Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GMW 14057 PDF

Caricato da

JOECOOL67Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

GMW 14057 PDF

Caricato da

JOECOOL67Copyright:

Formati disponibili

WORLDWIDE

ENGINEERING Material Specification GMW14057

STANDARDS

Weld Acceptance Criteria and Repair Procedures

Resistance Spot Welds - Steel

1 Introduction

Note: Nothing in this standard supercedes applicable laws and regulations.

Note: In the event of conflict between the English and domestic language, the English language shall take

precedence.

This standard applies to steels approved by GM for Resistance Spot Welding (RSW).

1.1 Purpose. This standard provides the acceptance criteria and repair procedures for resistance spot welds in

automotive products for which GM is responsible for establishing or approving product design.

1.2 Applicability. The criteria established in this standard become mandatory when referenced on a weld design

document. Deviations from any weld criteria provided in this standard must be identified on a weld design

document or other product design document.

1.3 Remarks. Welded structures are considered satisfactory when they carry the intended service loads for a

required period. Service loads on weldments in a vehicle are varied in both type and magnitude and cannot be

addressed by this standard. Therefore, while the weld quality criteria of this standard are consistent with service

loading requirements, they have been established specifically for use in process and product monitoring. Any

attempted application of this document to other uses, such as post-crash weld quality assessment, may lead to

an erroneous result or conclusion. Discrepant welds by retaining a portion of their engineering properties may

still contribute to the integrity of the assembly.

1.4 Clarification. For clarification of this standard or editorial comments, email the GM Global Weld Council at

weld.council@gm.com.

Proposed changes to this standard must be presented to the Global Weld Council. To suggest a change to this

standard, reference the “Procedure for Weld Standard Changes” on the Global Weld Council’s web page.

2 References

Note: Only the latest approved standards are applicable unless otherwise specified.

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

2.1 External Standards/Specifications.

None

2.2 GM Standards/Specifications.

GMW14058

GMW15563

2.3 Additional References.

GM Global Customer Audit Procedure - Appearance Zones

Global Manufacturing System (GMS) Operating Guidelines and Global Launch Manual

3 Requirements

3.1 General Acceptance Criteria.

3.1.1 Individual Spot Weld Criteria. There are multiple visual and measurable attributes that are used to

evaluate spot weld quality. These attributes are divided into two categories: attributes that make the weld

discrepant; and attributes that do not make the weld discrepant, but the attribute is undesirable for appearance

or processing.

3.1.2 Categories of Spot Welds. There are two categories of spot welds: structural and process.

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 1 of 10

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

3.1.2.1 Structural Spot Welds. Structural spot welds are installed for performance of the welded product. All

spot welds are structural unless specifically noted as process welds on the weld design document.

3.1.2.2 Process Spot Welds. Process spot welds are installed to facilitate in-process assembly, but are not

required for structural performance of the product. Process spot welds must be approved by Product and

Manufacturing Engineering and shown on the weld design document.

3.1.3 Adjacent, Missing or Cold Welds. Product detected with two or more adjacent structural spot welds that

are not installed (missing welds), or judged to be cold welds must be repaired regardless of the pattern tolerance.

3.2 Visual Acceptance Criteria.

3.2.1 Visual Attributes–Discrepant Welds. Welds that exhibit any of the following attributes are discrepant

welds.

3.2.1.1 Cracks. Spot welds with crack(s) around the circumference that are visible without the aid of

magnification, are discrepant welds. Spot welds with surface cracks confined within the impression left by the

electrodes are not discrepant welds. See Figure A1.

3.2.1.2 Holes. Spot welds that contain holes extending through the weld are discrepant welds and cause the

product to be nonconforming, regardless of the quantity tolerance. See Figure A2.

3.2.1.3 Edge Welds. Welds in which the spot weld imprint, as defined by the impression left by the electrodes,

is not contained within all edges of the sheet metal being welded are discrepant. See Figure A3, welds E and F.

3.2.1.4 Missing Welds. When fewer welds exist than are specified on the weld design document, the omitted

welds are discrepant.

3.2.2 Visual Attributes–Appearance and Processing Considerations. Welds that exhibit the following

attributes are undesirable either from an appearance or processing viewpoint. However, these attributes do not

make the weld discrepant and should not be used in determining weld pattern conformance.

3.2.2.1 Extra Welds. The number of spot welds installed shall not exceed the number specified on the weld

design document, except as required by the repair procedures described in 3.4 of this standard. The welding

process shall be adjusted to eliminate extra welds.

3.2.2.2 Whiskers. Welds exhibiting whiskers should have the welding process adjusted to eliminate the

condition. See Figure A4.

Note: Welds shall be free of whiskers when using ultrasonic inspection equipment to avoid damage to the

transducer.

3.2.2.3 Distortion. Spot welds in which the sheet surfaces are distorted more than 25 degrees from the normal

plane shall have the welding process adjusted to the original qualified setup in order to reduce the distortion to

less than 25 degrees. See Figure A5.

3.2.2.4 Thinning and Indentation. Spot welds exhibiting thinning greater than 30% of the total metal stackup

should have the welding process adjusted to the original qualified setup in order to reduce the thinning below

30%. See Figure A6.

3.2.2.5 Trim Edge Deformation. Welds in which the original edge of the weld flange is deformed by the

electrodes but whose spot weld imprint is contained within all edges of the sheet metal being welded are not

discrepant. The process shall be adjusted to the original qualified setup to eliminate the condition. See Figure

A3, welds C and D.

3.2.2.6 Surface Eruption. Surface eruption is an upsurge of the sheet surface adjacent to the electrode cap

imprint. See Figure A7. The appearance criteria for surface eruption are listed in Appendix A.

3.2.2.7 Spatter. Spatter is weld metal expulsion that remains attached to surface(s) adjacent to the weld. See

Figure A4. The appearance criteria for spatter are listed in Appendix A.

3.2.3 Perceptual Quality Requirements. Spot welds visible to the customer in strategic areas of the body are

to be considered Perceptual Quality (PQ) spot welds (reference the GM Global Customer Audit (GCA) Procedure

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

– Appearance Zones). Product Quality Standards are to be utilized to document the appearance acceptance

standards addressing the desired weld spot precision (alignment, spacing, concentricity) and prominence

(indentation, distortion, whiskers). Spot welds not meeting appearance standards should have the process

adjusted to the original qualified setup to eliminate the undesirable condition.

3.3 Measurable Acceptance Criteria.

3.3.1 Weld Location. Spot welds must be properly located relative to design location as indicated on the weld

template and to each other as follows.

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 2 of 10

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

In a pattern consisting of a single in-line row of welds in which a distinct product feature provides visual

reference to the end weld, an end weld installed greater than 10 mm in radial distance from the design

location is a discrepant weld. A distinct product feature must be a visible trim edge or other recognizable

part feature that is perpendicular or nearly perpendicular to the row of welds and within 30 mm of the end

weld.

For all other welds, a spot weld installed greater than 20 mm in a radial distance from the design location is

a discrepant weld.

If the spacing between two adjacent welds in a pattern consisting of a single in-line row of welds exceeds

the design spacing by greater than 20 mm, the weld furthest from the design location is a discrepant.

3.3.2 Weld Size. The weld size may be measured by either using the weld button (Figure A8), the weld nugget

(Figure A9), or the fusion zone. A spot weld is discrepant when the measured weld size at each faying surface

is less than the minimum acceptable weld size specified in Table 1.

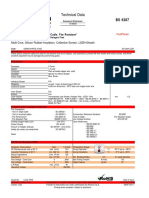

Table 1: Minimum Acceptable Weld Size

Determining Thickness

Minimum Acceptable Weld Size

(DT)

0.60 to 0.64 mm 3.0 mm

0.65 to 1.29 mm 4.0 mm

1.30 to 1.89 mm 5.0 mm

1.90 to 2.59 mm 6.0 mm

2.60 to 3.25 mm 7.0 mm

3.3.2.1 Two (2) Thickness Welds. To determine the acceptable weld size for a two thickness weld (two loose

pieces or one loose to two previously welded), use the metal thickness (t) of the thinner of the two layers being

welded to determine the weld size as listed in Table 1.

3.3.2.2 Three (3) Thickness Welds. To determine the acceptable weld size for a three thickness weld (three

loose pieces) use the metal thickness (t) of the thinner of the two layers at each interface to determine the

acceptable weld size. However, in the case where the thinnest layer is stacked between two thicker layers use

the second thickest piece (t) to determine the acceptable weld size for both welds.

3.3.2.3 Interfacial Fracture. With certain steels or types of loading, a weld button may not always result from

destructive testing. In these cases of interfacial fracture, examination of the fusion zone must be used to

determine weld size. Criteria for evaluation of the fusion zone must be in accord with an approved Product

Quality Standard.

3.3.2.4 Cold Welds. Weld locations that do not produce a weld button after a destruct test and are not interfacial

fractures are cold welds. Cold welds are discrepant welds.

3.3.2.5 Laminated Vibration Damping Steel. The minimum weld size specified in Table A1 is required only at

the faying surface for laminated steel. There are no minimum weld size requirements for the interface between

the layers of the laminated steel.

For purposes of determining the minimum weld size, the laminated steel shall be treated as one sheet whose

thickness is equal to the sum of the two outer sheets and the inner visco-elastic layer as shown in Figure A10.

3.4 Disposition/Repair Procedure.

3.4.1 Spot Weld Pattern Conformance Criteria. A pattern is a collection of spot welds to which a tolerance is

applied to meet structural requirements and for determining manufacturing acceptance of the product. The

default pattern is all structural spot welds on the structure installed at the same manufacturing plant. The quantity

tolerance for the single default pattern is no more than 5% of the total weld count can be discrepant.

The spot weld pattern is conforming when the number of acceptable spot welds (not discrepant per the

requirements of this standard) within a pattern meets or exceeds the default pattern tolerance or the tolerance

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 3 of 10

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

as stated on the weld design document. Manufacturing acceptance of product is based on all patterns

conforming. Disposition of product nonconforming to this standard shall be handled in accord with GM Global

Quality Requirements for Corrective Action and Nonconforming Material.

Note: Two or more adjacent missing or breaking welds cause pattern nonconformance regardless of the quantity

tolerance. Structural spot welds with holes cause the pattern to be nonconforming regardless of the quantity

tolerance.

3.4.2 Repair Exceptions. An exception to specified product repair requirements may be permitted provided

there is documented review and approval by the responsible Product Engineer allowing the suspect product to

deviate from specification and pattern conformance criteria.

3.4.3 Surface Appearance. Spot weld surface appearance criteria are not used in determining weld pattern

conformance.

3.4.4 Process Spot Welds. Process spot welds are not to be used in determining weld pattern conformance.

Process welds containing holes require product repair.

3.4.5 Repair Procedures. When required spot welds shall be repaired according to the procedures specifically

authorized by the appropriate Product Engineer. In the absence of an engineering approved repair procedure,

the following repair methods shall be used in the following order of preference.

3.4.5.1 Resistance Spot Weld Repair. Spot weld with a weld gun that is qualified for the metal types and

thicknesses to be welded. One repair spot weld shall be added for each spot weld being repaired. Repair spot

welds must meet the requirements of this standard. Locate repair spot welds as close as possible to the original

designated weld location without overlapping the existing spot weld.

3.4.5.2 Arc Weld Repair. Arc weld repair of laminated steels is not permitted.

3.4.5.3 Arc Spot or Plug Weld Repair. For each spot being repaired, weld using MIG plug or Arc spot with steel

filler wire. The Arc spot or MIG weld shall conform to the applicable arc spot and plug weld acceptance criteria

standard. All repair personnel using this method of repair must be periodically qualified and approved following

local procedures.

3.4.5.4 Arc Fillet Weld Repair. A MIG fillet weld may be used for two metal thickness joints. The MIG repair

weld must be located as close as possible to the original designated weld location and must be a minimum of

20 mm in length. The repair welds must conform to GMW14058. All repair personnel using this method of repair

must be periodically qualified and approved following local procedures.

4 Manufacturing Process

4.1 Process Control. The welding source is responsible for establishing practices and test methods to assure

that the criteria of this standard are met, and are consistent with the GM Joining and Dispense Process

Control Procedure (GMW15563).

5 Notes

5.1 Glossary.

Arc Spot: A weld type which uses a timed arc welding process to penetrate through the surface sheet into

adjoining sheets fusing them together.

Cold Weld: A weld that does not produce a weld button after a destruct test. At the faying surface of a cold weld,

there is no indication of fusion. Cold welds do not indicate a nugget when the weld is cross-sectioned.

Crack: A fracture type discontinuity characterized by a sharp tip and high ratio of length to width of opening

displacement on the exterior surface. See Figure A1.

Distortion: Angle of displacement that the sheet surfaces are distorted from the normal plane. See Figure 5.

Edge Weld: A condition in which the spot weld imprint, as defined by the impression left by the electrodes is not

contained within all edges of the sheet metal being welded. See Figure A3, welds E and F.

Extra Welds: The number of spot welds that exceed the number specified on the weld design document.

Faying Surface: The mating surface of two members to be welded. See Figure A11.

Hole: A perforation in the spot weld that allows light to travel through the material from one exterior surface to

the opposing exterior surface of the weld. See Figure A2.

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 4 of 10

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

Indentation: The depression on the sheet surfaces caused by the welding electrodes. See Figure A6.

Interfacial Fracture: A fracture mode of a spot weld where all or part of the weld nugget separates through the

plane of the weld at the faying surface.

MIG: MIG welding is welding in an atmosphere of inert gas, which means welding with a shielding gas that does

not react with other substances. The process is also called MIG welding even when the inert gas is mixed with

small quantities of O2, CO2, H2 or similar substances. MIG also may be referred to as solid wire welding or Gas

Metal Arc Welding.

Missing Welds: The number of spot welds not installed as specified on the weld design document.

Original Qualified Setup: The weld parameters established and documented during Weld Verification. Also

referred to as Initial Qualified Setup.

Pearls: See Weld Spatter.

Product Quality Standard (PQS): Measurable requirements for product characteristics, which when satisfied

ensure the product meets internal and external customer requirements. (Refer to GMS Operating Guidelines

and Global Launch Manual.)

Radial Distance: The distance between two points. For spot weld location tolerance the radial distance is the

measurement from the center of the spot weld design location to the center of the installed spot weld.

Surface Eruption: Upsurge of the metal surface adjacent to the weld imprint. See Figure A7.

Thinning: The amount of the original total metal stackup thickness reduced by the welding process. See Figure

A6.

Trim Edge Deformation: A condition in which the original edge of the weld flange is deformed by the electrodes

but whose spot weld imprint is contained within all edges of the sheet metal being welded. See Figure A3, welds

C and D.

Weld Button: That part of the weld that tears out in a peel or chisel test. See Figure A8.

Weld Button Size: The weld button size of a symmetrical (round) button is the diameter of the button. The weld

button size of an asymmetrical (oval or oblong) button is calculated by adding the measurement of the major

axis to the measurement of the minor axis and dividing by 2. See Figure A12. The measurements are to be taken

at the faying surface. See Figure A13.

Weld Design Document: A product document that describes welding requirements such as number of welds,

location of welds, applicable weld standards, weld patterns, surface appearance classification, weld notes etc.

Weld Expulsion: Molten metal that is extruded from between the sheets being welded or from the interface

between the outer sheet metal surface and the electrode(s). See Figure A4.

Weld Imprint: The impression left in the metal surface by the electrodes after welding. See Figure A3.

Weld Nugget: The weld nugget is that part of the weld where fusion is evident at the faying surface and

extending into the parent metal resulting in a metallurgical structure change. See Figure A9.

Weld Nugget Size: The weld nugget size is the dimension of the fusion zone measured from a macro section

examination or weld cross section. See Figure A9.

Weld Size: Resistance Spot Weld Size refers to either the weld button size or the weld nugget size.

With certain steels or types of loading, a weld button may not always result from a peel or tensile test. In these

cases of interfacial fracture, examination of the fusion zone must be used to determine weld size.

Weld Spatter: Weld expulsion metal that remains attached to an adjacent metal surface away from the

electrodes. The visible weld spatter is sometimes referred to as pearls. See Figure A4.

Weld Template: An inspection device used to evaluate weld location. Templates are typically created by plotting

the weld spot location as defined by the weld design document on a transparent overlay for comparison to the

actual weld locations. See Figure A14.

Whiskers: Sharp weld expulsion metal that remains attached to the metal surface adjacent to the weld imprint.

See Figure A4.

5.2 Acronyms, Abbreviations, and Symbols.

DT Determining Thickness

GCA Global Customer Audit

GMS Global Manufacturing System

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 5 of 10

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

PQ Perceptual Quality

PQS Product Quality Standard

RSW Resistance Spot Welding

6 Coding System

This standard shall be referenced in other documents, drawings, etc., as follows:

GMW14057

7 Release and Revisions

This standard was originated in August 2004. It was first approved by the CCRW Global Council in December

2005. It was first published in January 2006.

Issue Publication Date Description (Organization)

1 JAN 2006 Initial publication.

2 OCT 2009 Reformat to approved GMW Welding template. Revised weld surface

appearance criteria, clarified weld size measurement criteria. Moved

and renumbered figures to Appendix A. (GM Global Weld Council)

3 AUG 2011 Update to address acceptance criteria for adjacent missing or

breaking welds and for welds with visible surface cracks or holes.

(GM Global Weld Council)

4 OCT 2012 Updated to align weld appearance requirements with Perceptual

Quality Best Practices (section 3.2.3). (GM Global Weld Council)

5 JAN 2014 Edits to section 2.3, 3.2.2.4, 3.2.3, 3.3.1, and 3.4.1. Section 3.2.2.6

(thinning) combined with 3.2.2.4 (renumbered paragraphs as

necessary), and radial distance added to glossary. (GM Global Weld

Council)

6 APR 2014 Changed references of Gas Metal Arc Welding to MIG. Edit to

Table 1 and added two and three thickness welds to Section 3.3.

Eliminated Appendix B. (GM Global Weld Council)

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 6 of 10

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

Appendix A

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

Figure A1: Surface Cracks Figure A2: Hole

Weld Spatter

F

Edge Weld

E Whiskers

D Trim Edge

Deformation

C

B

Spot Weld

A

Weld Expulsion

Figure A3: Edge Weld Figure A4: Weld Expulsion

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 7 of 10

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

B

A E D

Angle of Distortion

C

% Thinning = 100 - E x 100

B+D

Figure A5: Distortion Figure A6: Indentation and Thinning

Figure A7: Surface Eruption Figure A8: Weld Button

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 8 of 10

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

Measure Weld Size at Faying Surface

Figure A9: Weld Nugget Size Figure A10: Laminated Steel

d1

Faying

Surface

d2

Figure A11: Faying Surface Figure A12: Weld Button Size

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 9 of 10

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

GM WORLDWIDE ENGINEERING STANDARDS GMW14057

Figure A13: Weld Button Measurement

--``,,``,`,`,`,,``,```,-`-``,```,,,`---

Figure A14: Weld Template

© Copyright 2014 General Motors Company All Rights Reserved

April 2014 Page 10 of 10

Copyright General Motors Company Order Number: W1682030

Provided by IHS under license with General Motors Company Sold to:BOPP-BUSCH MFG CO [981557100001] - WILLIAM.BUSCH@BOPPBUSCH.COM,

No reproduction or networking permitted without license from IHS Not for Resale,2015-02-09 20:56:15 UTC

Potrebbero piacerti anche

- Adiabatic Shear Localization: Frontiers and AdvancesDa EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddNessuna valutazione finora

- Friction Stir Welding of Dissimilar Alloys and MaterialsDa EverandFriction Stir Welding of Dissimilar Alloys and MaterialsValutazione: 3 su 5 stelle3/5 (1)

- Weld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelDocumento8 pagineWeld Acceptance Criteria and Repair Procedures Drawn-Arc Welded Automotive Studs, Nuts and Brackets - SteelMuhammad AliNessuna valutazione finora

- GMW16536 Sealer-In Welded Struct Aug2011Documento9 pagineGMW16536 Sealer-In Welded Struct Aug2011Taofiq AbiolaNessuna valutazione finora

- Engineering Standards: Material Specification Metals GM6435MDocumento6 pagineEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovNessuna valutazione finora

- GMW16215Documento7 pagineGMW16215JOECOOL67100% (1)

- TL245 English 2004Documento8 pagineTL245 English 2004Elliott RussellNessuna valutazione finora

- The World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionDocumento2 pagineThe World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionSquidwardNessuna valutazione finora

- Astm B117Documento12 pagineAstm B117aldairlopesNessuna valutazione finora

- M0140 (2014-N) NES: Salt Spray TestingDocumento11 pagineM0140 (2014-N) NES: Salt Spray TestingBea RiveraNessuna valutazione finora

- VCS 1027 1449 - 循环耐腐试验Documento14 pagineVCS 1027 1449 - 循环耐腐试验Wei Yue ZhuanNessuna valutazione finora

- Is 11169-2 (1989) - Steels Forcold Heading - Cold Extrusion, Part 2 - Stainless SteelDocumento11 pagineIs 11169-2 (1989) - Steels Forcold Heading - Cold Extrusion, Part 2 - Stainless SteelVISHAL kUMARNessuna valutazione finora

- Oxygen-Free Copper in Wrought Forms For Electron DevicesDocumento6 pagineOxygen-Free Copper in Wrought Forms For Electron DevicesErick Vargas100% (1)

- VW 011 03Documento22 pagineVW 011 03Alexandre UrquizaNessuna valutazione finora

- 521+technical Data Sheet V-6Documento2 pagine521+technical Data Sheet V-6TeenTeen GaMingNessuna valutazione finora

- VW01155 en 2005-02-01Documento8 pagineVW01155 en 2005-02-01koalaboi0% (1)

- Rheocasting of Semi-Solid A357 AluminumDocumento7 pagineRheocasting of Semi-Solid A357 AluminumikehrpNessuna valutazione finora

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocumento9 pagineFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNessuna valutazione finora

- Ball Joint TesterDocumento3 pagineBall Joint TesterManikanta MechNessuna valutazione finora

- TSB1503G 9 P 1Documento18 pagineTSB1503G 9 P 1kk_pammu_915176926Nessuna valutazione finora

- GMW14872 - Cyclic Corrosion Laboratory TestDocumento22 pagineGMW14872 - Cyclic Corrosion Laboratory TestZAPSENessuna valutazione finora

- Wsf-M4d618-A 31au05Documento4 pagineWsf-M4d618-A 31au05Yan WendelNessuna valutazione finora

- GM500M - September 2010Documento8 pagineGM500M - September 2010JOVANY LOPEZNessuna valutazione finora

- Corporate Engineering Test ProcedureDocumento19 pagineCorporate Engineering Test ProceduresyahmitoNessuna valutazione finora

- QQ N 290aDocumento17 pagineQQ N 290aBryan MartinezNessuna valutazione finora

- Automotive Gray Iron Castings: Standard Specification ForDocumento5 pagineAutomotive Gray Iron Castings: Standard Specification ForJosé Ramón GutierrezNessuna valutazione finora

- An Investigation of Switching Behaviors of Bimetallic-Disk ThermostatsDocumento55 pagineAn Investigation of Switching Behaviors of Bimetallic-Disk Thermostatspindurs1Nessuna valutazione finora

- Engineering Material Specification: Not To Be Used For New DesignDocumento5 pagineEngineering Material Specification: Not To Be Used For New Designjavier ortizNessuna valutazione finora

- WSS M1P94 ADocumento9 pagineWSS M1P94 AAleks SenaNessuna valutazione finora

- Carbide Banding - Effect On FatigueDocumento15 pagineCarbide Banding - Effect On FatigueSteve Green100% (1)

- Metal Forming Process and DefectsDocumento7 pagineMetal Forming Process and DefectsPradeep Kumar BowmarajuNessuna valutazione finora

- Laser WeldingDocumento11 pagineLaser WeldingnkalaiNessuna valutazione finora

- SurveyScoringGuidelines W-HTX 2000Documento58 pagineSurveyScoringGuidelines W-HTX 2000guzinetti100% (1)

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDocumento7 pagineAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzNessuna valutazione finora

- Tennant 1550 Parts ManualDocumento528 pagineTennant 1550 Parts ManualUmar ShamsudinNessuna valutazione finora

- B253.25617 Prepar AlumDocumento7 pagineB253.25617 Prepar Alumasistente calidadNessuna valutazione finora

- 402 - 2015 - Product EspecificationDocumento272 pagine402 - 2015 - Product EspecificationGustavo CarreraNessuna valutazione finora

- Types of FixturesDocumento2 pagineTypes of FixturesgeraldNessuna valutazione finora

- Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and RivetsDocumento19 pagineDetermining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and RivetsJ. Fabián MenaNessuna valutazione finora

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Documento13 pagineNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNessuna valutazione finora

- Caterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled DocumentDocumento14 pagineCaterpillar: Confidential Green - Reproduction Constitutes An Uncontrolled DocumentDinar OjakNessuna valutazione finora

- Jsae Jaso c615-1989Documento18 pagineJsae Jaso c615-1989pranayNessuna valutazione finora

- Ford 970Documento4 pagineFord 970amanNessuna valutazione finora

- FORD WX200 Rev2014Documento4 pagineFORD WX200 Rev2014Amandeep SinghNessuna valutazione finora

- Preventing Scale Loss During Heat Treatment & Hot Forging - With ImagesDocumento17 paginePreventing Scale Loss During Heat Treatment & Hot Forging - With ImagesSrikar Shenoy100% (1)

- Geomet 321Documento2 pagineGeomet 321Satnam Rachna FastenersNessuna valutazione finora

- Why Intensity Isn't Dependent On Exposure Time: Lessons in Intensity and CoverageDocumento1 paginaWhy Intensity Isn't Dependent On Exposure Time: Lessons in Intensity and CoverageUmit AytarNessuna valutazione finora

- Automobile Vibration AnalysisDocumento18 pagineAutomobile Vibration AnalysisDavid PomaNessuna valutazione finora

- Proceso de LimpiezaDocumento17 pagineProceso de LimpiezaPatricioNessuna valutazione finora

- Astm A313 2003Documento7 pagineAstm A313 2003ArefkhanNessuna valutazione finora

- Geomet 500 PDFDocumento2 pagineGeomet 500 PDFKaran Chadha100% (1)

- Araymond Tinnerman Catalog IndustrialDocumento137 pagineAraymond Tinnerman Catalog IndustrialG.L. HuyettNessuna valutazione finora

- Mil I 17563CDocumento18 pagineMil I 17563Cchitti409Nessuna valutazione finora

- B343 92a Reapproved 2014 PDFDocumento3 pagineB343 92a Reapproved 2014 PDFNinad PawarNessuna valutazione finora

- F 382 - 99 - Metallic Bone Plates1Documento11 pagineF 382 - 99 - Metallic Bone Plates1Siddharth Jain100% (1)

- WSS-M1A346-A - Calidad de ChapaDocumento12 pagineWSS-M1A346-A - Calidad de ChapaDANIEL DIAZNessuna valutazione finora

- Coating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetDocumento6 pagineCoating Weight and Chemical Analysis of Zinc-Nickel Alloy Electrolytically Coated On Steel SheetROHITNessuna valutazione finora

- MIL-PRF-23377 Rev. KDocumento19 pagineMIL-PRF-23377 Rev. KRoban BieberNessuna valutazione finora

- Method of Shearing Test For Lap Joint Welded: Nissan Engineering StandardDocumento5 pagineMethod of Shearing Test For Lap Joint Welded: Nissan Engineering StandardRicardo F.A.Nessuna valutazione finora

- Guide to Load Analysis for Durability in Vehicle EngineeringDa EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonValutazione: 4 su 5 stelle4/5 (1)

- GMW 14669 Table CDocumento1 paginaGMW 14669 Table CJOECOOL67Nessuna valutazione finora

- BuehlerMotor Supplier Code of ConductDocumento4 pagineBuehlerMotor Supplier Code of ConductJOECOOL67Nessuna valutazione finora

- AS10169Documento11 pagineAS10169JOECOOL67Nessuna valutazione finora

- GMW15777Documento40 pagineGMW15777JOECOOL67Nessuna valutazione finora

- Buhler Global Quality Manual V1.0Documento35 pagineBuhler Global Quality Manual V1.0JOECOOL67Nessuna valutazione finora

- Buhler Global Quality Manual V1.0Documento35 pagineBuhler Global Quality Manual V1.0JOECOOL67Nessuna valutazione finora

- GMW 14669 Table CDocumento1 paginaGMW 14669 Table CJOECOOL67Nessuna valutazione finora

- GMW6076MDocumento3 pagineGMW6076MJOECOOL67Nessuna valutazione finora

- Buhler Global Quality Manual V1.0Documento35 pagineBuhler Global Quality Manual V1.0JOECOOL67Nessuna valutazione finora

- GM1738NA Rev 2.0Documento35 pagineGM1738NA Rev 2.0JOECOOL67Nessuna valutazione finora

- Gm1738na 4.0Documento39 pagineGm1738na 4.0JOECOOL67Nessuna valutazione finora

- GRA2092 Projection Weld Nut EP WorkbookDocumento69 pagineGRA2092 Projection Weld Nut EP WorkbookJOECOOL67Nessuna valutazione finora

- Supplier Readiness Check List T1XXHeavyDocumento9 pagineSupplier Readiness Check List T1XXHeavyJOECOOL67Nessuna valutazione finora

- Fairfax Contact ListDocumento1 paginaFairfax Contact ListJOECOOL67Nessuna valutazione finora

- GM 1927-43 Supplier Launch Audit - XLSX-GM ConfidentialDocumento8 pagineGM 1927-43 Supplier Launch Audit - XLSX-GM ConfidentialJOECOOL670% (1)

- Astm d1654 08 New PDFDocumento4 pagineAstm d1654 08 New PDFKhan ShahzebNessuna valutazione finora

- GM 1927-73 Shut-Down Start-Up Audit 3-19-2020Documento32 pagineGM 1927-73 Shut-Down Start-Up Audit 3-19-2020JOECOOL670% (1)

- Process To Request Cost Recovery SubpackageDocumento29 pagineProcess To Request Cost Recovery SubpackageJOECOOL67Nessuna valutazione finora

- IATF 16949 GM CSR Sept 2017Documento26 pagineIATF 16949 GM CSR Sept 2017Selvaraj SNessuna valutazione finora

- Plex Control Panel Plant 1 Rev.3Documento39 paginePlex Control Panel Plant 1 Rev.3JOECOOL67Nessuna valutazione finora

- Suppliers - How To Upload A Document Into APQP 06jul15 (English) PDFDocumento11 pagineSuppliers - How To Upload A Document Into APQP 06jul15 (English) PDFJOECOOL67Nessuna valutazione finora

- GMW 14057Documento10 pagineGMW 14057JOECOOL67Nessuna valutazione finora

- Corrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01Documento1 paginaCorrective Action Report (CAR) : Form1001 CAR-KMR - e Page 1 of 1 Revision: 6 Reference: Organizational Instruction 8.5.01JOECOOL67Nessuna valutazione finora

- F-870-001 Process Alarm LimitsDocumento2 pagineF-870-001 Process Alarm LimitsJOECOOL67Nessuna valutazione finora

- Bopp-Busch Quality ManualDocumento50 pagineBopp-Busch Quality ManualJOECOOL67Nessuna valutazione finora

- Non Standard Part HandlingDocumento1 paginaNon Standard Part HandlingJOECOOL67Nessuna valutazione finora

- BasicsDocumento65 pagineBasicsBas RamuNessuna valutazione finora

- Carbomastic 15 PDS 2013Documento2 pagineCarbomastic 15 PDS 20134508366279Nessuna valutazione finora

- Student Safety Sheets: EthanolDocumento1 paginaStudent Safety Sheets: EthanolNina FairuzNessuna valutazione finora

- Flowserve Durco CatalogDocumento36 pagineFlowserve Durco CatalogbryandownNessuna valutazione finora

- MK GMB 07 Wettability Cap Pressure SaturationDocumento28 pagineMK GMB 07 Wettability Cap Pressure SaturationRoni Hepson TambunNessuna valutazione finora

- ABS Under 90m - Part 4Documento356 pagineABS Under 90m - Part 4blindstrom42Nessuna valutazione finora

- API 571 Damage Mechanisms Affecting Fixed Equipment in The Refining Industry PDFDocumento5 pagineAPI 571 Damage Mechanisms Affecting Fixed Equipment in The Refining Industry PDFOrlando19490% (1)

- ISO 1459 Hots Dip GalvanizingDocumento4 pagineISO 1459 Hots Dip GalvanizingLe Van TamNessuna valutazione finora

- Recycle and Management of Waste Lead Acid BatteriesDocumento9 pagineRecycle and Management of Waste Lead Acid BatteriesJoyce Wm WongNessuna valutazione finora

- E831BDocumento4 pagineE831BDenis JimenezNessuna valutazione finora

- Monarch's Waterproofing PDFDocumento31 pagineMonarch's Waterproofing PDFMonarch DigitalNessuna valutazione finora

- Stud Welding Instruction ManualDocumento5 pagineStud Welding Instruction Manualedwin jimenezNessuna valutazione finora

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocumento1 paginaSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNessuna valutazione finora

- Technical Specifications For 132 KV LineDocumento214 pagineTechnical Specifications For 132 KV LineHemant Kumar Sharma80% (10)

- Q1 MsaDocumento18 pagineQ1 MsadhuntNessuna valutazione finora

- Epoxy CuringDocumento8 pagineEpoxy CuringUrban Renewal Development100% (1)

- Dry WallDocumento5 pagineDry WallNakul NayanNessuna valutazione finora

- TriNano Ultra Precision CMM (White Paper)Documento6 pagineTriNano Ultra Precision CMM (White Paper)TriNanoNessuna valutazione finora

- 05 - Sulzer - Separator InternalsDocumento53 pagine05 - Sulzer - Separator InternalsVicente RegulezNessuna valutazione finora

- Bomba Gardner Denver TeeDocumento56 pagineBomba Gardner Denver Teejulioramca100% (2)

- IDB - DOAS Submittal Rev2Documento78 pagineIDB - DOAS Submittal Rev2Jamie CheNessuna valutazione finora

- Product Life Cycle and LifeDocumento3 pagineProduct Life Cycle and LifejoelNessuna valutazione finora

- 4KN Enuk V3 1Documento8 pagine4KN Enuk V3 1MustaphaMehdiHamamineNessuna valutazione finora

- Industrial Training Report 18se02ch014Documento9 pagineIndustrial Training Report 18se02ch014Alis Navadiya0% (1)

- Bezinal3000 2010Documento2 pagineBezinal3000 2010tanto_deep_15Nessuna valutazione finora

- MICODocumento4 pagineMICOmaniamsonNessuna valutazione finora

- Over Voltage Under Voltage RelayDocumento1 paginaOver Voltage Under Voltage RelayVirender RanaNessuna valutazione finora

- ANSWER MPSM Johor Kimia Kertas 3 Set 2 2018 PDFDocumento8 pagineANSWER MPSM Johor Kimia Kertas 3 Set 2 2018 PDFSiti Hajar Abd HamidNessuna valutazione finora

- Project: 4 Doors Duplex Type Boarding House: Item Materials Qty. Unit U/P AmountDocumento4 pagineProject: 4 Doors Duplex Type Boarding House: Item Materials Qty. Unit U/P AmountReynaldo PesqueraNessuna valutazione finora

- Comfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаDocumento28 pagineComfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаJohn SmithNessuna valutazione finora