Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MC - Issue 23-MASTER PDF

Caricato da

ds_engenharia8817Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MC - Issue 23-MASTER PDF

Caricato da

ds_engenharia8817Copyright:

Formati disponibili

ELECTRIC FIRE PUMP CONTROLLER

INSTRUCTION MANUAL

SERIAL NO.

MODEL NO.

MCA / MCP / MCR / MCO

MCY / MCS / MCT

FOR VERSION

23

MASTER CONTROL SYSTEMS, INC.

P.O. BOX 276 • 910 NORTH SHORE DRIVE • LAKE BLUFF, ILLINOIS 60044, USA

TELEPHONE: 847-295-1010 • FAX: 847-295-0704

www.mastercontrols.com

Table of Contents

Page 2: MC* Controller Labeled – Diagram

Page 3: General Description and Application

Page 4: Included Options

: Installation

Page 5: Connections

Page 6: Control Wiring, Jumper Connections and Typical Options

Page 8: Jumper Settings

Page 9: Selector Switch / Pressure Switch Settings

Page 10: Pressure Settings and Examples

Page 11: Weekly Test Procedure

Page 12: Startup Procedures

• Preliminary Checks

• Startup Checklist

Page 15: BEFORE YOU LEAVE!

Page 16: Operating Procedures

Page 17: Replacement Parts - Electric Fire Pump Controllers

Page 18: Maintenance

Page 19: Model DR Digital Pressure and Alarm Recorder

Drawings:

-External Wiring Diagram

-Schematic Diagram

-Piping Connection

Option and Modification Drawings

Master Control Systems, Inc. -1- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

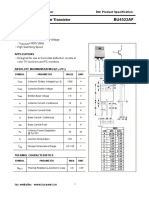

Visual Indicators and MC* Series Controller

Digital Display -Labeled Diagram-

Visual Indicators and

Digital Display

Isolating Switch

2

Selector Switch

Circuit Breaker

3 (Disconnecting Means)

Start (Pushbutton)

Stop (Pushbutton)

Emergency Manual Operator

Latch

-Our display shows three sections of

information: Pump Alarms1 on Emergency Manual Operator

the top section, Pump Status LEDs2

are shown just below this, and a digital Pressure Sense Line

read-out3 is shown on the bottom. Piping Connections.

Line Chassis

Instruction Manual

Control Unit

Pressure Switch Settings

Display box

Isolating Switch

Circuit Breaker

Current Transformers

Contactor

Emergency Manual Operator Bar

Master Control Systems, Inc. -2- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

GENERAL DESCRIPTION and APPLICATION

Master combined Manual and Automatic Electric Fire Pump Controllers meet all of the requirements of NFPA-20,

Standard for the Installation of Centrifugal Fire Pumps. Their purpose is to automatically start an electric motor

driven fire pump to provide the required water pressure and volume for proper operation of an automatic sprinkler

system in the event of a fire.

-Model MCA controllers provide full voltage (across-the-line) direct-on-line starting for three phase motor

driven fire pumps. These controllers are used where local power limitations do not restrict the motor starting

in-rush (locked rotor) current.

-Model MCP controllers provide part winding reduced inrush (partial voltage) starting for three phase motor

driven fire pumps. These controllers are used where local power limitations restrict the motor starting in-rush

(locked rotor) current.

-Model MCR controllers provide primary reactor reduced inrush (reduced voltage) starting for three phase

motor driven fire pumps. These controllers are used where local power limitations restrict the motor starting

in-rush (locked rotor) current.

-Model MCO controllers provide wye-delta (star-delta) open transition reduced inrush (reduced voltage)

starting for three phase motor driven fire pumps. These controllers are used where local power limitations

restrict the motor starting in-rush (locked rotor) current.

-Model MCY controllers provide wye-delta (star-delta) closed transition reduced inrush (reduced voltage)

starting for three phase motor driven fire pumps. These controllers are used where local power limitations

restrict the motor starting in-rush (locked rotor) current.

-Model MCS controllers provide reduced inrush (reduced voltage) ramp starting and ramp stopping (soft

start/soft stop) for three phase motor driven fire pumps. These controllers are used where local power

limitations restrict the motor starting in-rush (locked rotor) current, and/or where hydraulic conditions

warrant. They utilize a solid state motor starter for the start and stop ramp functions which is bypassed with a

motor contactor for normal or emergency full voltage running. A mode switch selects between normal

operation or full voltage (across the line) starting operation.

-Model MCT controllers provide autotransformer reduced inrush (reduced voltage) starting for three phase

motor driven fire pumps. These controllers are used where local power limitations restrict the motor starting

in-rush (locked rotor) current.

WARNING - DANGER OF LETHAL ELECTRICAL SHOCK AND ARC FLASH

HAZARD - USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT (PPE) IN

ACCORDANCE WITH NFPA 70E.

Do NOT defeat any Interlocks or Safety Features or Equipment or Circuitry

LETHAL voltages are NORMALLY present

-This equipment is LIKELY to be SERVICE ENTRANCE equipment.

-Foreign Voltages (Supervisory Power) may be present.

-Very high SHORT CIRCUIT (Fault) Currents are NORMALLY present.

This equipment MUST be serviced ONLY by QUALIFIED PERSONNEL.

-Obtain and wear Proper Level of Personal Protection Equipment (PPE) BEFORE attempting to open

equipment; including panels, covers, or doors; and BEFORE attempting to service this equipment.

-Follow ALL Safety and Personal Protection Equipment (PPE) requirements of NFPA-70E.

Master Control Systems, Inc. -3- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

Included Options (G3)

Option Name Description

A Minimum Run Timer: Factory set for 10 minutes. Automatic and manual capabilities.

D Sequence start: 1 – 99 seconds

F Pump Running light

H Withstand Rating of 100,000 Amps with voltage between 200 – 480, full service

I Instrumentation (adds digital readout)

J Failure to Start light and SPDT contacts

DR Digital Pressure and Alarm Recorder with USB port

P Digital pressure display

R Remote and Deluge Valve Start

SP Single Phase Protection in accordance with NFPA 20

T Weekly Test

Mod 21 Lockout Circuit (external contact required – Not FM Approved)

INSTALLATION

The fire pump controller and all of its wiring and plumbing should be installed in accordance with the requirements

given below and the external wiring diagram(s) near the end of this manual. It should also be installed in accordance

with the requirements of NFPA-20, Standard for the Installation of Centrifugal Fire Pumps, and the requirements of

NFPA-70, the National Electric Code, as well as any local requirements. Incoming routing, protection and wiring

must meet service entrance requirements, if applicable.

LOCATION - Controllers should be located as close as practical to the motors they control. This location should be

within sight of the motor and in an area free from dripping and spraying water.

RATINGS - Check that the system voltage and the motor nameplate voltage and horsepower ratings agree with the

controller nameplate voltages and horsepower ratings before beginning installation.

MOUNTING - Controllers should be securely mounted and bolted to noncombustible surface or structure. The use

of a (3 inch) housekeeping pad is recommended when needed to keep the bottom of the controller dry.

CONDUIT ENTRANCE - Conduit entrance can be made either through the top or bottom of the enclosure.

WARNING - FOREIGN METALLIC DEBRIS, SUCH AS DRILLING CHIPS OR DEBRIS, CAN CAUSE

A DANGEROUS AND/OR DAMAGING ELECTRICAL FAULT WHEN THE EQUIPMENT

IS ENERGIZED. BE SURE TO PROTECT ALL ELECTRICAL PARTS FROM

METALLIC DEBRIS DURING INSTALLATION.

Use appropriate waterproof conduit hubs to keep water out of controller. Use the same type hubs as shown on the

controller nameplate "Enclosure Type". When controllers suitable for outside installation are used, be sure the

appropriate weatherproof conduit hub is used. Provide a sun roof, if required, to avoid excessive temperature

build-up within the controller.

PIPING CONNECTIONS - A 1/2 inch nominal (trade size) metallic corrosion resistant (brass or 300 series stainless

steel) Pressure Sense Line with two 3/32" orifices should be connected from the fire protection system to the

bulkhead fitting located on the side of the controller. Secure this sense line as needed to prevent vibration or damage.

For further installation details, consult NFPA-20 or see Piping Diagram drawing located in the drawing section of

this manual.

Master Control Systems, Inc. -4- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

CONNECTIONS

POWER CONNECTIONS –

MCA - The three phase input power conductors are connected to the Isolating Switch (IS) line terminals L1,

L2 & L3. The output motor wiring is connected to the bottom of the Main Contactor "M" load side terminal

lugs T1, T2, and T3. Refer to the External Wiring diagram for details.

MCP – The three phase input power conductors are connected to the Isolating Switch (IS) line terminals L1,

L2 & L3. The output motor wiring is connected to the bottom of the Main Contactors “M1” and “M2” load

side lugs T1-T2-T3 and to T7-T8-T9. Refer to the External Wiring diagram for details.

MCR - The three phase input power conductors are connected to the Isolating Switch (IS) line terminals L1,

L2 & L3. The output motor wiring is connected to the bottom of the Main Contactor “M” load side terminal

lugs T1, T2, and T3. Refer to the External Wiring diagram for details.

MCO - The three phase input power conductors are connected to the Isolating Switch (IS) line terminals L1,

L2 & L3. The output motor wiring is connected to the bottom of the Main Contactor M1 & M2 load side

terminal lugs T1-T2-T3 and to T6-T4-T5 or T12-T10-T11. Refer to the External Wiring diagram for details.

MCY – The three phase input power conductors are connected to the Isolating Switch (IS) line terminals L1,

L2, & L3. The output motor wiring is connected to the bottom of the Main Contactors “M1” & “M2” load

side terminal lugs T1-T2-T3 and to T6-T4-T5 or T12-T10-T11. Refer to the External Wiring diagram for

details.

MCS – The three phase input power conductors are connected to the Isolating Switch (IS) line terminals L1,

L2 & L3. The output motor wiring is connected to the bottom of the Main Contactor “M” load side terminal

lugs T1, T2, and T3. Refer to the External Wiring diagram for details.

MCT – The three phase input power conductors are connected to the Isolating Switch (IS) line terminals L1,

L2, & L3. The output motor wiring is connected to the bottom of the Main Contactor “M” load side terminal

lugs T1, T2, and T3. Refer to the External Wiring diagram for details.

MOTOR CIRCUIT CONDUCTORS - All motor circuit conductors must be sized according to the National Electric

Code (NFPA-70) on a continuous duty basis. Insulation for these conductors should be chosen so it will not be

affected by the surrounding environment and have an insulation temperature rating at least 90 degrees C.

The ampacity of the wire is based on 125% of the motor full load current (FLA) using the 60 or 75 degree C wiring

table. The outgoing motor wiring is reduced to:

-58% of this value for wye-delta (MCO or MCY) controllers.

OR

-50% of this value for part winding (MCP) controllers.

The outgoing terminals are rated for copper conductors only.

NOTE: Be sure to secure conductors in such a manner so they will not move or interfere or rub against any

components or mechanisms in the controller. Protect against contact with sharp edges or corners.

Note that the controller is Service Entrance Rated. A dual grounding lug is provided for service entrance grounds or

for enclosure bonding. No neutral connection is provided or needed. The controller is suitable for use on either three

wire or four wire systems without the use of a neutral.

Master Control Systems, Inc. -5- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

Control Wiring, Jumper Connections and Typical Options

REMOTE ALARM CONNECTIONS - Observe the contact rating limitations shown on the wiring diagram.

1. Pump Running Signal - Terminals numbered 5, 6, and 7 provide a form "C" set of contacts which transfer

when the motor current is detected. Contacts on terminals 5 and 6 close in the alarm (motor running) state,

while contacts on terminals 6 and 7 open in the alarm (motor running) state.

2. A.C. Power Failure Signal - Terminals numbered 8, 9, and 10 provide a form "C" set of contacts which

transfer when any phase of the incoming normal power fails. Contacts on terminals 8 and 9 close in the

alarm state, while contacts on terminals 9 and 10 open in the alarm state.

3. Phase Reversal Signal - Terminals numbered 11, 12, and 13 provide a form "C" set of contacts which

transfer when any two phases of the incoming power are reversed. Contacts on terminals 11 and 12 close in

the alarm state, while contacts on terminals 12 and 13 open in the alarm state.

4. Option "A" (G3) - Automatic Stop - Controllers are normally equipped for Manual Stop. Plug-in a MC-OM

module for Automatic Stop operation. Standard modules have a fixed 10 minute minimum running

shut-down delay time. Press the miniature pushbutton, when present on the MC-OM module, to shorten the

minimum running delay time for test purposes.

NOTE: The minimum run timer (Automatic Stop Operation) should not be used on sole supply pumps (see

NFPA-20). Sole supply pumps should be set Manual Stop operation.

5. Option “G” – Supervisory Power Failure Start. Terminals numbered 23 and 24 are provided for connection

of Supervisory Power. See “Supervisory Power Input” above.

6. Option “H” (G3) -100,000 Amp Short Circuit Rating - Controller rated for 100,000 Amps at 480 Volts.

7. Option “J” (G3) Failure To Start – Terminals 14,15 and 16 provide a form C set of contacts which transfer

after a start demand is received and the water has yet to start. Contacts on terminals 14 and 15 close in the

alarm state, while contacts on terminals 15 and 16 open in the alarm state.

8. Option “K” – Built-in Alarm System. Terminals numbered 23 and 24 are provided for connection of

Supervisory Power. See “Supervisory Power Input” above.

9. Option "R” (G3) - Remote Momentary Start (Pushbutton) - Controllers so equipped are shipped with a

jumper wired between terminals numbered 1 and 3 to prevent the controller from automatically starting when

this feature is not used or not wired. To use the remote start feature, remove the jumper and wire the

normally closed (momentary) contacts from the remote switch(s). Several may be wired in series.

Deluge Valve Start - Controllers so equipped are also shipped with a jumper wired between terminals

numbered 1 and 2 to prevent the controller from automatically starting when this feature is not used or not

wired. To use the deluge valve start feature, remove the jumper and wire the normally closed (maintained)

contacts from the deluge valve switch(s). Several may be wired in series.

10. Option “T” – Weekly Test (G3) - Provides a weekly test circuit and drain valve solenoid to automatically test

the fire pump once a week by pressure drop. See Weekly Test Procedure for further instructions.

11. Mod. DR (G3) – Digital Recorder with 4000 pressure and alarm points, USB and RS232

Master Control Systems, Inc. -6- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

12. Mod. 21 - Lockout Contacts (G3) - To use this feature, wire normally open contact(s) to terminals 1 and 4.

These contact(s) close to lockout or shutdown the fire pump. Closing these external contacts will lockout or

shutdown all start conditions (demands) except the Local START pushbutton. Jumper must be enabled.

NOTE: This option is not allowed on FM sites. Contact your FM agent for special use applications!

13. Mod. “SP” (G3) - Single-Phase Protection per NFPA 20

Master Control Systems, Inc. -7- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

JUMPER SETTINGS:

Minimum Run LED:

-Indicates that the Minimum Run

Timer is timing when flashing.

Minimum Run Timer Short Cycle:

-Overrides the 10 minute stop

timer, stops the controller when

held down for 8 seconds.

Auto / Manual Stop Jumper:

-Determines if the controller

stops automatically after the 10

minute Minimum Run Timer or

manually by pressing the Stop

Pushbutton. Place the Jumper

In DIS for Manual Stop.

Lockout Jumper:

-To enable this option place the

jumper in the ENA position.

Remote Jumper:

-To enable this option place the

jumper in the ENA position.

Deluge Jumper:

-To enable this option place the

jumper in the ENA position.

Sequence Start:

-Set the amount of time (3s/div)

Sequence Start LED:

-Blinks while timing the

Sequence Start setting.

Deluge Valve: Remote Start:

-Wire in the Normally Closed -Wire in the Normally Closed

contacts on the Deluge Valve pushbutton for Remote Start operation

for start operation between between terminals 1 and 3.

terminals 1 and 2.

Master Control Systems, Inc. -8- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

SELECTOR SWITCH / PRESSURE SWITCH SETTINGS:

Selector Switch

Digital Display

START Pressure setting

SYSTEM Pressure

RESET Pressure setting

Pressure Switch Settings:

RESET Setting

START Setting

Digital Recorder Functions:

DR TIME Pushbutton

-Will send the current

time set in the Digital

Recorder.

USB Reset Pushbutton

RS232 Serial Port

USB Connection

RESET Pushbutton

Master Control Systems, Inc. -9- Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

PRESSURE SETTINGS:

NOTE: If you need to adjust the Start Setting, simply adjust the Start Setting and the Reset Setting will automatically

adjust to maintain the differential. When adjusting the Reset Setting you will change the pressure differential; the

Start Setting will remain the same. These two functions will not overlap at any point.

Changing the Start Setting

Original Reset Setting: 80 Auto-Adjusted Reset Setting: 110

New Start Setting: 100 Goal Met!

Original Start Setting: 70 Goal: 100

Notice how the original 10 psi pressure differential between the Start and Reset Setting remained the same!

* * *

Example 2

Desired Differential Setting: 5 psi

Another example – Your Reset Setting is at 80, and your Start Setting is at 70. You wish to adjust the Reset Setting to

obtain a 5 psi differential. Simply adjust the Reset Setting to 75 psi as shown below:

Goal: 5 psi

Reset Setting: 80

Differential

Reset Setting: 75 Goal Met!

Start Setting: 70 Start Setting: 70

Master Control Systems, Inc. - 10 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

WEEKLY TEST PROCEDURE:

WEEKLY TEST MODEL A:

If you have Weekly Test part number 647999 OR 618248 use the following instructions, otherwise see below.

+ / - Pushbutton Menu OK

1. Press the “Menu” button to begin

2. Set the current time using the + / - pushbuttons (hour, minute, day) then hit OK to proceed

3. Select which program mode you will be setting, P01 or P02 – begin with P01

a. P01 corresponds to the START time for your weekly test

b. P02 corresponds to the STOP time for your weekly test

4. Set the start time for your weekly test first by hour, minute, then day. Press OK.

5. Repeat steps 1-4 for P02.

NOTE: Make sure to set the interval between P01 and P02 appropriately to ensure your weekly test does not run

for an incorrect amount of time.

WEEKLY TEST MODEL B:

For part number 650915

START pushbutton

1. Press the START pushbutton to initiate a weekly cycle at that precise

moment every week.

a. For example: if you press the start button Sunday at noon, every

proceeding Sunday at noon the weekly test will self-initiate.

b. Note: be sure enable jumper J8 is in the On position

c. If you wish to change the weekly test time and date, simply press

the START push button at the new time.

2. To disable, unlatch and unplug white connector.

Part Number White Connector Latch

Master Control Systems, Inc. - 11 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

START-UP PROCEDURE

WARNING - LETHAL SHOCK AND ARC FLASH HAZARD, USE APPROPRIATE PERSONAL

PROTECTIVE EQUIPMENT (PPE) IN ACCORDANCE WITH NFPA 70E.

WARNING - BOTH HIGH VOLTAGES AND HIGH CURRENTS ARE PRESENT - TO AVOID THE

POSSIBILITY OF ELECTROCUTION OR INJURY, DO NOT TOUCH ANY CIRCUIT

CONDUCTOR UNTIL IT HAS BEEN DETERMINED BY MEASUREMENT TO BE DEAD.

USE EXTREME CAUTION TO AVOID TOUCHING OR SHORTING LIVE TERMINALS.

WARNING - TO PREVENT THE POSSIBILITY OF SERIOUS PERSONAL INJURY DUE TO AN

ELECTRICAL FAULT, BE SURE THE DOOR IS CLOSED AND LATCHED BEFORE

CLOSING THE ISOLATING SWITCH OR OPERATING THE CONTROLLER.

WARNING - FOREIGN VOLTAGE MAY BE PRESENT. CONTROLLERS EQUEPPED WITH OPTION

“K” OR “G” UTILIZE AUXILIARY BRANCH CIRCUIT POWER (120 Vac / 60 Hz OR 220

Vac / 50 Hz) WHICH IS NOT SWITCHED OR CONTROLLED. ALWAYS TURN OFF OR

DISCONNECT THE EXTERNAL SOURCE OF POWER BEFORE ATTEMPTING TO

SERVICE THE CONTROLLER.

PRELIMINARY CHECKS (Prior to Start-up)

CAUTION - Perform these preliminary checks BEFORE Energizing the controller.

1. Make absolutely sure that the system (power supply) voltage, motor nameplate voltage and horsepower

ratings correspond to the controller nameplate voltages and horsepower ratings.

2. Inspect for and remove any metal chips which may have fallen in the controller during installation.

3. Remove all shipping ties and packing material that may not yet have been removed. In particular, check the

contactor or contactors for full movement of the plunger.

4. Check all control wires for tightness.

5. Check that all connectors are seated and latched.

6. Check that all printed circuit boards in the black card cage (MC-CU) are fully seated.

7. Check all connections in the power path of the motor and any Ground or Grounded conductors for tightness.

Re-torque any loose connections to the component manufacturers specifications. Contact Master Control

Systems for any that are not marked.

8. Check the motor contactor for proper seating. Hold a thin piece of paper against one of the contactor pole

faces and operate the Manual Mechanical Operator mechanism. The paper should be tightly held.

9. Make final adjustment on the circuit breaker Trip Unit setting. Check the range chart inside the door to see

that the range setting of the MC-TM Trip Monitor module is correct for the motor nameplate full load current

(FLA or FLC). The trip setting should be at the motor FLA or the next higher setting.

10. Set the accelerate time for the desired amount:

a. Does not apply for MCA

b. MCP, MCR, MCT set zero to ten seconds. The factory setting is 3 seconds.

c. MCY, MCO set zero to ten seconds. The factory setting is 7 seconds.

d. MCS is factory set to 9 seconds. See Soft Starter instructions for other settings.

Master Control Systems, Inc. - 12 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

START-UP PROCEDURE

START-UP CHECKLIST

I. ENERGIZING CONTROLLER

A. Close and Latch the controller door.

B. With the controller door closed, close the Isolating Switch (IS), then close the Circuit Breaker (CB).

C. Check that the Power On indicating lamp is lit.

D. Check Phase Reversal alarm lamp. If lit, open the Circuit Breaker and Isolating Switch and open the door.

Set the Phase Sequence Toggle Switch on the MC-CU chassis to the opposite position.

E. Re-Close and latch the controller door, Isolating Switch (IS), and Circuit Breaker (CB).

F. Pump Rotation Check: Check for motor rotation by jogging (bumping) the motor. Do this by pressing and

holding the Stop pushbutton, then, the Start pushbutton. Momentarily release the Stop pushbutton. Finally,

release the Start pushbutton, then release the Stop pushbutton. If the pump runs backwards, open the Circuit

Breaker (CB), the Isolating Switch (IS), and have the electrician reverse two of the three motor leads at the

contactor output ("T") terminals to change rotation, if required. Re-close the door(s), Isolating Switch (IS),

and the Circuit Breaker (CB).

G. Running Voltage Check: Push the Start pushbutton to start and run the motor. On units equipped with

Option "I" (Built-in Digital Meter), use the Meter Selector Switch to measure all three line to line voltages.

_H. Running Current Check: Measure the three motor currents. Check to see that they do not exceed the motor's

nameplate full load running current multiplied by the service factor. Check that the motor currents are within

5% of each other.

II. MANUAL MECHANICAL OPERATOR START

A. Pull up on the Manual Operator. Check that the Main contactor actuates electrically about half way thru the

handle travel and that the motor starts.

B. Slide spring latch under Manual Operator handle, not in it. The entire Emergency Manual Operator

should be resting on the latch. Check that the motor remains running.

C. Lift up on the Manual Operator handle to unlatch, then release it. Check for any binding or friction. Check

that the contactor drops out about half way thru the handle travel and that the motor stops.

III. ENERGIZING THE CONTROLLER FOR STAND-BY OPERATION

A. Pressurize the system using the Jockey Pump or by Running the Fire Pump. This is to avoid pump starting

while setting the Pressure Switch Start and Reset set points.

B. Close the Circuit Breaker and Isolating Switch. Set the METER SELECTOR SWITCH to the SYSTEM PRESSURE

position. The digital meter display is the system pressure in psig (pounds per square inch, gauge).

C. To check the pump Start set point, place the METER SELECTOR SWITCH to the START PRESSURE position and

observe the reading on the digital display. The value displayed is the pump Start pressure set point. The

pump will start whenever the system pressure is at or below this value.

Master Control Systems, Inc. - 13 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

START-UP PROCEDURE

START-UP CHECKLIST (continued)

D. To check the pump Reset set point, METER SELECTOR SWITCH to the RESET PRESSURE position and observe

the reading on the digital display. The value displayed is the pump Reset pressure point. On controllers set

for Automatic Stop, the controller will stop the pump whenever the system pressure is at or above this value

if the Minimum Run Timer has timed out.

E. Use the test valve to drop pressure to check for pump pressure loss starting. Use the Stop pushbutton to stop

the pump to leave it in service.

F. Make sure the pump discharge valve is open and that any other valves are properly set.

Master Control Systems, Inc. - 14 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

CONFIGURATION CHECKLIST:

Fill in the blanks or circle the chosen settings:

1. Minimum Run Timer Setting: ________ minutes.

2. Sequence Start Setting: __________ seconds.

3. Lockout Jumper Setting: ENABLED / DISABLED.

4. Remote Start Jumper: ENABLED / DISABLED.

5. Deluge Start Jumper: ENABLED / DISABLED.

6. Pressure Setting -

i. Start Setting: _________ psi.

ii. Reset Setting: _________ psi.

BEFORE YOU LEAVE!

1. Place the Isolating Switch (IS) in the ON position.

2. Place the Circuit Breaker (CB) in the ON position.

3. Drop the pressure at the side of the controller. The motor will start.

4. Press the STOP pushbutton. The motor will stop.

5. The Controller is now ready to operate.

Master Control Systems, Inc. - 15 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

OPERATING PROCEDURES:

EMERGENCY STOPPING - Pull the Circuit Breaker handle down to open the breaker and stop the motor.

WARNING: OPEN THE ISOLATING SWITCH BEFORE ATTEMPTING TO OPEN THE DOOR OR

SERVICE THE UNIT.

Energizing Controller: When energizing the controller for the first time after installation or after any service to the

controller, the motor, or motor wiring follow the "Start-up and Test Procedure" found earlier in this manual. For

other cases, follow the Operating Instructions on the instruction plates on the controller door.

Stand-by (Fire Protection) Service: The normal stand-by (automatic start) configuration for the controller is for both

the Isolating Switch and the Circuit Breaker to be in the closed (on) position. The green Power On, and Supervisory

Power On (if present) indicators should be lit. The motor should be off and no other indicators lit. The Audible

Alarm (if so equipped) should be silent.

De-energizing Controller: To de-energize the controller, make sure the manual operator is off. Operate the STOP

pushbutton to ensure the main contactor is open, then open the Circuit Breaker and then the Isolating Switch. All

lights should be off. Complete operating instructions are posted on the controller door.

CAUTION: DISCONNECT SUPERVISORY POWER IF PRESENT (USED WITH EITHER OPTIONS "G"

OR "K") AT ITS SOURCE BEFORE SERVICING THE CONTROLLER.

Manual Electric Starting: Momentarily press the START pushbutton. Note, this is not a latching pushbutton.

Manual Mechanical (Emergency) Starting: Pull up on the MANUAL OPERATOR handle and slide the latch bolt

knob under the operator to the right to engage and hold the handle lever. To stop the fire pump motor, pull up on

MANUAL OPERATOR to release the latch bolt and then release the operator handle quickly.

NOTE: In most cases, an electrical assist will engage or drop-out at around one half of the handle travel.

Stopping the Motor: If the motor is running under Manual Mechanical start, follow the above directions to

disengage the manual mechanical operator. In all other cases, press the STOP pushbutton to stop the motor.

CAUTION: IF THE MOTOR RESTARTS AFTER THE STOP pushbutton IS RELEASED, THERE IS AN

ACTIVE PRESSURE OR REMOTE DEMAND FOR THE FIRE PUMP. THE PUMP WILL

HAVE TO BE TAKEN OUT OF SERVICE TO STOP THE MOTOR. MAKE SURE THE PUMP

IS NOT NEEDED BEFORE THE NEXT STEP.

To take the PUMP OUT OF SERVICE, press and hold the STOP pushbutton and open (turn off) the Circuit

Breaker(s) then both Isolating Switches. Note that both of the Isolating Switches and Circuit Breaker(s) are load

break rated.

WARNING: THIS LEAVES THE FIRE PUMP OUT OF SERVICE RESULTING IN EITHER

REDUCED FIRE PROTECTION OR NO FIRE PROTECTION.

Master Control Systems, Inc. - 16 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

ELECTRIC FIRE PUMP CONTROLLERS – REPLACEMENT PARTS:

DESIGNATION DESCRIPTION MCS PART NUMBER

Complete Chassis Assemblies

MC-LC Line Voltage Transformer and Relay Chassis 586XXX

MC-CU Control Unit Chassis and Module Card Cage 647XXX

MC-OP Aux. Relay & Option Chassis 647XXX

(Supplied only with certain options)

Plug-In Control Module Board Assemblies

MC-PM Power Supply, Voltage & Phase Sequence Monitor 647111

MC-PM Power Supply, Voltage & Phase Sequence (1 Phase) 647112

MC-TM Current & Circuit Breaker Trip Monitor 537XXX

MC-TC Control Logic & Timing Module w/o Mod. 85 647131

MC-TC Control Logic & Timing Module – Reduced Voltage 647135

MC-OM Option Module (Opt. A,D,R,21) 595439

MC-ATB Accelerate Timer Daughter Board Module 647201

Door Mtd. Digital Readout & Display Board

MC-MD Meter & LED Display Panel (13 LEDS) 64977X

MC-MD Meter & LED Display Panel (16 LEDS) 64977X

MC-PAB Pressure Transducer Amp. Board 647XXX

MC-MIB Meter Interface Daughter Board 647XXX

Cabinet Mounted Control Components

MC-ALS Kit Audible Alarm - Silence 400875

MC-ALS Kit Audible Alarm - Buzzer 402618

START “START” Pushbutton Switch 400875

STOP “STOP” Pushbutton Switch 400875

IS Isolating Sw. Operating Handle w/ Door Interlock 400654

CB Circuit Breaker Operating Handle (w/o Door Interlock) 800685

MC-MO Manual Mechanical Emergency Operator Handle 800685

MOLS Manual Operator Limit Switch 801110

S.A. Surge Arrester 208 thru 480 Vac Controllers 303481

S.A. Surge Arrester 600 Vac Controllers 303482

F1,F2,F3 Fuse, Surge Arrester, 480 Vac, 100kA, Standard 204219

F1,F2,F3 Fuse, Surge Arrester, 600 Vac, 200kA, Controllers 204319

Plug-In Relays

RY1 1 form “X”, 24 VDC, Standard MC-LC 617020

RY2 1 form “X”, 24 VDC, Models O,Y,T MC-LC 617020

RY3 1 form “X”, 24 VDC, Models Y MC-LC 617020

RY4 1 form “X”, 24 VDC, Models P,R,O,Y,T MC-LC 617020

NOTE: When ordering replacement parts, you MUST supply the SERIAL NUMBER and MODEL NUMBER of

the Controller in which parts are to be used.

Master Control Systems, Inc. - 17 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

MAINTENANCE

WARNING - LETHAL SHOCK AND ARC FLASH HAZARD, USE APPROPRIATE PERSONAL

PROTECTIVE EQUIPMENT (PPE) IN ACCORDANCE WITH NFPA 70E.

WARNING - BOTH HIGH VOLTAGES AND HIGH CURRENTS ARE PRESENT - TO AVOID THE

POSSIBILITY OF ELECTROCUTION OR INJURY, DO NOT TOUCH ANY CIRCUIT

CONDUCTOR UNTIL IT HAS BEEN DETERMINED BY MEASUREMENT TO BE

DEAD. USE EXTREME CAUTION TO AVOID TOUCHING OR SHORTING LIVE

TERMINALS.

WARNING - TO PREVENT THE POSSIBILITY OF SERIOUS PERSONAL INJURY DUE TO AN

ELECTRICAL FAULT, BE SURE THE DOOR IS CLOSED AND LATCHED BEFORE

CLOSING THE ISOLATING SWITCH OR OPERATING THE CONTROLLER.

WARNING - FOREIGN VOLTAGE MAY BE PRESENT. CONTROLLERS EQUEPPED WITH

OPTION “K” OR “G” UTILIZE AUXILIARY BRANCH CIRCUIT POWER (120 Vac / 60

Hz OR 220 Vac / 50 Hz) WHICH IS NOT SWITCHED OR CONTROLLED. ALWAYS

TURN OFF OR DISCONNECT THE EXTERNAL SOURCE OF POWER BEFORE

ATTEMPTING TO SERVICE THE CONTROLLER.

On a weekly basis with the door(s) closed and latched, perform a test of the controller by dropping the pressure at

the pressure sensing line next to the controller or by using the Weekly Test function provided with this controller.

In addition to the pressure drop test, remote starting or deluge valve starting should be tested if used.

On an annual basis, a complete Start-up and Test Procedure outlined in the previous section of this manual should

be performed.

During the annual testing, qualified personnel should be present to inspect the inside of the controller and check:

• All control wires for tightness

• That all connectors are seated and latched

• That all printed circuit boards in the black card cage (MC-CU) are fully seated

• All connections in the power path for tightness. Re-torque any loose connections to the component

manufactures’ specifications. Contact Master Control Systems, Inc. for any that are not marked.

• For any indication of water marks on any of the components. Replace every component that has water

marks on it.

• For any indication that the wire insulation is cracking.

If any operation of the controller does not function correctly, or the inspection reveals any of the above problems, contact

Master Control Systems, Inc. at mastercontrols.com for service recommendations.

Master Control Systems, Inc. - 18 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

Model DR

Digital Pressure and Alarm Recorder

Modification “XDR” (G3) in Fire Pump Controller

Installation and Instruction Manual

Table of Contents

Page 20: General

Page 21: Initial Connection

- USB Flash Drive

- RS232 Connectivity

Page 25: Setting the Date and Time

Page 26: Normal Operation

Page 27: System Commands

Page 28: Hyperterm for Vista

Master Control Systems, Inc. - 19 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

GENERAL

Overview: The Master Control Systems, Inc. Model DR Digital Recorders is specifically designed to

communicate through an RS-232 serial port directly to a lap-top computer, USB Flashdrive or, if Modification

DRT is installed, a network server. This recorder constantly monitors the system pressure, at a rate of three times

per second, and records it into permanent non-volatile solid state memory (NVSRAM or EEPROM) every hour or

when the pressure changes by more the 5 psi (default setting) from the last saved value. The DR recorder also

monitors and records all alarm and status change events into memory. All recorded alarm and pressure data are

time stamped with the date and time of the event recorded. Alarm & Pressure data is recorded in to separate data

buffers and do not interact with each other. These recorders are completely independent of the fire pump

controller and vice versa. Failure of one does not impede the function of the other.

Fire Pump Controller Option Designations: The model DR digital pressure and alarm recorder is included in

modification code (G3).

Equipment Provided: The system consists of:

1) Solid State Pressure transducer

2) Operator push button to control unit reset, USB reset, and time function.

3) RS-232 customer serial port for data access and control.

4) USB Flash Drive accessibility

Connectivity: Controllers equipped with Mod. Code DRT are network enabled. This allows direct connection to

an Ethernet hub or server for connection to a Local Area Network (LAN) or a Wide Area Network (WAN) or

Internet Access. It uses TCP/IP protocol and is assigned an IP address which can be changed in the field. A work

sheet is supplied with the appropriate network parameters. A customer supplied IP address and sub-net mask can

be pre-programmed by the factory upon notification.

Master Control Systems, Inc. - 20 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

INITIAL CONNECTION

Using the USB Flash Drive:

CPY RST

CPY Light

RS232 port

USB port

1) Plug in your USB Flash Drive to the USB Port - the CPY light will turn solid orange, signaling the

transfer of data has begun.

2) When the CPY light turns green, remove your USB Flash Drive.

3) If the USB Flash Drive is removed too quickly, the CPY light will flash red and no data will be

saved. Remove the USB Flash Drive and press the CPY RST button, then repeat step 1

4) Connect your USB Flash Drive to your computer and look for an excel file with the extension

“.csv.” The file name will be coded in the following fashion:

10F28P34.csv, where: 10 = year 2010

F = 06 = June

28 = Day

P = 16th hour = 4PM

34 = minute

Master Control Systems, Inc. - 21 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

INITIAL CONNECTION – Continued

5) The following are sample screenshots of both electric and diesel recordings:

Electric Diesel

6) Save the file as an excel file to avoid any formatting errors

Using the RS232 Port:

1) Plug in the RS232 cable from your computer to the Display Box (cable not included)

2) Open up Hyperterm. If you use Vista, see P. 38 before continuing on to step 3.

Master Control Systems, Inc. - 22 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

INITIAL CONNECTION - Continued

3) Enter a name for your new connection to the Master Digital Pressure Recorder as shown here.

4) Change the Connect Using: to COM1 (or as appropriate to your computer).

Master Control Systems, Inc. - 23 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

INITIAL CONNECTION - Continued

5) Change the following information:

a. Bits per second: 9600

b. Data bits: 8

c. Parity: None

d. Stop Bits: 1

e. Flow Control: Xon / Xoff

6) Press OK. Wait approximately 5 seconds for the next screen to load, which should look like this:

Master Control Systems, Inc. - 24 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

INITIAL CONNECTION - Continued

7) You can now find a shortcut to your connection for future references by going to Start Æ All

Programs Æ Accessories Æ Communications Æ HyperTerminal Æ Name Of Connection.

Setting the Time and Date (if necessary):

At the Welcome Screen shown in step 6 above, type the following:

a. “H3” <RETURN>

b. T=Day number followed by month/day/year hour:min:sec in 2-digit numeric form then

<RETURN>. This sets the time in a 24 hour format.

c. To verify you have input the correct date, type “T” then <RETURN>

d. For Example: T=01 1/20/09 15:22:00

i. This will input a time of Monday (01) January 20th, 2009 (1/20/09) at 3:22:00PM (15:22:00)

Downloading Data:

1) Click on the Transfer tab at the top and click Start Capture.

2) At the Welcome screen shown in step 5, you may now type C6 for Alarm data (Digital Recorder

only), C7 for Pressure Data or C8 for Current Pressure. Press <RETURN> and the data will begin

to be captured, as shown in the following picture.

3) After the data is done downloading, click the Transfer tab Æ Capture Text Æ Stop. You can now

save the file as whichever name you wish to a file specified by you.

Master Control Systems, Inc. - 25 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

NORMAL OPERATION (default constants)

Switches and LEDs - The back of the display box provides a Security switch, a Send Status push button, and a

Reset push button along with system and diagnostic LEDs.

The TM pushbutton sends the present time to the connected lap-top or network adapter.

The Reset pushbutton resets all the hardware and software to their initial states.

The USB reset pushbutton clears all USB faults.

The following status LEDs are provided on the display back box:

CPY – Solid yellow light indicates the unit is copying data, solid green light indicates completion of data

transfer,

red light indicates failed transfer.

INIT - Indicates that the unit is going through initialize operations.

PROC - Indicates that the unit is running in the general program. It should always be flashing.

XMT - Indicates the unit is transmitting data through the RS232 port

RCV - Indicates the unit is receiving data from the RS232 port

CONN -Indicates that the unit is properly connected and ready to communicate. This connection may be made

by a lap top computer, network server or an external modem.

+5V - Indicates that +5 VDC power is available.

Master Control Systems, Inc. - 26 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

SYSTEM COMMANDS

(H1) CONTROL CODES USED

C0 Hardware reset (same as power up reset)

C6 Send alarm data buffer

Add ",MM/DD/YY" for starting date

C6- Reverse order of information for download

C7 Send pressure data buffer

Add ",MM/DD/YY" for starting date

C7- Reverse order of information for download

C9 Toggle display between PSI and Bar

(H3) TIME & DATE ENTRY

Type "T=" followed by the day number

followed by month/date/year hour:min:sec

in 2-digit numeric form then <RETURN>.

Set time in 24-hr format. To check type

"T" then <RETURN>.

EXAMPLE: Type "T=07 10/19/96 16:04:00"

<RETURN>. This enters Sunday, October 19, 1996

at 4:04:00 in the afternoon.

The last character in the time message before

the "+" sign is the daylight savings setting.

A "0" for OFF or a "1" for ON. To change this

setting, do a time set as above ending with a

"0" or "1" as required, factory default is 1.

See manual for more detailed information.

Master Control Systems, Inc. - 27 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

Hyperterm and Microsoft Vista:

NOTE: Microsoft Vista no longer contains Hyperterm by default. There is, however, a way to get Hyperterm to

work on your Vista computer provided that you have an old XP computer:

1) Make sure your computer has a serial port. If not, you need to purchase a USB to Serial Port Adapter.

2) Search for the following files on your old XP computer:

-htrn_jis.dll

-hypertrm.exe

-HYPERTRM (this file is of the type “DL_File”)

-Hypertrm.dll

This was a

separate search.

3) Once you have the above files, copy them into a single folder on your new Vista computer.

Open Hyperterm through the Hypertrm.exe file, and continue with Step 3 on P.21.

Master Control Systems, Inc. - 28 - Lake Bluff, Illinois

MC_ Issue 23-v02 2012.1.13

OPTION AND MODIFICATION DRAWINGS

NOTE: The following drawings are applicable to controllers with model numbers which indicate that

they are equipped with the following. See controller nameplate for complete model number.

OPTION DESCRIPTION DRAWING

O Auxiliary Alarm & Option Chassis 16350, 16450

K Built-in Alarm Panel 16659

MODIFICATION

X (FOLLOWED BY)

17A or 17B Aux. Motor Run Contacts 16423

17C or 17D Aux. Power Failure Contacts 16426

17E or 17F Aux. Phase Reversal Contacts 16429

19 Strip Heater 16430

20 Strip Heater w/Thermostat 16430

20A Strip Heater w/Humidistat 16430

33 Auxiliary 115 VAC Output 16484

LSC Low Suction Cut-Off Chassis 16691

Potrebbero piacerti anche

- Electric Fire Pump Controller Instruction Manual: Serial NoDocumento38 pagineElectric Fire Pump Controller Instruction Manual: Serial NoJhonNessuna valutazione finora

- Starters For Centrifugal Chillers: Installation, Operation and Maintenance ManualDocumento56 pagineStarters For Centrifugal Chillers: Installation, Operation and Maintenance ManualMuhammad Javed BhattiNessuna valutazione finora

- Starters For Centrifugal Chillers: Installation, Operation and Maintenance ManualDocumento84 pagineStarters For Centrifugal Chillers: Installation, Operation and Maintenance ManualJorge CotzomiNessuna valutazione finora

- First Course of Programmable Logic Controllers PLCS: Abdelbary Center For Computer Training and Technical StudiesDocumento116 pagineFirst Course of Programmable Logic Controllers PLCS: Abdelbary Center For Computer Training and Technical Studieswapij51282100% (1)

- LMR ManualDocumento23 pagineLMR Manualvalerio.garibayNessuna valutazione finora

- Komatsu Forklift Manuals and DiagramsDocumento87 pagineKomatsu Forklift Manuals and DiagramsVrshtyr0% (1)

- MC - G4 Issue 02-v03-drwgsDocumento58 pagineMC - G4 Issue 02-v03-drwgsJhonNessuna valutazione finora

- dokumen.tips_cumins-ps0500-service-manualpdfDocumento33 paginedokumen.tips_cumins-ps0500-service-manualpdfMuthalagu J (Aravindh)Nessuna valutazione finora

- DataKom 040 USERDocumento45 pagineDataKom 040 USERsebastianNessuna valutazione finora

- DK-40 Compressor Controller User ManualDocumento45 pagineDK-40 Compressor Controller User ManualVykintas ImbrasasNessuna valutazione finora

- CUMINS PS0500 Service Manual PDFDocumento33 pagineCUMINS PS0500 Service Manual PDFnoor alam ShaikhNessuna valutazione finora

- PED Start Um EN Feb00Documento19 paginePED Start Um EN Feb00Mamadou Djibril Ba100% (1)

- Mc31a Rev5Documento33 pagineMc31a Rev5sanju939Nessuna valutazione finora

- 09 12 MG33MF02Documento209 pagine09 12 MG33MF02Aleksandar StankovićNessuna valutazione finora

- Product Specification: Programmable Microprocessor-Based Gen Set Controller For Electronic J1939 CAN Bus Diesel EnginesDocumento17 pagineProduct Specification: Programmable Microprocessor-Based Gen Set Controller For Electronic J1939 CAN Bus Diesel EnginesJavierNessuna valutazione finora

- DataKom 040 - USERDocumento45 pagineDataKom 040 - USERKhaleel Khan100% (1)

- JPC ManualDocumento6 pagineJPC ManualJaluadi AdiNessuna valutazione finora

- Devices and Symbol Lecture PDFDocumento5 pagineDevices and Symbol Lecture PDFjayson platinoNessuna valutazione finora

- PL SeriesDocumento49 paginePL Seriesgoogle manNessuna valutazione finora

- INVERTA (Three Phase) User ManualDocumento24 pagineINVERTA (Three Phase) User ManualDario MontillaNessuna valutazione finora

- Tec40 User v2Documento45 pagineTec40 User v2sebastian100% (1)

- CONTROL UNIT TMC - 230 - /11: DM - TurretsDocumento22 pagineCONTROL UNIT TMC - 230 - /11: DM - TurretsVladimir100% (4)

- Operation Manual NSFC01-02 Lift Door ControllerDocumento39 pagineOperation Manual NSFC01-02 Lift Door ControllerHƯNG NGUYỄN THANHNessuna valutazione finora

- Switching Power Supply Design With The PIC16F785: ElectricalDocumento22 pagineSwitching Power Supply Design With The PIC16F785: Electricalyogendra.shethNessuna valutazione finora

- GEK-65280 MKII Control Panel ManualDocumento168 pagineGEK-65280 MKII Control Panel ManualAmarDameneNessuna valutazione finora

- Programming Guide AQUADocumento230 pagineProgramming Guide AQUADejan MihailovicNessuna valutazione finora

- 25 A 20Documento9 pagine25 A 20s_barriosNessuna valutazione finora

- Digital Automatic Voltage Regulator Operation and Maintenance ManualDocumento454 pagineDigital Automatic Voltage Regulator Operation and Maintenance ManualNaresh Pattanaik100% (1)

- Instrumentation and Control FundamentalsDocumento32 pagineInstrumentation and Control FundamentalsdadizNessuna valutazione finora

- Volume 1 PDFDocumento301 pagineVolume 1 PDFNaresh Pattanaik100% (1)

- Elr - Mpel or Dmpel ManualDocumento10 pagineElr - Mpel or Dmpel Manualdurgaprasad reganiNessuna valutazione finora

- User Manual: Hat530 Ats ControllerDocumento26 pagineUser Manual: Hat530 Ats Controllerrjcp01Nessuna valutazione finora

- Devices and symbolDocumento6 pagineDevices and symbolbtciched23Nessuna valutazione finora

- 5 - Manual Software DuplomaticDocumento53 pagine5 - Manual Software DuplomaticLuiz Gustavo Pastrello100% (1)

- 1. Prius U100Documento2 pagine1. Prius U100mecanicadeautoswsNessuna valutazione finora

- Troubleshooting SMPS Problems: (PWM Type)Documento4 pagineTroubleshooting SMPS Problems: (PWM Type)Jibon DasNessuna valutazione finora

- MERCURY OUTBOARD MOTOR PCM DiagnosticsDocumento20 pagineMERCURY OUTBOARD MOTOR PCM DiagnosticsKaivan Kalyaniwalla100% (2)

- Vector Surge Relay - MRG20000Documento20 pagineVector Surge Relay - MRG20000t_syamprasadNessuna valutazione finora

- Standard Submittal PackageDocumento10 pagineStandard Submittal PackageTarek AsfourNessuna valutazione finora

- Actuator With Integral ControlDocumento4 pagineActuator With Integral Controlysr3ee6926Nessuna valutazione finora

- CON2000MP3ADocumento23 pagineCON2000MP3AManelNessuna valutazione finora

- Delomatic 3 Data Sheet 4921240164 UkDocumento2 pagineDelomatic 3 Data Sheet 4921240164 Ukdali.marouenNessuna valutazione finora

- High-Tech Generator Protection RelayDocumento20 pagineHigh-Tech Generator Protection RelayLuka YannamNessuna valutazione finora

- Dec40 - User Service Rev5-0Documento42 pagineDec40 - User Service Rev5-0Racob FherdzNessuna valutazione finora

- Chromalox 3910 ControllerDocumento34 pagineChromalox 3910 ControllerkmpoulosNessuna valutazione finora

- LLC3kW GUI ManualDocumento8 pagineLLC3kW GUI Manualreferenceref31Nessuna valutazione finora

- User Manual: HAT520N Ats ControllerDocumento15 pagineUser Manual: HAT520N Ats ControllerVinhNessuna valutazione finora

- HP374 Doosan Service ManualDocumento90 pagineHP374 Doosan Service ManualRAPID EQUIPMENT RENTALNessuna valutazione finora

- GT305-SP OperatingDocumento34 pagineGT305-SP OperatingemekaokaekwuNessuna valutazione finora

- DPM-3 Operator ManualDocumento38 pagineDPM-3 Operator Manualariel perezNessuna valutazione finora

- Table of Contents for Solar Pump Installation ManualDocumento18 pagineTable of Contents for Solar Pump Installation ManualBonkoungou DominiqueNessuna valutazione finora

- Project Report Speed Control of Induction MotorDocumento47 pagineProject Report Speed Control of Induction MotorSanjivee SachinNessuna valutazione finora

- Vdocuments - MX Seg Nb2Documento34 pagineVdocuments - MX Seg Nb2KrzysztofNessuna valutazione finora

- O&M Manual for SMPS Based Integrated Power Supply SystemDocumento40 pagineO&M Manual for SMPS Based Integrated Power Supply Systemr k mishraNessuna valutazione finora

- Automatic Gen.-Set Controller For AMF and Mains Parallel OperationDocumento56 pagineAutomatic Gen.-Set Controller For AMF and Mains Parallel Operationdudu_vitoria92% (12)

- Nstallation and Iring: HapterDocumento46 pagineNstallation and Iring: HapterKurabachew EndeshaweNessuna valutazione finora

- Módulo Transfer Capricorn ATS 740Documento4 pagineMódulo Transfer Capricorn ATS 740memocritoNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDa EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Transistor Bu4508dx OriginalDocumento2 pagineTransistor Bu4508dx Originalds_engenharia8817Nessuna valutazione finora

- Coneções GrooveDocumento167 pagineConeções Grooveds_engenharia8817Nessuna valutazione finora

- English Grammar SecretsDocumento66 pagineEnglish Grammar SecretsMbatutes94% (33)

- BU4522AFDocumento2 pagineBU4522AFds_engenharia8817Nessuna valutazione finora

- Electric Fire Pump Controller Instruction Manual: Mca / MCP / MCR / Mco Mcy / Mcs / MCTDocumento59 pagineElectric Fire Pump Controller Instruction Manual: Mca / MCP / MCR / Mco Mcy / Mcs / MCTds_engenharia8817Nessuna valutazione finora

- Electrical InstallationDocumento3 pagineElectrical Installationds_engenharia8817Nessuna valutazione finora

- PLM GT Programs Fire Protection Safety FormsDocumento7 paginePLM GT Programs Fire Protection Safety Formsds_engenharia8817Nessuna valutazione finora

- Diesel Electric Fire Pumpset Manual 2Documento68 pagineDiesel Electric Fire Pumpset Manual 2ds_engenharia8817Nessuna valutazione finora

- Installation and Maintenance Manual For Diesel Engine Fire Pump Controller Automatic Controller Model GPDDocumento22 pagineInstallation and Maintenance Manual For Diesel Engine Fire Pump Controller Automatic Controller Model GPDds_engenharia8817Nessuna valutazione finora

- Sisitema Electrico2Documento125 pagineSisitema Electrico2Alexis SotoNessuna valutazione finora

- 150W Single Output With PFC Function: SeriesDocumento2 pagine150W Single Output With PFC Function: SeriesPKDiannaNessuna valutazione finora

- Circuito Panel IncendioDocumento11 pagineCircuito Panel Incendiods_engenharia8817Nessuna valutazione finora

- Gstdef Defining Tool User's ManualDocumento27 pagineGstdef Defining Tool User's Manualds_engenharia8817Nessuna valutazione finora

- I-9102 Intelligent Photoelectric Smoke Detector ManualDocumento7 pagineI-9102 Intelligent Photoelectric Smoke Detector Manualds_engenharia8817Nessuna valutazione finora

- F60UP30DN Fairchild SemiconductorDocumento5 pagineF60UP30DN Fairchild Semiconductords_engenharia8817Nessuna valutazione finora

- GST200Documento56 pagineGST200muhammadfaisal32717Nessuna valutazione finora

- Data 20sheet 20acionador 20manual 20 - 20ingl C3 AAs PDFDocumento1 paginaData 20sheet 20acionador 20manual 20 - 20ingl C3 AAs PDFds_engenharia8817Nessuna valutazione finora

- Augmented Reality For Network Management and SecurityDocumento98 pagineAugmented Reality For Network Management and SecurityNathan Reynolds100% (1)

- CArrier Comfort View PDFDocumento116 pagineCArrier Comfort View PDFAsad IqbalNessuna valutazione finora

- Checkpoint R65 Secure Platform Secure Platform Pro Admin GuideDocumento148 pagineCheckpoint R65 Secure Platform Secure Platform Pro Admin Guideralph.peusens100% (2)

- Jan M Rabaey Digital IC DesignDocumento39 pagineJan M Rabaey Digital IC DesignwearoleNessuna valutazione finora

- Network Basics: Ipaddress Netmask Gateway Dns Server Ip (If Any) Hostname Tcp/Ip Service OnDocumento48 pagineNetwork Basics: Ipaddress Netmask Gateway Dns Server Ip (If Any) Hostname Tcp/Ip Service OnAkang Zaenal MasterMamayukeroNessuna valutazione finora

- Protect Your Privacy with Firewalls, VPNs, Tor and MoreDocumento2 pagineProtect Your Privacy with Firewalls, VPNs, Tor and MoreharissaNessuna valutazione finora

- Computer Concepts 2012: Parsons:: OjaDocumento21 pagineComputer Concepts 2012: Parsons:: OjaMd. Arif Istiaque FarhanNessuna valutazione finora

- Distributed and Collaborative Marketplaces PDFDocumento45 pagineDistributed and Collaborative Marketplaces PDFPaulo Cesar FrancoNessuna valutazione finora

- OMU - Mark - 2 - Rev-C AxellDocumento2 pagineOMU - Mark - 2 - Rev-C AxellGaneshwaranNessuna valutazione finora

- CiscoLive! OpenStack Lab LABCLD-2225Documento180 pagineCiscoLive! OpenStack Lab LABCLD-2225jakub_zenNessuna valutazione finora

- Guide About Tcpip Connections Between Pcs and Siemens PlcsDocumento11 pagineGuide About Tcpip Connections Between Pcs and Siemens Plcsnathan_allgrenNessuna valutazione finora

- CSG Intermediate BrochureDocumento11 pagineCSG Intermediate BrochureLeonardo CapoNessuna valutazione finora

- 2nd Periodical ExamDocumento3 pagine2nd Periodical ExamJefersonNessuna valutazione finora

- CISA Exam 100 Practice QuestionDocumento22 pagineCISA Exam 100 Practice Questionharsh100% (1)

- Assignment 2Documento10 pagineAssignment 2Devandran KrisnanNessuna valutazione finora

- s11 Network ManagementDocumento5 pagines11 Network ManagementAndy TenorioNessuna valutazione finora

- Power System Protection - Siemens Power Engineering GuideDocumento38 paginePower System Protection - Siemens Power Engineering GuideAboNajoolNessuna valutazione finora

- Evaluating Functional Level StrategiesDocumento6 pagineEvaluating Functional Level Strategiesimpeccable1999Nessuna valutazione finora

- Oracle Exalytics Installation and AdministrationDocumento92 pagineOracle Exalytics Installation and AdministrationGarik ManNessuna valutazione finora

- Cisa V2575 - 220623 - 075416Documento168 pagineCisa V2575 - 220623 - 075416Ashfaaq CurimbaccusNessuna valutazione finora

- The Buyers Guide To Remote Machine MonitoringDocumento24 pagineThe Buyers Guide To Remote Machine MonitoringsuhasNessuna valutazione finora

- Skytrack Paper enDocumento28 pagineSkytrack Paper enemisamkoNessuna valutazione finora

- Assignment 3Documento4 pagineAssignment 3Shubham ThorboleNessuna valutazione finora

- Mapping Approach of ITIL Service Management Processes To ISO/IEC 27001 ControlsDocumento8 pagineMapping Approach of ITIL Service Management Processes To ISO/IEC 27001 ControlsJournal of ComputingNessuna valutazione finora

- BEMS ManualDocumento111 pagineBEMS Manual이아름Nessuna valutazione finora

- Ds r16 - Unit-4 (Ref-2)Documento15 pagineDs r16 - Unit-4 (Ref-2)Hemanth SankaramanchiNessuna valutazione finora

- List of Approved FYPs 2015-16Documento23 pagineList of Approved FYPs 2015-16Nabeel A K JadoonNessuna valutazione finora

- CS 8100SC Family User GuideDocumento56 pagineCS 8100SC Family User GuideBam BamNessuna valutazione finora

- Frauds in Indian BanksDocumento59 pagineFrauds in Indian BanksPayal AmbhoreNessuna valutazione finora

- A Performance Comparison of X.25, Frame Relay and ATM in High Speed Networks-A ReviewDocumento10 pagineA Performance Comparison of X.25, Frame Relay and ATM in High Speed Networks-A ReviewIssiakou AboubakarNessuna valutazione finora