressure vessels,

castings and general metal work, and it lends itself to a production environment where many parts are

inspected daily.

SKL-WP2 is listed on the QPL SAE AMS 2644 Qualified Product List.

BENEFITS Maximize operator comfort and safety

Dependable and convenient to use • Promotes better inspection quality by

• Easy to carry and use in the field with providing the operator with a more

the convenient aerosol cans which are comfortable work environment

carefully designed for consistent, even • Reduces discomfort from strong odors

coverage and maximum test area coverage • Exceeds all EHS requirements, does not

• Use in all conditions without the need for contain NPEs or phthalates

darkness or UV lights

• Quickly and completely covers the entire FEATURES

test surface due to high surface wetting

• Easy, water-wash removal

Wide application versatility • ISO 3452 sensitivity level #2

• Inspect a wide range of components • Can be used with Method A or Method C

without fear of corrosion or specification • Vivid, high-contrast red color

non-conformance • Superior flaw resolution

• Meets AMS 2644 and is NDT-approved for • Good surface wetting

professional industrial applications • Optimized capillary action

• Reduced processing cost per part due to • Works in visible light

excellent washability, which is especially • Very low toxicity

useful for large parts and cast components • Low odor

• NDT-spec compliant

Maximum indication detection

• Produces strong, vibrant indications thanks

to the bright, vibrant red color, especially

when used with SKD-S2 solvent-based

developer

Revised: December 2017 magnaflux.com

Product Data Sheet

SPECIFICATION COMPLIANCE PROPERTIES

• AECL Flash Point > 200°F / 93°C

• AMS 2644

• ASME Density 0.87 g/cc / 7.30 lb/gal

• ASTM E1417

Viscosity

• ASTM E165 (at 100°F / 38°C)

7.89 cs

• Boeing BAC 5423 PSD 6-46 or 8-4

• Boeing PS-21202 NPE-Free Yes

• GE P50YP107

• ISO 3452

• MIL-STD-2132 USE RECOMMENDATIONS

• MIL-STD-271

• NAVSEA T9074-AS-GIB-010/271 Penetrant Testing, Visible

NDT Method

• QPL SAE AMS 2644 Dye

Type Type 2

APPLICATIONS Method(s) A/C

Defect location: open to surface Sensitivity Level ISO 3452 sensitivity level #2

Ideal for:

Required No special equipment need-

• Wide range of applications Equipment ed

• Large parts Temperature

40 to 125°F / 4 to 52°C

• Castings Range

• Forgings 1 aerosol can will cover

approximately 65 ft2 / 6 m2

• Welds Coverage

1 gal will cover approximately

• Pressure vessels

1,200 ft2 / 111 m2

• Tubular goods

Defect examples:

• Cracks PACKAGING

• Leaks Aerosol can, case of 12 01-5190-78

• Incomplete weld penetration 1 gal / 3.78 L jug, case of 4 01-5190-35

• Incomplete weld fusion

• Undercutting 5 gal / 18.9 L pail 01-5190-40

• Slag inclusions 55 gal / 208 L drum 01-5190-45

• Flux inclusions

• Weld porosity

HEALTH AND SAFETY

Review all relevant health and safety information

before using this product. For complete health and

safety information, refer to the product Safety Data

Sheet, which is available at www.magnaflux.com.

Revised: December 2017 magnaflux.com

Potrebbero piacerti anche

- Purnanandalahari p3D4Documento60 paginePurnanandalahari p3D4anilkumar100% (1)

- Facelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger FaceDocumento136 pagineFacelift at Your Fingertips - An Aromatherapy Massage Program For Healthy Skin and A Younger Faceugur gebologluNessuna valutazione finora

- Aligning With New Digital Strategy A Dynamic CapabilitiesDocumento16 pagineAligning With New Digital Strategy A Dynamic Capabilitiesyasit10Nessuna valutazione finora

- Oracle Time and Labor - Data SheetDocumento5 pagineOracle Time and Labor - Data Sheetbilaltanoli@gmail.comNessuna valutazione finora

- Rust O Cap: Surface Tolerant EpoxyDocumento3 pagineRust O Cap: Surface Tolerant EpoxySanthana SaravanaNessuna valutazione finora

- SKL WP2 - Product Data Sheet - English PDFDocumento2 pagineSKL WP2 - Product Data Sheet - English PDFPako PaezNessuna valutazione finora

- Skl-Wp2: Water Washable Visible Dye PenetrantDocumento2 pagineSkl-Wp2: Water Washable Visible Dye PenetrantTahseen AhmedNessuna valutazione finora

- High-contrast solvent developer for NDT inspectionsDocumento2 pagineHigh-contrast solvent developer for NDT inspectionsDarwin EnriqueNessuna valutazione finora

- Level 3 Water Washable Fluorescent Penetrant: Product Data SheetDocumento2 pagineLevel 3 Water Washable Fluorescent Penetrant: Product Data SheetDinda MaharaniNessuna valutazione finora

- Level 3 Post Emulsifiable Fluorescent Penetrant: Product Data SheetDocumento2 pagineLevel 3 Post Emulsifiable Fluorescent Penetrant: Product Data SheetAnand AmanNessuna valutazione finora

- Lipophilic Emulsifier: Product Data SheetDocumento2 pagineLipophilic Emulsifier: Product Data SheetMiguelNessuna valutazione finora

- SKC-S: NDT Cleaner & RemoverDocumento2 pagineSKC-S: NDT Cleaner & Removerஅன்புடன் அஸ்வின்Nessuna valutazione finora

- Product Data Sheet for High-Sensitivity Level 3 Water Washable Fluorescent Penetrant ZL-67Documento3 pagineProduct Data Sheet for High-Sensitivity Level 3 Water Washable Fluorescent Penetrant ZL-67KadirOzturkNessuna valutazione finora

- ZL 440 Product Data SheetDocumento3 pagineZL 440 Product Data SheetVishal ChudasamaNessuna valutazione finora

- ZL 405 Product Data SheetDocumento2 pagineZL 405 Product Data SheetVishal ChudasamaNessuna valutazione finora

- Skl-Wp2: Water-Washable Visible PenetrantDocumento3 pagineSkl-Wp2: Water-Washable Visible PenetrantRussell ShacklefordNessuna valutazione finora

- Excellent washability penetrant for casting flawsDocumento2 pagineExcellent washability penetrant for casting flawsZahedShareefNessuna valutazione finora

- Protective & Marine Coatings: Acrolon™ 218 HsDocumento4 pagineProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNessuna valutazione finora

- Lipophilic Emulsifier: Product Data SheetDocumento2 pagineLipophilic Emulsifier: Product Data SheetyuzivengamNessuna valutazione finora

- ZP-9F Solvent Developer Data SheetDocumento2 pagineZP-9F Solvent Developer Data SheetDarwin EnriqueNessuna valutazione finora

- Protective & Marine Coatings: Acrolon™ 218 HsDocumento4 pagineProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNessuna valutazione finora

- FF1021 Acoutstical Smoke Sealant SheetDocumento2 pagineFF1021 Acoutstical Smoke Sealant SheetChinith012Nessuna valutazione finora

- Catalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Documento15 pagineCatalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Samuel VelizNessuna valutazione finora

- Acrolon 218 HS Acrylic PolyurethaneDocumento4 pagineAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNessuna valutazione finora

- Carboguard 636 XT PDSDocumento4 pagineCarboguard 636 XT PDSCarlos Rojas HandalNessuna valutazione finora

- Cepsa Hidrostar HVLP: Lubricants For Industrial UseDocumento1 paginaCepsa Hidrostar HVLP: Lubricants For Industrial UseVladislav TrempoletsNessuna valutazione finora

- Cepsa Hidrosic HLP: Lubricants For Industrial UseDocumento1 paginaCepsa Hidrosic HLP: Lubricants For Industrial UseVladislav Trempolets100% (1)

- HYDRAULIC 37 Anti-Wear OilDocumento1 paginaHYDRAULIC 37 Anti-Wear OilSami KahtaniNessuna valutazione finora

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocumento4 pagineProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNessuna valutazione finora

- Carbozinc 858: Selection & Specification DataDocumento4 pagineCarbozinc 858: Selection & Specification DataNico RoisnerNessuna valutazione finora

- #2 Yellow: Non-Fluorescent Magnetic ParticlesDocumento2 pagine#2 Yellow: Non-Fluorescent Magnetic ParticlesSandro ChiliquingaNessuna valutazione finora

- Acrolon 218 HsDocumento4 pagineAcrolon 218 HsKARENNessuna valutazione finora

- Carboguard 635 Thinned 50% - Sealer PDSDocumento5 pagineCarboguard 635 Thinned 50% - Sealer PDSjakeNessuna valutazione finora

- Specseal LC Endothermic Firestop Sealant: ApplicationsDocumento2 pagineSpecseal LC Endothermic Firestop Sealant: ApplicationsKarim TarekNessuna valutazione finora

- #1 Gray: Non-Fluorescent Magnetic ParticlesDocumento2 pagine#1 Gray: Non-Fluorescent Magnetic ParticlesReadersmoNessuna valutazione finora

- Product Data Sheet for #8A Red Non-fluorescent Magnetic ParticlesDocumento2 pagineProduct Data Sheet for #8A Red Non-fluorescent Magnetic ParticlesSankar KrishnanNessuna valutazione finora

- Acrolon 218 FTDocumento4 pagineAcrolon 218 FTEdwin VSNessuna valutazione finora

- Carboguard 891 Product Data SheetDocumento4 pagineCarboguard 891 Product Data SheetPrakashNessuna valutazione finora

- Interzinc 2265: Product DescriptionDocumento4 pagineInterzinc 2265: Product DescriptionIsabelo AbaoNessuna valutazione finora

- Proximity Sensors and Limit Switches: Time-Tested, Robust and Reliable ControlDocumento8 pagineProximity Sensors and Limit Switches: Time-Tested, Robust and Reliable ControlidontlikeebooksNessuna valutazione finora

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocumento4 pagineProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNessuna valutazione finora

- Technical Data Sheet Jazeera Green Care JA-16056: DescriptionDocumento3 pagineTechnical Data Sheet Jazeera Green Care JA-16056: DescriptionAhmad BougeisNessuna valutazione finora

- Steelshield Ve: Product DescriptionDocumento2 pagineSteelshield Ve: Product DescriptionMoin AltafNessuna valutazione finora

- 4010 TDS EnglishDocumento1 pagina4010 TDS EnglishJose Luis Ramirez RamirezNessuna valutazione finora

- DATA SHEET Industrial Enamel BlancoDocumento4 pagineDATA SHEET Industrial Enamel BlancoAlfredo OrellanaNessuna valutazione finora

- Cermithane Tds en 2Documento2 pagineCermithane Tds en 2Hawraz MuhammedNessuna valutazione finora

- Apcoguard SF 725Documento3 pagineApcoguard SF 725kiran vargheseNessuna valutazione finora

- DOWSIL™ 3-1965 Conformal Coating: Features & BenefitsDocumento3 pagineDOWSIL™ 3-1965 Conformal Coating: Features & Benefitsquang trinhNessuna valutazione finora

- KTex BrochureDocumento12 pagineKTex BrochureEndra BudimansyahNessuna valutazione finora

- Sigmaprime 700Documento7 pagineSigmaprime 700Trịnh Minh KhoaNessuna valutazione finora

- Technical Data Sheet Jazeera Selfmastic JI-66009: DescriptionDocumento3 pagineTechnical Data Sheet Jazeera Selfmastic JI-66009: Descriptionsalam nazarNessuna valutazione finora

- Technical Data Sheet Jazeera Novel Plus JA-16051: DescriptionDocumento3 pagineTechnical Data Sheet Jazeera Novel Plus JA-16051: DescriptionAhmad BougeisNessuna valutazione finora

- Protective Industrial Enamel CoatingDocumento4 pagineProtective Industrial Enamel CoatingAna CabreraNessuna valutazione finora

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocumento7 pagineAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNessuna valutazione finora

- Interlac 1 Gris MamaparoDocumento4 pagineInterlac 1 Gris Mamaparowilfran villegasNessuna valutazione finora

- Carboguard 890 GFDocumento4 pagineCarboguard 890 GFDuongthithuydungNessuna valutazione finora

- Acrylic Elastomeric Paint Technical DataDocumento3 pagineAcrylic Elastomeric Paint Technical DataAhmad BougeisNessuna valutazione finora

- Carboquick 200 PDSDocumento4 pagineCarboquick 200 PDSMarcelo Alejandro MarinoNessuna valutazione finora

- Anti-carbonation acrylic elastomeric paintDocumento3 pagineAnti-carbonation acrylic elastomeric paintAhmad BougeisNessuna valutazione finora

- ZChek PDS PTDocumento2 pagineZChek PDS PTharshileng3992Nessuna valutazione finora

- PPG Hi-Temp™ 1027 HDDocumento5 paginePPG Hi-Temp™ 1027 HDMarleo MorenoNessuna valutazione finora

- 400 UkDocumento4 pagine400 UkAhmed IbrahimNessuna valutazione finora

- Interzinc 75V: Zinc-Rich EpoxyDocumento4 pagineInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNessuna valutazione finora

- Beuys Begleitheft en ScreenDocumento18 pagineBeuys Begleitheft en Screensofijawt0% (1)

- Analysis I - SyllabusDocumento3 pagineAnalysis I - SyllabusJUan GAbrielNessuna valutazione finora

- Silyzer 300 - Next Generation PEM ElectrolysisDocumento2 pagineSilyzer 300 - Next Generation PEM ElectrolysisSaul Villalba100% (1)

- English 2.2 FPT PolytechnicDocumento10 pagineEnglish 2.2 FPT PolytechnicKieu Mai Trang (FPL HCM)0% (1)

- Bronchogenic CarcinomaDocumento13 pagineBronchogenic Carcinomaloresita_rebongNessuna valutazione finora

- Final Exam IN Sample QuestionsDocumento27 pagineFinal Exam IN Sample QuestionsJI TEN100% (1)

- Sri Lanka, CBSLDocumento24 pagineSri Lanka, CBSLVyasIRMANessuna valutazione finora

- Family Culture and Traditions PaperDocumento7 pagineFamily Culture and Traditions PaperAmit JindalNessuna valutazione finora

- Sequence TransformationDocumento2 pagineSequence Transformationbrown222Nessuna valutazione finora

- Vee 2003Documento14 pagineVee 2003Syed faizan Ali zaidiNessuna valutazione finora

- Armitage Tutorial for Cyber Attack ManagementDocumento54 pagineArmitage Tutorial for Cyber Attack Managementworkmumbai3870Nessuna valutazione finora

- A Comparison of Fuel Cell Testing Protocols PDFDocumento7 pagineA Comparison of Fuel Cell Testing Protocols PDFDimitrios TsiplakidesNessuna valutazione finora

- ExportDocumento18 pagineExportDolon MukherjeeNessuna valutazione finora

- Camp ApplianceDocumento1 paginaCamp ApplianceflyzalNessuna valutazione finora

- V Bhebhe PDFDocumento63 pagineV Bhebhe PDFVusi BhebheNessuna valutazione finora

- Xbox Accessories en ZH Ja Ko - CN Si TW HK JP KoDocumento64 pagineXbox Accessories en ZH Ja Ko - CN Si TW HK JP KoM RyuNessuna valutazione finora

- Oposa vs. Factoran 224 Scra 792Documento28 pagineOposa vs. Factoran 224 Scra 792albemartNessuna valutazione finora

- Format For Handout - Comparative Models of EducationDocumento5 pagineFormat For Handout - Comparative Models of EducationAdrian AsiNessuna valutazione finora

- Lesson Plan Garbage Gym GameDocumento3 pagineLesson Plan Garbage Gym Gameapi-272479731Nessuna valutazione finora

- APA - 7thed - UCW Student Paper TemplateDocumento4 pagineAPA - 7thed - UCW Student Paper Templatesimerpreet3Nessuna valutazione finora

- Year 2 - Push and Pull FPDDocumento18 pagineYear 2 - Push and Pull FPDRebecca LNessuna valutazione finora

- Booklet English 2016Documento17 pagineBooklet English 2016Noranita ZakariaNessuna valutazione finora

- Final Case Study 0506Documento25 pagineFinal Case Study 0506Namit Nahar67% (3)

- Dental Management of Patients With HemophiliaDocumento5 pagineDental Management of Patients With HemophiliaarjayNessuna valutazione finora

- Rise of NationalismDocumento19 pagineRise of NationalismlolaNessuna valutazione finora

- MarasiNews Issue 12Documento47 pagineMarasiNews Issue 12Sunil Kumar P GNessuna valutazione finora