Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

p103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control System

Caricato da

Anandu AshokanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

p103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control System

Caricato da

Anandu AshokanCopyright:

Formati disponibili

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF ACCESS CONTROL

SYSTEM

METHOD STATEMENT FOR INSTALLATION OF ACCESS CONTROL SYSTEM

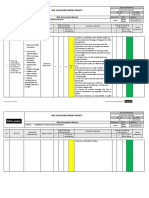

Document No: P103-STTS-GEC-ASI-MS-ELE-013

REV. DATE DESCRIPTION GENFOCUS CONSULTANT

PREPARED APPROVED

000 27-05-18 Issued for Approval QA/QC PM

DOCUMENT No. REV DATE

P103-STTS-GEC-ASI-MS-ELE-013 000 28-05-2018 Page 0 of 5

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF ACCESS CONTROL

SYSTEM

1.0 PURPOSE

1.1 The purpose of this method statement is to define procedure to be followed during

installation of Access Control System.

2.0 SCOPE

2.1 The scope of this method statement is to provide guidelines for installation and Testing of

Access Control. All works shall be conducted in conformance with relevant project

drawings /specifications and good industry practices.

3.0 TOOLS & EQUIPMENTS

3.1 Temporary Network Switch

3.2 Punch down Tool

3.3 Cable Tracker

3.4 Cable Drum Stand and Shaft

3.5 Pulling Wire or Rope

3.6 Safety gloves and safety helmet

3.7 Steel Fish Tape

3.8 General Tools

4.0 RESPONSIBILITY

4.1 PROJECT MANAGER:

4.1.1 To be the focal point for all over interfaces and other communications with the company

and contractor as required during project execution.

4.1.2 Ensure that adequate quality measures are being undertaken.

4.1.3 He shall identify and secure necessary resources, determining the task that must be

completed, assigning the tasks and delegating authority.

4.1.4 He is responsible for planning of site organization, resource mobilization, subcontracting,

site operation, construction methods and scheduling.

DOCUMENT No. REV DATE

P103-STTS-GEC-ASI-MS-ELE-013 000 28-05-2018 Page 1 of 5

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF ACCESS CONTROL

SYSTEM

4.1.5 Ensure all the keys staffs are on site during execution.

4.1.6 He shall coordinate all site safety issues to HSE Personnel for corrective Action.

4.1.7 Main point of contact on site for safety issues.

4.2 SITE ENGINEERS/ SUPERVISOR

4.2.1 Responsible for the coordination of all electromechanical activities, coordination with

other discipline and between various subcontractors on sites

4.2.2 Ensure all permits are available for works on site and all safety precautions are taken.

4.2.3 Responsible to ensure sufficient and adequate resources are secured and provided to MEP

subcontractor.

4.2.4 To direct and coordinate with MEP subcontractor and other MEP Engineers for effective

execution on site.

4.2.5 To report back to Division Manager/ Project Manager relevant MEP progress,

bottlenecks cost control and other issues.

4.2.6 Reviewing MEP Daily, Weekly & Monthly Progress reports.

4.2.7 Responsible for completing of all MEP punch items and project close out, handover

documentation and operation maintenance manual, training etc.

4.3 QA/QC ENGINEER

4.3.1 Ensure all inspections are raised and conducted as per the contract specifications,

approved shop drawings & Method statements.

4.3.2 Ensure all current issues of procedures, approved material and shop drawing and

standards are available at the point of use.

DOCUMENT No. REV DATE

P103-STTS-GEC-ASI-MS-ELE-013 000 28-05-2018 Page 2 of 5

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF ACCESS CONTROL

SYSTEM

4.3.3 Ensure the total quality control for installation work. He shall liaise with Company for

inspection of installation works.

4.3.4 Inspect for any damage during, handling and storage.

4.3.5 Monitor the quality of work & insure that fulfilment of specified requirement and that all

quality records related to work are completed.

4.3.6 Ensure the work is completed as per quality requirements.

4.3.7 Contractor shall inspect the same work to initiate IRF for company approval.

4.3.8 Maintain Comprehensive inspection and test records for any further references

4.4 HSE OFFICER

4.4.1 Toolbox talk has to be conducted and all the hazards have to be identified before starting

the work.

4.4.2 To make sure that Personnel Protective Equipment’s (PPE) are used by the Task Force

during execution at site.

4.4.3 Risk related to the activity shall be assessed and addressed as required.

4.4.4 To provide training for the work force in order to execute the activity safely.

4.4.5 Carry out regular and random inspection on site and record observation.

5.0 PROCEDURE

5.1 Before commencement of Access Control System Cabling, the following are required to be

carried out:

5.1.1 Before pulling the cables, the Conduits, ducts and trunking will be checked with the rope

inside to be assured that there are no blockages in the route

DOCUMENT No. REV DATE

P103-STTS-GEC-ASI-MS-ELE-013 000 28-05-2018 Page 3 of 5

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF ACCESS CONTROL

SYSTEM

5.1.2 Check material to be used are approved.

5.1.3 Check work area is clean and safe.

5.2 INSTALLATION OF ACCESS CONTROL SYSTEM EQUIPMENT

5.2.1 Installation checks will be recorded and witnessed on the installation check list.

5.2.2 Check whether all the units/equipment is free of damages.

5.2.3 Readers and Push buttons must be installed at the proper height.

5.2.4 Magnetic contacts and electric locks to be installed with coordination with the door

provider as per the supplied doors.

5.2.5 Check the 240 VAC power supply terminated properly in cabinet at respective

locations.

5.2.6 Check all electrical connections & terminal strip connections for tightness.

5.2.7 Check for proper incoming voltage to the system.

5.2.8 Ensure that all products installed as per the Consultant’s approval.

5.2.9 Check Cables are terminated properly with proper continuity tests.

5.2.10 Check the installed equipment’s are working properly using temporary network

switches.

5.2.11 Installation works to be protected.

DOCUMENT No. REV DATE

P103-STTS-GEC-ASI-MS-ELE-013 000 28-05-2018 Page 4 of 5

Potrebbero piacerti anche

- p103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesDocumento6 paginep103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesAnandu AshokanNessuna valutazione finora

- p103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureDocumento5 paginep103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureAnandu AshokanNessuna valutazione finora

- p103 Stts Gec Asi Ms Ele 014 - Method Statement For Installation of CCTV SystemDocumento7 paginep103 Stts Gec Asi Ms Ele 014 - Method Statement For Installation of CCTV SystemAnandu AshokanNessuna valutazione finora

- p103-Stts-gec-Asi-ms-ele-015 - Method Statement For Installation, Termination and Testing of Structured Cabling SystemDocumento9 paginep103-Stts-gec-Asi-ms-ele-015 - Method Statement For Installation, Termination and Testing of Structured Cabling SystemAnandu AshokanNessuna valutazione finora

- p103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayDocumento6 paginep103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayAnandu AshokanNessuna valutazione finora

- p103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization UnitsDocumento8 paginep103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization UnitsAnandu AshokanNessuna valutazione finora

- p103-Stts-gec-Asi-ms-hvac-009 Method Statement For Installation of Grills and DiffusersDocumento6 paginep103-Stts-gec-Asi-ms-hvac-009 Method Statement For Installation of Grills and DiffusersAnandu AshokanNessuna valutazione finora

- p103-Stts-gec-Asi-ms-hvac-003method Statement For Installation of Air Handling UnitsDocumento6 paginep103-Stts-gec-Asi-ms-hvac-003method Statement For Installation of Air Handling UnitsAnandu AshokanNessuna valutazione finora

- Method Statement of Diesel Generator-Rev 00Documento8 pagineMethod Statement of Diesel Generator-Rev 00midhun muraliNessuna valutazione finora

- p103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionDocumento7 paginep103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionAnandu AshokanNessuna valutazione finora

- p103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & TrunkingDocumento5 paginep103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & TrunkingAnandu AshokanNessuna valutazione finora

- MS For Installation of Drainage PipesDocumento20 pagineMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of Grills, Diffuser & LouversDocumento21 pagineMS For Installation of Grills, Diffuser & LouversAnandu AshokanNessuna valutazione finora

- MS For Installation of Toilet Exhaust FanDocumento20 pagineMS For Installation of Toilet Exhaust FanAnandu AshokanNessuna valutazione finora

- Method Statement - SCSDocumento9 pagineMethod Statement - SCSYazan ZahalqaNessuna valutazione finora

- MS For MEP IsolationDocumento19 pagineMS For MEP IsolationAnandu Ashokan67% (3)

- p103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Documento6 paginep103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Anandu AshokanNessuna valutazione finora

- Install MATV Distribution SystemDocumento7 pagineInstall MATV Distribution SystemDong VanraNessuna valutazione finora

- Method Statement For Installation of LV Power, Control and Low Current System Cables, Glands and AccessoriesDocumento5 pagineMethod Statement For Installation of LV Power, Control and Low Current System Cables, Glands and Accessoriesmidhun muraliNessuna valutazione finora

- Method Statement - Embedded ConduitsDocumento3 pagineMethod Statement - Embedded ConduitsSimeon James Defeo Villacrusis100% (1)

- HVAC Split Unit Installation Procedure - Method Statement HQDocumento7 pagineHVAC Split Unit Installation Procedure - Method Statement HQEngineer ZiaNessuna valutazione finora

- Installation of Electrical PanelsDocumento6 pagineInstallation of Electrical PanelsNidhin MohanNessuna valutazione finora

- Method Statement - ACSDocumento6 pagineMethod Statement - ACSYazan ZahalqaNessuna valutazione finora

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocumento11 pagineMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method of Statement For Fire AlarmDocumento9 pagineMethod of Statement For Fire AlarmUmair BaBerNessuna valutazione finora

- MS For Installation of Sanitary WaresDocumento22 pagineMS For Installation of Sanitary WaresAnandu AshokanNessuna valutazione finora

- 2-Method of Statment WiringDocumento15 pagine2-Method of Statment WiringSyed AtherNessuna valutazione finora

- Method Statement For Installation of BMS M Tower PDFDocumento16 pagineMethod Statement For Installation of BMS M Tower PDFAndrew HivNessuna valutazione finora

- Method of Statement (GPON& PABX)Documento8 pagineMethod of Statement (GPON& PABX)Muhammad IqbalNessuna valutazione finora

- MS-E018 Installation of Fire Alarm SystemDocumento8 pagineMS-E018 Installation of Fire Alarm Systema wasayNessuna valutazione finora

- UPS Installation Health & Safety DocumentsDocumento12 pagineUPS Installation Health & Safety Documentsshareyhou100% (2)

- Methof of Statement For Electrical PanelsDocumento10 pagineMethof of Statement For Electrical PanelsWaleed SalihNessuna valutazione finora

- Rev - 03 - Ms - Installation of Cable Tray or Trunking SystemDocumento7 pagineRev - 03 - Ms - Installation of Cable Tray or Trunking Systemanon_534254691Nessuna valutazione finora

- 11.method Statement Electrical WorkDocumento25 pagine11.method Statement Electrical Workشاز إياس100% (1)

- Method Statement & Risk Assessment Installation of Structured Cabling SystemDocumento16 pagineMethod Statement & Risk Assessment Installation of Structured Cabling SystemAbu Muhammed KhwajaNessuna valutazione finora

- 00 - MS - Telephone or Data System InstallationDocumento9 pagine00 - MS - Telephone or Data System Installationsudeep karunNessuna valutazione finora

- MS - Audio Visual System InstallationDocumento9 pagineMS - Audio Visual System InstallationDuel TimeNessuna valutazione finora

- 001 MEP - Method Floor&Wall PenetrationDocumento7 pagine001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- PKE - DAS - MS-CCTV - Testing & Commissioning 18-03-2017Documento8 paginePKE - DAS - MS-CCTV - Testing & Commissioning 18-03-2017Umair LiaqatNessuna valutazione finora

- T&C Method Statement For CCTVDocumento4 pagineT&C Method Statement For CCTVmohammadNessuna valutazione finora

- Method Statement For Electrical ServicesDocumento6 pagineMethod Statement For Electrical ServicesUmaira ZainalNessuna valutazione finora

- Method Statement For Instalation of CCTV Camera and Junction Boc FoundationDocumento18 pagineMethod Statement For Instalation of CCTV Camera and Junction Boc Foundationashishakare50% (2)

- DX SplitDocumento29 pagineDX Splitsiva_nagesh_2Nessuna valutazione finora

- MS For Installation of Chilled Water FlushinDocumento27 pagineMS For Installation of Chilled Water FlushinAnandu AshokanNessuna valutazione finora

- Installation & Termination of MATV System Method StatementDocumento17 pagineInstallation & Termination of MATV System Method StatementehteshamNessuna valutazione finora

- Method Statement LV Distribution Boards InstallationDocumento9 pagineMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- MSRA Installation of Firefighting SystemDocumento28 pagineMSRA Installation of Firefighting Systemadnan hanif100% (1)

- 00 - MS - Devices Wires InstallationDocumento8 pagine00 - MS - Devices Wires Installationhossam_24_6_722542Nessuna valutazione finora

- Method Statement For Alcatel Telephony System Installation Testing CommDocumento12 pagineMethod Statement For Alcatel Telephony System Installation Testing CommMuraryspotty0% (1)

- Installation of Electric Conduits Method StatementDocumento8 pagineInstallation of Electric Conduits Method Statementanon_534254691Nessuna valutazione finora

- Installation of Cable Ladders and TraysDocumento11 pagineInstallation of Cable Ladders and TraysImran Khan100% (1)

- Method Statement for GI & PVC Conduit InstallationDocumento6 pagineMethod Statement for GI & PVC Conduit InstallationDong Vanra100% (1)

- Rev - 10 - Ms - Installation of Lighting Control PanelDocumento8 pagineRev - 10 - Ms - Installation of Lighting Control Panelanon_534254691Nessuna valutazione finora

- Method Statement For Installation of Wiring DevicesDocumento6 pagineMethod Statement For Installation of Wiring DevicesMohammed Mujeeb Ali Fathaan100% (2)

- Testing & Commissioning of CCTV CameraDocumento6 pagineTesting & Commissioning of CCTV CameraJacob Joseph0% (1)

- 00 - MS - LV Switchgear and Motor Control Center InstallationDocumento8 pagine00 - MS - LV Switchgear and Motor Control Center Installationanon_534254691Nessuna valutazione finora

- Motorized Gate Method StatementsDocumento34 pagineMotorized Gate Method StatementsNideesh RobertNessuna valutazione finora

- LBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)Documento10 pagineLBS 007 LRED RAMS MEP HVAC 03 (Method Statement For Ventilation Fan)faizan khanNessuna valutazione finora

- Method Statement For Installation of Water Spray Deluge System - LPG TankDocumento13 pagineMethod Statement For Installation of Water Spray Deluge System - LPG Tankpunk cm100% (2)

- Installation of CCTV and Access SecurityDocumento9 pagineInstallation of CCTV and Access Securitysswahyudi100% (1)

- Method Statement For Structured Cabling System InstallationDocumento9 pagineMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Method Statement For Water Heaters InstallationDocumento9 pagineMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For Earthing and Lightning ProtectionDocumento12 pagineMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Fire Alarm and Emergency System InstallationDocumento9 pagineMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement For PPR Pipes and Fittings InstallationDocumento9 pagineMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNessuna valutazione finora

- Method Statement For PVC Conduits InstallationDocumento9 pagineMethod Statement For PVC Conduits InstallationAnandu AshokanNessuna valutazione finora

- Method Statement For Drainage Pipes InstallationDocumento11 pagineMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For Cable Tray and Truncking InstallationDocumento9 pagineMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNessuna valutazione finora

- Method Statement For GI Conduits InstallationDocumento9 pagineMethod Statement For GI Conduits InstallationAnandu AshokanNessuna valutazione finora

- Method Statement For PEX Pipes and Fittings InstallationDocumento9 pagineMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNessuna valutazione finora

- Method Statement LV Distribution Boards InstallationDocumento9 pagineMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocumento11 pagineMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- MS Cover SheetDocumento1 paginaMS Cover SheetAnandu AshokanNessuna valutazione finora

- Method Statement For Wiring Accessories InstallationDocumento9 pagineMethod Statement For Wiring Accessories InstallationAnandu AshokanNessuna valutazione finora

- MS For Installation of Sanitary WaresDocumento22 pagineMS For Installation of Sanitary WaresAnandu AshokanNessuna valutazione finora

- MS Comments SheetDocumento1 paginaMS Comments SheetAnandu AshokanNessuna valutazione finora

- Risk Assessment For Installation of Sanitary WaresDocumento14 pagineRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- RAMS EvaluationDocumento3 pagineRAMS EvaluationAnandu AshokanNessuna valutazione finora

- Risk Assessment For Installation of Ducts and AccessoriesDocumento17 pagineRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- MS For Installation of Duct & AccessariesDocumento21 pagineMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- Risk Assessment For Installation of Toilet Exhaust FanDocumento11 pagineRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment For Installation of Drainage PipesDocumento17 pagineRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Water Supply PipeDocumento18 pagineRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- MS For Installation of Drainage PipesDocumento20 pagineMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of Grills, Diffuser & LouversDocumento21 pagineMS For Installation of Grills, Diffuser & LouversAnandu AshokanNessuna valutazione finora

- MS For Installation of FF Pipes FittingsDocumento23 pagineMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- MS For Installation of Toilet Exhaust FanDocumento20 pagineMS For Installation of Toilet Exhaust FanAnandu AshokanNessuna valutazione finora

- Risk Assessment For Installation of Grill, Diffuser and LouversDocumento13 pagineRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- MS - Installation of Water Supply PipeDocumento20 pagineMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting SystemDocumento20 pagineRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- 23 3700 - Air Outlets and Inlets PDFDocumento8 pagine23 3700 - Air Outlets and Inlets PDFMohamed FawzyNessuna valutazione finora

- P10C-D201 Especificaciones Model CDocumento9 pagineP10C-D201 Especificaciones Model CWilliam ValenciaNessuna valutazione finora

- Es 7525 Installation Instructive 1Documento53 pagineEs 7525 Installation Instructive 1David RamírezNessuna valutazione finora

- Architectural Interiors TerminologiesDocumento2 pagineArchitectural Interiors TerminologiesHana YeppeodaNessuna valutazione finora

- Bim Execution Plan (Bimxp) : (Project Title)Documento8 pagineBim Execution Plan (Bimxp) : (Project Title)shashiNessuna valutazione finora

- Structural and Miscellaneous Steel Erection Specification - PIP STS05130Documento14 pagineStructural and Miscellaneous Steel Erection Specification - PIP STS05130fawad ali0% (2)

- Ms For Foundation Excavation and Casting.Documento6 pagineMs For Foundation Excavation and Casting.botchNessuna valutazione finora

- 23 09 23 Direct Digital Control Systems PDFDocumento43 pagine23 09 23 Direct Digital Control Systems PDFolivaresjhonNessuna valutazione finora

- DPIEDocumento106 pagineDPIEaliengineer953Nessuna valutazione finora

- Project Reference Catalogue: Balanced Cantilever BridgesDocumento26 pagineProject Reference Catalogue: Balanced Cantilever BridgesRaymond Sent75% (4)

- Rurban Loft R0Documento14 pagineRurban Loft R0Pankaj Kumar SamantarayNessuna valutazione finora

- Water Supply Shop DrawingDocumento8 pagineWater Supply Shop DrawingBelal ElsayedNessuna valutazione finora

- Three-story Office Building Project ScheduleDocumento37 pagineThree-story Office Building Project Scheduleሙዳየ ግእዝNessuna valutazione finora

- CV: Nguyen Minh Cuong's MEP ExperienceDocumento9 pagineCV: Nguyen Minh Cuong's MEP Experiencekhanh41paceNessuna valutazione finora

- Toaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRDocumento9 pagineToaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRNitin JadhavNessuna valutazione finora

- Door InstallationDocumento2 pagineDoor Installationyusz7857% (7)

- Presentation Repair of Storage TankDocumento28 paginePresentation Repair of Storage TankAbdul ManafNessuna valutazione finora

- Villa at Dubai: (Boq:Hvac System)Documento17 pagineVilla at Dubai: (Boq:Hvac System)Mohammed AzharNessuna valutazione finora

- METHOD STATEMENT For Tiles and Natural Stone and RepairsDocumento9 pagineMETHOD STATEMENT For Tiles and Natural Stone and RepairsJoseph Allan TolentinoNessuna valutazione finora

- Guidelines 1Documento18 pagineGuidelines 1Er Suresh KumarNessuna valutazione finora

- Mechanical Engineer BIM Modeler ResumeDocumento2 pagineMechanical Engineer BIM Modeler ResumeKhalid Bin BreikNessuna valutazione finora

- E16406Documento11 pagineE16406HOFFERNessuna valutazione finora

- Rammed Aggregate Pier Construction and Quality Control Procedures For The Impact SystemDocumento39 pagineRammed Aggregate Pier Construction and Quality Control Procedures For The Impact SystemvillarpolancoNessuna valutazione finora

- CV of Farooq KhalilDocumento2 pagineCV of Farooq KhalilHaseeb AhmedNessuna valutazione finora

- Gracel'S Enterprises: General SpecificationsDocumento17 pagineGracel'S Enterprises: General SpecificationsRhanie Nitsuga GnoldubatNessuna valutazione finora

- 1TB01005-005C17 - Hah-Xx-Xx-Sdw-Me-10005-C1-Dwg-Equipment Positioning - General Plan (B)Documento2 pagine1TB01005-005C17 - Hah-Xx-Xx-Sdw-Me-10005-C1-Dwg-Equipment Positioning - General Plan (B)MAZHAR ALINessuna valutazione finora

- Itp For Plumbing Amp Drainage SystemDocumento98 pagineItp For Plumbing Amp Drainage Systemtristan guarinoNessuna valutazione finora

- Aluminium Curtain WalDocumento28 pagineAluminium Curtain WaljatinNessuna valutazione finora

- NHP SHD Submitted Schedule 06th Jun 2019v1 EditDocumento3 pagineNHP SHD Submitted Schedule 06th Jun 2019v1 EditWilfrid DutruelNessuna valutazione finora

- General Construction SpecificationsDocumento34 pagineGeneral Construction Specificationsrickomama80% (5)