Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Reproducible Low-Gloss Powder Coatings Using Novel Polyester Resin System

Caricato da

Urban Renewal DevelopmentTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Reproducible Low-Gloss Powder Coatings Using Novel Polyester Resin System

Caricato da

Urban Renewal DevelopmentCopyright:

Formati disponibili

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 1

Matting without mixing

The production of matte finish powder coatings Inside buildings, decorative and functional elements

currently requires dry blending of two incompatible exposed to artificial light, such as ceiling panels or

resins, or expensive GMA or PUR chemistries for lamp holders, are often coated with matte or semi-matte

exterior coatings. A new ‘single shot’ HAA-cured UV-resistant powders to avoid excessive disturbing light

system allows low and reproducible gloss levels to reflections.

be obtained by mixing two specific polyester resins Automotive trim parts are painted with matte to semi-matte

together before extrusion. Gloss is controlled by powder coatings to offer an attractive contrast to the high

selection of the polyesters and their mixing ratio. gloss car body finish. Those applications typically require

extended weather-resistance which can only be achieved

One-shot resin system creates reproducible low-gloss with so-called super-durable polyester systems.

exterior finishes Another application in the field of sporting equipment is dull

Benoit De Becker matte powder coatings applied on bicycle frames.

John Jacquin Military applications traditionally require a dull matte surface

Alessandro Minesso finish for functional reasons. Low gloss surfaces will be

Dietmar Fink* rendered less visible by reflecting less sunlight.

Powder coating has been developing for a number of These applications altogether represent about 20 % of the

years as an environmentally-friendly option for surface outdoor decorative powder market, or an overall volume

finishing applications. It has penetrated many segments of approximately 100,000 MT worldwide. Requirements

in the coatings industry and powder-coated items can be in these markets, in addition to the lower gloss levels,

found almost everywhere in our daily life. will be those typical of high quality outdoor paints, which

In many coating applications there is a preference in include superior weather resistance, flow and mechanical

the market for matte finishes. Different methods and properties. Easy workability and reproducibility of results

matting agents exist for indoor and outdoor durable powder are also of the utmost importance for both the paint maker

coatings. The matting effect will in each case depend on and applicator alike.

the combination of the resin, hardener, matting agent and The resin technology presented in this article will offer these

paint formulation. One area in which there are limitations in performance levels in both standard and super-durable

terms of reliability and adaptability of the matte level is that quality together with gloss levels between 5 and 40 units as

of powder coatings formulated for outdoor applications. measured at a 60 ° angle.

A new technology is presented here that will make it

possible to formulate outdoor hydroxyalkylamide (HAA)- Current matte finish technologies have limitations

based coatings to obtain a reproducible high quality matte Most matte and semi-matte outdoor resistant powder

finish with gloss level between 5 and 40 units with good coatings are based on dry-blend technology, where two

overall properties. The new one-shot matte technology is powders with different reactivity levels have to be produced

based on patent-pending polyester chemistries used in and mixed together either directly after the extrusion

combination with HAA for exterior grade powder coatings. process as chips and then co-ground or mixed as previously

fine ground powders. The matting effect is then generated

Matte finishes serve many different purposes during the curing process of the two different powders.

Matting effects in coatings can be desired for many different When the reactive powder is already cross-linked, the

reasons. In some applications strong light reflection has to slower reacting powder is still in the melting phase and

be minimised with the help of matte coatings. Matte finishes embeds the other cured one. This causes a so-called

can also be used to conceal substrate defects, surface incompatibility effect, which is visible as a lower gloss level

irregularities, or even dirt and dust particles on the coating in the powder film. The matte dry-blend technology has,

surface. In most cases, however, matte powder coatings are however, some inherent limitations.

used to achieve specific aesthetic and design aims. Due to inhomogeneities in the cured film, a so-called

Matte finish paints are in high demand both in growth sparkling effect is often visible. It varies with the particle size

segments such as architectural applications and in high distribution of the dry-blended powders. The coarser the

value speciality application such as sporting goods, glass particle size, the stronger the sparkling effect. In addition,

coating and military applications. Some examples of critical the mechanical properties are limited, due to the relatively

applications include: weak bonding between the two phases of the powders.

Dull matte paints are used to give an elegant finish on glass During recycling of the dry-blend powder in an automatic

bottles. application booth, there is a danger of increasing the gloss

High-end office furniture is typically painted with a matte to over time, as the two phases of the dry-blended powder

semi-matte finish that complements novel designs. have different charging behaviour due to the different

Architectural elements such as window frames can now physical-chemical characteristics of the binder system and

be powder coated with wood-effect designs that typically the slightly different particle size distribution, which leads to

perform best at low gloss levels. selective powder recovery and application.

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 2

There are additional costs associated with the production of might be useful for specific applications, but are not always

dry-blended powder since two powder materials have to be reproducible see Figure 1.

produced to obtain a single matte dry-blend powder. Lack With the standard one-shot matte polyester resins one

of reproducibility also translates into yield losses, which in can obtain powder coatings with very good mechanical

turns also mean extra cost for the powder manufacturer properties, better than any equivalents made by dry-blend

and/or the applicator. technology. The system also shows good storage stability

properties: powders do not change their reactivity, flow and

Two main systems used for dull matte finishes flexibility. Physical stability is also good full properties are

Dull matte finishes can be achieved either by use of retained after 28 days at 40 °C.

a glycidyl methacrylate (GMA) hardener or with a one- Curing the one-shot matte HAA powders at different

shot polyester powder system based on hydroxy-functional temperatures produces very consistent gloss levels.

polyester blends cross-linked with blocked isocyanate, that The weathering properties of the dull-matte combination

is, PUR or polyurethane technology. These systems both polyester 1 (Ac-Nr. 90) and polyester 2 (Ac-Nr. 25) resins

provide superior dull-matte finishes that are typically used with HAA are good for GSB and Qualicoat approvals with

in speciality applications. However, as in the case of the gloss retention after 12 months in Florida (5 ° South) well

matte dry-blend, those technologies suffer from some key above 50 %. As an alternative resin to polyester 2, one can

limitations. use the super-durable polyester 3 (Ac-Nr. 30), which offers

Systems based on a GMA acrylic matting hardener show further improvements in weathering properties (see Figure

limitations in mechanical properties and to a certain 2).

extent, sensitivity to other binder systems in respect of

contamination. It is also a rather expensive chemistry which Different resins provide matte to semi-matte effects

has limited the penetration of the technology in niche The two resins denoted as polyester 4 (Ac-Nr. 85) and

applications. polyester 5 (Ac-Nr. 33) can be used in ratios from

The one-shot PUR technology is the most expensive dull 45/55 to 55/45 to formulate powders of different gloss

matte binder system, as it requires a large quantity of levels from matte to semi-matte with good weathering

costly isocyanate hardener. The system is sensitive during resistance and good overall paint properties. Compared

the extrusion process, as different or varying dispersion to dry-blend technology with polyester 6 (Ac-Nr. 48)

conditions have a significant influence on the matting level. and polyester 7 (Ac-Nr. 20) the new resin combination

A new patent-pending "Crylcoat" technology is being offers a homogeneous, non-sparkling matting effect, better

developed to address the needs for matte finishes in mechanical properties and good reproducibility within the

the outdoor powder coating market. The target of the recommended formulation ratios (see Figures 3 and 4).

development is a binder system that allows premixing of all There are four so-called super-durable types, polyester 8

the ingredients necessary to produce in a single formulation (Ac-Nr. 90) and polyester 9 (Ac-Nr. 21) available which

a powder coating with the desired reproducible gloss level can be used to formulate powders with dull-matte gloss-

that uses standard production processing equipment. levels, and polyester 10 (Ac-Nr. 90) and polyester 11 (Ac-

By selecting the right product pair in the new range of one- Nr. 30) for different gloss-levels from matte to semi-matte

shot carboxylic polyesters it is possible to adjust the gloss with excellent weathering properties and good overall paint

to the desired level in a reproducible way. The products are properties. The new resin combinations offer homogeneous

available in standard and super-durable grades, and are paint properties, non-sparkling matting effect and good

designed to be used in combination with HAA. reproducibility within the recommended formulation ratios.

(Figure 5).

Dull-matte to matte finishes are readily achieved

The new matte technology is very robust in relation to Further improvements are being studied

the production process. Either the twin-screw or mono- Ongoing developments in the area of one-shot technology

screw extruder technology used under standard conditions for matte finishes are targeted at specific market needs for

results in comparable matte gloss levels. The smoothness special applications.

of the film surface will be dependent on the binder content. A number of modifications to the binder system are being

For speciality applications that require superior flow it is investigated to achieve superior burnish resistance. The

recommended, depending on the colour shade, to work with latter is a typical issue when formulating ultra-low gloss paint

a relatively high concentration of resin. in dark shades.

As regards the curing agent, a number of hydroxyalkylamide Resin design optimisation is continuing, to broaden the

(HAA) hardeners are available on the market. scope of pigments that can be used for producing one-

"SF 45-10" is an HAA grade with lower functionality that shot matte coatings with superior flow. Flow modifiers and

yields gloss levels of about 10 units higher than the basic modifications to the resin are being investigated to further

HAA grades when used as hardener for the new one-shot reduce the impact of binder content on flow.

technology. Powders formulated with HAA modifications But already, a solution now exists that permits easy one-

such as "QM 1260" and used in directly fired gas- shot production of matte powder coatings. The patent-

ovens result, however, in significantly higher gloss levels, pending technology presented here provides an adjustable

according to our experiments, and are not recommended. gloss level in both standard and super-durable quality.

In order to formulate a robust, batch-to-batch reproducible The new system offers easier handling, with significant

matte powder coating, only ratios of polyester pairs that do cost advantages to the production process, and better

not exceed the range 55/45 to 45/55 are recommended. mechanical film properties. These had been two major

More extreme ratios result in higher gloss levels, which limitations so far in the field of matte outdoor resistant

powder coatings.

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 3

The different polyesters allow the production of matte paints

in a wide range from 5 to 40 gloss units as measured at 60

° incidence.

In times when matte finishes are becoming more and more

popular, and when the market is looking for cost-effective

formulation options, this new technology is ideal to replace

current technology systems for matting outdoor resistant

powder coatings, and also to allow the penetration of near

dull-matte finish in application segments where the former

solutions were too expensive to be considered.

Results at a glance

There is a considerable demand for matte finishes to

meet specific functional or aesthetic requirements in many

different market sectors. However, this is one area of

weakness for powder coatings, as gloss reduction must

normally be achieved by mixing two incompatible powders.

This dry blending process can produce problems such as

‘sparkle’ and variation of gloss levels if powder is recycled

during spraying. Where high exterior durability is required

it is necessary to use expensive GMA or PUR chemistries.

A new system for producing reproducible low gloss levels

has been developed, in which two specific polyester resins

are mixed together along with an HAA curing agent and

extruded to produce a ‘single shot’ matte powder. By

selection of the right polyesters and altering the mixing ratio

of the resins, low and very reproducible gloss levels can be

obtained. Super-durable polyesters are available to provide

very good exterior performance.

* Corresponding Author:

Dietmar Fink

Cytec

Tel. +32 (0)2 560 46 56

dietmar.fink@cytec.com

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 4

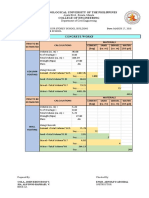

Figure 7: General comparison of properties between the new technology and

standard dry-blend systems

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 5

Figure 1: Robustness of the new

technology: low gloss levels are

obtained and are highly reproducible

so long as the mixing ratio of the

resins is close to 50/50

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 6

Figure 2: Selection of a resin pair

for dull matte finishes in relation to

durability requirements

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 7

Figure 3: Gloss variations produced by

changing the ratio between polyester 4

and polyester 5

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 8

Figure 4: Comparison of novel matte

one-shot technology to existing matte

HAA dry-blend powders

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 9

Figure 5: Properties of super-durable

one-shot dull-matte to semi-matte

(6-20 units to 25-35 units 60 ° gloss)

HAA powders

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 12/2009

Seite/Page: 10

Figure 6: Gloss retention of super-

durable one-shot dull-matte and semi-

matte HAA powders

Vincentz Network +++ Plathnerstr. 4c +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Oxidation and Reduction SPM Form 5Documento63 pagineOxidation and Reduction SPM Form 5Azie Nurul Akhtar85% (13)

- Epoxy CuringDocumento8 pagineEpoxy CuringUrban Renewal Development100% (1)

- IELTS WRITING 2017 Review PDFDocumento154 pagineIELTS WRITING 2017 Review PDFẤm LeeNessuna valutazione finora

- Portable Spectrophotometer CS 580 enDocumento6 paginePortable Spectrophotometer CS 580 enUrban Renewal DevelopmentNessuna valutazione finora

- Licowax PE 520Documento2 pagineLicowax PE 520Urban Renewal DevelopmentNessuna valutazione finora

- 06 VP PowderDocumento70 pagine06 VP PowderUrban Renewal DevelopmentNessuna valutazione finora

- Light-Duty Impact Tester Measures Materials ResistanceDocumento1 paginaLight-Duty Impact Tester Measures Materials ResistanceUrban Renewal DevelopmentNessuna valutazione finora

- Exactly your chemistry in plasticsDocumento1 paginaExactly your chemistry in plasticsUrban Renewal DevelopmentNessuna valutazione finora

- Light-Duty Impact Tester Measures Materials ResistanceDocumento1 paginaLight-Duty Impact Tester Measures Materials ResistanceUrban Renewal DevelopmentNessuna valutazione finora

- BYK-Gardner ISO Impact Tester: Top of Tube Is Not ShownDocumento1 paginaBYK-Gardner ISO Impact Tester: Top of Tube Is Not ShownUrban Renewal DevelopmentNessuna valutazione finora

- 1 s2.0 S2352179118302382 MainDocumento5 pagine1 s2.0 S2352179118302382 MainIrfan IsdhiantoNessuna valutazione finora

- Elastomeric Sealing Compound Specification for BuildingsDocumento33 pagineElastomeric Sealing Compound Specification for BuildingsSivaram KottaliNessuna valutazione finora

- bizurado-silvaco-PIN Detector Thesis PDFDocumento143 paginebizurado-silvaco-PIN Detector Thesis PDFombraga1896Nessuna valutazione finora

- FYP1-presentation Slide PDFDocumento18 pagineFYP1-presentation Slide PDFMirza Farouq BegNessuna valutazione finora

- Smaw 12 Module 1Documento7 pagineSmaw 12 Module 1Francis Rico Mutia RufonNessuna valutazione finora

- Matachana - AP4 - Water Treatment System For Steriliser - User ManualDocumento8 pagineMatachana - AP4 - Water Treatment System For Steriliser - User ManualWahidi AzaniNessuna valutazione finora

- 10.1016/j.powtec.2017.06.053: Powder TechnologyDocumento46 pagine10.1016/j.powtec.2017.06.053: Powder TechnologychandiniNessuna valutazione finora

- Pile Jacking FullTextDocumento223 paginePile Jacking FullTextGeorge Ardianda CrNessuna valutazione finora

- Microstructure-Property Correlations For Hard, Superhard, and Ultrahard MaterialsDocumento244 pagineMicrostructure-Property Correlations For Hard, Superhard, and Ultrahard MaterialsJH ShinNessuna valutazione finora

- Item 510-1Documento2 pagineItem 510-1Engineer LeeNessuna valutazione finora

- Isocure: Concrete Curing AgentDocumento1 paginaIsocure: Concrete Curing AgentshafiullahNessuna valutazione finora

- Clean Surfaces and Floors Lesson Explains TechniquesDocumento47 pagineClean Surfaces and Floors Lesson Explains TechniquesEmerson Cruz0% (1)

- List of notifications prepared as of 22 March 2018Documento13 pagineList of notifications prepared as of 22 March 2018Anonymous F1xtU2RNessuna valutazione finora

- Colloidal Stability OctoberDocumento4 pagineColloidal Stability OctoberOzi Adi SaputraNessuna valutazione finora

- 2 Concrete Works CompuDocumento14 pagine2 Concrete Works CompuALFONSO RAPHAEL SIANessuna valutazione finora

- Boe (Boiler Operation Engineer) Short Type Question Answer-2 For Examination - AskpowerplantDocumento15 pagineBoe (Boiler Operation Engineer) Short Type Question Answer-2 For Examination - AskpowerplantRaju MaityNessuna valutazione finora

- Affect of Elements On SteelDocumento82 pagineAffect of Elements On SteelAditya PratapNessuna valutazione finora

- CgtophDocumento2 pagineCgtophcristian orihuelaNessuna valutazione finora

- E1225-13 Standard Test Method For Thermal Conductivity of Solids Using The Guarded - Comparative PDFDocumento10 pagineE1225-13 Standard Test Method For Thermal Conductivity of Solids Using The Guarded - Comparative PDFFernando Gastañaga Flores100% (2)

- Reinforced Concrete Column Interaction DiagramsDocumento33 pagineReinforced Concrete Column Interaction DiagramsJamal RkhNessuna valutazione finora

- Determination of Parameters For Hyperbolic Model of SoilsDocumento13 pagineDetermination of Parameters For Hyperbolic Model of SoilsRamiro ChairezNessuna valutazione finora

- EtdDocumento161 pagineEtdrazmian2010Nessuna valutazione finora

- Chondroitin sulfate sodium analytical methods guideDocumento3 pagineChondroitin sulfate sodium analytical methods guideAchmad LatiefNessuna valutazione finora

- Jinko Solar Photovoltaic Module Installation GuideDocumento22 pagineJinko Solar Photovoltaic Module Installation GuideFriedrichNessuna valutazione finora

- 10 Handbook Standard For Portable Fire ExtinguishersDocumento205 pagine10 Handbook Standard For Portable Fire ExtinguishersJosesin SinsinNessuna valutazione finora

- Manganese Bronze Data SheetDocumento10 pagineManganese Bronze Data SheetKapil HarchekarNessuna valutazione finora

- Complaint AnalysisDocumento8 pagineComplaint AnalysisJKP OperationNessuna valutazione finora

- Replacement of Bearings in The Golden Horn Bridge PDFDocumento3 pagineReplacement of Bearings in The Golden Horn Bridge PDFVCNessuna valutazione finora

- Sample Questions - Chapter 13Documento6 pagineSample Questions - Chapter 13Rasel IslamNessuna valutazione finora