Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asme B31.3 Process Piping Course Supplement: Becht

Caricato da

NurSarahDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asme B31.3 Process Piping Course Supplement: Becht

Caricato da

NurSarahCopyright:

Formati disponibili

ASME B31.

3 PROCESS PIPING COURSE SUPPLEMENT Page 50

Rev. 6/2/06

PIPING MATERIAL SPECIFICATION WORKSHOP

Develop a piping material specification for styrene monomer.

Design conditions are from Problems 1 and 2 on page 25.

o Condition 1: ____________ psi (bar) at ____________ ºF (ºC)

o Condition 2: 50 psi (3.5 bar) at 735ºF (390ºC)

o Pipe wall thicknesses are as determined from calculations on page 32.

Pressure Class ____300________

Item NPS Range Sch/Rating Description

(DN Range)

Pipe ¾ 160 Seamless carbon steel pipe, ASTM A106 Gr B, ASTM A53 Type S Gr

(20) B, or API 5L Gr B

1–2 XS Seamless carbon steel pipe, ASTM A106 Gr B, ASTM A53 Type S Gr

(25 – 50) B, or API 5L Gr B

3–4 STD Seamless carbon steel pipe, ASTM A106 Gr B, ASTM A53 Type S Gr

(80 – 100) B, or API 5L Gr B

6 – 12 XS Seamless carbon steel pipe, ASTM A106 Gr B, ASTM A53 Type S Gr

(150 – 300) B, or API 5L Gr B

Nipples ¾ - 1½ 160 Seamless carbon steel pipe, ASTM A106 Gr B, ASTM A53 Type S Gr

(20 – 40) B, or API 5L Gr B

Fittings

¾ 6000 Forged carbon steel, ASTM A105, ASME B16.11, socket weld 90 EL,

(20) 45 EL, TEE, PLUG, COUPLING, CAP, AND REDUCER. UNIONS are

prohibited.

1-1½ 3000 Forged carbon steel, ASTM A105, ASME B16.11, socket weld 90 EL,

(25 – 40) 45 EL, TEE, PLUG, COUPLING, CAP, AND REDUCER. UNIONS are

prohibited.

2 – 12 Match pipe Wrought carbon steel, ASTM A234 Gr WPB, ASME B16.9, buttweld 90

(50 – 300) LR EL, 45 LR EL, TEE, CAP AND REDUCER

Flanges ¾-1½ 300 Forged carbon steel, ASTM A105, ASME B16.5 socket welding raised

(20 – 40) face

2 - 12 300 Forged carbon steel, ASTM A105, ASME B16.5 welding neck raised

(50 – 300) face, bore to match pipe

Gaskets ¾ - 12 300 Spiral wound ASME B16.20 with 304 SS windings (yellow centering

(20 – 300) ring), flexible graphite filler (gray stripe) and standard inner ring NPS

10 (DN 250) and larger

Bolting ¾ - 12 - Low alloy steel bolting, ASTM A193 Gr B7 stud with 2 ASTM A194 Gr

(20 – 300) 2H nuts

BECHT ENGINEERING COMPANY, INC.

ASME B31.3 PROCESS PIPING COURSE SUPPLEMENT Page 50

Rev. 6/2/06

What should be used for branch construction? [Note that the answer will different for different size combinations.]

Sample from Process Industry Practices (PIP) PN03CS1S01

Note that when branch connection fittings (Weldolet) are specified, the requirements for these components

should be described as well, e.g., “Forged carbon steel ASTM A105, MSS SP-97”. When ordering buttweld

branch connection fittings, both the header and branch wall thicknesses should be specified.

Sample Notes:

NOTES:

01 The pipe and fittings are adequate for the full flange rating.

02 All buttwelding component thicknesses shall match pipe thicknesses.

03 Threaded joints are permitted only at outlet of vent and drain valves, at hydrostatic connections, at outlet of

instrument take-off valves, and to match equipment.

05 Integrally reinforced branch connections are permitted outside the sizes shown in the branch connection

table.

13 Welding neck flanges shall be used against buttweld fittings.

19 Sch 160 pipe and pipe nipples shall be used for threaded connections for sizes NPS ½ – 1 ½ (DN 15 – 40).

26 To be used only when indicated on the P&ID.

27 Pipe and pipe components thicker than ½ inch (12.7 mm) may require impact tested materials when the

minimum design metal temperature is below 100ºF (38ºC) (See ASME B31.3, paragraph 323.2.2).

136 Sch XS pipe shall be used for threaded connections for NPS 2 (DN 50).

BECHT ENGINEERING COMPANY, INC.

Potrebbero piacerti anche

- Pipeline Stress Analysis With Caesar IIDocumento16 paginePipeline Stress Analysis With Caesar IIznikfarNessuna valutazione finora

- Dots in ASME B36.10 Under Schedule TableDocumento5 pagineDots in ASME B36.10 Under Schedule TableIbrahim BashaNessuna valutazione finora

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDa EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- Solution Manual Fundamentals of Engineering Thermodynamics Moran MJ and HN Shapiro DD Boettner M B Bailey Chapter 1 6 and 9Documento8 pagineSolution Manual Fundamentals of Engineering Thermodynamics Moran MJ and HN Shapiro DD Boettner M B Bailey Chapter 1 6 and 9osamaNessuna valutazione finora

- Insulation Calculation For 36 inDocumento18 pagineInsulation Calculation For 36 inSaepul RochmanNessuna valutazione finora

- Arun Kumar S (Piping Design Engineer) - ResumeDocumento3 pagineArun Kumar S (Piping Design Engineer) - ResumepavanNessuna valutazione finora

- The Feasibility of Transporting Hydrogen in Existing PipelinesDocumento9 pagineThe Feasibility of Transporting Hydrogen in Existing PipelinesomiitgNessuna valutazione finora

- Pipe Stress Analysis Complete Course From PassDocumento2 paginePipe Stress Analysis Complete Course From Passsleiman shokr100% (1)

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureDocumento1 paginaSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilNessuna valutazione finora

- MyChemE Calculating Pressure Drops in Straight PipeDocumento8 pagineMyChemE Calculating Pressure Drops in Straight PipeShantanuNessuna valutazione finora

- Design Code Requiring Surge AnalysisDocumento3 pagineDesign Code Requiring Surge AnalysisSharun SureshNessuna valutazione finora

- 0000 A0 060 Cal 0001Documento418 pagine0000 A0 060 Cal 0001vignesh558855Nessuna valutazione finora

- Design of Cross PipelineDocumento33 pagineDesign of Cross Pipelineannu300Nessuna valutazione finora

- Datahseet For Strainer With Air EliminatorDocumento4 pagineDatahseet For Strainer With Air Eliminatorvinoj chandranNessuna valutazione finora

- Industrial Pressure MeasurementDocumento49 pagineIndustrial Pressure MeasurementArjay T. EspinoNessuna valutazione finora

- Static Method of Wind Analysis of Piping Systems in Caesar II Using Pressure Vs Elevation MethodDocumento6 pagineStatic Method of Wind Analysis of Piping Systems in Caesar II Using Pressure Vs Elevation MethodPrakashNessuna valutazione finora

- TGE Brochure 2010Documento12 pagineTGE Brochure 2010ankeshkatochNessuna valutazione finora

- LPG Blending Facilities - List of Documents For TenderDocumento235 pagineLPG Blending Facilities - List of Documents For TenderManish MehtaNessuna valutazione finora

- OISD Tank Farm Rules The Piping Engineering WorldDocumento1 paginaOISD Tank Farm Rules The Piping Engineering Worldrenger20150303Nessuna valutazione finora

- PipingDocumento4 paginePipingramthecharm_46098467Nessuna valutazione finora

- MOHD AZWAN BIN MUHAMAD - Piping DesignerDocumento3 pagineMOHD AZWAN BIN MUHAMAD - Piping DesignerAzwanNessuna valutazione finora

- Lecture 1 - Classification of Heat ExchangersDocumento47 pagineLecture 1 - Classification of Heat ExchangersAhmed HelmiNessuna valutazione finora

- Piping Stress Man Hour EstimationDocumento3 paginePiping Stress Man Hour EstimationDayo IdowuNessuna valutazione finora

- PL Re 401 - 00Documento5 paginePL Re 401 - 00SinaNessuna valutazione finora

- How Do You Carry Out Estimation? Ans: 1. Input From BidDocumento21 pagineHow Do You Carry Out Estimation? Ans: 1. Input From BidSunil ShaNessuna valutazione finora

- August 2012 IssueDocumento56 pagineAugust 2012 IssueGas, Oil & Mining Contractor Magazine100% (1)

- SE-00-L-SD 1001 Engineering Specification For Piping Design - Rev04Documento29 pagineSE-00-L-SD 1001 Engineering Specification For Piping Design - Rev04Isares PodkohNessuna valutazione finora

- RC443 DS 000 2542 0001 Rev2 LNG Storage TankDocumento13 pagineRC443 DS 000 2542 0001 Rev2 LNG Storage TankDjamel EeddinNessuna valutazione finora

- An Exergy Analysis of Small-Scale Liquefied Natural Gas (LNG)Documento15 pagineAn Exergy Analysis of Small-Scale Liquefied Natural Gas (LNG)feraldoNessuna valutazione finora

- Bestline Mining Supplies LTD - 2010 EditionDocumento50 pagineBestline Mining Supplies LTD - 2010 EditionTalabarteria RaygozaNessuna valutazione finora

- CV of Ramoni Saidi A. Piping EngrDocumento8 pagineCV of Ramoni Saidi A. Piping EngrAnonymous qaI31HNessuna valutazione finora

- Engineered Spring SupportsDocumento43 pagineEngineered Spring SupportsNestor Barranco RadaNessuna valutazione finora

- Type of Drgs and IDC Draft 4-6-19Documento31 pagineType of Drgs and IDC Draft 4-6-19Zahoor AhmedNessuna valutazione finora

- Company Profile SISTECH CONSULTANTSDocumento6 pagineCompany Profile SISTECH CONSULTANTSnagarajhebbarNessuna valutazione finora

- Prabhu - CV - Structural DesignerDocumento4 paginePrabhu - CV - Structural DesignerprabhutmuNessuna valutazione finora

- Mueller Strainer Manual (Ms 185ss 186ss)Documento2 pagineMueller Strainer Manual (Ms 185ss 186ss)Jack YangNessuna valutazione finora

- Engineering Design Basis FOR Project: Client: Projec T: Job No.Documento11 pagineEngineering Design Basis FOR Project: Client: Projec T: Job No.Priyanka KumariNessuna valutazione finora

- SAECS Company ProfileDocumento8 pagineSAECS Company ProfileBec EnggNessuna valutazione finora

- 007-Stand Post Type Fire HydrantDocumento6 pagine007-Stand Post Type Fire HydrantshabahatNessuna valutazione finora

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocumento5 paginePetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNessuna valutazione finora

- Properties of AirDocumento4 pagineProperties of AirRhea FayeNessuna valutazione finora

- E1N SpecDocumento6 pagineE1N SpecprathameshNessuna valutazione finora

- Process Skid TrainingDocumento5 pagineProcess Skid TrainingrutujaNessuna valutazione finora

- API 610 Check CaesarDocumento22 pagineAPI 610 Check CaesarSeptian Firdaus100% (1)

- Equipment List Including Long Lead ItemsDocumento6 pagineEquipment List Including Long Lead Itemspapilolo2008Nessuna valutazione finora

- NTF in DS LG 001 Data Sheet Level GaugeDocumento4 pagineNTF in DS LG 001 Data Sheet Level GaugeRicardo NapitupuluNessuna valutazione finora

- Chapter 8 Steam PipingDocumento14 pagineChapter 8 Steam PipingChen WsNessuna valutazione finora

- Technical Specification For Supply of Valves Table - 1: Manuf'S OfferDocumento11 pagineTechnical Specification For Supply of Valves Table - 1: Manuf'S OfferRadhakrishnan Sreerekha100% (1)

- Thermal BowingDocumento8 pagineThermal BowingA. VenugopalNessuna valutazione finora

- About UsDocumento32 pagineAbout UsSubbu Ram PNessuna valutazione finora

- Comparison of FEM, HMI and CMAA Classifications - ProservCrane GroupDocumento3 pagineComparison of FEM, HMI and CMAA Classifications - ProservCrane Groupengin gürayNessuna valutazione finora

- Temp StrainersDocumento12 pagineTemp StrainersRahul Lavand100% (1)

- Gail Gas Limited City Gas Distribution Project DewasDocumento9 pagineGail Gas Limited City Gas Distribution Project DewasankeshkatochNessuna valutazione finora

- 7a. Steel Pipeline FittingDocumento37 pagine7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- Dimensional & Material Standards For Piping ComponentsDocumento3 pagineDimensional & Material Standards For Piping ComponentsaasattiNessuna valutazione finora

- Material Selection 1Documento21 pagineMaterial Selection 1yulianus_srNessuna valutazione finora

- Astm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Documento13 pagineAstm International Bsi - British Standards Institute: 1387 (Bs en 10255:2004)Vishal MistryNessuna valutazione finora

- Piping Material Classes: NotesDocumento16 paginePiping Material Classes: NotesVedran KosanovicNessuna valutazione finora

- PipingDocumento21 paginePipingsubashNessuna valutazione finora

- Pghu Eh Lspds 002004 Rev 0Documento43 paginePghu Eh Lspds 002004 Rev 0BhoyPachoNessuna valutazione finora

- Cutting Opera Tion Takes Onl Y 24HRS: User ListDocumento2 pagineCutting Opera Tion Takes Onl Y 24HRS: User ListNurSarahNessuna valutazione finora

- Oilandgas PDFDocumento138 pagineOilandgas PDFNurSarahNessuna valutazione finora

- Oilandgas PDFDocumento138 pagineOilandgas PDFNurSarahNessuna valutazione finora

- ETP Slides PresentationFinalDocumento15 pagineETP Slides PresentationFinalNurSarahNessuna valutazione finora

- United States Patent: Cross Et Al. (10) Patent N0.: (45) Date of PatentDocumento11 pagineUnited States Patent: Cross Et Al. (10) Patent N0.: (45) Date of PatentNurSarahNessuna valutazione finora

- MSE 212 Material Science Lab Experiment (3) : Tensile Test: Submitted byDocumento13 pagineMSE 212 Material Science Lab Experiment (3) : Tensile Test: Submitted byRewanNessuna valutazione finora

- Puddle FlangeDocumento11 paginePuddle Flangeviresh haldankarNessuna valutazione finora

- Sanyo ScrollDocumento50 pagineSanyo ScrollBruno CoutoNessuna valutazione finora

- LECTURE 5 - T-Beams and Doubly ReinforcementDocumento34 pagineLECTURE 5 - T-Beams and Doubly ReinforcementHowell TungolNessuna valutazione finora

- Sika PDS - E - Sika Pocket Grout PDFDocumento2 pagineSika PDS - E - Sika Pocket Grout PDFlwin_oo2435Nessuna valutazione finora

- Three Way Valve - Mixing & Diverting TypeDocumento7 pagineThree Way Valve - Mixing & Diverting TypehorascanmanNessuna valutazione finora

- Wu - Glass Deramic Foams From Coal Ash and Waste Glass - Production and CharacterisationDocumento9 pagineWu - Glass Deramic Foams From Coal Ash and Waste Glass - Production and CharacterisationArgiliathNessuna valutazione finora

- Structural Idealization For Deep Beams With Web OpeningsDocumento11 pagineStructural Idealization For Deep Beams With Web OpeningsnevinkoshyNessuna valutazione finora

- Duct RsesDocumento18 pagineDuct RsesSameer AbdullahNessuna valutazione finora

- Design of Slab FormsDocumento27 pagineDesign of Slab FormsZevanyaRolandTualaka100% (1)

- 7117 PVC Gray HeavyDocumento2 pagine7117 PVC Gray Heavyzattie89Nessuna valutazione finora

- Design Application & Installation Information: Service ConditionsDocumento10 pagineDesign Application & Installation Information: Service ConditionsjoechengshNessuna valutazione finora

- DolocharDocumento17 pagineDolocharswatishree.7150% (1)

- Mech 473 Lectures: Professor Rodney HerringDocumento40 pagineMech 473 Lectures: Professor Rodney HerringWalid Ben AmirNessuna valutazione finora

- Penggunaan Honeycomb Pada GedungDocumento15 paginePenggunaan Honeycomb Pada GedungNikmatulloh RahmanNessuna valutazione finora

- Green Pin Shackles - Certificates Overview and Specifications - 0Documento1 paginaGreen Pin Shackles - Certificates Overview and Specifications - 0Eduardo SolanoNessuna valutazione finora

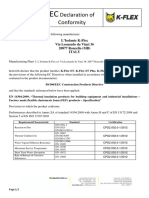

- Marquage CE - Gamme K-Flex ST PDFDocumento2 pagineMarquage CE - Gamme K-Flex ST PDFJuan Santos100% (1)

- DPA110DHA1CP - Product SpecificationsDocumento1 paginaDPA110DHA1CP - Product SpecificationsJohn Luke LinharesNessuna valutazione finora

- Guide To Machining Specialty AlloysDocumento156 pagineGuide To Machining Specialty AlloysRolandNessuna valutazione finora

- Reinforced Concrete Bridge Deck DesignDocumento11 pagineReinforced Concrete Bridge Deck DesignAhmad AlamNessuna valutazione finora

- Jindal Stainless Steel Pipe Price ListDocumento8 pagineJindal Stainless Steel Pipe Price ListvivekNessuna valutazione finora

- General Sections Rule 093A: 093. Grounding Conductor and Means of ConnectionDocumento11 pagineGeneral Sections Rule 093A: 093. Grounding Conductor and Means of ConnectionrvasilevaNessuna valutazione finora

- Data Sheet A-10: Alloy TypeDocumento3 pagineData Sheet A-10: Alloy Typemohamed AdelNessuna valutazione finora

- What Is A Fatigue Test?: High Cycle Fatigue (HCF)Documento4 pagineWhat Is A Fatigue Test?: High Cycle Fatigue (HCF)Taif AlhashimNessuna valutazione finora

- Pistolet 12eDocumento7 paginePistolet 12eAboumaachar IssamNessuna valutazione finora

- Upvc Profile CatalogueDocumento19 pagineUpvc Profile CatalogueSafin BiswasNessuna valutazione finora

- Pile Foundations v1.00 Oct2010Documento17 paginePile Foundations v1.00 Oct2010Munteanu DanNessuna valutazione finora

- Girth Gear WearDocumento6 pagineGirth Gear Wearho-fa100% (2)

- Klingenburg DehumidifierDocumento7 pagineKlingenburg DehumidifieripraoNessuna valutazione finora