Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Brush Seating Correctly

Caricato da

edgarlimasDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Brush Seating Correctly

Caricato da

edgarlimasCopyright:

Formati disponibili

www.easa.

com March 1999

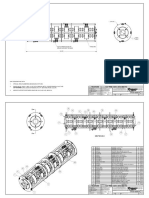

DC Motors: Final Testing Procedures

Without A Dynamometer

By Chuck Yung

EASA Technical Support Specialist

Editor’s Note: This is the first in a two-part box it was seated in.

series on DC motor repair procedures. Remember, the

brushes should be

EASA’s Engineering and Technical Support sanded until contact

Department has received many calls over the past with the commutator is

few months concerning repairs on DC motors. 100 percent.

Most callers have asked for tips on troubleshoot- The neutral position is in the center of the brush

ing to make sure repairs are handled correctly. contact zone with the commutator. As a partially

Prior to assembly, all windings should be tested seated brush wears in, the contact zone broadens

for shorts, grounds and correct polarity. and shifts the center of the contact area away from

After a DC motor is assembled and ready to test the neutral position.

run, a few simple checks will greatly reduce the After the brushes are fully seated, use dry

chance of motor problems. The following compressed air to blow any carbon dust out of the

procedures should be motor. (If possible,

especially helpful to cover the armature

those shops that windings while

don’t have a dyna- If neutral is adjusted with the brushes partially seating the

mometer. seated (as shown), it will be the mid- brushes.)

point between A and B. When the

Adjusting Brush brushes wear to full contact, the Adjusting

Box Height neutral setting will be the mid-

Neutral

Brush boxes should point between A and C. The

Connect a volt-

be adjusted so that all actual neutral position does not

change, so the motor will arc meter across two

are the same height adjacent brush-

as the brushes become fully

above the commuta- holder studs and

seated.

tor. On most ma- A B C apply 110 volts AC

chines, this height to the shunt fields.

should be between The better the

1/16 inch and 1/8 inch, although some larger neutral setting, the lower the indicated voltage will

machines may specify clearances as great as 1/4 be. Shift the brushholder assembly back and forth

inch. Consult the manufacturer specifications for to obtain the lowest possible reading. It is some-

the particular machine if in doubt. Use a spacer of times possible to obtain a zero voltage reading,

the desired thickness to set the brush-box clear- and readings below 0.010 volt are normal.

ance. Teflon will not scratch the commutator and it Once in a great while, a DC machine has a

conforms to the shape, although other material also “false” or “soft” neutral. A low reading may be

will work. obtained, but it is not the true neutral position. At

the false neutral position, the voltage reading is

Seating Brushes not as low as that of the true neutral.

First, fully seat the brushes using fine (100

grit), non-conductive sandpaper. It may be easier

to seat the brushes a few at a time, especially with Next month: How to verify correct interpole

large machines with a lot of brushes (16 or more). polarity, compound machines and brush spacing.

In that case, be sure to install each brush in the

Potrebbero piacerti anche

- Title: DC Machines: Host: Hytec Power Inc Speaker: Engr. Joyce Allan A. Guingab, REEDocumento10 pagineTitle: DC Machines: Host: Hytec Power Inc Speaker: Engr. Joyce Allan A. Guingab, REELloydNessuna valutazione finora

- DC Motor Hard Copy ReportDocumento13 pagineDC Motor Hard Copy ReportShang Divina Ebrada100% (1)

- Fuctioning of The Collector & Effect of The Magnetomotive Force in The ArmatureDocumento4 pagineFuctioning of The Collector & Effect of The Magnetomotive Force in The ArmatureDavid Acevedo CardonaNessuna valutazione finora

- 45 16255 EE321 2015 1 1 1 Week 9 10Documento22 pagine45 16255 EE321 2015 1 1 1 Week 9 10Zakaria MaazazNessuna valutazione finora

- Morgan - Carbon Brushes Technical Handbook PDFDocumento20 pagineMorgan - Carbon Brushes Technical Handbook PDFkamal_khan85Nessuna valutazione finora

- tr1000 Eng ManDocumento5 paginetr1000 Eng ManMhamad melhemNessuna valutazione finora

- News November 03Documento4 pagineNews November 03Hilal AchrafNessuna valutazione finora

- Commercial-Style CP Dipole FMDocumento5 pagineCommercial-Style CP Dipole FMStephen Dunifer100% (2)

- EmotorDocumento6 pagineEmotoregy-powerNessuna valutazione finora

- Type CMR, Instalacion.Documento4 pagineType CMR, Instalacion.Mario MarquezNessuna valutazione finora

- Ge Ge752 User Manual 15 20Documento6 pagineGe Ge752 User Manual 15 20RICHARDNessuna valutazione finora

- How To Build A Hamon Resistor Divider NetworkDocumento6 pagineHow To Build A Hamon Resistor Divider NetworkNoneNessuna valutazione finora

- TR16 Battery Tester InstructionDocumento2 pagineTR16 Battery Tester InstructionJoe SmithNessuna valutazione finora

- Electronics Transformer DesignDocumento17 pagineElectronics Transformer DesignReziNessuna valutazione finora

- M100T-M5000T 990-003100 Rev EDocumento4 pagineM100T-M5000T 990-003100 Rev Ekuna rathoreNessuna valutazione finora

- GLE IMEM TREND Fault 67-71Documento7 pagineGLE IMEM TREND Fault 67-71Ash100% (1)

- Armature Winding of DC Machines May Be of The Lap or The Wave TypeDocumento3 pagineArmature Winding of DC Machines May Be of The Lap or The Wave TypeHanz SadiaNessuna valutazione finora

- 14.horizontal Assembly: Bucking UnitDocumento8 pagine14.horizontal Assembly: Bucking UnitBivolaru AndreiNessuna valutazione finora

- Armature Reaction of DC GeneratorDocumento16 pagineArmature Reaction of DC GeneratorAndrew Pontanal100% (1)

- Where Compensating Windings and Interpoles Are Used?: Ed For This PurposeDocumento3 pagineWhere Compensating Windings and Interpoles Are Used?: Ed For This PurposeMelanie Jane Agader CortezNessuna valutazione finora

- Pressure Loss Installation Instructions: Typical Energy Calculation: 1. LiquidDocumento1 paginaPressure Loss Installation Instructions: Typical Energy Calculation: 1. LiquidmelisaBNessuna valutazione finora

- Brushless DC Electric MotorDocumento24 pagineBrushless DC Electric MotorBrent CarlNessuna valutazione finora

- HF Antenna TunerDocumento3 pagineHF Antenna TunerMahmoud ShaabanNessuna valutazione finora

- Extraefi - Co.Uk Reset Problems: Ms1-Extra and Ms2-ExtraDocumento8 pagineExtraefi - Co.Uk Reset Problems: Ms1-Extra and Ms2-Extraasser_salehNessuna valutazione finora

- Kayezelle Mendoza AC DC Lab4Documento11 pagineKayezelle Mendoza AC DC Lab4Jaloyd MacalalagNessuna valutazione finora

- 4 Motors: D.C. Motors Principles of D.C. MotorsDocumento10 pagine4 Motors: D.C. Motors Principles of D.C. MotorsmanjunathagNessuna valutazione finora

- Interpoles of DC GeneretorsDocumento20 pagineInterpoles of DC GeneretorsSankha PattanayakNessuna valutazione finora

- 7-1 Machine DiagnosisDocumento19 pagine7-1 Machine DiagnosisyfmihweasaNessuna valutazione finora

- CAPT CouplingsDocumento33 pagineCAPT Couplingshermes alberto consuegra gonzalezNessuna valutazione finora

- XTR 2016 - 2CHDocumento24 pagineXTR 2016 - 2CHBrian PinillaNessuna valutazione finora

- 244 HyGain Quad AntennaDocumento21 pagine244 HyGain Quad AntennaJorge AguilarNessuna valutazione finora

- User'S Guide: Shunt Meter Test Kit Model Smts-25 & (Extened Range XR)Documento8 pagineUser'S Guide: Shunt Meter Test Kit Model Smts-25 & (Extened Range XR)Heidi CoxNessuna valutazione finora

- Chevrolet Radio Diagram 1951Documento8 pagineChevrolet Radio Diagram 1951jimmyNessuna valutazione finora

- University of Sharjah Electrical and Electronics Engineering Electromechanical Systems PROJECT (Fall Semester 2010-2011)Documento13 pagineUniversity of Sharjah Electrical and Electronics Engineering Electromechanical Systems PROJECT (Fall Semester 2010-2011)sara_shedid100% (1)

- Ta1 96 2013-Brushes SPRKNG Mach-Maint-Single-PagesDocumento4 pagineTa1 96 2013-Brushes SPRKNG Mach-Maint-Single-PagesArunNessuna valutazione finora

- Reluctance Motor: University of The Philippines Los Baños, Laguna AY 2010-2011Documento16 pagineReluctance Motor: University of The Philippines Los Baños, Laguna AY 2010-2011Dela Cruz リッチェルNessuna valutazione finora

- Electricity - GeneratorsDocumento14 pagineElectricity - GeneratorsAayush AgrawalNessuna valutazione finora

- Synchronous Drive InstallationDocumento4 pagineSynchronous Drive InstallationryanmackintoshNessuna valutazione finora

- Eee225 02-1Documento39 pagineEee225 02-1Djirangmor JosephNessuna valutazione finora

- Eee225 02Documento20 pagineEee225 02Djirangmor JosephNessuna valutazione finora

- PhysicsDocumento20 paginePhysicsTanmay SharmaNessuna valutazione finora

- One-Masted SloopDocumento3 pagineOne-Masted Sloopbearbullride10Nessuna valutazione finora

- Synchronous Motor Control - Bulletin 1900 Measurement Requirements For Brush-Type MotorsDocumento4 pagineSynchronous Motor Control - Bulletin 1900 Measurement Requirements For Brush-Type MotorsJose Antonio GdNessuna valutazione finora

- Cable & Coaxial TerminationsDocumento2 pagineCable & Coaxial TerminationsMartin SilisqueNessuna valutazione finora

- Latest Transformers Questions AnswersDocumento7 pagineLatest Transformers Questions AnswersInstrumentation ToolsNessuna valutazione finora

- CCUM21Documento4 pagineCCUM21Ranjit Das100% (1)

- RME REE Review QuestionsDocumento32 pagineRME REE Review QuestionsAllan BitonNessuna valutazione finora

- WoundRotorTips 1112Documento3 pagineWoundRotorTips 1112andres monederoNessuna valutazione finora

- IEC 56-63-71-80 - Nema Frame 56 D.C. Motors: Installation and MaintenanceDocumento7 pagineIEC 56-63-71-80 - Nema Frame 56 D.C. Motors: Installation and MaintenanceJoel EncaladaNessuna valutazione finora

- How To Use MPI Yokes PDFDocumento12 pagineHow To Use MPI Yokes PDFAhmed Gomaa100% (1)

- EF-140S and EF-140S/H: 40 Meter Linear Loaded DipoleDocumento26 pagineEF-140S and EF-140S/H: 40 Meter Linear Loaded Dipolesboonuy331Nessuna valutazione finora

- Lecture 4Documento5 pagineLecture 4Shaheryar MansoorNessuna valutazione finora

- AC Commutator Motors Repulsion Series Motor UniversalDocumento3 pagineAC Commutator Motors Repulsion Series Motor UniversalwhrferNessuna valutazione finora

- Rme Ree Review QuestionsDocumento34 pagineRme Ree Review QuestionsRandy RandyNessuna valutazione finora

- Axial "Hunting" of 2-Pole Motors: Causes and Cures: Attraction/RepulsionDocumento3 pagineAxial "Hunting" of 2-Pole Motors: Causes and Cures: Attraction/Repulsionkimpatrick19Nessuna valutazione finora

- DC MachinesDocumento67 pagineDC Machinesvachna ramNessuna valutazione finora

- CH-2-DC MachineDocumento83 pagineCH-2-DC MachineÙm ØrthøbøyNessuna valutazione finora

- EEE-183, DC Generators, Working PrinciplesDocumento21 pagineEEE-183, DC Generators, Working PrinciplesPiyas ChowdhuryNessuna valutazione finora

- A CircularlyDocumento5 pagineA CircularlyJavier Santiago BorghiNessuna valutazione finora

- ACS800 Programa de Mantenimiento PDFDocumento1 paginaACS800 Programa de Mantenimiento PDFedgarlimasNessuna valutazione finora

- Woodward Speed Droop PDFDocumento8 pagineWoodward Speed Droop PDFedgarlimas100% (1)

- Codigos de Eventos CaterpillarDocumento8 pagineCodigos de Eventos CaterpillaredgarlimasNessuna valutazione finora

- Simple Tests To Assure Proper DC Motor Performance: Drop Testing Fields (Shunt, Series, Interpoles)Documento2 pagineSimple Tests To Assure Proper DC Motor Performance: Drop Testing Fields (Shunt, Series, Interpoles)edgarlimasNessuna valutazione finora

- g05 Frenos Be Sew-EurodriveDocumento55 pagineg05 Frenos Be Sew-EurodriveedgarlimasNessuna valutazione finora

- Manual de Miller Maquina de SoldarDocumento108 pagineManual de Miller Maquina de Soldaredgarlimas100% (1)

- Hazardous Location SpecificationsDocumento1 paginaHazardous Location SpecificationsedgarlimasNessuna valutazione finora

- Arrancador Con Rele de Sobrecarga Estado SolidoDocumento8 pagineArrancador Con Rele de Sobrecarga Estado SolidoedgarlimasNessuna valutazione finora

- Bearings Insulated J20AA Tpi 206 de enDocumento22 pagineBearings Insulated J20AA Tpi 206 de enedgarlimasNessuna valutazione finora

- Catalog - Festoon Systems, I-Beam, 314-330 SeriesDocumento24 pagineCatalog - Festoon Systems, I-Beam, 314-330 SeriesedgarlimasNessuna valutazione finora

- Catalog - Festoon Systems, C-Track-Stretch WireDocumento36 pagineCatalog - Festoon Systems, C-Track-Stretch WireedgarlimasNessuna valutazione finora

- RectifiersDocumento1 paginaRectifiersedgarlimasNessuna valutazione finora

- Electric Suspended MagnetsDocumento5 pagineElectric Suspended MagnetsedgarlimasNessuna valutazione finora

- Hoods Instruction ManualDocumento20 pagineHoods Instruction ManualedgarlimasNessuna valutazione finora

- Service Instructions: Syntron Electromechanical Direct Drive Vibratory Feeder Model: MF-400-EDocumento19 pagineService Instructions: Syntron Electromechanical Direct Drive Vibratory Feeder Model: MF-400-EedgarlimasNessuna valutazione finora

- Circuit BrakerCutler Hammer 4160 Breaker 69C3076Documento72 pagineCircuit BrakerCutler Hammer 4160 Breaker 69C3076edgarlimasNessuna valutazione finora

- Emerg Lighting-0601597 A-Install InstrDocumento4 pagineEmerg Lighting-0601597 A-Install InstredgarlimasNessuna valutazione finora

- Cuttler Hammer BreakersDocumento66 pagineCuttler Hammer BreakersedgarlimasNessuna valutazione finora

- Anillos Colectores de Potencia ElecticaDocumento2 pagineAnillos Colectores de Potencia ElecticaedgarlimasNessuna valutazione finora

- Inclinimetro Boom RDSR3 BA 09 - BrochDocumento3 pagineInclinimetro Boom RDSR3 BA 09 - BrochedgarlimasNessuna valutazione finora

- Coupling FALK PDFDocumento8 pagineCoupling FALK PDFedgarlimasNessuna valutazione finora

- Xa Se100582a 0 PDFDocumento2 pagineXa Se100582a 0 PDFedgarlimasNessuna valutazione finora

- Go Switch Product CatalogDocumento69 pagineGo Switch Product CatalogedgarlimasNessuna valutazione finora

- Homeopatia Vibracional RatesDocumento45 pagineHomeopatia Vibracional RatesAugusto Bd100% (4)

- Review of Ventura's "An Overview of Child Psychology in The Philippines"Documento2 pagineReview of Ventura's "An Overview of Child Psychology in The Philippines"Irene CayeNessuna valutazione finora

- State of The Art in Research On MicrogridsDocumento36 pagineState of The Art in Research On MicrogridsDulal MannaNessuna valutazione finora

- S P 01958 Version 2 EPD OVO ArmchairDocumento16 pagineS P 01958 Version 2 EPD OVO ArmchairboiNessuna valutazione finora

- Marisa Wolf Final New ResumeDocumento2 pagineMarisa Wolf Final New Resumeapi-403499166Nessuna valutazione finora

- Maxwell's Equations and Stoke's TheoremDocumento26 pagineMaxwell's Equations and Stoke's TheoremTuya ErdenejargalNessuna valutazione finora

- SafetyStock OverviewDocumento3 pagineSafetyStock OverviewJosue FonsecaNessuna valutazione finora

- The Four Types of Gaps and How To Play Them PDFDocumento17 pagineThe Four Types of Gaps and How To Play Them PDFshaikiftakar100% (2)

- Ericsson Private 5G Solution BriefDocumento5 pagineEricsson Private 5G Solution BriefTanesan WyotNessuna valutazione finora

- MODULE 1 - Contemporary WorldDocumento4 pagineMODULE 1 - Contemporary WorldaapNessuna valutazione finora

- Solution Manual-Statistical Physics of Particles by Meheran KardarDocumento165 pagineSolution Manual-Statistical Physics of Particles by Meheran KardarDanielle Nguyen7% (14)

- Livro Spectrochemical AnalysisDocumento9 pagineLivro Spectrochemical AnalysisRicardo PossebonNessuna valutazione finora

- Lay Planning TypesDocumento1 paginaLay Planning TypesGaurav Shakya100% (1)

- Guru ShishyaDocumento3 pagineGuru ShishyacktacsNessuna valutazione finora

- Mother Tongue Based Instruction in The Newly Implemented K To 12 Curriculum of The PhilippinesDocumento16 pagineMother Tongue Based Instruction in The Newly Implemented K To 12 Curriculum of The PhilippinesEi JayNessuna valutazione finora

- Revised LabDocumento18 pagineRevised LabAbu AyemanNessuna valutazione finora

- The Names of Allah and Their ReflectionsDocumento98 pagineThe Names of Allah and Their ReflectionsSuleyman HldNessuna valutazione finora

- Complete DaikinDocumento11 pagineComplete DaikinAGNIDEEP BAIDYANessuna valutazione finora

- Assignment On Unstable or Astatic Gravimeters and Marine Gravity SurveyDocumento9 pagineAssignment On Unstable or Astatic Gravimeters and Marine Gravity Surveyraian islam100% (1)

- Project in Precal: Mary Joyce MolinesDocumento11 pagineProject in Precal: Mary Joyce MolinesJaja KeykNessuna valutazione finora

- Iso 16232 10 2007 en PDFDocumento8 pagineIso 16232 10 2007 en PDFyağmurNessuna valutazione finora

- REM630 Broch 756825 LRENdDocumento6 pagineREM630 Broch 756825 LRENdsihamuNessuna valutazione finora

- Week 1 Macro (DDR)Documento49 pagineWeek 1 Macro (DDR)Stevie Sean100% (1)

- Chemistry Previos Papaer 313Documento19 pagineChemistry Previos Papaer 313Ashu GuptaNessuna valutazione finora

- BROMINE Safety Handbook - Web FinalDocumento110 pagineBROMINE Safety Handbook - Web Finalmonil panchalNessuna valutazione finora

- Climate Declaration: For White Corex PlasterboardDocumento1 paginaClimate Declaration: For White Corex PlasterboardAbdullah BeckerNessuna valutazione finora

- Language Loss in Waray: Ni Voltaire Q. UyzonDocumento23 pagineLanguage Loss in Waray: Ni Voltaire Q. UyzonMary Rose OmbrogNessuna valutazione finora

- Directorate of Technical Education, Maharashtra StateDocumento47 pagineDirectorate of Technical Education, Maharashtra StatePandurang GunjalNessuna valutazione finora

- Ip TunnelingDocumento15 pagineIp TunnelingBon Tran HongNessuna valutazione finora

- Pamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFDocumento9 paginePamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFNiKhil GuPtaNessuna valutazione finora