Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Installation Instructions Type B, C, CR and Co PDF

Caricato da

perezismaelTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Installation Instructions Type B, C, CR and Co PDF

Caricato da

perezismaelCopyright:

Formati disponibili

AIR MOVEMENT PRODUCTS

FIRE DAMPERS

INSTALLATION INSTRUCTIONS

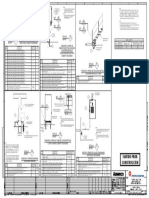

NOTE: ATTACHMENTS MUST NOT

ATTACHING FIRE DAMPERS TO SLEEVES ATTACHMENTS

ENTER BLADE CHANNEL OR THEY

MAY CAUSE INTERFERENCE WITH

Fire dampers must be attached to sleeves as shown in

BLADE CLOSURE. NARROW LINE

fig. 1. All four sides of the damper frame must be

BLADE AND ULTRA THIN DAMPERS DO

attached to the sleeve with one row of attachments on CHANNEL NOT HAVE FLANGE FOR

each side of the blade channel. Attachments must be

ATTACHMENTS AND MUST BE

spaced a maximum of 6" on centers and a maximum of

WELDED TO SLEEVE.

2" from corners. A minimum of 4 attachments (2 on each

side of the blade channel) per side (16 per damper) are 2"

MA

required. One of the methods of attachment shown below X

must be used.

D A M P E R

- Tack or spot welds.

- No. 10 sheet metal screws. 6"

MA

- 1/4" bolts and nuts. X

- 3/16" steel pop rivets.

SECURING FIRE DAMPER AND SLEEVES AT

BE TAC

TO WALL AND FLOOR OPENINGS FIG

.1

S HM

EV TAG EN

EN G T

LY ERE S CA

SP D N

AC OR

ED

Fire damper and sleeve assemblies must be installed in

F I R E

wall and floor openings using retaining angles on each

side of the wall or floor as described below:

- Retaining angles must be a minimum of 16 gauge steel

and have a minimum of 11/2" x 11/2" legs.

- Retaining angles must be attached to the sleeve using WALL OR FLOOR

the procedures and methods described hereunder.

The angles must be attached to all 4 sides of the sleeve

1"

with butt joints at each corner. A minimum of two N

MI RLA

P

attachments are required on each side, top and bottom. E

IN

G OV

The angles need not be attached to each other at the IN

E TA LE

R G

corners. AN

VE

EE

- Retaining angles must completely cover the clearance SL

CT

DU

space between the sleeve and the wall/floor opening,

plus overlap the wall/floor a minimum of 1". This

TYPE "CO"

coverage OVAL

includes SLEEVE

all corners (fig. 2).

2"

MA

- Retaining angles should not be fastened to the wall/ X

6"

floor material. The angles should only sandwich the wall/ MA

X

floor and allow for damper/sleeve expansion during 6"

MA

periods of intense heat. X

2"

MA

X

- For grille installation, angle legs may be reversed and

one leg inserted into the wall/floor opening providing the

required clearance is maintained between angle leg

fasteners and the wall/opening.

CONNECTING DUCTS TO FIRE DAMPER SLEEVE

- For grille installation, angle legs may be reversed and

one leg inserted into the wall / floor opening providing

the required clearance is maintained between angle leg

fasteners and the wall / opening.

SSIF

LA IE

D

C

INSTALLATION INSTRUCTIONS

MULTIPLE SECTIONS FIRE DAMPERS

When multiple sections are shipped unassembled,

UL

R

IN CONFORMANCE TO

UNDERWRITERS LABORATORIES

REQUIREMENTS

installer shall fasten dampers together.

Email: kbe@kbelebanon.com -- www.kbelebanon.com

Ref : FD ALL STATED SPECIFICATION ARE SUBJECTED TO CHANGE WITHOUT NOTICE OR OBLIGATION.

40 KBE 2010

AIR MOVEMENT PRODUCTS

FIRE DAMPERS

INSTALLATION INSTRUCTIONS

BREAKAWAY CONNECTIONS

Breakaway Style Transverse Joints

-Transverse joints illustrated at right have always been PLAIN "S" SLIP HEMMED "S" SLIP DOUBLE "S" SLIP

approved as breakaway connections . SMACNA

testinghas also approved the following variations as

breakaway connections.

-Standing "S" joints can be applied with no. 10 INSIDE SLIP JOINT PLAIN "S" SLIP STANDING "S" (ALT.)

sheet metal screws (through joint and duct) subject to

the following limitations: Maximum 2 screws in each side

and in bottom joint.

Transverse joints illustrated can be applied as top and STANDING "S" STANDING "S"

STANDING "S" (ALT.)

bottom joints with Drive Slip - side joints in duct heights (BAR REINFORCED) (BAR REINFORCED)

up to 20 inches.

Round and Oval Duct Breakaway Connections

DRIVE SLIP JOINT

Round or flat oval ducts connected to type R, CR or CO

damper collars may use no. 10 sheetmetal screws as

follows:

Ducts to 22" wide (or dia.) and smaller may use 3

screws.

Ducts larger than 22" wide (or dia.) may use 5 screws.

NOTE: All breakaway connections described may have

duct sealantapplied in accordance with SMACNA

reccomendations.

Manufactured Flanged System Breakaway

6" long 1/16" max. Fire Damper

Flanged connection systems manufactured by Ductmate, thickness plastic

Sleeve

cleats 12" c-c

Ward, and Nexus are approved as breakaway (min. 1 per side)

connections when installed as illustrated.

Flanged system angles

(Attach per

SSIF

LA IE INSTALLATION INSTRUCTIONS

manufacturers

instructions)

D

C

IN CONFORMANCE TO

UL

R

UNDERWRITERS LABORATORIES

REQUIREMENTS

Do not bolt corners

Duct

Neoprene Gasket

between all angles

STD. CLIP

PROPRIETARY FLANGE SYSTEM BREAKAWAY CLIP SPACING

LENGTH

CONNECTIONS (TDC by Lockformer, TDF by Engle) 6" 6" 9" 6"

60" DUCT

3 REQD

TDC and TDF systems are approved as breakaway

connections when installed as described in the TDC or 7" 7"

48" DUCT

TDF addendum to the SMACNA Duct construction

3 REQD

Standards except the corners may not be bolted.

Standard 6" metal clip may be used with spacing as 5" 5"

36" DUCT

shown in diagram. 3 REQD

5" 5"

24" DUCT

SLEEVE DUCT 2 REQD

18" DUCT

& SMALLER CL

TYPICAL TDC/TDF JOINT 1 REQD

DUCT

Email: kbe@kbelebanon.com -- www.kbelebanon.com

Ref : FD ALL STATED SPECIFICATION ARE SUBJECTED TO CHANGE WITHOUT NOTICE OR OBLIGATION.

41 KBE 2010

AIR MOVEMENT PRODUCTS

FIRE DAMPERS

INSTALLATION INSTRUCTIONS

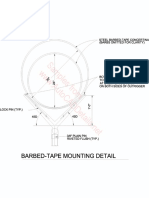

MOUNTING ANGLES DUCT CONNECTION

Secure mounting angles to the sleeve and not to the wall The installation of the damper and all duct connections

or floor. Mounting angles to frame the four sides of the to the damper sleeve shall conform to NFPA-90A and the

sleeve on both faces. SMACNA Fire, Smoke and Radiation Damper Installation

When reverse mounting angles are used the size of the Guide. All duct connections shall also conform to UL555.

opening must be increased to maintain the specified Connecting ducts shall not be continuous but shall

expansion clearance between the angle / fasteners and terminate at the damper sleeve. Duct connections to the

the opening. Angles shall be a minimum of 11/2" x 11/2" x sleeve will be either of the breakaway or rigid types,

16 gauge on dampers 36” x 50” and smaller. For breakaway types are listed below.

dampers greater than 36” x 50”, angles to be a minimum The following determines if the connections are to be

of 11/2" x 11/2" x 14 ga. Fasten angles to the sleeve rigid or breakaway.

using 1/4" dia. bolts and nuts or by welding with beads For rigid type duct connections, sleeve shall be a

1/2" in length, or with No. 10 steel sheet metal screws, minimum of 16 GA on dampers not exceeding 36" wide

or with 3/16" steel rivets. Fasteners or weld beads shall or 24" high or 24" diameter and 14 ga on larger units.

be 8" maximum on centers. Dampers supplied with thinner sleeves will require a

breakaway connection of the following type. Plain "S"

slip, double "S" slip shown below. All connections not

listed as breakaway shall be considered as rigid.

ACCESS Breakaway joints of the types shown below shall have no

more than two No.10 (4.8 mm) diameter sheet metal

screws on each side and on the top and bottom located

Suitable access must be provided for damper inspection

in the center of the slip pocket and shall penetrate both

and servicing. Where it is not possible to achieve

sides of the slip pocket. Breakaway joints of the type

sufficient size access, it will be necessary to install a

shown below are permitted on the top and bottom of

removable section of duct.

horizontal ducts (vertical dampers) with flat slips not

exceeding 20 inches (508 mm) in length on the sides.

CAULKING MAINTENANCE

Caulking is allowed between the mounting angles and Dampers shall be maintained in intervals as stated in

the damper sleeve, and between the mounting angles NFPA-90A, Appendix B, unl ess local codes require more

and the floor or wall construction. Caulking is not allowed frequent inspections. Check the fuse link, check the

between the damper sleeve and the wall or floor inside stainless steel closure springs where furnished, cycle

the opening. Caulk shall be one of the following: damper and check for free operation and complete

Dow Corning RTV 732, or a UL approved substitute. closure, clean with mild detergent or solvent, secure

damper open with fusible link.

DOUBLE "S" SLIP INSIDE SLIP JOINT HEMMED "S" SLIP

PLAIN "S" SLIP

STANDING "S" SLIP STANDING "S" SLIP STANDING "S"

STANDING "S" (ALT.)

(BAR REINFORCED) (ANGLE REINFORCED)

SSIF

LA IE INSTALLATION INSTRUCTI

INSTALLATION INSTRUCTIONS

ONS

D

C

IN C ONFORMANCE T

CONFORMANCE O

TO

UL

R

U NDERWRITERS LAB

UNDERWRITERS

REQUIREMENTS

R EQUIREMENTS

ORATORIES

LABORATORIES

Email: kbe@kbelebanon.com -- www.kbelebanon.com

Ref : FD ALL STATED SPECIFICATION ARE SUBJECTED TO CHANGE WITHOUT NOTICE OR OBLIGATION.

42 KBE 2010

AIR MOVEMENT PRODUCTS

FIRE DAMPERS

INSTALLATION INSTRUCTIONS

MOUNTING SEE NOTES

ANGLE 1&3

SLEEVE 6" MAX.

1" MIN.

1" MIN.

TYPE "B"

MOUNTING ANGLE (MIN. 10 GA.)

M

2" MAX.

DUCT

DU T

GRILLE TO BE A

MINIMUM 26 GAUGE

STEEL OR .025" THICK

FIRE SLEEVE

SLEEVE ALUMINUM

DAMPER

DAMPER

MOUNTING ANGLE

TYPE "B-1" MOUNTING DAMPER BEHIND A GRILLE

1. Perimeter mounting angles to be a minimum of 11/2

MOUNTING ANGLE

x 11/2 x 16 GA on dampers 36” x 50” and smaller. For

dampers greater than 36” x 50”, angles to be a minimum

SLEEVE

of 11/2 x 11/2 x 14 GA.

2. Grille to flange fasteners cannot penetrate fire wall

(see note 4).

3. Secure angles to sleeve only, so as to frame the wall

opening. Fasten to the sleeve only using the same

SEE NOTE 1

means as required for fastening the damper to the

sleeve.

TYPE "CR" 4. Grille to flange attachment by means of 1/4" dia. pop

rivets, #8 sheet metal screws or #8 bolts and nuts.

Fasteners to be plated steel or stainless steel, minimum

The factory supplied 22 GA. collar to 18 GA cap The

two fasteners per side.

factory supplied 22 GA. collar to 18 GA cap connection

under the following conditions:

1. Round unit duct diameters are no larger than 52"

2. Oval duct sizes are no larger than 58" W x 29"H.

3. Duct gauges shall conform to the SMACNA or ASHRAE

duct standard.

4. Duct diameters of 22 inches (559 mm) and smaller

shall have three (3) No. 10 (4.8 mm) diameter sheet

SSIF

metal screws evenly spaced around the circumference of LA IE INSTALLATION INSTRUCTIONS

D

C

the duct. IN CONFORMANCE TO

5. Duct diameters greater than 22 inches and up shall

have five (5) sheet metal screws evenly spaced around

UL

R

UNDERWRITERS LABORATORIES

REQUIREMENTS

the circumference of the duct.

6. Dampers outside of these restrictions (ie) multiple

dampers and special size and application dampers must

use a 4" wide drawband connection as shown in the

SMACNA Fire, Smoke, and Radiation Damper Installation

Guide.

Email: kbe@kbelebanon.com -- www.kbelebanon.com

Ref : FD ALL STATED SPECIFICATION ARE SUBJECTED TO CHANGE WITHOUT NOTICE OR OBLIGATION.

43 KBE 2010

Potrebbero piacerti anche

- ANSI-SMACNA 2006 HvacDuctStandardsDocumento64 pagineANSI-SMACNA 2006 HvacDuctStandardsErica MorrisonNessuna valutazione finora

- Inertial Navigation SystemsDocumento8 pagineInertial Navigation SystemsRadunNessuna valutazione finora

- DW13294103Documento72 pagineDW13294103p_jankoNessuna valutazione finora

- B-Line Clamps PDFDocumento364 pagineB-Line Clamps PDFNarendra Reddy BhumaNessuna valutazione finora

- Assignment 1: Part 1 Locate of Relief Dehydrogenation of Isopropyl Alcohol (IPA) To Acetone Piping & Instrumentation DiagramDocumento3 pagineAssignment 1: Part 1 Locate of Relief Dehydrogenation of Isopropyl Alcohol (IPA) To Acetone Piping & Instrumentation DiagramHewYanNessuna valutazione finora

- Metal Working For ElectronicsDocumento1 paginaMetal Working For ElectronicsJonathan ReaNessuna valutazione finora

- Ac 036630 001Documento1 paginaAc 036630 001navaronefraNessuna valutazione finora

- Boundary Layer and Flow Control: Its Principles and ApplicationDa EverandBoundary Layer and Flow Control: Its Principles and ApplicationNessuna valutazione finora

- 5 - ElectricalDocumento129 pagine5 - ElectricalMulti PhaseNessuna valutazione finora

- Seismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2Documento35 pagineSeismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2jakeer7100% (2)

- FH v1 PDFDocumento114 pagineFH v1 PDFDan BirkenheadNessuna valutazione finora

- Steam Tracer Header and Branch Connection DetailsDocumento1 paginaSteam Tracer Header and Branch Connection DetailsSathiyaseelan Sakthi ShanmugamNessuna valutazione finora

- Hvac Method StatementDocumento74 pagineHvac Method StatementnafoukhNessuna valutazione finora

- M AcuDocumento3 pagineM AcuarkiTOM18100% (2)

- High Speed Door Installation ManualDocumento8 pagineHigh Speed Door Installation ManualDuan PhamNessuna valutazione finora

- Flying Scale Models Issue 180 2014-11Documento68 pagineFlying Scale Models Issue 180 2014-11PeterNessuna valutazione finora

- DrawingDocumento25 pagineDrawingankitNessuna valutazione finora

- 15 SmacnaDocumento9 pagine15 Smacnaarln_605551822Nessuna valutazione finora

- Alfa Laval S927 FO PurifierDocumento209 pagineAlfa Laval S927 FO Purifieriacovosf836100% (3)

- BBQ Chicken M-01Documento1 paginaBBQ Chicken M-01agflamesengineering.salesNessuna valutazione finora

- 9134001EC Decorum Sink ENDocumento2 pagine9134001EC Decorum Sink ENInterplan Puerto RicoNessuna valutazione finora

- NF SD FF NS 004Documento1 paginaNF SD FF NS 004Adnan AkhtarNessuna valutazione finora

- Ds tr10 4 en UsDocumento2 pagineDs tr10 4 en UsMuhammad Haroon AsgharNessuna valutazione finora

- 11 Bc-Building SkinDocumento1 pagina11 Bc-Building SkinAshwin AdveNessuna valutazione finora

- 151XST Product InformationDocumento2 pagine151XST Product InformationAlfonso LeónNessuna valutazione finora

- WMSOU XX P0x InstallDocumento2 pagineWMSOU XX P0x InstallzeljkoNessuna valutazione finora

- 463562suppl IomDocumento2 pagine463562suppl IomOmar DDCNessuna valutazione finora

- File 1448492388Documento1 paginaFile 1448492388Remy MendozaNessuna valutazione finora

- Restraint: FJ Restraint Flexible Expansion JointDocumento3 pagineRestraint: FJ Restraint Flexible Expansion JointAl JameelNessuna valutazione finora

- الرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFDocumento12 pagineالرموز الكهربائية المستخدمة في رسم المخططات الكهربائية PDFAbdullah TalibNessuna valutazione finora

- 2 / " Pressure, Vacuum & Turbo Gauges: Installation Instructions 1 16Documento2 pagine2 / " Pressure, Vacuum & Turbo Gauges: Installation Instructions 1 16Tânia RodriguesNessuna valutazione finora

- Installation Guide For Sure-Seal Drip Edge: 1-1/2" SS RING Shank NailDocumento2 pagineInstallation Guide For Sure-Seal Drip Edge: 1-1/2" SS RING Shank NailConstantin GubavuNessuna valutazione finora

- Ace 00480 01001 R5Documento2 pagineAce 00480 01001 R5ClarkFedele27Nessuna valutazione finora

- General Notes:: Legend & SymbolsDocumento1 paginaGeneral Notes:: Legend & SymbolsEdwin VelascoNessuna valutazione finora

- Std-Comp Dead Ends-ACSRDocumento12 pagineStd-Comp Dead Ends-ACSRLutfi ArdiansyahNessuna valutazione finora

- Motion Control: Vibration Dampers 1700, 1700AA SeriesDocumento4 pagineMotion Control: Vibration Dampers 1700, 1700AA SeriesAndre Luis Fontes FerreiraNessuna valutazione finora

- Tsubaki Power Lock Ad N SeriesDocumento5 pagineTsubaki Power Lock Ad N SeriesRizal IephoNessuna valutazione finora

- Instruction Sheet Is Dw1824 - Style Number Dw1824C:: Package ContentsDocumento4 pagineInstruction Sheet Is Dw1824 - Style Number Dw1824C:: Package Contentsdayshift5Nessuna valutazione finora

- This Site: Location MapDocumento1 paginaThis Site: Location MapMario MuliNessuna valutazione finora

- Fire Rated JointingDocumento4 pagineFire Rated JointingPrakash RaoNessuna valutazione finora

- Surge Arresters: Storm Trapper H.E. (High Energy) Low Voltage Distribution Class MOV Surge ArresterDocumento6 pagineSurge Arresters: Storm Trapper H.E. (High Energy) Low Voltage Distribution Class MOV Surge ArresterRodrigo RamirezNessuna valutazione finora

- 4yy23 1Documento24 pagine4yy23 1y.cruzNessuna valutazione finora

- Máscara de Soldado Demonio: #MyfortnitemaresDocumento10 pagineMáscara de Soldado Demonio: #MyfortnitemaresVictor MontielNessuna valutazione finora

- Mak KahDocumento1 paginaMak KahEder MikhailNessuna valutazione finora

- 1 Tablas Bolinter, Fittings & Valves-FinalDocumento21 pagine1 Tablas Bolinter, Fittings & Valves-FinalTIPAZONessuna valutazione finora

- PRO 1000 Vertical Non Programmable Thermostat Installation GuideDocumento24 paginePRO 1000 Vertical Non Programmable Thermostat Installation GuideEnrique EspinosaNessuna valutazione finora

- Ansul Design #007 Kidde Booth SystemDocumento8 pagineAnsul Design #007 Kidde Booth SystemJhoNessuna valutazione finora

- Inst. ManualDocumento8 pagineInst. ManualHamoud Al khayatiNessuna valutazione finora

- HR3 Skylight Install ManualDocumento13 pagineHR3 Skylight Install ManualAlfrreddo SotoNessuna valutazione finora

- NSH 7 Element 2 Meter Beam AntennaDocumento3 pagineNSH 7 Element 2 Meter Beam AntennaGeroldo 'Rollie' L. QuerijeroNessuna valutazione finora

- Submittal Sheet Indicator Posts c653812cDocumento12 pagineSubmittal Sheet Indicator Posts c653812cThiago Fabricio Chuiz MallquiNessuna valutazione finora

- Chemscan UV-2150 ManualDocumento31 pagineChemscan UV-2150 ManualTMNessuna valutazione finora

- General Notes Table 1: Bearing Baseplate AssemblyDocumento20 pagineGeneral Notes Table 1: Bearing Baseplate AssemblyLeon ZhouNessuna valutazione finora

- Ttrucklite Flasher PDFDocumento5 pagineTtrucklite Flasher PDFfrank mutaleNessuna valutazione finora

- Technical Specification: Attic Ladder LWPDocumento2 pagineTechnical Specification: Attic Ladder LWPAaron nowlanNessuna valutazione finora

- LOMANCO (Installation Manual) OR4 Omniridge Ridge VentDocumento2 pagineLOMANCO (Installation Manual) OR4 Omniridge Ridge VentKarma Pema DorjeNessuna valutazione finora

- ElectricalDocumento7 pagineElectricaldomesNessuna valutazione finora

- Rail Injector Girs12: FeaturesDocumento2 pagineRail Injector Girs12: FeaturesAndrea VaccariNessuna valutazione finora

- Hazardous Location Strobe Light: Model 151XSTDocumento2 pagineHazardous Location Strobe Light: Model 151XSTGusValParNessuna valutazione finora

- Federal Signal 151XSTDocumento2 pagineFederal Signal 151XSTLogan Marquez AguayoNessuna valutazione finora

- DIY Lycoming O-290-G Carburetor Heat & Intake Box From Sport Aviation 1968 01Documento2 pagineDIY Lycoming O-290-G Carburetor Heat & Intake Box From Sport Aviation 1968 01Charles KussNessuna valutazione finora

- Emitido Para: Detail Detail Rigid Steel Conduit GroundingDocumento1 paginaEmitido Para: Detail Detail Rigid Steel Conduit GroundingKevin GarcíaNessuna valutazione finora

- Car Equlizer - PianolaDocumento1 paginaCar Equlizer - PianolaMic XNessuna valutazione finora

- Shade Assembly Instructions:: 6 Corporate Parkway Goose Creek, Sc. 29445Documento1 paginaShade Assembly Instructions:: 6 Corporate Parkway Goose Creek, Sc. 29445dayshift5Nessuna valutazione finora

- R FencesDocumento82 pagineR FencesArman Man100% (1)

- GE ER N TES: Flash G Bea O A D Sign Stal IonsDocumento4 pagineGE ER N TES: Flash G Bea O A D Sign Stal IonsEdwinDiane TandayuNessuna valutazione finora

- CircuitotermostatoDocumento2 pagineCircuitotermostatowalker28Nessuna valutazione finora

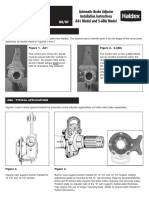

- Installation Guide: Automatic Brake Adjuster Installation Instructions AA1 Model and S-ABA ModelDocumento6 pagineInstallation Guide: Automatic Brake Adjuster Installation Instructions AA1 Model and S-ABA ModelPaul Del CarmenNessuna valutazione finora

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDa EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNessuna valutazione finora

- Wall Sleeves: Pipe A-44Documento4 pagineWall Sleeves: Pipe A-44perezismaelNessuna valutazione finora

- 23 05 29 - HVAC Hangers and SupportsDocumento9 pagine23 05 29 - HVAC Hangers and SupportsperezismaelNessuna valutazione finora

- Eyewashinspection Checklist 2012 - 0Documento1 paginaEyewashinspection Checklist 2012 - 0perezismaelNessuna valutazione finora

- Pryco, Inc.: The Content of This Catalog Is Subject To Change Without NotificationDocumento40 paginePryco, Inc.: The Content of This Catalog Is Subject To Change Without NotificationperezismaelNessuna valutazione finora

- Installation Instructions Type B, C, CR and CoDocumento4 pagineInstallation Instructions Type B, C, CR and CoperezismaelNessuna valutazione finora

- Mss SP 69pdf PDFDocumento18 pagineMss SP 69pdf PDFperezismaelNessuna valutazione finora

- Hvac Interview QuestionDocumento8 pagineHvac Interview QuestionperezismaelNessuna valutazione finora

- Hvac Interview QuestionDocumento8 pagineHvac Interview QuestionperezismaelNessuna valutazione finora

- Hilti Malaysia Product Catalogue Chapter 11 - FirestopDocumento14 pagineHilti Malaysia Product Catalogue Chapter 11 - FirestopperezismaelNessuna valutazione finora

- 3 NEPROPLAST CPVC PipesFlowGuard EmailDocumento12 pagine3 NEPROPLAST CPVC PipesFlowGuard EmailperezismaelNessuna valutazione finora

- JR HydrantBroch - spm2147 1411Documento36 pagineJR HydrantBroch - spm2147 1411perezismaelNessuna valutazione finora

- Emergency Eyewash and Drench Shower ProgramDocumento16 pagineEmergency Eyewash and Drench Shower ProgramperezismaelNessuna valutazione finora

- Computer Simulation and Applications in Life Sciences: Dr. Michael Emmerich & Dr. Andre Deutz LiacsDocumento37 pagineComputer Simulation and Applications in Life Sciences: Dr. Michael Emmerich & Dr. Andre Deutz LiacsperezismaelNessuna valutazione finora

- Discrete-Event Simulation - Simulation Practices and TrendsDocumento29 pagineDiscrete-Event Simulation - Simulation Practices and TrendsperezismaelNessuna valutazione finora

- 39HQ - AhuDocumento96 pagine39HQ - AhuperezismaelNessuna valutazione finora

- Ball Valves StandardDocumento1 paginaBall Valves StandardAbdullah FazilNessuna valutazione finora

- Laterally Loaded Pile With Plaxis 3dDocumento5 pagineLaterally Loaded Pile With Plaxis 3dteomalancuNessuna valutazione finora

- A Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationDocumento31 pagineA Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationManuel AlemanNessuna valutazione finora

- LecturenotesDocumento59 pagineLecturenotesTyo Spider-MenkNessuna valutazione finora

- Me 422 Industrial Hydraulics I Laboratuar Exercise Book: Adopted From Festo DitacticDocumento14 pagineMe 422 Industrial Hydraulics I Laboratuar Exercise Book: Adopted From Festo DitacticMustafa ŞafakNessuna valutazione finora

- Experimental Investigation of The Biaxial Behaviour of An Aluminum SheetDocumento30 pagineExperimental Investigation of The Biaxial Behaviour of An Aluminum SheetSayyadh Rahamath BabaNessuna valutazione finora

- Dcam PT 66 Training Module 15.1 FundamentalsDocumento57 pagineDcam PT 66 Training Module 15.1 FundamentalsSThaneasMurNessuna valutazione finora

- Cooling System in IC Engine - Types, Advantages, Disadvantages (PDF)Documento7 pagineCooling System in IC Engine - Types, Advantages, Disadvantages (PDF)Shivam SinghNessuna valutazione finora

- User's Guide: Adash 4900 - Vibrio IIIDocumento40 pagineUser's Guide: Adash 4900 - Vibrio IIIVladimir KojicNessuna valutazione finora

- 964019E PRV ElectricDocumento2 pagine964019E PRV ElectricHugh SagoNessuna valutazione finora

- 24 M Plano HidraulicoDocumento18 pagine24 M Plano Hidraulicomiguel angelNessuna valutazione finora

- JR - Fluid Controls Brochure - SPM0838-FOR-WEBDocumento16 pagineJR - Fluid Controls Brochure - SPM0838-FOR-WEBMai Tuan AnhNessuna valutazione finora

- GE Codigos Error Estufas, Lavavajillas, Microondas PDFDocumento5 pagineGE Codigos Error Estufas, Lavavajillas, Microondas PDFElvis Jesus Landa ReyesNessuna valutazione finora

- Chapter 9. Flow Over Immersed Bodies: The Amount of Information Obtained From Purely Theoretical Methods Is LimitedDocumento34 pagineChapter 9. Flow Over Immersed Bodies: The Amount of Information Obtained From Purely Theoretical Methods Is LimitedJaokNessuna valutazione finora

- Behavior of Concrete Liquid Containing Structures Subjected To Seismic LoadingDocumento12 pagineBehavior of Concrete Liquid Containing Structures Subjected To Seismic LoadingBilal Bin AslamNessuna valutazione finora

- C-4100NC 524-96101 To 524-Xxxxx Parts ManualDocumento91 pagineC-4100NC 524-96101 To 524-Xxxxx Parts ManualMuhammad FarabiNessuna valutazione finora

- Hyster 3 TONDocumento738 pagineHyster 3 TONahmedaljamel433Nessuna valutazione finora

- Executive SummaryDocumento11 pagineExecutive SummaryNitish Kumar SinghNessuna valutazione finora

- Balkumari Higher Sec. School: 2. Answer, in Brief, Any Two QuestionsDocumento3 pagineBalkumari Higher Sec. School: 2. Answer, in Brief, Any Two QuestionsRabindra Raj BistaNessuna valutazione finora

- Documentacion 5549393Documento4 pagineDocumentacion 5549393Marcelo San MartinNessuna valutazione finora

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Documento14 pagineProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhNessuna valutazione finora

- Experiment NoDocumento4 pagineExperiment Nodhanesh tandanNessuna valutazione finora

- 2017 - OTR Tyre Line-Up PDFDocumento14 pagine2017 - OTR Tyre Line-Up PDFOscar Correa MercadoNessuna valutazione finora

- Analysis of Single Row Deep Groove Ball BearingDocumento5 pagineAnalysis of Single Row Deep Groove Ball BearingKIRUBHAKARANNessuna valutazione finora