Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

How To Make A Gun Barrel: Spare & Tuning Parts For IPSC

Caricato da

buidoi sonrauTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

How To Make A Gun Barrel: Spare & Tuning Parts For IPSC

Caricato da

buidoi sonrauCopyright:

Formati disponibili

How to Make a Gun Barrel

Firearms, more commonly known as guns, are

used by outdoor hunting enthusiasts. Some

hunters may choose to make their own guns,

rather than buying them, to get a custom

firearm. The most difficult part of building a gun

is to create a barrel that will direct the fired

round at the desired target. The barrel also

imparts a spin to the round as it travels down

the barrel, which gives the round gyroscopic

stabilization as it flies to the target. Use these

tips to learn how to make a gun barrel.

Steps

1 Choose the type of steel to be used

for the gun barrel. The steel chosen

must have a strength of 100,000 psi (689476

kPA) to withstand the force of the gasses

that propel the round. The steel should have

a hardness of 25 to 32 on the Rockwell scale

so that the steel is strong enough to contain

the pressure necessary to propel the round

through the barrel, but not so brittle that it

will be harmed by the machining operations

to be performed. Obtain 1.25 inch (31.75

mm) rods from a specialty steel mill. Ask for

a quality certification on the steel. Specify

that the steel must be stress relieved at the

steel mill.

Select 4140 chrome moly steel. Chrome

moly steel is the least expensive

alternative. It also is easier to chemically

blacken, if desired, to give a traditional

look to the barrel.

Decide on 416 stainless steel. Stainless

steel is more expensive than chrome

moly Steel. Stainless steel barrels have

have a longer service life and are result

in a more accurate firearm than do

chrome moly steel barrels.

manufacturing of

Spare & Tuning spare and tuning

Parts for IPSC parts, targets &

CZ, STI, Tanfoglio, accessories for

SigSauer IPSC Sports

eemann-tech.com

2 Cut a piece of steel for the barrel

stock. Cut a length of steel around 28

inches (71.1 cm) to 30 inches (711.2 mm to

762 mm). Ensure that the ends of the barrel

stock are true in parallelism to each other,

are faced off and are perfectly round.

3 Drill the barrel. Drill down the interior

lengthwise to a diameter about 5

thousandths of an inch (0.127 mm) less than

the desired finished bore diameter of the

barrel. A special drill, known as a deep hole

drill, must be used to drill the barrel. The

deep hole drill will hold the tungsten carbide

drill bit still and spin the barrel to perform the

drilling. Drilling will be liquid cooled and will

proceed at about 1 inch (25.4 mm) per

minute. Total time to drill the hole will be

about 30 minutes.

4 Ream the barrel. Work a tungsten

carbide bore reamer down the finished

drill hole of the barrel, using liquid coolant as

the reamer works. The reamer will expand

the hole to the desired finished bore, and

smooth the inner drilled surface of the barrel

as it creates the final desired bore.

5 Rifle the barrel. Rifling consists of spiral

grooves in the bore, which will impart a

spin to the fired round as it travels down the

barrel. This spin will gyro stabilize the flight

of the fired round. Determine the number of

rifling grooves to be placed in the bore and

the amount of twist to be put on the rifling

grooves. Consult with experts in the field of

gun barrel making to determine this

information. Find these experts at specialty

gun barrel making shops.

Make the first rifling groove. Insert a tube

mounted with the rifling hook cutter box

down the bore of the barrel. Draw the

rifling hook cutter box through the bore

while rotating the barrel at a rate

recommended by the expert to give the

desired rifling spin.

Add more rifling grooves. Index the

barrel to the starting position for the next

groove. Draw the rifling hook cutter box

through the bore while rotating the barrel

at a rate recommended by the expert to

give the desired rifling spin.

Finish the rifling. Repeat passes through

the bore with the rifling hook cutter box

as needed.

Ad

6 Lap the barrel to fine polish the bore.

Insert the barrel lapping rod into the bore

until it is about 4 inches (101.6 mm) from

1 end of the bore. Pour molten lead into

the end of the bore and allow it to

harden.

Push the lap out of the barrel. Push the

lapping rod forward until the now

solidified lead slug, called the lead lap, is

exposed. Cover the lead lap with lapping

paste, which is similar to valve grinding

paste.

Complete the lapping. Run the lead lap

up and down the length of the barrel

about 50 times, applying more lapping

paste as necessary.

Ad

Advertisement

You're helping people by reading wikiHow

wikiHow's mission is to help people learn,

and we really hope this article helped you.

Now you are helping others, just by visiting

wikiHow.

Global Glimpse partners with over 80 high

schools to provide a two-year leadership, civic

engagement, and college preparatory program

centered on an international immersion

experience in a developing country. Students

from diverse backgrounds are encouraged to

bring their new-found perspectives back to

take action in their local high schools and

home communities.

Click below to let us know you read this

article, and wikiHow will donate to Global

Glimpse on your behalf. Thanks for helping us

achieve our mission of helping people learn

how to do anything.

Yes, I read the article

Community Q&A

How would a Damascus twist barrel be

forged?

Answered by wikiHow Contributor

Forge a billet to the length that is needed. The

barrel will need to be perfectly square. Then,

twist the square billet. Make sure that it's 1-4

inches wider than it needs to be. Then, cool grind

to your desired shape, heat treat, and etch.

How do I make a gun barrel from steel?

Answered by wikiHow Contributor

You would need a forge and blacksmithing

experience.

How do I make a rifling?

Answered by wikiHow Contributor

First, find a tube that fits into the barrel. Next, get

a long drill rod and cut measured grooves into

the barrel. If you're having difficulty, go to a

blacksmith instead.

8.8 bolts OK for making a barrel? Their

strength is 21 - 32 HRC.

Answered by wikiHow Contributor

The Idahoan says yes, but admits he was trying

to make a pistol barrel using simple tools, as

shown by the roughness of the finished product.

What materials could withstand a melting

point of 1668 C for rifling?

Answered by wikiHow Contributor

Titanium has a melting point of 1668 degrees C,

but tungsten can withstand more. However,

tungsten also has greatly reduced strength at

those temperatures.

Tips

When ordering steel, be aware that most

specialty steel mills have a 20 ton

minimum order.

Things You'll Need

Steel rod

Steel cutting and working tools

Deep hole drill

Barrel reaming drill

Rifling hook cutter

Barrel lapping rod

Related wikiHows

How to

Make a Real Gun

How to

Make a Suppressor

How to

Buy Firearms in California

How to

Make Black Powder

How to

Acquire a Gun License in New Jersey

How to

Buy a Gun

How to

Mail a Firearm

How to

Clean a Gun

How to

Get Your Federal Firearms License

How to

Buy a Gun in Florida

How to

Buy a Firearm in Michigan

How to

Avoid Being Shot

How to

Buy a Firearm in Texas

How to

Apply for a CCW in California

Ad

About This Article

Co-authors: 9

Updated: July 27, 2015

Views: 343,165

Article Rating: 80% - 409 votes

Categories: Guns and Shooting

Sources and Attribution

Did this article help you?

Yes No

prise Me

ur

S

wikiHow to...

Potrebbero piacerti anche

- Bladesmithing From Scrap Metal: How to Make Knives With Leaf Springs, Saw Blades, Railroad Spikes, and FilesDa EverandBladesmithing From Scrap Metal: How to Make Knives With Leaf Springs, Saw Blades, Railroad Spikes, and FilesValutazione: 4.5 su 5 stelle4.5/5 (3)

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyDa EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyValutazione: 5 su 5 stelle5/5 (4)

- How To Drill A Rifle BarrelDocumento6 pagineHow To Drill A Rifle BarrelMaria Donoghue50% (2)

- About Barrels..Documento5 pagineAbout Barrels..Ikkasama NaguenneNessuna valutazione finora

- Absolute Beginners Guide To Metal Lathe DrillingDocumento4 pagineAbsolute Beginners Guide To Metal Lathe DrillingRandy WilsonNessuna valutazione finora

- Basic Hinge Making TechniqueDocumento12 pagineBasic Hinge Making TechniqueGiNessuna valutazione finora

- Drilling Rifle BarrelsDocumento2 pagineDrilling Rifle Barrelsalpmal_infoNessuna valutazione finora

- Barrel1оружие 12Documento8 pagineBarrel1оружие 12Сергей МельничукNessuna valutazione finora

- SGRImproDocumento5 pagineSGRImproAdven TuresNessuna valutazione finora

- Caliber Conversions TableDocumento5 pagineCaliber Conversions TableVishwas Kumar SinghNessuna valutazione finora

- Rifling ButtonsDocumento5 pagineRifling ButtonsGyörgy Murvai100% (2)

- How To Coose RazorDocumento7 pagineHow To Coose RazorAndrei CretuNessuna valutazione finora

- Report IceDocumento6 pagineReport IceLevin HawthornNessuna valutazione finora

- Model 70 AccurizingDocumento3 pagineModel 70 Accurizingswdotson100% (1)

- How A Gun Barrel Was MadeDocumento12 pagineHow A Gun Barrel Was MadeHerman KarlNessuna valutazione finora

- Equipment List For Beginner Bullet CastersDocumento4 pagineEquipment List For Beginner Bullet CastersBrad PortelliNessuna valutazione finora

- Zipguns, Pipe Guns and Silencers: SS Knights of The Ku Klux KlanDocumento33 pagineZipguns, Pipe Guns and Silencers: SS Knights of The Ku Klux KlanBrian Mcdowell86% (14)

- Pivot Replacement: ChecklistDocumento7 paginePivot Replacement: Checklistottershaw57Nessuna valutazione finora

- Forming 223 Rem Brass For The Nagant RevolverDocumento19 pagineForming 223 Rem Brass For The Nagant Revolverscout50Nessuna valutazione finora

- Chapter 8Documento6 pagineChapter 8BOOBSIE B.Nessuna valutazione finora

- Bullet Plating Using The Caswell Plating Copper Kit.: FlashDocumento26 pagineBullet Plating Using The Caswell Plating Copper Kit.: Flashjimbo2032Nessuna valutazione finora

- Bladesmithing: 101 Bladesmithing FAQ: Answers to Your Burning Knifemaking Questions About Forging, Stock Removal, Tools, and Heat TreatmentDa EverandBladesmithing: 101 Bladesmithing FAQ: Answers to Your Burning Knifemaking Questions About Forging, Stock Removal, Tools, and Heat TreatmentNessuna valutazione finora

- The Rifle Barrel: Chuck HawksDocumento6 pagineThe Rifle Barrel: Chuck Hawksmrek68100% (1)

- 2 - How To Make A SilencerDocumento5 pagine2 - How To Make A SilencerFlavio Marçal100% (3)

- Workshop Hints Pivot Replacement: ChecklistDocumento8 pagineWorkshop Hints Pivot Replacement: Checklistottershaw57Nessuna valutazione finora

- As Published Knives IllustrDocumento6 pagineAs Published Knives IllustrPista BalogNessuna valutazione finora

- Platines Et Percage IPE 240Documento7 paginePlatines Et Percage IPE 240ol beNessuna valutazione finora

- Bladesmithing: Advanced Guide to Bladesmithing: Forge Pattern Welded Damascus Swords, Japanese Blades, and Make Sword Scabbards: Knife Making Mastery, #3Da EverandBladesmithing: Advanced Guide to Bladesmithing: Forge Pattern Welded Damascus Swords, Japanese Blades, and Make Sword Scabbards: Knife Making Mastery, #3Valutazione: 5 su 5 stelle5/5 (1)

- Bullet Weight TwistDocumento2 pagineBullet Weight TwistMike KunditNessuna valutazione finora

- Fixed Blade BroadheadsDocumento14 pagineFixed Blade BroadheadshuurlingNessuna valutazione finora

- Week5 AmmunitionDocumento6 pagineWeek5 Ammunitionruui chizakuraNessuna valutazione finora

- 45ACP Hollow PointDocumento5 pagine45ACP Hollow PointTactic Otd ArgNessuna valutazione finora

- Fazer ParafusoDocumento10 pagineFazer ParafusoZarcano FariasNessuna valutazione finora

- Lee Enfield ManualDocumento14 pagineLee Enfield ManualMike100% (5)

- TIG Welding Pipe - Weld Techniques and How To Walk The CupDocumento4 pagineTIG Welding Pipe - Weld Techniques and How To Walk The Cupkhairy2013Nessuna valutazione finora

- Abs 2017 Fastenercatalog WebDocumento32 pagineAbs 2017 Fastenercatalog WebsenthuranNessuna valutazione finora

- Information Assurance and Risk Management Strategies Manage Your Information Systems and Tools in The Cloud Bradley Fowler Full ChapterDocumento68 pagineInformation Assurance and Risk Management Strategies Manage Your Information Systems and Tools in The Cloud Bradley Fowler Full Chapterchristopher.perez844100% (4)

- Proteus FramebuildingDocumento114 pagineProteus FramebuildingMark JohanssonNessuna valutazione finora

- Making Your Own Rivets - The AK Files ForumsDocumento7 pagineMaking Your Own Rivets - The AK Files Forumsscout50Nessuna valutazione finora

- How Do You Forge A Katana WSDocumento5 pagineHow Do You Forge A Katana WSDarko тралалаNessuna valutazione finora

- New M39Documento20 pagineNew M39Justin Lane Hayes100% (2)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderDa EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderValutazione: 5 su 5 stelle5/5 (2)

- Boiler Making Hints - by Mike PavieDocumento2 pagineBoiler Making Hints - by Mike Paviehbpr9999Nessuna valutazione finora

- DrillingDocumento61 pagineDrillingAjay RanaNessuna valutazione finora

- Ballistics: Dr. WalkerDocumento81 pagineBallistics: Dr. WalkerBALAKRISHNANNessuna valutazione finora

- Proteus FramebuildingDocumento114 pagineProteus Framebuilding1726giangNessuna valutazione finora

- Corbin Technical Bulletin Volume 1Documento38 pagineCorbin Technical Bulletin Volume 1aikidomoyses0% (1)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosDa EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNessuna valutazione finora

- Making A Longwood Cigar - RevisedDocumento12 pagineMaking A Longwood Cigar - RevisedInform7105Nessuna valutazione finora

- PaintBall Sound SuppressorDocumento6 paginePaintBall Sound SuppressorJulio IglasiasNessuna valutazione finora

- Dead Drop DeviceDocumento7 pagineDead Drop DeviceAgino MottoNessuna valutazione finora

- Sterling Gun Drill CatalogDocumento18 pagineSterling Gun Drill Catalogjkruise100% (1)

- Swwheelgun 2Documento24 pagineSwwheelgun 2Robert SzklanyNessuna valutazione finora

- Firearm Ammunition and Cartridge CasesDocumento5 pagineFirearm Ammunition and Cartridge CasesDomingo John-h Wyler CainoyNessuna valutazione finora

- The Shade Tree Knife MechanicDocumento9 pagineThe Shade Tree Knife MechanicbooghybNessuna valutazione finora

- Survival Slingshot Instructions and Customization Guide 2014Documento6 pagineSurvival Slingshot Instructions and Customization Guide 2014Yağmur LeylakNessuna valutazione finora

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDa EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersValutazione: 3.5 su 5 stelle3.5/5 (2)

- Intermediate Guide to Bladesmithing: Make Knives, Swords and Forge Damascus: Knife Making Mastery, #2Da EverandIntermediate Guide to Bladesmithing: Make Knives, Swords and Forge Damascus: Knife Making Mastery, #2Valutazione: 4.5 su 5 stelle4.5/5 (2)

- Traditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesDa EverandTraditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesValutazione: 5 su 5 stelle5/5 (1)

- Safari - 17:56, Ngày 11 THG 7, 2018 PDFDocumento1 paginaSafari - 17:56, Ngày 11 THG 7, 2018 PDFbuidoi sonrauNessuna valutazione finora

- New Doc 2018-07-11 22.44.30 - 20180711225451Documento1 paginaNew Doc 2018-07-11 22.44.30 - 20180711225451buidoi sonrauNessuna valutazione finora

- 3 PDFDocumento1 pagina3 PDFbuidoi sonrauNessuna valutazione finora

- Safari - 17:56, Ngày 11 THG 7, 2018 PDFDocumento1 paginaSafari - 17:56, Ngày 11 THG 7, 2018 PDFbuidoi sonrauNessuna valutazione finora

- READMEDocumento1 paginaREADMEbuidoi sonrauNessuna valutazione finora

- Sci NB Mod 2 LSN 3Documento4 pagineSci NB Mod 2 LSN 3Ramses octavio Rodriguez ocanasNessuna valutazione finora

- iPQ-Center Webvideo Star TTB MA R1 42 en PDFDocumento32 pagineiPQ-Center Webvideo Star TTB MA R1 42 en PDFHamid KharazmiNessuna valutazione finora

- Ge Fairchild Brochure PDFDocumento2 pagineGe Fairchild Brochure PDFDharmesh patelNessuna valutazione finora

- Tesla Magazine Vol4Documento48 pagineTesla Magazine Vol4jonathan100% (1)

- Siemens Internship ReportDocumento84 pagineSiemens Internship Reportujjawalbhojawala100% (1)

- Adaptive Cruise ControlDocumento5 pagineAdaptive Cruise ControlIJIRSTNessuna valutazione finora

- Chapter 5 AGVDocumento76 pagineChapter 5 AGVQuỳnh NguyễnNessuna valutazione finora

- Biomediacal Waste Project FinalDocumento43 pagineBiomediacal Waste Project Finalashoknr100% (1)

- Tuesday, 16 November 2021 - Afternoon Discovering ElectronicsDocumento20 pagineTuesday, 16 November 2021 - Afternoon Discovering Electronicsnvmalt070Nessuna valutazione finora

- Aesculap Saw GD307 - Service ManualDocumento16 pagineAesculap Saw GD307 - Service ManualFredi PançiNessuna valutazione finora

- DCS YokogawaDocumento17 pagineDCS Yokogawasswahyudi100% (1)

- Upaam 1135891 202105060749199700Documento18 pagineUpaam 1135891 202105060749199700Kartik KapoorNessuna valutazione finora

- Fama Fraternitatis Rosae Crucis PDFDocumento2 pagineFama Fraternitatis Rosae Crucis PDFJudy50% (2)

- Pref - 2 - Grammar 1.2 - Revisión Del IntentoDocumento2 paginePref - 2 - Grammar 1.2 - Revisión Del IntentoJuan M. Suarez ArevaloNessuna valutazione finora

- Shell Gadus: Designed To Do More. Just Like Our Greases - Shell GadusDocumento2 pagineShell Gadus: Designed To Do More. Just Like Our Greases - Shell Gadusperi irawanNessuna valutazione finora

- 4 5803133100506483687Documento245 pagine4 5803133100506483687Malik HamidNessuna valutazione finora

- Rankine-Hugoniot Curve: CJ: Chapman JouguetDocumento6 pagineRankine-Hugoniot Curve: CJ: Chapman Jouguetrattan5Nessuna valutazione finora

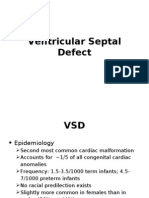

- Ventricular Septal DefectDocumento9 pagineVentricular Septal DefectpepotchNessuna valutazione finora

- Multiple Choice Enzymes Plant and Animal NutritionDocumento44 pagineMultiple Choice Enzymes Plant and Animal Nutritionliufanjing07Nessuna valutazione finora

- Tsel Manual ThermoselDocumento25 pagineTsel Manual ThermoselPedro AlvelaisNessuna valutazione finora

- Analysis of LaminatedDocumento31 pagineAnalysis of LaminatedKaustubh JadhavNessuna valutazione finora

- Book BindingDocumento14 pagineBook Bindingpesticu100% (2)

- Eliminating Oscillation Between Parallel MnosfetsDocumento6 pagineEliminating Oscillation Between Parallel MnosfetsCiprian BirisNessuna valutazione finora

- GLP BmsDocumento18 pagineGLP BmsDr.Subhashish TripathyNessuna valutazione finora

- Viscous Fluid Flow Frank M White Third Edition - Compress PDFDocumento4 pagineViscous Fluid Flow Frank M White Third Edition - Compress PDFDenielNessuna valutazione finora

- Texto CuritibaDocumento1 paginaTexto CuritibaMargarida GuimaraesNessuna valutazione finora

- Sch3u Exam Review Ws s2018 PDFDocumento4 pagineSch3u Exam Review Ws s2018 PDFwdsfNessuna valutazione finora

- FAJASDocumento891 pagineFAJASCecilia GilNessuna valutazione finora

- PTP S3Documento8 paginePTP S3Yongyin SHENGNessuna valutazione finora