Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

c71b2992-1074-465d-a258-84e816857170

Caricato da

Tyler GoodwinCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

c71b2992-1074-465d-a258-84e816857170

Caricato da

Tyler GoodwinCopyright:

Formati disponibili

WT COOLANT SUPRA

Corrosion inhibitor in coolant circuits

WT COOLANT SUPRA is cooling liquid non monoethylene glycol and based on WT supra, a so-

called “Water Treatment” agent: it is an aqueous concentrate of specific organic corrosion and

cavitations inhibitors. Its special formula – containing absolutely no phosphates, nitrites, amines,

boron, nitrates or silicates – gives it two important properties: first of all WT COOLANT SUPRA is

non-polluting and, secondly, it is long-lasting.

APPLICATIONS

Engine Cooling As a 10% solution in water , WT COOLANT SUPRA will protect. Cooling

circuits in diesel and gas engines:

an combined heat and power plants or electricity power stations requiring no

antifreeze protection but needing efficient heat transfer

in ships engines.

Cars, Van, Truck, Buses, Heavy Equipment, constructing machines and

agricultural tractor requiring no antifreeze protection but needing efficient

heat transfer

on the factory test bed during running-in and for the protection of the engine

block against corrosion between leaving the factory and entering service.

Heat transfer systems (such as heating plant or secondary circuits in

cogeneration units) employing an aqueous.

CUSTOMER BENEFITS

Enhanced protection Thanks to its organic technology, WT COOLANT SUPRA protects circuits much

against corrosion and better against cavitations and corrosion than conventional "water treatment"

cavitations products.

No deposit formation The absence of any inorganic ingredients (such as phosphates, nitrites, etc.) means

that no hard deposits are formed, especially around the top of liners, cylinder heads,

heat exchanger tubes and electric heaters. As a result :

Heat transfer is sustained

Lower disposal/ recycling Anti-corrosion and anti-cavitations properties are maintained

costs There is no risk of pipe erosion due to hard particles in circulation

Protects the environment The circuit remains clean.

The active ingredients in WT COOLANT SUPRA are non-polluting, and confer the

same properties on the circuit fluid so long as it does not contain any toxic

substances such as mono-ethylene glycol (a routine ingredient of ordinary

Better heat transfer at

antifreezes). These properties allow it to be used in domestic heating installations.

lower cost

When no antifreeze protection is needed, filling a heat transfer circuit with WT

SUPRA after emptying out conventional antifreeze gives better performance –

thanks to the fluid’s higher thermal capacity – at lower cost.

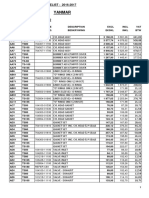

CHARACTERISTIC

Properties Methods Units Typical

Colour Blue

Concentration WT Supra 10%

SG at 20°C ASTM D1122 1.007

pH ASTM D1287 8.44

The typical characteristics mentioned represent mean values.

A 10% dilution is recommended when WT COOLANT SUPRA is used to protect the cooling circuits of engines when

these are being run in on the test bed and during periods of storage (2 months).

FLUSHING PROCEDURE

Installations containing deposits arising from construction (new facilities) or corrosion (those already in service), must be

flushed out very carefully.

Procedures:

1/ Circulate the existing fluid for at least an hour to bring the deposits into suspension.

2/ Drain the cooling circuits completely (clean out low points and retention zones).

3/ Check the heating elements and the expansion tank: clean out if any deposits are found.

4/ Flush with pure water (at least twice), circulating the water throughout the circuit.

Drain and check that deposits are not blocking the filters.

5/ Drain the entire circuit.

6/ Fill with WT COOLANT SUPRA.

Note: For MSDS, Storage / Handling and other technical support, please contact:

PT. Total Oil Indonesia

Ph. : +62-21-759 16999

Fax. : +62-21-759 16555 Update (Jan 2012)

Potrebbero piacerti anche

- Modifiable Skills MatrixDocumento84 pagineModifiable Skills MatrixTyler GoodwinNessuna valutazione finora

- D85ess P2uDocumento1 paginaD85ess P2uTyler GoodwinNessuna valutazione finora

- Update Unit Ready 21062022Documento1 paginaUpdate Unit Ready 21062022Tyler GoodwinNessuna valutazione finora

- Spare Parts and Lubricants ListingDocumento46 pagineSpare Parts and Lubricants ListingTyler GoodwinNessuna valutazione finora

- Maintain Nomat Parts Antika-1Documento2 pagineMaintain Nomat Parts Antika-1Tyler GoodwinNessuna valutazione finora

- Form Permintaan BarangDocumento148 pagineForm Permintaan BarangTyler GoodwinNessuna valutazione finora

- NOMAT Description Part Number PriceDocumento3 pagineNOMAT Description Part Number PriceTyler GoodwinNessuna valutazione finora

- Makenda Sales Yanmar Price ListDocumento14 pagineMakenda Sales Yanmar Price ListTyler GoodwinNessuna valutazione finora

- Form Monthly Report Redo1Documento2 pagineForm Monthly Report Redo1Tyler GoodwinNessuna valutazione finora

- PDFDocumento2 paginePDFairsys7projecNessuna valutazione finora

- Crane Graple AnggaDocumento1 paginaCrane Graple AnggaTyler GoodwinNessuna valutazione finora

- Book 1Documento4 pagineBook 1Tyler GoodwinNessuna valutazione finora

- Ubah Harga NanaDocumento2 pagineUbah Harga NanaTyler GoodwinNessuna valutazione finora

- Material No Keterangan Satuan Plant Max Stock LevelDocumento1 paginaMaterial No Keterangan Satuan Plant Max Stock LevelTyler GoodwinNessuna valutazione finora

- WQ 2Documento2 pagineWQ 2Tyler GoodwinNessuna valutazione finora

- 87 11qqqDocumento10 pagine87 11qqqTyler GoodwinNessuna valutazione finora

- Daily equipment maintenance reportDocumento4 pagineDaily equipment maintenance reportTyler GoodwinNessuna valutazione finora

- 5 1 Icsc2010 032Documento14 pagine5 1 Icsc2010 032Tyler GoodwinNessuna valutazione finora

- List of SAP T-CodesDocumento18 pagineList of SAP T-CodesastinetNessuna valutazione finora

- TSR Inta ATVV40035Documento18 pagineTSR Inta ATVV40035Tyler GoodwinNessuna valutazione finora

- Safety Alert From Sangatta - Truck RD3138 Reversed Into An RD3351 Which Was Moving Forward at Dumping PointDocumento2 pagineSafety Alert From Sangatta - Truck RD3138 Reversed Into An RD3351 Which Was Moving Forward at Dumping PointTyler Goodwin100% (1)

- Shutdown Task Komatsu 530M - UpDate 1Documento3 pagineShutdown Task Komatsu 530M - UpDate 1Tyler GoodwinNessuna valutazione finora

- Plan Cycle Invest Tools Equip 2011Documento12 paginePlan Cycle Invest Tools Equip 2011Tyler GoodwinNessuna valutazione finora

- Epsilon Manual PDFDocumento32 pagineEpsilon Manual PDFarturo91Nessuna valutazione finora

- Modifiable Skills MatrixDocumento82 pagineModifiable Skills MatrixRichard Thodé JrNessuna valutazione finora

- Bolt Double Wheel SJNWDocumento6 pagineBolt Double Wheel SJNWTyler GoodwinNessuna valutazione finora

- Maintenance Schedule WorksheetDocumento2 pagineMaintenance Schedule WorksheetRanu JanuarNessuna valutazione finora

- TCODESDocumento3 pagineTCODESTyler GoodwinNessuna valutazione finora

- SAP Inventory Management TcodesDocumento26 pagineSAP Inventory Management TcodesTyler GoodwinNessuna valutazione finora

- AGCO InstallDocumento10 pagineAGCO InstallTyler GoodwinNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Endcarriage - KZL-S 315Documento116 pagineEndcarriage - KZL-S 315Josip Nuno CoricNessuna valutazione finora

- ACS SCPI Programming Guide V1 0Documento29 pagineACS SCPI Programming Guide V1 0Pedro Boanerges Paz RomeroNessuna valutazione finora

- Aneka Cloud IntroductionDocumento36 pagineAneka Cloud IntroductionPradeep Kumar Reddy ReddyNessuna valutazione finora

- Anti AgingDocumento5 pagineAnti AgingsaturninojonesNessuna valutazione finora

- THREE MODELS FOR GIFTEDDocumento5 pagineTHREE MODELS FOR GIFTEDWanRezawanaWanDaudNessuna valutazione finora

- Wall e WorksheetDocumento1 paginaWall e WorksheetJoPaisNessuna valutazione finora

- Activities For Teens and AdultsDocumento130 pagineActivities For Teens and AdultsDonata Marletta100% (12)

- Project Vetting Worksheet-9472538Documento4 pagineProject Vetting Worksheet-9472538kovzsanNessuna valutazione finora

- Five Necessairy Condition For Project SuccessDocumento2 pagineFive Necessairy Condition For Project SuccessSimeon Petos100% (1)

- Embedded Systems - Fs 2018: Figure 1: Simplified Task States Diagram in FreertosDocumento8 pagineEmbedded Systems - Fs 2018: Figure 1: Simplified Task States Diagram in FreertosPhạm Đức HuyNessuna valutazione finora

- Gafti AP Apeo SopDocumento8 pagineGafti AP Apeo SopManoj ChaudhariNessuna valutazione finora

- 3rd BeatitudeDocumento18 pagine3rd BeatitudeDonna ANessuna valutazione finora

- Costing 1 PDFDocumento8 pagineCosting 1 PDFSamyNessuna valutazione finora

- BoilerDocumento7 pagineBoilerXie ShjNessuna valutazione finora

- Broadcasting Modernity by Yeidy M. RiveroDocumento34 pagineBroadcasting Modernity by Yeidy M. RiveroDuke University Press100% (2)

- Final QuestionDocumento5 pagineFinal QuestionrahulNessuna valutazione finora

- HPS100 2016F SyllabusDocumento6 pagineHPS100 2016F SyllabusxinNessuna valutazione finora

- Revision WorksheetDocumento1 paginaRevision WorksheetTashana GoweNessuna valutazione finora

- Thermal Comfort Bioclimatic Architecture StrategiesDocumento21 pagineThermal Comfort Bioclimatic Architecture StrategiesJayshree RokdeNessuna valutazione finora

- Answer:: Near Relax Medical Hall, Vattepally, Falaknuma, HyderabadDocumento2 pagineAnswer:: Near Relax Medical Hall, Vattepally, Falaknuma, HyderabadMohammed RaeesuddinNessuna valutazione finora

- IB Source AnalysisDocumento8 pagineIB Source AnalysisRita LimNessuna valutazione finora

- Fx2n PLC Manual 2adDocumento8 pagineFx2n PLC Manual 2adYuwarath SuktrakoonNessuna valutazione finora

- MyFax User GuideDocumento47 pagineMyFax User Guidesanjaya 黄保元Nessuna valutazione finora

- Porirua Harbour Patterns and Rates of Sedimentation ReportDocumento65 paginePorirua Harbour Patterns and Rates of Sedimentation ReportPaul MarlowNessuna valutazione finora

- SDO City of Malolos-Math5-Q4M1-Area of A Circle-Ramirez EWDocumento25 pagineSDO City of Malolos-Math5-Q4M1-Area of A Circle-Ramirez EWKris Bernadette David100% (1)

- IMO Class 3 Sample Paper 2017 18Documento3 pagineIMO Class 3 Sample Paper 2017 18sunil KumarNessuna valutazione finora

- Yokogawa CS3000 PDFDocumento72 pagineYokogawa CS3000 PDFWalid AissaNessuna valutazione finora

- The Modern World SystemDocumento30 pagineThe Modern World SystemDey afNessuna valutazione finora

- Spitler McQuiston Lindsey 93 2Documento11 pagineSpitler McQuiston Lindsey 93 2Shafawati ShahneelNessuna valutazione finora