Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DBS11011-12 - Operator Manual DM100 Danelec Marine

Caricato da

Adi PrasetyoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DBS11011-12 - Operator Manual DM100 Danelec Marine

Caricato da

Adi PrasetyoCopyright:

Formati disponibili

Operator’s Manual

For the DM100-2014 VDR

Document Number DBS11011

Version Number 1.2

Date June 2014

P/N (hard copy) 9302721-12

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

Revision record

Version Date Description

1.0 April 2014 Original issue of document

1.1 May 2014 Minor revision

1.2 June 2014 Minor revision

DBS11011-12 Page 2/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

Contents

REVISION RECORD ........................................................................................................... 2

1 SCOPE AND PURPOSE .......................................................................................... 5

1.1 References ................................................................................................................ 5

1.2 Terms and Abbreviations .......................................................................................... 5

2 SYSTEM OVERVIEW ............................................................................................... 6

2.1.1 Data Acquisition Unit (DAU) ............................................................................... 6

2.1.2 VDR Bridge Control Panel (BCP)....................................................................... 6

2.1.3 Bridge Microphone Units (BMU) ........................................................................ 6

2.1.4 Fixed capsule ..................................................................................................... 7

2.1.5 Float-free capsule .............................................................................................. 7

2.1.6 Remote Video Interface (RVI) ............................................................................ 7

2.1.7 Sensor Interface Unit (SIU) ................................................................................ 7

2.2 Maximum number of supported interfaces ................................................................ 8

3 OPERATION ............................................................................................................. 9

3.1 Bridge Control Panel ................................................................................................. 9

3.1.1 Alarm display ..................................................................................................... 9

3.1.2 Self-test – Operational Performance Test .......................................................... 9

3.1.3 Setting the display brilliance level to default ...................................................... 9

4 OPERATION OF THE DM100 DAU ....................................................................... 10

4.1 Data Processing Unit (DPU).................................................................................... 11

4.1.1 Power LEDs ..................................................................................................... 11

4.1.2 AC breaker ....................................................................................................... 11

4.1.3 AC inlet ............................................................................................................ 11

4.1.4 Battery switch................................................................................................... 12

4.1.5 VDR status LED ............................................................................................... 12

4.1.6 Main CPU LED................................................................................................. 12

4.1.7 LEDs in the Ethernet connectors ..................................................................... 12

5 OPERATION OF THE NON-MODULAR COMPACT SIU ...................................... 13

5.1 LEDs on the Uni-rack .............................................................................................. 13

5.1.1 AC LED ............................................................................................................ 13

5.1.2 AC breaker ....................................................................................................... 13

5.1.3 Ethernet link and activity indicators .................................................................. 14

5.1.4 UR address ...................................................................................................... 14

6 OPERATION OF THE MODULAR SIU .................................................................. 15

6.1 LEDs on Module Rack ............................................................................................ 15

6.1.1 AC LED ............................................................................................................ 15

6.1.2 Link indications ................................................................................................ 15

DBS11011-12 Page 3/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

6.1.3 AC breaker ....................................................................................................... 15

6.1.4 LEDs in the Ethernet connector ....................................................................... 16

6.1.5 Allocation of system labels for digital interfaces ............................................... 16

6.1.6 MR address...................................................................................................... 16

7 OPERATION OF STANDARD RVI 02-004 AND RVI 02-004D (POE) ................... 17

7.1 Operation of RVI with AC power supply .................................................................. 18

7.1.1 RVI address ..................................................................................................... 18

7.1.2 Ethernet ports .................................................................................................. 18

7.1.3 ST LED ............................................................................................................ 18

8 ERROR CODES ..................................................................................................... 19

8.1 Error codes ............................................................................................................. 19

9 SERVICE AND MAINTENANCE ............................................................................ 27

9.1 Verification of the VDR functionality following service on any sensor ..................... 27

9.2 List of most common spare parts ............................................................................ 27

DBS11011-12 Page 4/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

1 Scope and purpose

Operator's Manual for the DM100-2014 VDR. The DM100-2014 complies with IEC 61996-1 Ed.2

which applies to VDRs installed from 1st of July 2014.

1.1 References

DBS10704 Installation Manual for DM100/DM400 VDR compact Sensor Interface Unit

DBS10956 Installation Manual for DM100-2014 VDR

DBS11010 Inspectors and Authorities Manual for DM100-2014 VDR

DBS10919 Installation Manual for Remote Video Interface with PoE RVI 02-004, RVI 02-004D

9200327 Installation Manual for DM400, DM500 VDR Sensor Interface Unit

9200331 Installation Manual for Remote Video Interface for DM200, DM300, DM400, DM500

1.2 Terms and Abbreviations

BCP Bridge Control Panel

BMU Bridge Microphone Unit

DAU Data Acquisition Unit

DPU Data Processing Unit (located inside the DAU)

OPT Operational Performance Test (self-test according to IEC 61996-1 Ed.2)

SIU Sensor Interface Unit

RVI Remote Video Interface

NAS Network attached storage (option used for external extended backup)

DBS11011-12 Page 5/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

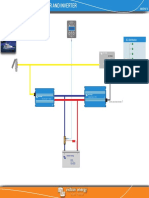

2 System overview

Ethernet PoE

STP CAT5 Fixed

Capsule

Float-free

Ethernet PoE capsule

Ethernet PoE DAU STP CAT5

STP CAT5

BCP

Ethernet STP

CAT5/CAT6 Images from

BMU RADAR and ECDIS

BMU Ethernet PoE

BMU STP CAT5

BMU Optional

BMU Remote

BMU Video I/F

Ethernet

6 x BMU STP CAT5

Video inputs (2)

VHF Serial inputs (12) Analog or DVI from

e.g. GPS e.g. RADAR

SIU

Serial inputs (8) Analog inputs (8) Digital inputs (64)

VDR System overview (typical configuration)

2.1.1 Data Acquisition Unit (DAU)

The Data Acquisition Unit contains the Data Processor Unit (DPU). The DAU must be installed

indoors in the proximity of the bridge.

2.1.2 VDR Bridge Control Panel (BCP)

The BCP must be installed on the bridge either in a console or mounted on a bulkhead. The BCP is

the interface for the VDR Operational Performance Test which must be carried out regularly. VDR

system errors will also be shown here as a caution (steady yellow light).

2.1.3 Bridge Microphone Units (BMU)

A number of BMUs must be installed on the bridge (console, ceiling or bulkhead mounted).

Watertight outdoor BMUs for the bridge wings are available.

DBS11011-12 Page 6/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

2.1.4 Fixed capsule

The fixed data capsule (“the orange box”) must be installed on an “external deck close to the

vessels center line” - typically on the external deck above the bridge.

2.1.5 Float-free capsule

The float-free capsule is an additional data capsule which is required according to IEC 61996-1

ed2.0. It must be installed in the same way as an EPIRP.

2.1.6 Remote Video Interface (RVI)

The RVI is optional equipment. An RVI may be used to capture video from, for example, a

RADAR which is unable to send images to the VDR using Ethernet; i.e. typically older equipment.

The RVI must be installed indoors, normally close to the RADARs. It must be connected to the

DAU with a cable which may be up to 100m in length.

2.1.7 Sensor Interface Unit (SIU)

The SIU is optional equipment. An SIU is needed if, for example, door status cannot be provided

using a serial or Ethernet interface on the VDR.

A standard non-modular compact SIU has 8 serial interfaces, 8 analog interfaces and 64 digital

interfaces. A modular SIU also exists which can be configured to have other combinations of

interfaces. The SIU must be installed indoors. It must be connected to the DAU with an Ethernet

cable up to 100m long.

DBS11011-12 Page 7/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

2.2 Maximum number of supported interfaces

If needed, additional equipment may be used to make larger or non-standard configurations. The

maximum number of supported interfaces for a VDR is listed below:

Type of input Maximum configuration

Ethernet interfaces* 7 on DAU

Serial inputs 40 (12 on DAU + 3 modules)

Analog inputs 32 (2 modules)

Digital inputs 128 (8 modules)

Audio inputs 14 (10 on DAU + 4 on RAI )

Video inputs** 4 (2 RVIs)

* For configuration of the VDR, acquiring network data and acquiring image data.

** The VDR records up to 8 image tracks. Four of these tracks may be used for recording images acquired by a Remote

Video Interface (optional equipment).

DBS11011-12 Page 8/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

3 Operation

3.1 Bridge Control Panel

The BCP is the primary user interface for an installed operational VDR. It serves two purposes:

• Alarm (caution) display

• Interface for initiating VDR self-test (Operational Performance Test)

3.1.1 Alarm display

The VDR will generate an alarm message (caution) if a system error is detected. An alarm message

will be displayed on the BCP and the yellow caution indicator will be illuminated. No audible alarm

will be generated and alarms should not be acknowledged. Alarm messages will be cleared and the

caution indicator turned off when the cause of error is resolved.

3.1.2 Self-test – Operational Performance Test

An Operational Performance Test (OPT) of the VDR must be carried out regularly, and always after

service and maintenance which may affect the operation of the VDR. An OPT is best done while

the vessel is en route and all navigation equipment is switched on. A service agent must be

contacted if the OPT report shows problems which cannot be fixed by the master on the vessel.

Click on “F2” and follow the instructions in order to carry out an OPT.

3.1.3 Setting the display brilliance level to default

Pressing the DIM bottom for 5-7 seconds will restore the display brilliance level.

DBS11011-12 Page 9/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

4 Operation of the DM100 DAU

The door to the DAU must be locked after the VDR has been installed and is operating normally.

This section of the manual is only relevant during installation and service.

AC breaker AC inlet I/F for I/F for

Program

memory capsule float-free

VGA I/F for I/F for I/F for I/F for I/F to

Service interface

console DPU SIU RDI BCP RVI IAS

VDR status

Termination Interfaces Ethernet Audio

LED Battery

resistors for for serial data ports interfaces

switch

SI00 - SI03 Main CPU Power status

Service mode

switch status LED LEDs

DBS11011-12 Page 10/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

4.1 Data Processing Unit (DPU)

The DPU is the main computer in the system. It is basically a PC, but it has been designed from

scratch in a completely different manner in order to withstand environmental stress which far

exceeds what an ordinary industrial PC can tolerate.

4.1.1 Power LEDs

BAT LED (blue)

Steady light Battery fully charged OK

Blinking (1Hz) Charging battery OK

Blinking (5Hz) Battery is not detected Error

Off The battery switch on the DPU is “OFF” (Error)

AC LED (blue)

Steady light AC power OK OK

Off AC power failed Error

ERR LED (red)

Steady light The internal power control circuit has Error

failed

Off The internal power control circuit is OK

operating

OK LED (blue)

Steady light Power to DPU present OK

Off No power to the DPU Error (note 1)

4.1.2 AC breaker

The AC breaker is a combination of a fuse and a manually operated switch, i.e. it can be used to

manually switch off the AC power sources, but it will also pop out automatically if too much

current is drawn from the power source or if overvoltage is detected.

Warning: The AC breaker must be released (popped out) and the

battery switch on the front of the DPU must be in its “Off” position in

order to switch the unit fully off.

4.1.3 AC inlet

The main power source for the VDR is the ship’s AC (110V-230V).

DBS11011-12 Page 11/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

4.1.4 Battery switch

The battery switch indirectly controls a relay between the DPU and the battery pack. When

switching the VDR off; do the following: Pop out the AC breaker and briefly move the battery

switch to its “OFF” position. Move the battery switch back to its “ON” after the VDR is turned off.

4.1.5 VDR status LED

The status of the system is displayed using a tri-color LED. The BCP will display text messages and

error codes explaining the problem(s) if the LED becomes yellow or red.

VDR status LED (tri color)

Steady green The information displayed is just OK

information

Steady yellow The information displayed is a warning. (OK)

The system is still fully operational but

may fail soon. Contact a service agent if

the problem cannot be rectified.

Steady red The information displayed contains Error

information about system errors which

prevent normal operation. Contact a

service agent if the problem cannot be

rectified.

4.1.6 Main CPU LED

The main CPU LED is controlled by the power control circuit which will become active as the first

circuit after power is applied. The power circuit uses the LED to show information about the main

CPU.

OFF The power circuit has not started yet – (OK)

this should take a few seconds only.

Green 1Hz The power circuit is waiting for the main (OK)

CPU to start (boot load) – may take up to

two minutes

Steady green The main CPU is operating normally OK

Steady red The main CPU is not responding Error

4.1.7 LEDs in the Ethernet connectors

Two LEDs are integrated into each Ethernet connector. The left LED will be illuminated when a

communication link is established and shows the speed (yellow = 100Mbit/sec, green =

1000Mbits/sec). The right LED (green) will be illuminated when a communication link is

established and will flicker depending on the traffic load.

DBS11011-12 Page 12/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

5 Operation of the non-modular compact SIU

Uni Rack Ethernet linkEthernet port

UR address and activity AC LED AC Breaker AC inlet

indicators

Serial I/F Analog I/F Digital I/F

Uni-rack with 16 analog interfaces

5.1 LEDs on the Uni-rack

5.1.1 AC LED

Indicates the power (AC) is present.

5.1.2 AC breaker

The AC breaker is a combination of a fuse and a manually operated switch, i.e. it can be used to

manually switch off the power source, but it will also pop out automatically if too much current is

drawn from the power source.

DBS11011-12 Page 13/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

5.1.3 Ethernet link and activity indicators

The LINK LED (right) will be illuminated (yellow) when a communication link is established to the

DAU. The ACT LED (left) will flicker (green) depending on the traffic load.

5.1.4 UR address

Must be set to “0” for the first SIU and “1” for an additional second SIU.

DBS11011-12 Page 14/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

6 Operation of the modular SIU

Module Rack

MR address Ethernet Link indications AC LED AC Breaker AC inlet

ports for slots

Serial I/F Analog I/F Digital I/F

module module modules

Module Rack with six modules

6.1 LEDs on Module Rack

6.1.1 AC LED

Indicates the power (AC) is present.

6.1.2 Link indications

Indicates that the Module Rack has detected a module in the corresponding slot.

6.1.3 AC breaker

The AC breaker is a combination of a fuse and a manually operated switch, i.e. it can be used to

manually switch off the power source but it will also pop out automatically if too much current is

drawn from the power source.

DBS11011-12 Page 15/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

6.1.4 LEDs in the Ethernet connector

Two LEDs are integrated into each Ethernet connect. The right LED (yellow) will be illuminated

when a communication link is established to the DAU. The LED will flicker depending on the

traffic load. The left LED is not used. Please notice that the behavior of the LEDs is different from

other parts of the system for example the DAU.

6.1.5 Allocation of system labels for digital interfaces

Card number in VDR Interface number in VDR

configuration configuration and VDR

Explorer

Digital I/F module in Slot 3 1 DI00 – DI15

Digital I/F module in Slot 4 2 DI16 – DI31

Digital I/F module in Slot 5 3 DI32 – DI47

Digital I/F module in Slot 6 4 DI48 – DI63

6.1.6 MR address

Must be set to “0” for the first SIU and “1” for an additional second SIU.

DBS11011-12 Page 16/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

7 Operation of standard RVI 02-004 and RVI 02-004D (PoE)

The DM100 will normally use an RVI 02-004 and RVI 02-004D for image capture. Another type

exists (see section 7.1) which may be used if the “Power over Ethernet” ports on the DPU are used

for other purposes.

RVI 02-004

RVI 02-004D

RVI address:

Must be set to “0”

for the first RVI and Ethernet link and speed Ethernet link and activity Ethernet port with PoE

“1” for a second RVI (Yellow) (Green)

RVI 02-004(D) rear panel

DBS11011-12 Page 17/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

7.1 Operation of RVI with AC power supply

This type is only used if the “Power over Ethernet” ports on the DPU are being used for other

purposes.

RVI address Ethernet port ST LED AC inlet Video I/F module

7.1.1 RVI address

Must be set to “0” for the first RVI and “1” for a second RVI.

7.1.2 Ethernet ports

ETH A must be connected to the DAU. Note that the LEDs in the Ethernet connectors (RJ45) are

inactive for this unit.

7.1.3 ST LED

The Status LED (Yellow) will flash (1Hz) after power on and then become steady if a

communication link is established to the DAU. The LED will always be switched off after one

minute.

DBS11011-12 Page 18/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

8 Error codes

Error codes and messages will be displayed by the BCP.

8.1 Error codes

004 SYSTEM The VDR has encountered an unrecoverable system error. Reboot

FATAL ERROR the system. If the error persists, the most probable cause is a

defective CPU board or defective system RAM

036 CONFIG The VDR was unable to save the configuration. Please retry. This

Unable to save error is only expected to occur during configuration (installation) of

the system

042 CONFIG The VDR is unable to find any configuration at all. Replace the

Configuration failed compact flash in the DPU (a properly made boot flash contains a

default configuration from which the system can start). Restore a

backup of the configuration.

054 ALARM The system is running on battery. Both the main power and the

Running on battery emergency power are absent. If there is a general power failure on

the vessel, ignore this message; otherwise check the power supply

in the DAU. Consult section 4 for details.

056 AUDIO The microphone test failed. Force a microphone test (this is a

Microphones failed feature on the BCP). This test will reveal which microphone is

causing the problem. Check that the “BMU active” checkbox is

unchecked for non-existing microphones. Check the cable for

microphone(s) reported as faulty. Test the inputs on the audio

interface module with a spare microphone. Replace microphones

which are reported faulty if no other error is discovered.

058 AUDIO One or more microphones are using too much power. The cabling

Power short circuit and microphones must be checked.

060 STATUS The system is not receiving UTC from the GPS. Check that GPS is

UTC timeout on. Check the signal from the GPS (use serial monitor in VDR

explorer, WEB status or VGA status display). If no signal is

present check the cable otherwise check that the configuration has

been done correctly.

070 PSU The communication between the power supply circuit and the main

Communication failed CPU in the DPU has been interrupted. If the error persists, the DPU

is probably defective.

074 SERIAL module 1 The serial data interface module on the SAP board in the DPU

Missing (SI00-07) cannot be detected. If the error persists, the DPU is probably

defective.

076 VIDEO module 1 VIDEO module 1 cannot be detected. The most probable cause is

Missing (VD01-02) that the cable to the RVI from the DPU is disconnected or the RVI

is defective. In addition, for an AC powered RVI: Power to the RVI

is switched off, the internal Ethernet cable in the RVI is

disconnected or the video interface module is defective.

078 AUDIO module 1 The audio data interface module on the SAP board in the DPU

Missing (MIC1-AUD5) cannot be detected. If the error persists, the DPU is probably

defective.

DBS11011-12 Page 19/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

081 NETWORK IMAGE More than one source (e.g. an ECDIS) is sending images with the

Duplicate Location same Location ID. Inspecting the received images using the

monitor tool in the VDR configurator may help. Check the setup of

sources which are sending images to the VDR

083 NETWORK IMAGE A source (e.g. an ECDIS) is sending images with “Location ID”

From 'new' Location marked as ‘new’, i.e. the source has not been configured correctly

yet. Inspecting the received images using the monitor tool in the

VDR configurator may help locate the source.

087 IMAGE The combined size of the received images exceeds the allocated

Too big images space in a record. Use the “Analysis of recorded data” utility on the

BCP or in the configurator tool to determine the cause. If the

problem relates to image data, carry out an OPT and check the

recorded images.

089 VIDEO The radar image does not have the size defined in the

091 VD0n wrong size configuration. Check the size of the image from the radar. If

093 correct, check calibration and settings for the video channel.

095

096 Not configured The VDR has started up using the default configuration. Configure

Configure VDR the system correctly. The VDR is unable to operate correctly using

the default configuration since at least the GPS antenna position

and vessel ID must be entered.

108 VIDEO module 1 The VDR could not detect the video module in RVI#1 following

Not started system startup. The most probable cause is that the power to the

RVI is switched off, the cable to the RVI from the DPU is

disconnected, the internal Ethernet cable in the RVI is disconnected

or the video interface module is defective.

110 AUDIO module 1 The audio data interface module on the SAP board in the DPU

Not started cannot be detected following system startup. If the error persists,

the DPU is probably defective.

112 SERIAL module 1 The serial data interface module on the SAP board in the DPU

Not started cannot be detected following system startup. If the error persists,

the DPU is probably defective.

117 PSU battery The battery switch on the front of the DPU is in the “OFF”

Battery switch “OFF” position.

118 PSU battery The power supply is unable to detect the battery pack. Check that

Not present the battery pack is connected to the DPU. If the error persists for

more than five minutes, the batteries are probably defective.

120 PSU battery The charger was unable to fully charge the battery within a pre-

Could not be charged defined time. Switch the battery switch on the DPU “OFF” briefly

and then “ON”. If the error returns (this may take 18 hours), the

battery pack is defective and must be replaced.

124 PSU The output voltage from the battery pack has dropped below 16V.

Low output voltage This message will appear shortly before the battery is discharged

when the VDR is operating from the battery only. This message

will not appear if the battery pack is new and was fully charged,

since the VDR will power down automatically after two hours

when operating from the batteries (well before the voltage drops

below 16V).

DBS11011-12 Page 20/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

If AC power is present (and the AC fuse/breaker is pushed) while

this error is displayed, the DPU must be repaired.

128 AUDIO module 2 This will only happen if audio module 2 (the Remote Audio

Missing (AUD6) Interface) is enabled in the VDR configuration. Check the cable to

the Remote Audio Interface.

130 xxxxxx xxxxxx = SERIAL, VIDEO, AUDIO

132 Module duplicate Two modules with identical system locations have been detected.

134 Restart the system. If the error persists, check the installation and

the VDR configuration.

136 xxxxxx xxxxxx = SERIAL, ANALOG, DIGITAL, VIDEO, AUDIO

138 Wrong rack type A module is located in a rack (DPU, SIU or RVI) where it is not

140 supposed to be. Check the installation.

142

144

146 AUDIO module 2 This will only happen if audio module 2 (the Remote Audio

Not started Interface) is enabled in the VDR configuration. Check the cable to

the Remote Audio Interface.

148 SERIAL The VDR configuration is not consistent with the physical

Module in wrong slot configuration of the VDR; for example, an additional serial module

is not installed in the slot which is specified in the VDR

configuration.

150 AUDIO The VDR configuration is not consistent with the physical

Module in wrong slot configuration of the VDR; for example, the additional remote audio

interface is not connected to the port on the DPU which is specified

in the VDR configuration.

152 VIDEO The VDR configuration is not consistent with the physical

Module in wrong slot configuration of the VDR; for example, the additional remote video

interface is not connected to the port on the DPU which is specified

in the VDR configuration.

160 EXTERNAL BACKUP The system is unable to record data to the extended external backup

Not recording disk (NAS). If no other relevant errors e.g. #162 are displayed, the

NAS is probably defective.

162 EXTERNAL BACKUP The communication to the extended external backup disk (NAS)

Cannot find has been interrupted. Check that the extended external backup disk

is installed correctly (e.g. is the LAN cable connected to DPU).

Reboot system. If the error persists, the most probable cause is a

defective/misconfigured NAS.

172 NETWORK Data Too much network data is being transmitted to the VDR. Network

Accumulated Excess data in this context does not include image data. Try to determine

what is wrong using the VDR Explorer i.e. check what is received

on NI200 – NI215

180 SYSTEM The VDR is in service mode. It is possible to make changes to the

In Service Mode VDR configuration. When this is done, the mode switch on the

DPU front must be set to position “Normal operation”.

182 BCP The DPU is unable to communicate with the Bridge Control Panel.

Communication error Check the cable from the DPU to the BCP. Reboot the system. If

the error persists, the most probable cause is a faulty cable or BCP.

184 ALARM The communication to the Bridge Alert Management system has

DBS11011-12 Page 21/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

BAM comm. timeout been interrupted.

190 DPU The primary fan in the DPU has failed. The secondary fan in DPU

CPU fan failed will serve as a backup until the problem is rectified. The VDR will

be able to operate normally unless the secondary fan also fails

(error 191). This problem must be rectified latest at the next APT.

191 DPU The secondary fan in the right side of the DPU has failed. This is

Backup fan failed only a major problem if also the primary fan has failed (error 190).

300- SERIAL Mandatory serial data is not received. Check that the source is on.

307 Timeout on SIxx Check the signal from the source (serial monitor in VDR explorer,

WEB status or VGA status display). If no signal is present check

the cable and make sure that the configuration is correct.

320- NETWORK Channel Mandatory network data is not received on channel NI2xx. Check

335 Timeout on NI2xx that the source is switched on and active, check the cable and that

the VDR configuration is correct.

360- NETWORK Channel Too much network data is currently received on channel NI2xx.

375 Excess Data on NI2xx Check that the source is operating correctly. The VDR Explorer

may be used to monitor the data.

400- SERIAL Mandatory serial data is not received. Check that the source is on.

423 Timeout on SIxx Check the signal from the source (serial monitor in VDR explorer,

WEB status or VGA status display). If no signal is present check

the cable and make sure that the configuration is correct.

441 SERIAL module 2 For a DM100, the second serial module is integrated on the SAP

Missing (SI08-12) board in the DPU. The most probable cause is that the SAP board

in the DPU is defective.

442 ANALOG module 1 If only one module is affected:

Missing (AN00-15) A module has been removed or has failed. Check that the module is

443 DIGITAL module 1 installed correctly.

Missing (DI00-15)

444 DIGITAL module 2 If installed in a modular SIU the blue “link” LED for the module

Missing (DI16-31) must be illuminated. If the LED is already illuminated switch the

445 DIGITAL module 3 power to the SIU off and on. If the error persists replace the

Missing (DI32-47) module.

446 DIGITAL module 4

Missing (DI48-63) If all modules in a SIU are affected:

Check the power to the SIU.

Check the cable from the SIU to the DAU and link status; see

section 4.1.7, 5.1.3 and 6.1.4.

If no error is found, try to restart both the DAU and the SIU (power

off and then on)

If the error persists, the DPU or the Module rack/Uni rack is

probably defective.

450- SIU xxxxxxx xxxxxxx = SERIAL, ANALOG, DIGITAL

452 Module in wrong slot A module has been misplaced. Modules must be installed

according to the VDR configuration.

460- SIU xxxxxxx xxxxxxx = SERIAL, ANALOG, DIGITAL

462 Wrong MR address A SIU with the wrong Module Rack address has been detected. Set

the MR/UR address to 0 or 1. See section 6.1.6

470- SIU xxxxxx xxxxxxx = SERIAL, ANALOG, DIGITAL

472 Module duplicate The VDR has detected two different modules with the same

MR/UR address and slot number. This may occur if two SIUs are

DBS11011-12 Page 22/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

connected to the DAU, with the same address.

480 VIDEO Recording of radar images to the FRM has been disabled which is

Illegal settings unacceptable for a VDR installation. The system configuration

must be changed, consult the Installation Manual.

482 VIDEO module 2 VIDEO module 2 cannot be detected. The most probable cause is

Missing (VD03-04) that that the cable to the RVI from the DPU is disconnected or the

RVI is defective. In addition, for an AC powered RVI: Power to the

RVI is switched off, the internal Ethernet cable in the RVI is

disconnected or the video interface module is defective.

484 RVI VIDEO An AC powered RVI with incorrect RVI address has been detected.

Wrong RVI address The RVI address must be 0 or 1. All RVIs connected to the VDR

must be setup in the VDR configuration.

500 ANALOG module 2 If only one module is affected:

Missing (AN16-31) A module has been removed or has failed. Check that the module is

501 DIGITAL module 5

Missing (DI64-79) installed correctly.

502 DIGITAL module 6 If installed in a modular SIU, the blue “link” LED for the module

Missing (DI80-95) must be illuminated. If the LED is already illuminated switch the

503 DIGITAL module 7 power to the SIU off and on. If the error persists replace the

Missing (DI96-111) module.

504 DIGITAL module 8

Missing (DI112-127) If all modules in a SIU are affected:

505 SERIAL module 3 Check the power to the SIU.

Missing (SI16-23) Check the cable from the SIU to the DAU and link status; see

506 SERIAL module 4 section 4.1.7, 5.1.3 and 6.1.4.

Missing (SI24-31) If no error is found, try to restart both the DAU and the SIU (power

off and then on)

If the error persists, the DPU or the Module rack/Uni rack is

probably defective.

550 STORAGE One or more types of data have not been recorded. If the error

Dataset incomplete persists then restart the VDR. Authorized service of the VDR is

required if this error still persists.

580 NETWORK IMAGE The network image processor in the DPU cannot be detected. If the

Missing (VD01-VD08) error persists, the most probable cause is that the network image

processor in the DPU is defective, i.e. the DPU must be repaired.

581- IMAGE No images are currently recorded on channel VDxx. Check the

588 VDxx no input image source and the cable. Enter the image calibration menu for

that channel and examine the image. Unused image channels must

be configured as inactive (the “Active” parameter must be

unchecked).

591- IMAGE The image recorded on channel VDxx exceeds the allocated space

598 VDxx image too large in the capsule. Check the video image for noise. Check the

calibration of the video channel. Check that “Image Format” in the

VDR configuration is set to PNG. Reduce the number "color mask

bits" if necessary.

701 CAPSULE The VDR is unable to record data to the fixed capsule. Another

Not recording error explaining why (e.g. #702 CAPSULE Cannot find) is

normally displayed in advance. Try to fix the preceding error.

Otherwise reboot the system.

DBS11011-12 Page 23/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

702 CAPSULE The VDR is unable to detect a fixed capsule. Check that the fixed

Cannot find capsule is connected correctly. If the error persists, the fixed

capsule is probably defective.

703 CAPSULE The VDR has detected a fixed capsule but is unable to get access to

Cannot access the memory. If the error persists, the fixed capsule is probably

defective.

704 CAPSULE, too many Too many write-errors (writing to the fixed capsule) have been

write errors detected by the DPU over a period of time. The most likely cause is

communication problems. Check the cable from the DPU to the

fixed capsule.

705 CAPSULE, too many Too many write-errors (writing to the FRM memory) have been

write errors detected by the fixed capsule over a period of time. The most likely

cause is serious communication problems or a defective fixed

capsule.

706 CAPSULE, too many Too many read-errors (reading back data from the fixed capsule)

read errors have been detected by the DAU over a period of time. The VDR

was unable to write and verify data despite several attempts. The

most likely cause is serious communication problems or a defective

fixed capsule.

707 CAPSULE, too many Too many read-errors (reading back data from the fixed capsule)

read errors have been detected by the fixed capsule over a period of time. The

VDR was unable to write data despite several attempts. The most

likely cause is serious communication problems or a defective

fixed capsule.

708 CAPSULE The VDR found too many data errors within a given interval when

Verification failed verifying the data written to the fixed capsule. The fixed capsule is

probably defective.

709 CAPSULE The amount of data collected for a 15-second period exceeds the

Record too big maximum allowed size for the fixed capsule. This is typically

caused by receipt of too much image data. Use the “Analysis of

recorded data” utility on the BCP or in the configurator tool to

determine the cause. If the problem relates to image data, carry out

an OPT and check the recorded images.

710 CAPSULE The amount of data received by the VDR exceeds the capacity of

Record-data too big the fixed capsule. This is typically caused by receipt of too much

image data. Use the “Analysis of recorded data” utility on the BCP

or in the configurator tool to determine the cause. If the problem

relates to image data, carry out an OPT and check the recorded

images.

721 FLOAT-FREE The VDR is unable to record data to the float-free capsule. Another

Not recording error explaining why (e.g. #722 FLOAT-FREE Cannot find) is

normally displayed in advance. Try to fix the preceding error,

otherwise reboot the system.

722 FLOAT-FREE The VDR is unable to detect the float-free capsule. Check that the

Cannot find float-free capsule is connected correctly. If the error persists, the

float-free capsule is probably defective.

723 FLOAT-FREE The VDR has detected a float-free capsule but is unable to get

Cannot access access to the memory. If the error persists, the float-free capsule is

DBS11011-12 Page 24/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

probably defective.

724 FLOAT-FREE, too many Too many write-errors (writing to the float-free capsule) have been

write errors detected by the DPU over a period of time. The most likely cause is

communication problems. Check the cable from the DPU to the

float-free capsule.

725 FLOAT-FREE, too many Too many write-errors (writing to the FRM memory) have been

write errors detected by the float-free capsule over a period of time. The most

likely cause is serious communication problems or a defective

float-free capsule.

726 FLOAT-FREE, too many Too many read-errors (reading back data from the float-free

read errors capsule) have been detected by the DPU over a period of time. The

VDR was unable to write and verify data despite several attempts.

The most likely cause is serious communication problems or a

defective float-free capsule.

727 FLOAT-FREE, too many Too many read-errors (reading back from the memory) have been

read errors detected by the float-free capsule over a period of time. The VDR

was unable to read back data despite several attempts. The most

likely cause is serious communication problems or a defective

float-free capsule.

728 FLOAT-FREE The VDR found too many data errors within a given interval when

Verification failed verifying the data written to the float-free capsule.

729 FLOAT-FREE The amount of data collected for a 15-second period exceeds the

Record too big maximum allowed size for the float-free capsule. This is typically

caused by receipt of too much image data. Use the “Analysis of

recorded data” utility on the BCP or in the configurator tool to

determine the cause. If the problem relates to image data, carry out

an OPT and check the recorded images.

730 FLOAT-FREE The amount of data received by the VDR has exceeded the capacity

Record-data too big of the float-free capsule. This is typically caused by receipt of too

much image data. Use the “Analysis of recorded data” utility on the

BCP or in the configurator tool to determine the cause. If the

problem relates to image data, carry out an OPT and check the

recorded images.

741 LONG-TERM The VDR is unable to utilize the VDR data disk for the long term

Not recording recording. Another error explaining why (e.g. #742 LONG-TERM

Cannot find) is normally displayed in advance. Try to reboot

system. If the error persists, the DPU is probably defective.

742 LONG-TERM The VDR is unable to detect the VDR data disk or utilize the disk

Cannot find for long term recording. Try to reboot system. If the error persists,

the DPU is probably defective

743 LONG-TERM The VDR has detected the VDR data disk but is unable utilize the

Cannot access disk. If the error persists, the disk is probably defective.

744 LONG-TERM, too many Too many write-errors (writing to the VDR data disk) have been

write errors detected by the DPU over a period of time. The most likely cause is

an internal problem in the DPU. If the error persists, the DPU must

be repaired.

745 LONG-TERM, too many Too many write-errors (writing to the VDR data disk) have been

write errors detected by the DPU over a period of time. The most likely cause is

DBS11011-12 Page 25/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

a defective VDR data disk (i.e. the SDD inside the DPU). If the

error persists, the DPU must be repaired.

746 LONG-TERM, too many Too many read-errors (reading back data from the VDR data disk)

read errors have been detected by the over a period of time. The VDR was

unable to read back data despite several attempts. The most likely

cause is an internal problem in the DPU. If the error persists, the

DPU must be repaired.

747 LONG-TERM, too many Too many read-errors (reading back data from the VDR data disk)

read errors have been detected by the long-term disk over a period of time. The

VDR was unable to read back data despite several attempts. The

most likely cause is a defective VDR data disk (i.e. the SDD inside

the DPU). If the error persists, the DPU must be repaired.

748 LONG-TERM The VDR found too many data errors within a given interval when

Verification failed verifying the data written to the VDR data disk.

749 LONG-TERM The amount of data collected for a 15-second period has exceeded

Record too big the maximum allowed size for the VDR data disk. This is typically

caused by receipt of too much image data. Use the “Analysis of

recorded data” utility on the BCP or in the configurator tool to

determine the cause. If the problem relates to image data, carry out

an OPT and check the recorded images.

750 LONG-TERM The amount of data received by the VDR exceeds the capacity of

Record-data too big the VDR data disk. This is typically caused by receipt of too much

image data. Use the “Analysis of recorded data” utility on the BCP

or in the configurator tool to determine the cause. If the problem

relates to image data, carry out an OPT and check the recorded

images.

901- SYSTEM FAILURE The software is not working properly. Restart the VDR and report

933 ERROR 901-933 this error if it is repeated.

970 SELF-TEST The amount of RAM is insufficient to start the VDR. Restart the

RAM size xxx MB, system, if the error persists then call for assistance.

Should be >= yyy MB

971 SELF-TEST Required networking interfaces are not available to start the VDR.

xx network interfaces Restart the system, if the error persists then call for assistance.

found, 4 required

972 SELF-TEST Required Video (VGA) circuitry could not be initialized. Restart

Failed to initialize the system, if the error persists then call for assistance

VGA

983 No communication The BCP has never been able to communicate with the DPU. The

to DPU most probable cause is a defective cable or that the VDR did not

boot up correctly.

984 No communication The initial communication was functional but the communication

to DPU has failed at some point. The most probable cause is that the VDR

has encountered a system error and completely stopped. Restart the

VDR. If the error persists, the DPU is probably defective.

DBS11011-12 Page 26/27

Operator's Manual for the DM100-2014 VDR

Copyright Danelec Marine A/S

9 Service and maintenance

The VDR requires an annual performance test carried out by a certified service organization. Please

refer to “Installation Manual for DM100-2014 VDR” for further details.

9.1 Verification of the VDR functionality following service on any

sensor

It is a requirement of the VDR standard that the functionality of the VDR is verified following

service on any sensor (e.g. the GPS) connected to the VDR. A self-test (Operational Performance

Test) may be started from the BCP, see section 3.1.2.

9.2 List of most common spare parts

P/N Description

1302116 Uni Rack UR 06-002 - 8ch analog

1302358 RVI with PoE (for DM100) 2 x 5 x BNC

1302365 RVI with PoE (for DM100) 2 x DVI-I

1302373 MK4 capsule with cradle, beacon and 50m cable

1302379 VDR Bridge Control Panel BCP

1302389 MK1 float-free capsule with 50m cable and junction box

1302646 BMU 003 - Bridge Microphone Unit Indoor, BMU-I 2014

1302647 BMU 004 - Bridge Microphone Unit Outdoor, BMU-O 2014

1302662 Cradle for MK4 capsule

1302726 DM100 DPU, DPU 100-01

2302807 Ethernet Interface for Capsule MK4 - assembled PCB

2302731 Set of fans (2) for DPU 100-01 (spare part)

2302786 Battery pack and fans(2) for DPU 100-01 (spare part)

3000671 Beacon replacement kit

3302519 50m zero halogen FTP CAT5 cable w. RJ45 and Wago for capsule MK4 and FF MK1

7302532 Boot flash for DM100-2014 VDR

9302376 Manual for compact Sensor Interface Unit (hard copy and CD)

9302719 Set of manuals for the DM100-2014 VDR (Hardcopy and CD)

DBS11011-12 Page 27/27

Potrebbero piacerti anche

- CMZ700 Yokogawa GyroDocumento84 pagineCMZ700 Yokogawa GyroAdi Prasetyo89% (9)

- Anthea - Service ManualDocumento19 pagineAnthea - Service Manualakhil100% (1)

- Apt - SVDR 3000Documento5 pagineApt - SVDR 3000hmmbaconNessuna valutazione finora

- Installation Manual DM800 ECDIS G2Documento67 pagineInstallation Manual DM800 ECDIS G2BeneDict Ben D100% (1)

- Nt920ahr Mkii ManualDocumento14 pagineNt920ahr Mkii ManualKuang Ah HockNessuna valutazione finora

- JUE-85 SSAS Option Operation Manual 7ZPSC0201Documento48 pagineJUE-85 SSAS Option Operation Manual 7ZPSC0201Adi Prasetyo40% (5)

- Installation Manual: VDR Voyage Master II, III and IVDocumento28 pagineInstallation Manual: VDR Voyage Master II, III and IVJay Sanchaniya100% (1)

- Radar Manual STN ATLASDocumento122 pagineRadar Manual STN ATLAScozdim86% (7)

- DBS10885-10 Installation Manaul For DM100 S-VDR PDFDocumento93 pagineDBS10885-10 Installation Manaul For DM100 S-VDR PDFSergey100% (1)

- Standart 20-22 Instalation ManualDocumento247 pagineStandart 20-22 Instalation ManualСергей Бородин100% (1)

- Service Parts Supply Status List For Discontinued Models As of 15 Nov 2012Documento3 pagineService Parts Supply Status List For Discontinued Models As of 15 Nov 2012Afrizal SetiawanNessuna valutazione finora

- SAILOR 6120 Installation ManualDocumento116 pagineSAILOR 6120 Installation ManualFernando Rebolo100% (1)

- Samyung SRG-3150DN+Instruction+ManualDocumento57 pagineSamyung SRG-3150DN+Instruction+ManualKuang Ah Hock100% (2)

- MRTS 7M Manual en v5.6.2Documento85 pagineMRTS 7M Manual en v5.6.2ИгорьNessuna valutazione finora

- Felcom 18 - 19 SSAS Manual PDFDocumento34 pagineFelcom 18 - 19 SSAS Manual PDFGeta EnacheNessuna valutazione finora

- JHS 32BInstruction ManualDocumento152 pagineJHS 32BInstruction Manualnavyeye100% (1)

- NW4000-10 VDR Ships and Operators Instruction Manual V 2.1.5Documento185 pagineNW4000-10 VDR Ships and Operators Instruction Manual V 2.1.5python0202Nessuna valutazione finora

- JAN-701B, 901B Installation ManualDocumento140 pagineJAN-701B, 901B Installation ManualAdi Prasetyo100% (2)

- Maris Navico Manuals ECDIS900 Users Guide Rel LDocumento309 pagineMaris Navico Manuals ECDIS900 Users Guide Rel LAdi PrasetyoNessuna valutazione finora

- A2 38+thermal+modellingDocumento57 pagineA2 38+thermal+modellingblem_0075Nessuna valutazione finora

- B737 3 ATA 27 L3 eDocumento296 pagineB737 3 ATA 27 L3 eAnonymous afPplXbc100% (2)

- Installation Manual RVIDocumento9 pagineInstallation Manual RVISachin SikkaNessuna valutazione finora

- RT4822 VHF-DSC Installation Manual: SailorDocumento20 pagineRT4822 VHF-DSC Installation Manual: Sailorvuhoan84Nessuna valutazione finora

- 7080 HandbookDocumento139 pagine7080 Handbookdony prabuNessuna valutazione finora

- Installation Manual For DM100Documento119 pagineInstallation Manual For DM100joaofelipe.msNessuna valutazione finora

- 707094E0, VDR Users ManualDocumento33 pagine707094E0, VDR Users Manualdidou135067% (3)

- JMA 9900 InstructionDocumento404 pagineJMA 9900 InstructionConstantinos Peppas100% (1)

- Headway VDRDocumento68 pagineHeadway VDRMahfooz AliNessuna valutazione finora

- Furuno Felcom 18 Installation ManualDocumento60 pagineFuruno Felcom 18 Installation ManualtariktunadNessuna valutazione finora

- Rutter VDR-100 G2 - G3 Diagnostic Checklist - Rev 8.0 PDFDocumento11 pagineRutter VDR-100 G2 - G3 Diagnostic Checklist - Rev 8.0 PDFajc2_1984100% (1)

- ED3051G532 Radar+Chartradar+Conning+Trackpilot 1100Documento340 pagineED3051G532 Radar+Chartradar+Conning+Trackpilot 1100Sergey RadzivonNessuna valutazione finora

- Radarpilot 1100Documento7 pagineRadarpilot 1100ioannides_christos100% (1)

- SVDR-Pro Installation 071015 Rev.1.2Documento76 pagineSVDR-Pro Installation 071015 Rev.1.2lollardNessuna valutazione finora

- Furuno Fa-150 InstallationDocumento57 pagineFuruno Fa-150 Installationpython0202Nessuna valutazione finora

- Master - Reset Yokogawa EML-500Documento1 paginaMaster - Reset Yokogawa EML-500Rodrigo VelosoNessuna valutazione finora

- DBS9200336 - Service Manual For Capsule and Backup Disc PDFDocumento14 pagineDBS9200336 - Service Manual For Capsule and Backup Disc PDFSergeyNessuna valutazione finora

- C-Plath 4000 Autopilot OperationDocumento142 pagineC-Plath 4000 Autopilot OperationPhilAustinNessuna valutazione finora

- Abcdef: Meridian Gyrocompass System ManualDocumento82 pagineAbcdef: Meridian Gyrocompass System ManualMorseunited100% (5)

- Furuno RadarDocumento195 pagineFuruno RadarПавел СубботинNessuna valutazione finora

- 98-130890-d Installation Manual Sailor 6300 MF-HF DSC 150w-150w Fcc-250w-500wDocumento80 pagine98-130890-d Installation Manual Sailor 6300 MF-HF DSC 150w-150w Fcc-250w-500wleo.wainer100% (1)

- User's Manual: D/S Repeater Converter MKC106ADocumento18 pagineUser's Manual: D/S Repeater Converter MKC106AAdi PrasetyoNessuna valutazione finora

- Password: Remarks Password Remarks Password C. Operation Unit Master Compass Code NoDocumento1 paginaPassword: Remarks Password Remarks Password C. Operation Unit Master Compass Code Noueg liepajaNessuna valutazione finora

- Navigat X MK2 ManualDocumento96 pagineNavigat X MK2 ManualNikola Kolev100% (3)

- 5.4 UAIS DEBEG 3400, Setting-to-Work and Configuration: Section 5.4.1 5.4.2 5.4.3Documento4 pagine5.4 UAIS DEBEG 3400, Setting-to-Work and Configuration: Section 5.4.1 5.4.2 5.4.3Balasaheb AdhalraoNessuna valutazione finora

- NavNet Service Manual B 7 19 2002 PDFDocumento296 pagineNavNet Service Manual B 7 19 2002 PDFErvin Luka TodiNessuna valutazione finora

- JMA-9100 Instruction ManualDocumento572 pagineJMA-9100 Instruction ManualLa DewaNessuna valutazione finora

- Jma9133sa PDFDocumento316 pagineJma9133sa PDFArlindo J LopesNessuna valutazione finora

- Samyung SRG 3150DN Instruction ManualDocumento57 pagineSamyung SRG 3150DN Instruction Manualradam100% (3)

- Maintenance Manual Maintenance Manual Maintenance Manual Maintenance ManualDocumento102 pagineMaintenance Manual Maintenance Manual Maintenance Manual Maintenance ManualЮрий. Б0% (1)

- 11 - NautoAlarm Serv - Man ++Documento22 pagine11 - NautoAlarm Serv - Man ++MariosNessuna valutazione finora

- E900 V2 Level 300 2018 PDFDocumento161 pagineE900 V2 Level 300 2018 PDFahmedshirazarNessuna valutazione finora

- Headway HMT-100 Operation ManualDocumento31 pagineHeadway HMT-100 Operation ManualTom MaboetieNessuna valutazione finora

- HMD h2326s (FDS) Final & Manual (LFFS) - 130902Documento163 pagineHMD h2326s (FDS) Final & Manual (LFFS) - 130902tosveNessuna valutazione finora

- 3027 Installation MZ v4Documento87 pagine3027 Installation MZ v4EvgeniiNessuna valutazione finora

- SIMRAD SAL R1a Installation ManualDocumento30 pagineSIMRAD SAL R1a Installation ManualPalaKhartikeyanNessuna valutazione finora

- 6301 MF HF User ManualDocumento74 pagine6301 MF HF User ManualHan Jum Kuang50% (2)

- DBS11010-12 Inspector's and Authoritie's ManualDocumento26 pagineDBS11010-12 Inspector's and Authoritie's Manualartur.damascenoNessuna valutazione finora

- Inspector's and Authorities' Manual - DBS11010-30Documento27 pagineInspector's and Authorities' Manual - DBS11010-30Akhil ViswanathanNessuna valutazione finora

- dm100 SVDRDocumento36 paginedm100 SVDRmehdi moghimiNessuna valutazione finora

- VDR DANELEC Operator ManualDocumento31 pagineVDR DANELEC Operator ManualDmytro OparivskyNessuna valutazione finora

- Inspectors and Authorities MannualDocumento20 pagineInspectors and Authorities MannualHenry DengNessuna valutazione finora

- Operators Manual Danelec VDR DM200-DM500Documento42 pagineOperators Manual Danelec VDR DM200-DM500Adi Prasetyo50% (2)

- Installation Mannual DM500 Remote Video InterfaceDocumento9 pagineInstallation Mannual DM500 Remote Video InterfaceHenry DengNessuna valutazione finora

- Distribution Unit 138-118 Service ManualDocumento27 pagineDistribution Unit 138-118 Service ManualBeneDict Ben DNessuna valutazione finora

- Operator VDR Svdrdbs00328 30Documento42 pagineOperator VDR Svdrdbs00328 30Khusni Eka WardanaNessuna valutazione finora

- DBS 00317 Operators Manual For Voyage Master II S-VDR and VDRDocumento24 pagineDBS 00317 Operators Manual For Voyage Master II S-VDR and VDRpremkumar settiNessuna valutazione finora

- DBS00328-31A - Operators Manual DM200-DM500 PDFDocumento42 pagineDBS00328-31A - Operators Manual DM200-DM500 PDFAdi PrasetyoNessuna valutazione finora

- NFC-296 Antenna EarthDocumento1 paginaNFC-296 Antenna EarthAdi PrasetyoNessuna valutazione finora

- User Manual-Hardware Danelec ECDIS DM800 PDFDocumento20 pagineUser Manual-Hardware Danelec ECDIS DM800 PDFAdi PrasetyoNessuna valutazione finora

- PS Unit Replacement Procedures JSS296Documento10 paginePS Unit Replacement Procedures JSS296Adi PrasetyoNessuna valutazione finora

- Operator Manual: EnglishDocumento68 pagineOperator Manual: EnglishAdi PrasetyoNessuna valutazione finora

- Blue Power Charger and InverterDocumento1 paginaBlue Power Charger and InverterAdi PrasetyoNessuna valutazione finora

- Simrad Repeaters Instruction Manual PDFDocumento40 pagineSimrad Repeaters Instruction Manual PDFBeneDict Ben DNessuna valutazione finora

- TT98-120343-G TT3000SSA Installation ManualDocumento31 pagineTT98-120343-G TT3000SSA Installation ManualAdi PrasetyoNessuna valutazione finora

- ECDIS900 - Technical Manual Rel HDocumento63 pagineECDIS900 - Technical Manual Rel HAdi Prasetyo100% (1)

- DM-D100 Inst Oper Manual DL850 Dolog 2X Replacement PDFDocumento12 pagineDM-D100 Inst Oper Manual DL850 Dolog 2X Replacement PDFAdi PrasetyoNessuna valutazione finora

- ADE Improvement ProcedureDocumento49 pagineADE Improvement ProcedureAdi PrasetyoNessuna valutazione finora

- TT98-120343-G TT3000SSA Installation ManualDocumento84 pagineTT98-120343-G TT3000SSA Installation ManualZied Nasri100% (2)

- R3016 Sea Clutter AdjustDocumento1 paginaR3016 Sea Clutter AdjustAdi PrasetyoNessuna valutazione finora

- DBS00328-31A - Operators Manual DM200-DM500 PDFDocumento42 pagineDBS00328-31A - Operators Manual DM200-DM500 PDFAdi PrasetyoNessuna valutazione finora

- ArgusRadar SRT-Adapter-Box TM en 988-10610-001 WDocumento39 pagineArgusRadar SRT-Adapter-Box TM en 988-10610-001 WAdi PrasetyoNessuna valutazione finora

- 010-Sys Comp of EMDocumento16 pagine010-Sys Comp of EMAdi PrasetyoNessuna valutazione finora

- Canbus Installation GuideDocumento11 pagineCanbus Installation GuideAdi PrasetyoNessuna valutazione finora

- MA TAG-C User Manual E Rev 2.0Documento12 pagineMA TAG-C User Manual E Rev 2.0Adi PrasetyoNessuna valutazione finora

- User's Manual: D/S Repeater Converter MKC106ADocumento18 pagineUser's Manual: D/S Repeater Converter MKC106AAdi PrasetyoNessuna valutazione finora

- CSS Xband and OTHR Radars PDFDocumento2 pagineCSS Xband and OTHR Radars PDFAdi PrasetyoNessuna valutazione finora

- Operator Manual: EnglishDocumento48 pagineOperator Manual: EnglishAdi PrasetyoNessuna valutazione finora

- cmz700 BL e 1st PDFDocumento6 paginecmz700 BL e 1st PDFAdi PrasetyoNessuna valutazione finora

- Operator Manual: EnglishDocumento48 pagineOperator Manual: EnglishAdi PrasetyoNessuna valutazione finora

- JLN-550 Instruction ManualDocumento48 pagineJLN-550 Instruction ManualAdi Prasetyo100% (1)

- CSS XBand and OTHR RadarsDocumento2 pagineCSS XBand and OTHR RadarsAdi PrasetyoNessuna valutazione finora

- Artificial Intelligence Project IdeasDocumento2 pagineArtificial Intelligence Project IdeasRahul PatraNessuna valutazione finora

- Electricity ExamDocumento4 pagineElectricity Examjorolan.annabelleNessuna valutazione finora

- Is 13529 1992Documento9 pagineIs 13529 1992Arjun M KumarNessuna valutazione finora

- How Satellite TV WorksDocumento6 pagineHow Satellite TV WorksAlpesh ThesiyaNessuna valutazione finora

- 74AC74 - 74ACT74 Dual D-Type Positive Edge-Triggered Flip-FlopDocumento10 pagine74AC74 - 74ACT74 Dual D-Type Positive Edge-Triggered Flip-FlopserviciobsasNessuna valutazione finora

- SRN/ SEN15/ SEN25: General Electric HornsDocumento2 pagineSRN/ SEN15/ SEN25: General Electric HornsRigoberto GomezNessuna valutazione finora

- Telefon PokładowyDocumento20 pagineTelefon PokładowysimdowNessuna valutazione finora

- How To Call - and Answer - A CQDocumento22 pagineHow To Call - and Answer - A CQMike HammondsNessuna valutazione finora

- Lilley & Gillie MK 2000 CompassDocumento24 pagineLilley & Gillie MK 2000 Compassborisgolodenko50% (2)

- Infineon Board Assembly Recommendations WaferLevelBGA Package v05 00 enDocumento21 pagineInfineon Board Assembly Recommendations WaferLevelBGA Package v05 00 enDiego SantosNessuna valutazione finora

- Color TFT LCD Monitor: Operating Instruction Model No. AN5601BDocumento4 pagineColor TFT LCD Monitor: Operating Instruction Model No. AN5601BKyaw Kyaw WinNessuna valutazione finora

- Skripsi Tanpa Bab Pembahasan PDFDocumento65 pagineSkripsi Tanpa Bab Pembahasan PDFYusuf FauziNessuna valutazione finora

- Ir155-4210-V004 D00377 D Xxen PDFDocumento6 pagineIr155-4210-V004 D00377 D Xxen PDFNuno Castro PereiraNessuna valutazione finora

- Measuring SolubilityDocumento6 pagineMeasuring SolubilitydebNessuna valutazione finora

- HiPowerSpec - 100AH High Power CellDocumento14 pagineHiPowerSpec - 100AH High Power Celll4bmult123Nessuna valutazione finora

- 2 Transistor FM Voice TransmitterDocumento3 pagine2 Transistor FM Voice TransmitterImran SyedNessuna valutazione finora

- AS372 ManualDocumento54 pagineAS372 ManualskcindyNessuna valutazione finora

- Pelco Dome CCTV Camera ics090-CA8Documento6 paginePelco Dome CCTV Camera ics090-CA8Jamie DeltonNessuna valutazione finora

- Handbook On Predictive Maintenance Through Network of Data Loggers Ver2 PDFDocumento96 pagineHandbook On Predictive Maintenance Through Network of Data Loggers Ver2 PDFamarsingh choudharyNessuna valutazione finora

- Spectralert® Series: Horns, Strobes, and Horn/StrobesDocumento4 pagineSpectralert® Series: Horns, Strobes, and Horn/Strobesmechengineer3Nessuna valutazione finora

- Performance Improvement of Synchronous Generator by Stator WindingDocumento6 paginePerformance Improvement of Synchronous Generator by Stator WindingIAEME PublicationNessuna valutazione finora

- Electrical Loading Estimation WorkstageDocumento15 pagineElectrical Loading Estimation WorkstageansonchongNessuna valutazione finora

- FP 08825 m.2.0Documento2 pagineFP 08825 m.2.0alijazizaibNessuna valutazione finora

- JPX202 MDF User Manual V3.0Documento130 pagineJPX202 MDF User Manual V3.0SamuelNessuna valutazione finora

- 3 B6 LM I Service Manual For Frannacranes: Revisione 23/01/2002Documento36 pagine3 B6 LM I Service Manual For Frannacranes: Revisione 23/01/2002M RefaiNessuna valutazione finora

- Bluetooth 5.1 Dual Mode Module Datasheet Version 1.5: FSC-BT1026x DatasheetDocumento38 pagineBluetooth 5.1 Dual Mode Module Datasheet Version 1.5: FSC-BT1026x DatasheetJuliano RettoreNessuna valutazione finora

- GRAS Catalog 2013Documento100 pagineGRAS Catalog 2013Cuauhtzin Alejandro Rosales Peña AlfaroNessuna valutazione finora

- R5000 Power Supply Unit Installation Guide: DetailsDocumento2 pagineR5000 Power Supply Unit Installation Guide: DetailsVinesh NaikNessuna valutazione finora