Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Teori - Butt Welding Procedure PDF

Caricato da

rosiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Teori - Butt Welding Procedure PDF

Caricato da

rosiCopyright:

Formati disponibili

Butt Welding Of Polyethylene Pipes

Butt fusion using a heated plate is a simple and quick jointing technique performed basically

by melting the pipe (fitting) ends and holding them together under controlled temperature,

time and pressure conditions. This technique is most suitable for pipe sizes of DN/OD 63

mm (DN/ID 50 mm) and above.

The butt welding equipment usually consists of:

• butt fusion machine (includes • power source (generator);

pump); • lint-free paper, cloth, or tissue;

• planing tool; • Isopropanol impregnated pipewipe or Isopropanol

• heating plate; (Isopropyl Alcohol);

• thermometer; • pipe rollers;

• timing device; • protective enclosures for some of the above.

• pipe cutter (saw);

Generic butt welding guidelines

Generic temperature and pressure parameters are shown in the table on the next page.

Drag pressure (minimum frictional resistance due to the weight of the pipe and an eventual

active drag pressure) should be added to the interface pressure. Avoid application of

excessive pressure or abrupt pressure build-up.

Generic time parameters shown in the table include:

• Heat soak time (heating time) necessary to obtain a sufficiently large melted zone.

This is the most important parameter.

• Changeover time should be as short as possible.

• Pressure build-up time necessary to gradually build up pressure.

• Cooling time should not be too short to avoid brittle weld due to internal stresses.

Other factors may significantly affect weld quality. The most important of these are:

• Working environment. Care shall be taken to keep the pipe (fitting) ends and heating

plate clean from dust, sand, clay, and shielded from wind (including inside the pipes)

and, as possible, from sun (to avoid uneven temperature distribution). Dirt is removed

using a clean lint-free cloth or by performing a “dummy weld”.

• Alignment. Misalignment should be kept as small as possible and should not exceed

10% of the pipe wall thickness.

Pipes of nominal outside diameter of 315 mm and over may be welded also using dual-

pressure butt fusion cycle according to UK Water Industry Specification WIS 4-32-08.

Information or advice contained in these guidelines or obtained from Waters & Farr otherwise is given in good faith. Waters & Farr

Waters & Farr make no warranty or representation regarding the information, opinions and recommendations contained in 105 Neilson St, Onehunga

the guidelines. Users of the guidelines are advised to seek and rely upon their own professional advice and assessment PO Box 13329, Onehunga

of the matters contained in the guidelines. Waters & Farr excludes all liability to any user of the guidelines for Auckland, New Zealand

consequential or indirect damages, or any other form of compensation or relief whatsoever for any acts or omissions of Phone +64 9 622 4036

Waters & Farr, arising out of or in connection with the use of the guidelines irrespective of whether the same arises at law, Fax +64 9 622 4037

inequity or otherwise.

Page 1 of 4 20-Nov-09 ISO9001 Registered

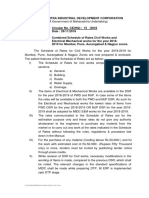

Schematically (not in scale), the butt fusion cycle is shown on the diagram below.

Pressure P

P1 P2 P3

Time t

t1 t2 t3 t4 t5 (t5+t6)

Butt fusion parameter guidelines are as follows:

Butt fusion parameters Units Value Value Comments

W&F ISO

recommendations 21307:2009(E)

Heating plate temperature °C 210 to 225 200 to 245

Heating pressure (interface P1 kPa 130 to 170 170 ± 20 Use formula below and add

pressure) drag pressure

Approximate initial bead mm 0.5 + 0.1×e 0.5 + 0.1×e e = mean wall thickness

width (max. 6 mm) rounded up, mm

Bead up time t1 sec. Varies

Heat soak pressure P2 kPa Drag only Drag only

Heat soak time t2 sec. 15×e (11 ± 1) ×e

Maximum heater plate t3 sec. 3 + 0.01×OD 0.1×e + 4 OD = nominal pipe outside

removal time diameter, mm

Maximum time to achieve t4 sec. 3 + 0.03×OD 0.4×e + 2 Use most of the time to

welding pressure gradually increase pressure

Welding and cooling P3 kPa 130 to 170 170 ± 20 Use formula below and add

pressure (interface drag pressure

pressure)

Welding Under pressure t5 e+3 Time in clamps

and

Without pressure t6 e+3

cooling

time e < 15 mm t5 min. 10 + 0.5×e At temperatures over 25°C

add 1 min. per °C

e > 15 mm t5 min. 1.5×e

To calculate pressure in the hydraulic system of the butt fusion machine use the following

formula:

pipe annulus area × interface pressure value,

hyd. cylinder area

where pipe annulus area = π×(OD – e)×e .

These parameters should be suitable for both PE 80 and PE 100.

Page 2 of 4 20-Nov-09 Waters & Farr

Generic butt fusion procedure may be basically divided into the following steps.

• Cut straight the pipe(s) to be welded.

• Reduce the drag resistance as much as possible (eg. using pipe rollers, etc.).

• Clean the pipe ends and the spigot ends of fittings by wiping them with a clean,

untreated, lint-free cloth. Remove all foreign matter.

• Clamp the pipe (fitting) in the butt fusion machine. The pipes should be properly aligned.

• Check that the butt fusion machine is compatible with the pipe outside diameter and butt

fusion cycle to be applied.

• Plane the pipe (fitting) ends by closing the butt fusion machine around the planing tool.

Closing pressure shall be sufficient to produce a steady flow of polyethylene slivers on

both sides of the rotating planing tool. The operation is complete when the pipe (fitting)

ends are parallel to each other (or when a minimal distance exists between the fixed and

movable jaws of the butt fusion machine).

• Lower the pressure while keeping the tool rotating. Move the clamp backwards, stop and

remove the planing tool. Remove all pipe chips from the planing operation and any

foreign matter with a clean, untreated, lint-free cloth. Do not touch the newly faced

surfaces with hands.

• Close the butt fusion machine, and check that the pipes are aligned (the pipe profiles

must be rounded and aligned with each other to minimise mismatch of the pipe walls).

The jaws of the butt fusion machine must not be loosened at any time or the pipe may

slip during fusion. If any adjustment at all is made on one or both inside clamps, then the

planing operation should be repeated.

• Gap between the pipe (fitting) ends shall be as small as possible. In whatever case, it

shall not exceed:

− 0.3 mm for OD < 225 mm;

− 0.5 mm for 225 mm OD 400 mm;

− 1 mm for OD > 400 mm.

• Measure the drag pressure (usually defined as the minimum pressure needed for very

slow movement of pipe or for holding pipes together during the above alignment).

• Check that the heating plate is at the correct temperature. Check that the surface

coating of the heating plate is intact and without scratches.

• Clean the plate with an Isopropanol impregnated pipewipe (or clean, untreated, lint-free

cloth moistened in Isopropanol), and allow it to dry.

• Clean the pipe ends (planed surfaces and at least 30 mm along the pipe from the ends)

with an Isopropanol impregnated pipewipe, and allow them to dry.

• Place the heating plate between the pipe (fitting) ends.

• Close the butt fusion machine around the heating plate with the pressure P1 (including

the drag pressure) till the specified bead width has been reached.

• Reduce pressure to a level at which contact is just maintained between the pipe (fitting)

ends and the heating plate (P2). Maintain the contact (without separation of the pipe

ends and the plate) for the heat soak time t2 duration (note, that the lower temperature

of the heating plates requires a slightly longer heat soak time).

Page 3 of 4 20-Nov-09 Waters & Farr

• When the heat soak time t2 has elapsed, quickly open the butt fusion machine, remove

the heating plate and having quickly checked the pipe ends for possible damage, close

the butt fusion machine again (this operation shall be done quickly within the specified

time t3). If melted plastic surface sticks to the heating plate, or is damaged, discontinue

the fusion operation, let the pipe ends cool, and start over from the beginning. Use

minimum pressure needed to bring the pipes together when closing the machine.

• Gradually increase pressure to the specified pressure P3. Use practically all of the

time t4. Note, that excessive pressure or too quick pressure application will squeeze too

much melt out of the fusion area resulting in a weakened (brittle) joint. The force applied

will cause each bead to roll back onto the pipe. The degree of bead roll-over may differ

between different pipe materials.

• Store the heating plate in the protective enclosure between fusion cycles.

• The butt fusion machine shall remain closed during the whole butt fusion time t4 and t5

(and t6).

• When the cooling period has elapsed (or when the surface of the bead is cool to the

touch), release the pressure in the butt fusion machine. Open the clamps.

• When removed from clamps, the pipe shall be handled with care (including when

removing the pipe). The pulling, installation or rough handling of the pipe should be

avoided till the weld has completely cooled (for at least an additional 30 minutes; this

does not prevent careful moving the butt-welding machine to the next weld).

• Examine the joint. Remove the bead, if required, using a purpose made tool (the bead

may be used to assess weld quality), and examine the joint again. If upon examination

the joint appears faulty, cup open and start over from the beginning.

We recommend testing a butt weld joint made from the pipe to be used and under the

intended welding conditions prior to installation.

Consider using dual-pressure butt fusion cycle according to ISO 21307:2009(E) for pipes

of wall thickness over 25 mm.

Page 4 of 4 20-Nov-09 Waters & Farr

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Katalog Smart Joint GapuraDocumento5 pagineKatalog Smart Joint GapurarosiNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Wasser Catalogue GPDocumento22 pagineWasser Catalogue GProsiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Air Valves VagDocumento8 pagineAir Valves VagrosiNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Gate Valve VAGDocumento5 pagineGate Valve VAGrosiNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- RICON Steel FittingDocumento22 pagineRICON Steel Fittingrosi50% (2)

- JZ Cast Iron FittingsDocumento8 pagineJZ Cast Iron Fittingsrosi100% (1)

- Tacmina Dosing Pump Cs2Documento8 pagineTacmina Dosing Pump Cs2rosiNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Description: Unit QTY Unit Price Amount SRDocumento7 pagineDescription: Unit QTY Unit Price Amount SRvin ssNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Alloy and Temper DesignationDocumento14 pagineAlloy and Temper DesignationKrishna KishoreNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Galvanized Rebar Vs Epoxy RebarDocumento4 pagineGalvanized Rebar Vs Epoxy RebarvintagerulzNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Plant - Room.Position - And.Size: DistributionDocumento26 paginePlant - Room.Position - And.Size: DistributionMhr IzadNessuna valutazione finora

- Silicone RubberDocumento25 pagineSilicone RubberAjinkya SatdiveNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- 02 Samss 005Documento13 pagine02 Samss 005eramioNessuna valutazione finora

- Gems E-4m17 Air Fin CoolersDocumento19 pagineGems E-4m17 Air Fin CoolersMochamad TaufikNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Coat Defects PDFDocumento72 pagineCoat Defects PDFkirubha_karan2000100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- BoefDocumento6 pagineBoefmetroroadNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Irco Chal P13R P10RDocumento2 pagineIrco Chal P13R P10RLam TranNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Air Intake SystemDocumento27 pagineAir Intake SystemrahulNranaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Coal SlagDocumento4 pagineCoal SlagSivaratnam NavatharanNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Odwadniacz Termostatyczny th13Documento1 paginaOdwadniacz Termostatyczny th13Fernando Moreno pereiraNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Astm C1550-3Documento9 pagineAstm C1550-3propertyNessuna valutazione finora

- Zinc and RefractoriesDocumento5 pagineZinc and RefractoriesJimmy MarNessuna valutazione finora

- Static and Dynamic Testing of Welded and Woven Mesh For Rock SupportDocumento11 pagineStatic and Dynamic Testing of Welded and Woven Mesh For Rock SupportAyleen LealNessuna valutazione finora

- West Bengal Schedule Rates of Sanitary & Plumbing Works 2015Documento125 pagineWest Bengal Schedule Rates of Sanitary & Plumbing Works 2015Arunashish Mazumdar100% (11)

- Combined Schedule of Rates Civil Works and Electrical Mechanical Works For The Year 2018-2019 For Mumbai Pune Aurangabad & Nagpur ZonesDocumento279 pagineCombined Schedule of Rates Civil Works and Electrical Mechanical Works For The Year 2018-2019 For Mumbai Pune Aurangabad & Nagpur ZonesmashaK100% (4)

- New SID ChecklistDocumento19 pagineNew SID ChecklistDhanny MiharjaNessuna valutazione finora

- Features and Benefits: Model CB 15-100 HP BoilersDocumento5 pagineFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- 4.5.33 Guidelines For Lime Stabilization PDFDocumento4 pagine4.5.33 Guidelines For Lime Stabilization PDFVictor Thobias100% (1)

- Manual Equipo 2 y 3Documento72 pagineManual Equipo 2 y 3Wakko20IPN100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- PropertiesDocumento6 paginePropertiesmarkalvinbonNessuna valutazione finora

- Typical Specifications: Model: Description: CertificationsDocumento1 paginaTypical Specifications: Model: Description: CertificationsLeo2pbNessuna valutazione finora

- Analyses and Use of Software Ansys and Franc2d For Fracture MechanicsDocumento8 pagineAnalyses and Use of Software Ansys and Franc2d For Fracture MechanicsPradeep KunduNessuna valutazione finora

- Is 4622 2003Documento27 pagineIs 4622 2003Apurba Haldar100% (1)

- Saic M 1073Documento6 pagineSaic M 1073Hussain Nasser Al- NowiesserNessuna valutazione finora

- CTV200 250 Pu V1.0 enDocumento28 pagineCTV200 250 Pu V1.0 entomNessuna valutazione finora

- Issue 03 Deterioration of Concrete - Types and Its Preventive MeasuresDocumento8 pagineIssue 03 Deterioration of Concrete - Types and Its Preventive Measuresankurshah1986100% (1)

- Mechanics of Solid (Mos) : Introduction - Concept of StressDocumento28 pagineMechanics of Solid (Mos) : Introduction - Concept of StressKHAKSARNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)