Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

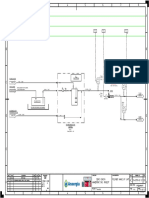

110 20-1 Samapa F Model

Caricato da

Rajkumar PritimaniDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

110 20-1 Samapa F Model

Caricato da

Rajkumar PritimaniCopyright:

Formati disponibili

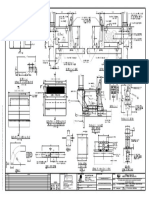

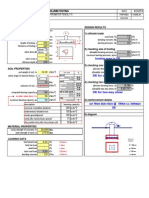

8Ø MESH @ 135 C/C

BOTHWAY

150

8Ø @ 150 C/C COMING FROM

VERTICAL WALL

150TH M- 25 25 DIA. G.I. PIPE RAILING

1200 SPECIFICATIONS :

COPPER LIGHTENING CONDUCTOR

25mm DIA 2.0 MT. LONG

4-12Ø 65X65X6 ANGLE IRON

65X65X6 ANGLE IRON

INLET PIPE

PUDDLE COLLARS

1000 HT. POSTS @ 1500 C/C PUDDLE COLLARS SHALL BE USED FOR CONNECTING THE INLET, OUTLET, OVERFLOW &

CONNECTED BY G.I. STRIP HOOPS 71

5

6-8Ø 1000 HT. POSTS @ 1500 C/C MS BUSH

PLATE FORM

SUPPORTING BEAM

WASHOUT PIPES TO THE RESERVOIR. ALL PUDDLES SHALL BE FIXED AT RIGHT ANGLE

25mm WIDE & 3mm THICK. TO THE RCC WALL DURING CASTING OF WALL. ALL PUDDLE COLLARS SHALL BE OF C.I.

MANHOLE

Dia 600mmx600 High

800X800

25 DIA. G.I. PIPE RAILING 8Ø STIRRUPS@ 150c/c HOOPS THE MINIMUM LENGTH SHALL BE AT LEAST 100 MM MORE THAN THE TOTAL FINISHED

THICKNESS OF THE WALLS AND SIZE OF THE PUDDLE COLLARS SHALL BE EQUAL TO THE

With Mosquito Proof Jali 300

200x150 TOP RING BEAM (M-30)

65X65X6 ANGLE IRON 150 SIZE OF THE RESPECTIVE PIPE.

150

FSL

1000 HT. POSTS @ 1500 C/C FLOAT VALVE SYSTEM

1200

TOP RING 200

R5704

25Ø G.I. PIPE RAILING 750 900 600 300 25 DIA HOLES

THE FLOAT VALVE SYSTEM SHALL BE INSTALLED AT THE END OF INLET PIPE IN EACH

150TH M- 30 12 NOS

BEAM200X150 150

300 FREE BOARD 150 OHSR. THE FLOAT VALVES FOR OHSR SHALL COMPRISES OF TWO FLOAT VALVES I.E.

150 200x150 TOP RING BEAM (M-30) M.S. LADDER 450 MM WIDE,

50x50x6 M.S. ANGLE IRON SPACING OF HOOP BARS OUTSIDE 150 MAIN FLOAT VALVES AND THE AUXILIARY FLOAT VALVE. THE DIFFERENT MATERIALS OF

150

300 FREE BOARD

AND 25 M.S. BARS WELDED 650Ø CONSTRUCTION FOR THE COMPONENTS & OTHER DETAILS SHALL BE AS PER TENDER

150TH AT TOP M- 30 AT 300 WITH M.S. CAGE

150 DOCUMENT.

FLOAT 150 1650 LADDER

FLOAT TANK

150

2650

150TH AT TOP M- 30 239 M.S. LADDER 450 MM WIDE, MADE UP OF 50MM X 50MM X 6MM M.S. ANGLE IRON AND

7000 DIA 815 4 MM GI SHEET

150 25MM M.S. BARS WELDED AT 300MM C/C SHALL BE PROVIDED OUTSIDE FROM THE

165

150 BALCONY TO TOP DOME IN OHSR. MS CAGE SHALL ALSO BE PROVIDED ON THIS LADDER.

ALUMINIUM LADDER 150 6-10Ø bars M.S. LADDER WITH ALL ITS COMPONENTS SHOULD BE SUITABLY PAINTED AS PER

900 750 400

150TH AT BASE M- 30

4700 400 750 150 8Ø VERTICAL BARS @ 150 c/c 815 FLOAT APPROVAL OF EIC. THE LADDERS IN ALL TYPE OF RESERVOIRS (I.E. CWR & OHSR) FROM

200TH M- 30

150 TOP DOME ROOF TO INSIDE PLATFORM AND FROM PLATFORM TO BOTTOM DOME IN THE

150

150 THRO. ON OUTER FACE M16

1000

8Ø@250c/c

800

CONTAINER SHALL BE OF ALUMINIUM.

SPACING OF HOOP BARS INSIDE 150 M.S. CAGE

BOLT

RAILING

R3852 150 135 thick

1650

3760

200 TH M-30 150 DEAD STORAGE

150 PLATFORM HAND RAILING SHALL BE PROVIDED ALONG THE STAIRS OF OHSR AND ON THE TOP

800

8Ø VERTICAL BARS

BEAM SUPPORTING

548

DOME OF OHSR. HAND RAILING AROUND THE PLATFORMS, BALCONY, STAIRS AND

467

1275 1275 150 BEAM

1800

2650 150 LANDINGS SHALL BE CONSISTING OF 25 MM DIAMETER MEDIUM B CLASS GI PIPES IN

150 @ 150 c/c ON INNER FACE TWO ROWS (ONE AT THE TOP AND OTHER AT MIDDLE LEVEL) AND 1000MM HIGH

37-8Ø

150 3500 VERTICAL POST 65X65X6 MM ANGLE IRON @> 1500MM CENTRE TO CENTRE PROPERLY

TYPICAL INLET

PANEL - 5 150 815

EMBEDDED IN THE CONCRETE(AT LEAST TWO VERTICAL ANGLES ARE TO BE PROVIDED

400DIA COLUMNS 150 5 Nos. 8Ø BARS ARRANGEMENT WHEREVER DISTANCE IS LESS) WITH ALL ACCESSORIES LIKE ELBOWS, TEES ETC.

6NOS. M- 25

150 2150 10Ø @100c/c

INCLUDING WELDING, THREADING AND EMBEDDING IN CEMENT CONCRETE FLOOR.

150 6-10Ø bars RAILING SHALL BE PROTECTED AGAINST CORROSION AFTER WELDING. THE PIPE SHALL

150 815

6-10Ø BARS 2#16Ø BARS 3 - 8Ø DIST. BARS PASS THROUGH HOLE IN THE VERTICAL ANGLE.

150 ON EACH FACE

161# 8Ø RADIAL BARS

WATER LEVEL INDICATOR

750 400 2350

DETAIL OF STAIR CASE (M-25)

3890

150 BEAM 300x300 150 WATER LEVEL INDICATOR SHALL BE CONSISTING OF AN APPROVED FLOAT AND AN IRON

COMING FROM 150 300 COUNTER WEIGHT CONNECTED TO A FLEXIBLE STAINLESS STEEL WIRE 4MM THICK

10Ø @100c/c

150 PASSING OVER PULLEY 70MM DIAMETER. THE PULLEYS SHALL BE PROPERLY FIXED

500x250 BRACE-1

CONE WALL AS 150 150 600

WITH STRUCTURE AND SHOULD HAVE A GUIDE SO THAT THE WIRE DOES NOT SLIP FROM

(M- 25) 120 900 1800

120 2#16Ø BARS THE PULLEY. THE SCALE SHALL BE CALIBRATED IN CENTIMETERS AND SHOULD CONSIST

2700 300

120 OF M.S. SHEET 20 GAUGE FIXED OVER WOODEN PLANK WITH AN M.S. ANGLE IRON

120 5-8Ø BARS ON EACH FACE FRAME OF 35MM X 35MM X 5MM AND PAINTED WITH WHITE ENAMEL BASE, LETTERS IN

20000 STAGING

900120 BLACK AND RED. THE SCALE SHALL BE LOCATED AND FIXED WITH RCC VERTICAL WALL

120 150TH AT BASE M- 30 +7190

OF OHSR/CWR/GLR.

2nd flight

10-10Ø HOOPS

PANEL - 4

400DIA COLUMNS VENTILATOR

+17090

3890

6NOS. M- 25 150 10Ø @ 160c/c ON +8840

DETAIL OF R.C.C. LADDER

VENTILATORS SHALL BE PROVIDED FOR ALL RESERVOIRS. THE SIZE OF VENTILATOR

ON EACH FACE 3rd flight 8th flight

BOTH WAYS 1700

SHALL BE APPROVED BY EIC IN CONSIDERATION TO THE TANK SIZE AND SHALL BE AS

200

PER SHOWN IN DRAWING WITH MOSQUITO PROOF JALI OF STAINLESS STEEL SHALL BE

10#10Ø FIXED AT THE OPENING. IT SHALL BE WELL PAINTED AND PROPERLY FIXED IN

HOOPS

CONCRETE. THICKNESS IN CASE OF MS SHALL BE NOT LESS THAN 3 MM. FOR SMALLER

500x250 BRACE-2

1000 6-10Ø BARS

COLUMN RESERVOIRS CI VENT PIPES OF DIA AS PER APPROVAL OF EIC SHALL BE PROVIDED.

(M- 25)

800 COLUMN 1275 LIGHTENING ARRESTER

675 LIGHTNING ARRESTER SHALL BE OF COPPER BAR OF 25MM DIA AND 2M LONG TO BE

900

161 # 8Ø @ 140 c/c ON EACH FACE 781 200TH M-30 400DIA COLUMNS

PROVIDED AT THE TOP OF OHSR. THIS IS TO BE CONNECTED BY A GI STRIP 25 MM WIDE

& 3MM THICK. THIS CONDUCTOR STRIP SHALL BE CONNECTED TO A 450 MM X 450MM X

SPACING MEASURED AT TOP EDGE 6NOS. M- 25

+5540

10Ø @100c/c

3MM THICK COPPER PLATE TO BE EMBEDDED BELOW THE AVERAGE GROUND LEVEL BY

OF CONE WALL 4-8Ø 1st flight

150

4 - 8Ø DIST. BARS

DIGGING A PIT. THE EARTHING SYSTEM SHALL COMPLY WITH INDIAN ELECTRICITY

PANEL - 3 +10490 2#16Ø BARS

3890

Ø400 +15440 RULES AND SHALL CONFIRM TO IS 3043. THE PIT SHALL BE REFILLED BY ALTERNATE

HOOPS 5100

400DIA COLUMNS

6NOS. M- 25 4th flight 7th flight LAYERS OF SALT AND COKE AND BALANCE SHALL BE FILLED WITH LOOSE SOIL. THE 40

500

8Ø BARS @200c/c 150 BEAM 300x300

600 300

MM DIA GI WATERING PIPE SHALL BE PROVIDED IN THE PIT. CARE SHALL BE TAKEN THAT

10Ø BARS @ 190c/c HAUNCH BARS 5-8Ø BARS T&B 300 10Ø @100c/c EARTH PIT DOES NOT SINK.

500x250 BRACE

SPACING MEASURED AT (M- 25) 800 PLINTH PROTECTION

10Ø BARS @ 190c/c RADIAL BARS AT TOP FACE 300

PLINTH PROTECTION WORKS FOR OHSR AND CWR IS TO BE PROVIDED ALL AROUND

LOWER EDGE OF CONE WALL 6-8Ø BARS

500x250 BRACE-3

(M- 25)

SPACING MEASURED AT LOWER EDGE OF DOME 300

2#16Ø BARS EACH RESERVOIR IN A 1 M CIRCULAR STRIP. IT SHALL CONSIST OF LAYING LEAN

CONCRETE 150 MM THICK IN M10, OVER COMPACTED SOIL. ALONG THIS PLINTH

PROTECTION PROVISION OF TOE WALL OF M15 GRADE CEMENT CONCRETE 150 MM

4#12Ø BARS 600 SECTION FOR WIDE OVER THE BASE OF LEAN CONCRETE OF M10 SHALL BE PROVIDED. SIDE SLOPE OF

UP

8Ø BARS @200c/c FLOAT VALVE PLATFROM PLINTH PROTECTION SHALL BE 1 IN 50 OUTWARD & PERIPHERAL SLOPE SHOULD BE 1 IN

+12140 8Ø BARS @200c/c (M-30)

DETAIL OF LANDING (M-25)

500. PLINTH PROTECTION WORKS TO BE CONSTRUCTED BELOW THE OH SERVICE

PANEL - 2 +13790 6#12Ø BARS

5th flight

3890

400DIA COLUMNS RESERVOIR, SHALL BE EXTENDED UP TO 1M FROM FALL OF BALCONY OR EDGE OF RAFT

6NOS. M- 25 6th flight

150 300 SLAB, WHICHEVER IS MORE..MINIMUM FREE SPACE BETWEEN PLINTH PROTECTION AND

DETAIL REINFORCEMENT

8Ø TIES FIRST BRACING OF ESR SHALL BE 1.6M.

6-8Ø @190c/c TIES SLOGAN AND LOGO

THE CONTRACTOR SHALL PAINT AN AREA OF 6MX3M ON THE VERTICAL WALL OF THE

PLAN SHOWING ARRANGEMENT OF STEPS

450

OF PROPER TANK (M-30)

TANK PORTION BY USING 3 COATS OF PLASTIC EMULSION PAINT OF SHADE AS

2 Lgg. stirrups 300 APPROVED BY ENGINEER IN CHARGE TO FORM A BASE FOR WRITING THE SLOGAN. THE

500x250 BRACE-4

500 (M- 25) 8Ø bars @ 300c/c SIZE & SHADE FOR PAINTING THE SLOGAN WILL BE APPROVED AND DIRECTED BY

100 X- SECTION OF COLUMN FOR ENGINEER IN CHARGE. THE LOGO SHOULD INDICATE THE NAME OF THE PROJECT, NAME

350 FLOAT VALVE PLATFROM OF THE VILLAGE AND THE CAPACITY OF THE RESERVOIR. THE SLOGAN SHALL BE AS

(M-30) DIRECTED BY THE ENGINEER-IN-CHARGE.

DETAIL "A" SCHEDULE OF COVER & OVERLAP 4-20Ø THROUGH 2 LEGGED STIRRUPS PIPE CLAMP

15-10Ø BARS 400 8Ø TIES @190 C/C TIES

DETAIL AT BALCONY LEVEL (M-30)

AT LEAST TWO CLAMP ON ONE STAGING SHALL BE PROVIDED OF 6MM THICK 50MM WIDE

PANEL - 1 MEMBER COVER WATER FACE/OUTER OVERLAP

400DIA COLUMNS MS FLAT FIXED ON PIPE & COLUMN.

3890

6NOS. M- 25 M-15 C.C. 1. TOP & BOTTOM DOME 45mm \ 30mm 26 Ø M.S. COWL 2 MM MAN HOLE COVER

150mm WIDE TOE 4-20Ø

2. TOP RING BEAM 45mm \ 30mm 50 Ø

WALL

THROUGH SQUARE MANHOLE COVER 800X800 MM SHALL BE PROVIDED. THE COVER SHALL BE

LEAN CONCRETE "A" 3. WALL, CONE WALL 45mm \ 30mm 50 Ø 2#12Ø ON MADE OF 5 MM THICK MS FLAT. THE FRAME SHALL BE MADE OF MS ANGLE 50*50*6. THE

160

160

160

160

160

167

167

167

160

160

160

160

160

160

160

S.S. MOSQUITO PROOF JALI

800

160

160

160

160

167

160

160

800

150 THICK - M 10

4. BALCONY 45mm \ 30mm 50 Ø EACH SIDE FACE 150 COVER SHALL BE CONNECTED TO THIS FRAME BY USING TWO NOS. STRUNG HINGES.

G.L. 5. BOTTOM RING BEAM 45mm \ 30mm 35 Ø

9-12Ø BARS LOCKING ARRANGEMENT SHALL BE PROVIDED.

750 250

450 300Ø

Ø5100

COMPACTED SOIL

6. COLUMN 40mm 40 Ø 125 125 FSL 150

3375 100

1000

300

7. FOUNDATION RING BEAM 35mm 50 Ø 4-16Ø 150 50 WIDE 3 TH. MS PLATE WELDED

300

300

200 1350 1350 200 8. FOUNDATION 50mm 50 Ø 4-16Ø THROUGH THROUGH 600 TO PIPE

2100 2100 9. STAIR CASE 35mm 50 Ø 2-12Ø BARS ON 400 2270 400

6900 ALUMINUM

EACH SIDE FACE 400

X- SECTION OF

LADDER

80

200

L- SECTION OF BOTTOM RING BEAM (M-30) BOTTOM RING BEAM X- SECTION OF

80

COLUMN (M-25)

D.I. INLET PIPE

200

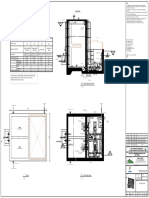

SECTIONAL ELEVATION Y

DETAIL OF VENTILATOR

80

200

D.I. OUTLET PIPE

Y'

C.I. PUDDLE

2-10Ø BARS ON CHECKED & FOUND O.K.

COLLAR

X' X'

EACH SIDE FACE 400 2270 400

3-16Ø THROUGH

400

250 250 250 250 3-16Ø 2-Y12 (TYP.)

THROUGH (BOTH FACES)

750

3-16Ø 0-20Ø+3-16Ø 2-20Ø+1-16Ø 0-20Ø+3-16Ø 2#10Ø ON

214

214

214

214

214

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

750

EACH SIDE FACE +5540

500

500

500

500

2-8Ø ON 2-8Ø ON 2-8Ø ON 2-8Ø ON 1st flight Legend :-

EACH SIDE FACE EACH SIDE FACE EACH SIDE FACE EACH SIDE FACE +7190

2nd flight 1. All written dimentions are to be followed & read in mm.

2 Lgg. stirrups 2 Lgg. stirrups 2 Lgg. stirrups 2 Lgg. stirrups 125 2-16Ø bars

5-16Ø THROUGH +8840

2-Y12 (TYP.)

8Ø bars @ 150c/c 8Ø bars @ 150c/c 8Ø bars @ 150c/c 8Ø bars @ 150c/c 2 LEGGED STIRRUPS 5-16Ø AT CENTRE 2. The size of bars at any portion can be changed according to avilable

3-16Ø 0-20Ø+3-16Ø 2-20Ø+1-16Ø 0-20Ø+3-16Ø 18-10Ø BARS THROUGH 3rd flight bars at site but steel area provided will remain same or more.

+10490 3. All P.C.C. will be done in M-15 grade.

X- SECTION OF X- SECTION OF X- SECTION OF X- SECTION OF

X- SECTION OF 2 Lgd stirrups 4th flight

+12140

4. All ring beam over columns, bottom dome, cone wall,

8Ø @150S.NO.

ADDITIONAL REINFORCEMENT

L- SECTION OF FOUNDATION RING BEAM (M-25) c/c balcony, vert. wall, top ring beam, top dome, will be casted in M-30

250

5th flight

BRACE-1 BRACE- 2 BRACE- 3 BRACE- 4 FOUNDATION RING BEAM 250 +13790

AT PIPE OPENINGS

grade except column, braces, foundation raft, foundation ring beam, stair-case &

(M-25) (M-25) (M-25) (M-25) 3-8Ø BARS 6th flight will be casted in M-25 grade.

2-16Ø bars

+15440

ARRANGEMENT OF FLOAT VALVE 5. R.C.C. ladder will be provided from last landing to balcony.

80

7th flight 6. The S.B.C. has been taken 18 T / SQ. MT. at 1000 below ground level.

4-8Ø BARS +17090 7. Tor steel grade fe-415 will be used.

RADIAL BARS PLACED AS:- 8th flight

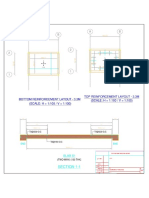

A - 12 mm DIA. BARS @ 250c/c FROM R = 1750 TO R = 3450 SECTION AT Y-Y' SECTION AT X-X'

A

B - 12 mm DIA. BARS @ 250c/c FROM R = 1350 TO R = 3170 A

A DETAILS OF FLIGHT

(ALL SPACING MEASURED AT R =2350 A B

B

A B

A B

B

890x890 A B

825x825 R.C.C. OVER HEAD SERVICE RESERVOIR

B

800x800

600 CAPACITY - 110,000 LITRES ON 20,000 STAGING.

B

INTERNAL PLATEFORM

A

AT TOP

AT -SAMAPA DISTRICT - AJMER.

B

2550

A

400DIA COLUMNS RADIAL BARS PLACED AS:-

OVER FLOW PIPE

OUTLET PIPE

800

B

INLET

A - 12 mm DIA. BARS @ 250c/c FROM R = 1750 TO R = 3450 PIPE

A

B - 12 mm DIA. BARS @ 250c/c FROM R = 1350 TO R = 3170

INLET PIPE

B

OVER FLOW PIPE

G.L. (ALL SPACING MEASURED AT R =2350 WASH OUT INTERNAL PLATEFORM

A

AT BOTTOM

250

50

B

INTERNAL PLATEFORM SV

AT BOTTOM OUTLET 75

A

PIPE BYEPASS

1000

DJ SV

B

450 450 150

750 SV with DJ

A

NRV

CLIENT -

B

300200 GOVERNMENT OF RAJASTHAN

600

PLAN OF MAN HOLE COVER 100

PHED PROJECT CIRCLE -AJMER

A

Ø600

100

110

110

110

110

110

150

160

160

160

160

160

TO VTC

1350 PROJECT -

100

110

110

110

110

110

150

160

160

160

160

160

1350

7-10mm Ø 7-10mm Ø

STRUNG HINGES 7-10mm Ø 7-10mm Ø

(2 NOS.) 700

2100

1000

700 1000 ELEVATION OF Work of Regional water supply scheme of 199 villages and their habitations of

2100

S.S. Flat 5mm 3450

3450 PIPING ARRANGEMENT PLAN P.S.Jawaja , Tehsil Beawar, District Ajmer, on Flouride control Project

ISA ANGLE 80x80x4

800x800 SUBMITTED BY:-

DETAIL OF FOUNDATION RAFT (M-25) PLAN OF FOUNDATION RAFT (M-25)

R.C.C. DOME

SECTION OF MAN HOLE COVER

INTERNAL PLAN DWG NO JB/GAMMON/ESR/DWG/001

FOR PLATFORM

DRAWN BY CAD FILE REVISION

SCALE

Potrebbero piacerti anche

- S 5 PDFDocumento1 paginaS 5 PDFlovely caturanNessuna valutazione finora

- Bus Shelter - Option 3Documento1 paginaBus Shelter - Option 3Manish KapadneNessuna valutazione finora

- 300MM DIA Pipe For Calbe Trench: B-1 (230X230) B-1 230X230Documento1 pagina300MM DIA Pipe For Calbe Trench: B-1 (230X230) B-1 230X230Rajkumar PritimaniNessuna valutazione finora

- 1/100 Section: Legends Chó Thých ®þa ChêtDocumento2 pagine1/100 Section: Legends Chó Thých ®þa Chêthung son NguyenNessuna valutazione finora

- Water Tank & Roof FloorDocumento17 pagineWater Tank & Roof FloorMahindaNessuna valutazione finora

- Typical Precast Parapet Details-Layout1Documento1 paginaTypical Precast Parapet Details-Layout1rahmanNessuna valutazione finora

- Footpath Sections All PDFDocumento1 paginaFootpath Sections All PDFANKESH SHRIVASTAVANessuna valutazione finora

- 4DRWG Bhagwanpura 100 KLFR ModelDocumento1 pagina4DRWG Bhagwanpura 100 KLFR ModelRajkumar PritimaniNessuna valutazione finora

- Foundation Plan: Foundation Layout & Column Schedule (SHEET-1 OF 2) SAMATVA-E-DD-01-R0Documento11 pagineFoundation Plan: Foundation Layout & Column Schedule (SHEET-1 OF 2) SAMATVA-E-DD-01-R0Parth K PatelNessuna valutazione finora

- S Biswal A3 2 SetDocumento1 paginaS Biswal A3 2 SetSatyaranjan MalikNessuna valutazione finora

- Plandoc 22 3465Documento1 paginaPlandoc 22 3465mohdnazirNessuna valutazione finora

- TCSDocumento2 pagineTCSNishanNessuna valutazione finora

- Detail of Super STRDocumento1 paginaDetail of Super STRShivam SharmaNessuna valutazione finora

- Schedule of Two Way Slab: Typ. Conventional Beam DetailDocumento1 paginaSchedule of Two Way Slab: Typ. Conventional Beam DetailLhewiz BrionesNessuna valutazione finora

- 42-42 DETAIL-42 41-41 DETAIL-41 40-40 DETAIL-40: NotesDocumento1 pagina42-42 DETAIL-42 41-41 DETAIL-41 40-40 DETAIL-40: NotesKARTHIK SGNessuna valutazione finora

- S1 PDFDocumento1 paginaS1 PDFleeedeeemeeeNessuna valutazione finora

- TCS Khamgaon-Tcs 1 PDFDocumento1 paginaTCS Khamgaon-Tcs 1 PDFFaraz hasan KhanNessuna valutazione finora

- Ns Iocl Tal E003Documento1 paginaNs Iocl Tal E003Titus PraveenNessuna valutazione finora

- Piling Layout PlanDocumento1 paginaPiling Layout PlanSyahir HamidonNessuna valutazione finora

- Sukhani GA With Levels PDFDocumento1 paginaSukhani GA With Levels PDFHimal KafleNessuna valutazione finora

- Staircase-3: DET - 139 E038 TypDocumento1 paginaStaircase-3: DET - 139 E038 TypKARTHIK SGNessuna valutazione finora

- Section B-B View A-A: Dimensional Detail Section of Retaining WallDocumento1 paginaSection B-B View A-A: Dimensional Detail Section of Retaining WallShivam SharmaNessuna valutazione finora

- Handrail For Staircase-3: NotesDocumento1 paginaHandrail For Staircase-3: NotesKARTHIK SGNessuna valutazione finora

- Handrail For Staircase-3: DET - 145 E040 TYP DET - 145 E040 TYPDocumento1 paginaHandrail For Staircase-3: DET - 145 E040 TYP DET - 145 E040 TYPKARTHIK SGNessuna valutazione finora

- Analysis Report Jkjt0058 Jaya Sakti 2Documento46 pagineAnalysis Report Jkjt0058 Jaya Sakti 2Mochammad Shokeh0% (2)

- Amer PDFDocumento1 paginaAmer PDFsaxraviNessuna valutazione finora

- Steel Frame DetailsDocumento1 paginaSteel Frame DetailsGlen CasugaNessuna valutazione finora

- MC - Mp.29-Hec-Mcq03-Zz-Sd-A-E-3971 (Type 6)Documento1 paginaMC - Mp.29-Hec-Mcq03-Zz-Sd-A-E-3971 (Type 6)waseem kausarNessuna valutazione finora

- Asphalt Footing3Documento37 pagineAsphalt Footing3Bert EngNessuna valutazione finora

- Box Culvert 2X2Documento6 pagineBox Culvert 2X2abhishek singhNessuna valutazione finora

- Bill of Material: Raft Detail 2 3023 MR-5 Top Flange Plate 125 X 5 2985 2 Bottom Flange Plate 125 X 5 2 2959Documento1 paginaBill of Material: Raft Detail 2 3023 MR-5 Top Flange Plate 125 X 5 2985 2 Bottom Flange Plate 125 X 5 2 2959Karthik NNessuna valutazione finora

- QP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficDocumento1 paginaQP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficnawajhaNessuna valutazione finora

- STR 106 Details of Rafter2 ModelDocumento1 paginaSTR 106 Details of Rafter2 ModelUDayNessuna valutazione finora

- 2011 04Documento94 pagine2011 04Adam Greenlaw0% (1)

- 1 x2x2 BoxDocumento20 pagine1 x2x2 BoxNilay GandhiNessuna valutazione finora

- Over Head Gantry 1Documento1 paginaOver Head Gantry 1darshanNessuna valutazione finora

- Circular Cover SlabDocumento1 paginaCircular Cover Slabvikash kumarNessuna valutazione finora

- P 2Documento1 paginaP 2AZTRID PEREZNessuna valutazione finora

- 'C' Section 1 - 1: Up Stream Side LHS RHS Down Stream SideDocumento5 pagine'C' Section 1 - 1: Up Stream Side LHS RHS Down Stream SideHegdeVenugopalNessuna valutazione finora

- Shortcol Circ 1 20Documento10 pagineShortcol Circ 1 20Andres Valdivia AyalaNessuna valutazione finora

- Gad 209+950 SH-1Documento1 paginaGad 209+950 SH-1ras_deepNessuna valutazione finora

- Perimeter WallDocumento1 paginaPerimeter WallBenson Mwathi MungaiNessuna valutazione finora

- 0b8e6a50 5Documento70 pagine0b8e6a50 5swoinkerNessuna valutazione finora

- Handrail For Staircase-2: NotesDocumento1 paginaHandrail For Staircase-2: NotesKARTHIK SGNessuna valutazione finora

- Drawing (26852) SignedDocumento7 pagineDrawing (26852) SignedSachin PawarNessuna valutazione finora

- Fire-Pump Room - Rev.cDocumento1 paginaFire-Pump Room - Rev.cwael72Nessuna valutazione finora

- Elevator Conc. Wall Detail: X.1 X.2 X.3 X.4 X.5 X.4' X.6 X.B C 1Documento1 paginaElevator Conc. Wall Detail: X.1 X.2 X.3 X.4 X.5 X.4' X.6 X.B C 1Bryan Joshua PandaanNessuna valutazione finora

- Bed Room: Layout False Ceiling PlanDocumento1 paginaBed Room: Layout False Ceiling PlanTEJAS TANKNessuna valutazione finora

- Retaining Wall CRP PLN PSS 01 01Documento103 pagineRetaining Wall CRP PLN PSS 01 01Asela UdayangaNessuna valutazione finora

- A2 PHC PIU COL FOOTING PLINTH Revised - 15.07.2020-Model PDFDocumento1 paginaA2 PHC PIU COL FOOTING PLINTH Revised - 15.07.2020-Model PDFPratikNessuna valutazione finora

- Rataining Wall DesignDocumento4 pagineRataining Wall Designanon_388492125Nessuna valutazione finora

- Engineering Consultants Group: Project Name Job Ref. Calc. by Date DateDocumento3 pagineEngineering Consultants Group: Project Name Job Ref. Calc. by Date DateIhab SorourNessuna valutazione finora

- E. S. T. I. M. A. T. I. O. N.: by Mohamad L. NaloDocumento45 pagineE. S. T. I. M. A. T. I. O. N.: by Mohamad L. NaloMohamad NaloNessuna valutazione finora

- RCC14 Crack WidthDocumento2 pagineRCC14 Crack WidthMohammad Twaha JaumbocusNessuna valutazione finora

- Gambar Kerja Jalan PDFDocumento1 paginaGambar Kerja Jalan PDFMudiasa MadeNessuna valutazione finora

- AMALFI 204 2D Electrical and False Ceiling DWG PDFDocumento1 paginaAMALFI 204 2D Electrical and False Ceiling DWG PDFathiraprNessuna valutazione finora

- Rafter Detail: Roofing InsulationDocumento1 paginaRafter Detail: Roofing InsulationRODEAN HOPE LACSINessuna valutazione finora

- Kanaba Overpass GADDocumento1 paginaKanaba Overpass GADSandipan DharNessuna valutazione finora

- Box CulvertDocumento9 pagineBox CulvertDonald HamiltonNessuna valutazione finora

- Crif Door Window Detail-601Documento1 paginaCrif Door Window Detail-601surbhi aggarwalNessuna valutazione finora

- 100 KL CWR GLR ModelDocumento1 pagina100 KL CWR GLR ModelRajkumar PritimaniNessuna valutazione finora

- 4DRWG Bhagwanpura 100 KLFR ModelDocumento1 pagina4DRWG Bhagwanpura 100 KLFR ModelRajkumar PritimaniNessuna valutazione finora

- Panel R RCDocumento1 paginaPanel R RCRajkumar PritimaniNessuna valutazione finora

- Control Room GaDocumento1 paginaControl Room GaRajkumar PritimaniNessuna valutazione finora

- RCC Sluice Valve Chamber DrawingDocumento1 paginaRCC Sluice Valve Chamber DrawingRajkumar Pritimani100% (2)

- 10klglr DesignokDocumento17 pagine10klglr DesignokRajkumar PritimaniNessuna valutazione finora

- My Lovely ResumeDocumento3 pagineMy Lovely ResumeJanicz BalderamaNessuna valutazione finora

- Changes in Bash Version 4.2 To Bash 4.3Documento123 pagineChanges in Bash Version 4.2 To Bash 4.3LordAjaxNessuna valutazione finora

- 21CS8133 Labassignment1Documento7 pagine21CS8133 Labassignment1Sai PraneethNessuna valutazione finora

- Syntel Mock 2Documento18 pagineSyntel Mock 2Ashutosh MauryaNessuna valutazione finora

- ViewSonic Q19wb-3 VS11578 Pow. Delta EADP-45AF BFDocumento70 pagineViewSonic Q19wb-3 VS11578 Pow. Delta EADP-45AF BFaladinthewizardNessuna valutazione finora

- Data Sheet: TDA1510AQDocumento12 pagineData Sheet: TDA1510AQGerardo PonceNessuna valutazione finora

- Team Building & Team WorkDocumento39 pagineTeam Building & Team WorkAmrita DasNessuna valutazione finora

- Laporan Beton 1Documento80 pagineLaporan Beton 1Seulgi BearNessuna valutazione finora

- Andrea BrennanDocumento2 pagineAndrea BrennanAnonymous tGJ2lopsNessuna valutazione finora

- DIY Homemade Septic System PDFDocumento9 pagineDIY Homemade Septic System PDFCebu CribsNessuna valutazione finora

- Ansi z245 2 1997Documento31 pagineAnsi z245 2 1997camohunter71Nessuna valutazione finora

- Spiral Welded Tubes BrochuresDocumento4 pagineSpiral Welded Tubes BrochuresSoumitra GuptaNessuna valutazione finora

- AD Merkblatt 2000 CodeDocumento4 pagineAD Merkblatt 2000 CodeoscartttNessuna valutazione finora

- History Desktop PublishingDocumento16 pagineHistory Desktop PublishingsanchezromanNessuna valutazione finora

- Miqro Vaporizer Owners ManualDocumento36 pagineMiqro Vaporizer Owners ManualJuan Pablo AragonNessuna valutazione finora

- ABS Buckling Requirements For OffshoreDocumento94 pagineABS Buckling Requirements For Offshorecurvedbrain100% (1)

- Sts Lesson 6Documento13 pagineSts Lesson 6Ivy Joy BelzaNessuna valutazione finora

- Preventa Safety Detection XCSE5311Documento2 paginePreventa Safety Detection XCSE5311Fernando MoreiraNessuna valutazione finora

- Gold Kacha Flyer 2012Documento2 pagineGold Kacha Flyer 2012gustavus1Nessuna valutazione finora

- Hydraulic & Pneumatic EquipmentDocumento183 pagineHydraulic & Pneumatic EquipmentArintoNessuna valutazione finora

- Backup Exec 12.5 AVVIDocumento6 pagineBackup Exec 12.5 AVVIcharanjit_singhNessuna valutazione finora

- J Proc CTRL Vol 19 2009 Q Wang K Astrom - Guaranteed Dominant Pole PlacementDocumento4 pagineJ Proc CTRL Vol 19 2009 Q Wang K Astrom - Guaranteed Dominant Pole PlacementmtichyscribdNessuna valutazione finora

- Microreactor P.4-19Documento22 pagineMicroreactor P.4-19dheannisrNessuna valutazione finora

- Datasheet - HK f7313 39760Documento7 pagineDatasheet - HK f7313 39760niko67Nessuna valutazione finora

- Bus & Cycle Signs & MarkingsDocumento5 pagineBus & Cycle Signs & MarkingsDaniel YitbarekNessuna valutazione finora

- Artemis Data SheetDocumento2 pagineArtemis Data SheetmahmoudNessuna valutazione finora

- Huawei RTN 980-950 QoS ActivationDocumento7 pagineHuawei RTN 980-950 QoS ActivationVenkatesh t.k100% (2)

- Revit LookupDocumento6 pagineRevit Lookupjuand_121Nessuna valutazione finora

- GD200A Manual EnglishDocumento269 pagineGD200A Manual Englishtran dieuNessuna valutazione finora

- Initial PID - 19-0379 A01 01Documento39 pagineInitial PID - 19-0379 A01 01rajap2737Nessuna valutazione finora