Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Symed Labs LTD, Unit-IV, Nalgonda Dist - EXE SUM ENG PDF

Caricato da

jyothiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Symed Labs LTD, Unit-IV, Nalgonda Dist - EXE SUM ENG PDF

Caricato da

jyothiCopyright:

Formati disponibili

EXECUTIVE SUMMARY OF

DRAFT EIA REPORT

OF

M/s. SYMED LABS LIMITED, UNIT - IV.

FOR

Expansion of Existing Drug Intermediate

Manufacturing Unit to Bulk Drug &

Intermediate Manufacturing Unit

AT

SURVEY NOs.163,163/A,163/B,164/A,164/B & 167,

PITTAMPALLY VILLAGE, CHITYAL MANDAL,

NALGONDA DISTRICT, TELANGANA STATE,

PREPARED BY

Rightsource Industrial Solutions Pvt. Ltd

Plot No: 203, H.No:5-36/203, Prashanthi Nagar,

IDA, Kukatpally, Hyderabad – 500072.

Ph: 040-65873137, 23070602, 23075699, 40126589.

Fax: 040-23070602. Mail: info@rightsource.co.in

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

1. INTRODUCTION

M/s. Symed Labs Ltd. Unit - IV, is an established Drug Intermediates

manufacturing unit at Survey Nos.163/A & 164/A, Pittampally Village, Chityal

Mandal, Nalgonda District, Telangana State.

Existing plant is in 2.24 Acres (9064.88 SQM) and acquired an additional land of

11.08 Acres (44838.82 SQM-Survey Nos.163, 163/B, 164/B, &167) adjacent to the

existing land. Now, the total Land area is 13.32 Acres (53903.71 SQM) having

Survey Nos.163,163/A,163/B,164/A,164/B &167. The company wishes to modify

their Drug Intermediates manufacturing facility to Bulk Drug & Intermediates

manufacturing facility. The company wishes to manufacture the proposed products

by replacing existing products after expansion.

The company proposes to invest an additional amount of Rs.40.0 Crores towards its

modernization and pollution control equipment.

The proposal is to obtain Environmental Clearance from the Ministry of Environment,

Forests and Climate Change (MoEFCC) and Consent Orders from SPCB to

manufacture proposed products with a total production capacity of 102.25 T/Month.

Draft EIA report is prepared considering the Terms of Reference (ToR) issued by

MoEFCC vide F. No. J-11011/87/2014-IAII (I) Dated 21st October 2014 and

Amended TOR issued on 29-07-2015.

1.1. PROJECT DESCRIPTION

The salient features of the unit are furnished below.

TABLE-1: SALIENT FEATURES OF THE PROJECT

Project location Details

Name of the project M/s. Symed Labs Ltd. Unit - IV

Survey Nos: 163, 163/A, 163/B, 164/A,

Location of the project 164/B, &167, Pittampally Village, Chityal

Mandal, Nalgonda District, Telangana State.

Latitude: 170 12’28.38” North

Latitude & Longitude Longitude: 790 00’ 56.28” East

Land acquired for the plant 13.32 Acres (53903.71SQM)

Present Land use of the project site Existing Industrial Land

Nearest village Pittampally - 2.57 Kms (ENE)

Nearest Mandal Chityala - 10 Kms (ENE)

Major urban Settlements Hyderabad - 48 KMs (WNW)

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 1

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

National Highway NH-9 -

Nearest Highway (Hyderabad- Vijayawada) – 2.6 Kms (NNW)

Chityala Railway Station – 13 Kms (E)

Nearest Railway station

Rajiv Gandhi International Airport (Hyderabad) -

Nearest Airport 60 Kms (WNW)

Major Industries near the plant site Adarsh steel Pvt Ltd

Nosch Labs Pvt Ltd

Divis Laboratories Ltd

Water Bodies with in 10kms radius Kandala vagu - 2.62 Kms (SW)

Ramalingeshwara cheruvu - 3.3 Kms (NW)

Halia vagu - 4.4 Kms (WNW)

Jalu vagu - 4.7 Kms (SW)

Devuni cheruvu - 5.3 Kms (NW)

Chinna vagu - 6.3 Kms (S)

Pedda vagu - 9.7 Kms (S)

2.0 PROCESS DESCRIPTION

The manufacturing process of Bulk Drug & Intermediates consists of chemical

synthesis extending to stages of processing involving different type of chemical

reactions. Total production capacity of Existing is 109.2 TPA and Proposal will be

1227.0 TPA. (Given in Table - 2 & 3). The unit will take adequate control measures

for storage and handling of Raw materials, solvents and cylinders with in factory

premises.

TABLE- 2: EXISTING PRODUCTS AND QUANTITIES

Therapeutic Quantity In Quantity In

S. No Product Name CAS Number

Category Kg/Month Kg/Day

Epalrestat Intermediate

Drug

1 (2-Methyl-3-Phenyl- 5445-77-2 500.00 16.67

Intermediate

Propenal)

Linezolid Intermediate

(5-Aminomethyl-3-(3-

Drug 240.00

2 Fluoro-4-Morpholin-4- 168828-90-8 7200.00

Intermediate

Yl-Phenyl)-

Oxazolidin-2-One)

Mosapride Citrate

Dihydrate Intermediate

(4-Amino-5-Chloro-2-

112885-41-3 Drug

3 Ethoxy-N-[4-(4-Fluoro- 1644.00 54.80

Intermediate

Benzyl)-Morpholin

-2-Ylmethyl]-

Benzamide)

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 2

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Racecadotril

Intermediate

Drug

4 (2-Benzyl- Not available 1900.00 63.33

Intermediate

Acryloylamino)-Acetic

Acid Benzyl Ester)

Thalidomide

Intermediate

Drug

5 ( 2-(2, 6-Dioxo- 53602-85-0 500.00 16.67

Intermediate

Tetrahydro-Pyran-3-Yl)-

Isoindole-1, 3-Dione)

Total 9100.00 303.34

The industry is permitted to manufacture only two products at any given

point of time.

TABLE- 3: PROPOSED PRODUCTS AND QUANTITIES AFTER EXPANSION

Quantity

Quantity In

S. No Product Name CAS Number Therapeutic Category In

Kg/Day

MT/Month

1 Amisulpride 71675-85-9 Neuroleptic agent 1.00 33.33

2 Carbidopa 93357-67-6 Anti parkinsonian agent 4.00 133.33

3 Carvedilol 72956-09-3 Cardiovascular Agent 4.00 133.33

Carvedilol

4 610309-89-2 Antihypertensive agent 0.20 6.67

Phosphate

Cinitapride

5 Hydrogen 66564-14-5 Gastroprokinetic Agent 0.10 3.33

tartrate

Dapoxetine

6 129938-20-1 Antidepressant 1.00 33.33

Hydrochloride

7 Epalrestat 82159-09-9 Oral anti diabetic agent 3.00 100.00

Non barbiturate

8 Eszopiclone 138729-47-2 0.05 1.67

Hypnotic

9 Fluconazole 86386-73-4 Antifungal 6.00 200.00

10 Iron sucrose 8047-67-4 Iron supplement 20.00 666.67

Itopride

11 122892-31-3 Antiulcer 4.00 133.33

Hydrochloride

Ketorolac

12 74103-07-4 Antipyretic agent 8.00 266.67

Tromethamine

Levocetirizine

13 130018-87-0 Antihistamine agent 0.60 20.00

Dihydrochloride

14 Levosulpiride 23672-07-3 3.00 100.00

Antiemetic agent

15 Linezolid 165800-03-3 Antibiotic 18.00 600.00

Mosapride citrate

16 63582-62-2 Gastroprokinetic 4.00 133.33

dihydrate

Ondansetron

17 Hydrochloride 103639-04-9 Antiemetic 1.00 33.33

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 3

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

18 Pregabalin 148553-50-8 Neuropathic Pain Agent 10.00 333.33

19 Racecadotril 81110-73-8 Anti diarrheals 6.00 200.00

Tamsulosin

20 106463-17-6 Anti-adrenergic 0.10 3.33

Hydrochloride

Tizanidine

21 64461-82-1 Skeletal muscle relaxant 0.10 3.33

Hydrochloride

22 Topiramate 97240-79-4 Anticonvulsant 6.00 200.00

23 Zotepine 26615-21-4 Neuroleptic agent 2.00 66.67

24 Zopiclone 43200-80-2 Nonbarbiturate Hypnotic 0.10 3.33

Total 102.25 3408.33

2.1 RESOURCE REQUIREMENT & INFRASTRUCTURE FACILITIES

A) Land Use Details:

M/s. Symed Labs Ltd. Unit - IV, is established plant is in 2.24 Acres (9064.88 SQM)

and acquired an additional land of 11.08 Acres (44838.82 SQM-Survey Nos.163, 163/B,

164/B, &167) adjacent to the existing land. Now, the total Land area is 13.32 Acres

(53903.71 SQM) having Survey Nos.163,163/A,163/B,164/A,164/B &167. The usage

details are given table 4.

TABLE- 4: EXISTING & PROPOSED LAND USE DETAILS

Area In SQM

S. No Description Existing Proposed

(After expansion)

1 Built up land 1311.34 12520.50

2 Roads 8640.02

3 Parking area 3218.82 2690.50

4 Open area 12246.66

5 Greenbelt area 4534.72 17806.03

Total 9064.88 53903.71

33% Of Land Allotted For Green Belt.

B) Existing & Proposed Water Consumption Details

The existing water consumption is 25.94 KLD, details are given below table.

TABLE- 5: EXISTING WATER CONSUMPTION DETAILS

S. No Purpose Water

Consumption

In KLD

1 Process &Washings 9.34

2 Boiler & Cooling Towers Make Up 14.00

3 DM Plant 0.10

4 Domestic 0.50

5 Gardening 2.00

Total 25.94

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 4

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

The Total water consumption for the proposed project is 271.22 KLD. Water

consumption details are given in below Table. No.6. Water requirement will be met

through Ground Water.

TABLE- 6: PROPOSED WATER CONSUMPTION DETAILS AFTER EXPANSION

Water Consumption

S. No Purpose

Details In KLD

1 Process 79.22

2 Washings 5.00

3 Boiler Daily Make up 41.00

4 Cooling towers Daily Make up 131.00

5 DM Plant 4.00

6 Scrubbing system 2.00

7 Domestic Usage 3.00

8 Gardening 6.00

Total 271.22

Out of Total Water consumption of 271.22 KLD an amount of 71.30 KLD of

water will be recovered by the ZLD system and reused, Hence, Total fresh

water requirement is 199.92 KLD and will be met from Ground Water.

C) Energy Requirement

Power requirement of proposed expansion project will be made available through

Telangana State Southern Power Distribution Corporation Limited [TSSPDCL]. Total

power requirement of proposed plant shall be 1100KVA.

D) Utilities:

For generation of Steam, the industry dropping existing 1.0 TPH coal fired boiler and

proposing 5.0TPH coal fired boiler, and 2.0TPH coal fired boiler as stand by. The

coal requirement will be met from government allocation or from local authorized

sources.

Dropping existing 125 KVA DG set, and proposing 500 KVA, 320 KVA & 250 KVA

DG sets for usage during the power failures. These DG sets are sufficient even for

the proposed expansion. The emission details are presented in bellow table No.7, 8

& 9.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 5

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 7: DETAILS OF UTILITIES FOR EXISTING & PROPOSED

Existing Proposed

S. No Description Capacity after

Dropped Continued

expansion

1.0TPH Dropped -

1 Coal fired 5.0TPH - - Proposed

boilers 2.0TPH - - Proposed

1 X 125 KVA Dropped -

2 DG Sets 1 X 500 KVA - - Proposed

1 X 250KVA - - Proposed

1 X 320KVA - - Proposed

3 Cooling 3X500 TR - - Proposed

Towers 2X300 TR - - Proposed

1X250 TR - - Proposed

1X200 TR - - Proposed

4 Electricity 850 KVA - Continued -

supply from - - Proposed

1100 KVA

TSSPDCL.

TABLE- 8: EMISSION CHARACTERISTIC DETAILS OF PROPOSED BOILERS

AFTER EXPANSION

5.0 TPH Coal fired *2.0 TPH Coal fired

Particulars Units Boiler Boiler

(Proposed) (standby)

Type of Fuel -- Indian Coal Indian Coal

Coal Consumption TPD 12.5 5.0

Ash Content % 47 47

Sulphur Content % 0.8 0.8

Nitrogen Content % 1.07 1.07

No. of Stacks No 1 1

Height of the Stack m 32 30

Diameter of Stack m 0.60 0.60

o

Temperature of Flue Gas C 110 95

Velocity of Flue Gas m/s 8.5 6.5

Particulate Matter at gm/sec 0.27 0.21

outlet of Bag filter (Based

on 115 mg/Nm3 at outlet)

Sulphur dioxide emission gm/sec 1.15 0.46

Oxides of Nitrogen gm/sec 1.54 0.57

emission

Multi cyclone Multi cyclone

Pollution control separator followed by separator followed by

-

equipment suitable pack of Bag suitable pack of Bag

filters filters

* 2.0 TPH coal fired boiler is kept as standby.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 6

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 9: STACK EMISSION DETAILS OF PROPOSED DG SETS AFTER

EXPANSION

Capacity Emission Emission Emission Stack Flue Gas Stack Flue gas

In KVA of SPM in Of SO2 in of NOx dia. Temp. in Height Velocity

mg/Nm3 mg/Nm3 In mg/Nm3 In m O

C in m In m/sec.

500 KVA 80.0 190.0 235.0 0.30 150 10 23.20

250KVA 65.0 110.0 135.0 0.30 250 10 18.50

320KVA 70.0 135.0 160.0 0.30 290 10 20.50

E) Pollution Control Equipment:

i) Cyclone separator: The denser particles which are carried away by boiler flue

gases will get separated in the cyclone separator and collected in the bottom of the

cyclone separator at a definite interval.

ii) Bag Filter: The boiler flue gases from cyclone separator enter into pack of bag

filters, where particulate matter will be separated leaving as cake on bags surface.

They are cleared by shaking or vibrating by pulse jet causing the filter cake to be

loosened and to fall in the Hopper.

iii) Boiler Stack: The adequate stack height (30-32 mts) will be provided for

pollutants (SO2, NOx, PM & CO) dispersed in a very large area so that ground level

concentration is within CPCB permissible limits.

iv) Scrubbers: Two scrubbers of 2-Stage are proposed to scrub the SO2. The

packing media in the scrubber is 25mm poly propylene rings.

The SO2 emissions are scrubbed by using C.S lye solution. The scrubbing system

will have two circulation pumps and scrubbing liquid tanks as required.

3. BASELINE ENVIRONMENTAL STATUS

3.1 Study Area Included In Environmental Setting

Studies were carried out in about 10 km radius area from the site with respect to

meteorology, flora, fauna, land and socio-economies of the area. Further sampling

and analysis of air quality, water quality, noise level and soil quality were carried out.

The air quality, water quality, noise level and soil quality in the study area is

evaluated based on this physical sampling and analysis.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 7

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

The base line data were monitored during the study period of October 2014 –

December 2014. The study team conducted site surveys and field experiments for

gathering the information on air quality, water quality, noise quality and soil quality.

3.2 CLIMATE OF THE STUDY AREA

A. Temperature:

During the study period the minimum and maximum temperatures were recorded as

14.80 °C and 32.50°C respectively.

B. Relative Humidity:

During the study period the minimum and maximum relative humidity at project site,

was recorded as 38.00 % and 63.00 % respectively.

C. Wind Pattern during Study Period

The analysis of the average wind pattern shows predominant winds from NNW,

WNW and N with wind frequencies of 12.3, 12.0 and 11.5 % respectively. The calm

conditions were prevailed for 30.2 % of the total time. Average wind speed 1.49 m/s.

D. Rainfall

No rainfall is observed during the study period at project site. The normal annual

rainfall in the District is 674.00 mm (Source: Central Ground Water Board).

3.3 SAMPLING LOCATION DETAILS

Total Seven locations were selected for Base line status. Air, Water & Noise results

are presented in Table 10, 11 & 12 respectively.

3.4 AMBIENT AIR QUALITY

The ambient air monitoring was carried out for 24 hours a day, twice a week for 12

week per location in the study area. Ambient Air Quality Monitoring (AAQM) was

carried out at eight locations during period of October 2014 – December 2014.

Particulate Matter (PM10): Maximum value of 61.55 μg/ m3 was recorded at

Plant Site.

Particulate Matter (PM2.5): Maximum value of 20.94 μg/ m3 was recorded at

Pisatigudem.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 8

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Sulphur Dioxide (SO2): Maximum value of Sulfur dioxide of 12.49 μg/ m3

obtained near the sampling location of Gundrampalli.

Oxides of Nitrogen (NOx): A maximum value of 16.23 μg/ m3 was prevailing

at the time of sampling at Gundrampalli sampling station.

Carbon Monoxide (CO): Maximum value of Carbon Monoxide of 0.64 mg/ m3

obtained near the sampling location of Pisatigudem.

Ammonia (NH3): Maximum value of Ammonia of 19.91 μg/ m3 obtained near

the sampling location of Plant Site.

Volatile Organic Compounds (VOCs)

Volatile Organic Compounds (VOCs) concentration in study area was found to

be Below Detectable Limit of I ppm

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 9

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

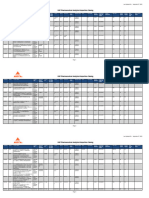

TABLE- 10: THE MAXIMUM, MINIMUM & 98 TH PERCENTILE VALUES FOR ALL THE

SAMPLING LOCATIONS

3 3 3 3 3 3

Name of PM10 (µg/M ) PM 2.5 (µg/M ) SO2 (µg/M ) NOX (µg/M ) CO (mg/M ) NH3 (µg/M )

Code Sampling

Min Max 98 th Min Max 98 th Min Max 98 th Min Max 98 th Min Max 98 th Min Max 98 th

Location

A1 Project Site 54.58 61.58 61.55 15.25 19.85 19.62 7.83 12.10 11.86 11.65 16.45 16.17 0.21 0.56 0.55 12.32 20.14 19.91

A2 Pisatigudem 43.12 55.63 55.45 14.21 21.63 20.94 8.26 11.25 11.20 12.11 15.54 15.41 0.33 0.64 0.64 11.14 17.58 17.52

A3 Bongonicheruvu 42.24 54.14 53.91 9.30 16.40 16.40 8.10 10.80 10.75 12.20 14.80 14.66 0.25 0.56 0.56 11.11 18.32 18.27

A4 Pitampally 44.21 57.25 56.92 14.28 19.21 18.67 8.14 11.63 11.46 12.14 15.33 15.20 0.21 0.58 0.57 12.28 17.21 16.90

A5 Chinna Kaparti 40.14 52.74 52.57 15.14 20.21 20.18 8.59 12.05 11.93 13.01 16.05 15.77 0.22 0.56 0.56 11.25 16.85 16.73

A6 Perepalli 45.32 55.14 54.73 14.14 21.22 20.73 8.25 11.25 11.25 12.20 15.54 15.30 0.24 0.59 0.59 11.22 17.11 16.76

A7 Gundrampalli 46.12 51.90 51.76 16.23 20.15 20.15 8.25 12.54 12.49 13.01 16.23 16.23 0.15 0.36 0.34 10.31 17.21 16.82

CPCB Standards’ 100.00 60.00 80.00 80.00 2.00 400.00

* VOCs Values monitored was Below Detectable Limit i. e 1 ppm

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 10

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

3.5 WATER QUALITY

Water sampling and subsequent analysis was carried out to determine both the

groundwater and surface water quality of the study area.

Ground water samples are collected at 7 locations and surface water samples was

collected at 4 locations in the study area. These samples were analyzed for physical

and chemical parameters to ascertain the Baseline status in the existing surface

water and ground water bodies.

TABLE-11: WATER ANALYSIS RESULTS

Ground water Surface water

S. No Parameters

Min Max Min Max

1 pH 7.18 7.65 7.89 8.56

2 Total dissolved solids (mg/l) 288.57 941.10 600.00 1246.70

3 Total hardness (mg/l) 180.00 420.00 300.00 400.00

4 Chlorides (mg/l) 49.98 314.90 189.90 499.80

5 Fluoride (mg/l) 0.78 1.8 <0.1 <0.1

6 Sulphates (mg/l) 23.55 104.30 65.56 106.40

Ground water samples collected from 7 locations within 10 km radius of the

plant site analyzed as per the Standard methods and the water quality of the

study area is found to be above limits for some parameters. And Heavy

Metals concentration in the analysis results is BDL (Below Detectable Limits)

with in 10KMs Radius.

Surface Water samples collected at 4 locations within 10 km radius from the

plant and water quality of the study area is found to be above limits for some

parameters. And Heavy Metals concentration in the analysis results is BDL

(Below Detectable Limits) with in 10KMs Radius.

3.6 NOISE ENVIRONMENT

Noise level monitoring was carried out at seven locations during the period of

October 2014 – December 2014.

During monitoring period, the LEQ (dB (A)) noise levels varied between 64.90 dB (A)

to 66.20 dB (A) during day time in the study area respectively.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 11

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Noise levels varied between 53.0 dB (A) to 55.70 dB (A) during night time in the

study area respectively.

The noise level varied at the same place at different times due to fluctuations in

traffic movements as well as commercial and domestic activities going on in the

study area but it was under the permissible limit as prescribed by CPCB.

TABLE-12: NOISE LEVELS OF THE STUDY AREA

CPCB CPCB

Name of the Day Time Night Time

S. No NORMS NORMS

place In Leq In Leq

(Day time) (Night time)

1. Plant Site 65.9 55.7

2. Pisatigudem 65.1 53.9

3. Bongoni cheruvu 64.9 53.0

4. Pitampally 65.5 55.1 75dB (A) 70dB (A)

5. Chinnakaparti 65.3 53.5

6. Perepalli 66.2 54.7

7. Gundrampalli 64.9 54.0

3.7 SOIL ENVIRONMENT

On data obtained, the soil quality at around the site is appropriate and normal in

terms of soil contaminants.

3.8 LAND USE/ LAND COVER OF THE STUDY AREA

Land use / Land cover map is prepared by visual interpretation of high-resolution

satellite data (Satellite Imagery Acquisition: 09-11-2014) and with the help of Survey

of India Topographic maps on 1: 50,000 scale. Two seasons’ data (Khariff year

2014) is used for the delineation of different units. The units are confirmed by the

ground truth/field visits.

TABLE-13: LAND USE / LAND COVER OF THE STUDY AREA

Area in Percentage

S. No LANDUSE Area in Sq. Km

(%)

1 Built- Up Land 14.130 4.5

2 Water bodies 20.096 6.4

3 Crop Land 232.046 73.9

4 Forest 1.256 0.40

5 Wastelands 46.472 14.80

Total 314.00 100

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 12

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

3.9 DEMOGRAPHIC AND SOCIO-ECONOMIC PROFILE

This Detailed Study of the Base-Line Data of Population, Gender Ratio, Rural &

Semi-Urban Demographic Distribution, Literacy Rate, Social Amenities available in

the study Area like, Transport, Sanitation, Drinking Water, Medical & Health

Facilities, Employment Rate and other Developmental Indices of Six Villages, falling

within 10 KMs of the Project-Influence Area and especially, that of ‘Pittampally’

Village, where the project site is located, are obtained from Primary Sources.

The total population of the study area is 19,002 in which 51.18% with

male population and 48.82% with female population while, the Demographic

distribution is 100% & 0% for Rural & Semi-Urban areas, respectively.

The Average Literacy rate in the study areas is 56.19 % while the rate

of Illiteracy is at an alarmingly high i.e., 53.85 % for Women and 34.23% for

Men Populations.

The total population of the study area is 19,002 out of which 9,169 are

employed, 9,206 are Other Non-Working Population while 627 are

Unemployed or still Employable.

All the Villages, in the study area, are electrified – both for Domestic Purpose

and common facilities like, Street Lights, Public Water Pumping, etc. and also

are provided with Domestic Water.

4.0 IDENTIFICATION, PREDICTION & MITIGATION MEASURES

4.1 Existing & Expected Air Environment

Existing Process Emissions Details

The Existing process emission from reactions are Sulfur dioxide (SO2) which is

scrubbed by using C. S. Lye solution, & Carbon dioxide (CO2) & Hydrogen (H2), and

is dispersed into Atmosphere.

TABLE-14: EXISTING PROCESS EMISSION DETAILS

Quantity In

S. No Name of the Gas Treatment Method

Kg/Day

Polluting Process Emission Details

1 Sulfur dioxide 44.00 Scrubbed by using C. S. Lye solution

Non- Polluting Process Emission Details

1 Carbon dioxide 26.00 Dispersed in to Atmosphere

2 Hydrogen Diffused by using Nitrogen through

0.80

Flame arrestor

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 13

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Expected Process Emissions Details

The Predicted Process emissions are SO2, CO2, and H2 which are liberated from

manufacturing process of proposed products.

TABLE-15: EXPECTED PROCESS EMISSION DETAILS

Quantity In

S. No Name of the Gas Treatment Method

Kg/Day

Expected Polluting Process Emission Details

1 Sulfur dioxide 88.00 Scrubbed by using C. S. Lye solution

Expected Non- Polluting Process Emission Details

1 Carbon dioxide 58.00 Dispersed in to Atmosphere

2 Hydrogen Diffused by using Nitrogen through

2.00

Flame arrestor

4.2 PROPOSED PROCESS EMISSION CONTROL SYSTEM

Scrubbers with 300 mm (Diameter) X 3 meters (Height) & 300mm (Diameter) X 3

meters (Height) capacities will be installed for control of process emissions. The

Schematic diagram of emission control system is given below.

FIGURE-1: SCHEMATIC DIAGRAM OF PROPOSED EMISSION CONTROL

SYSTEM

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 14

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

The Particulate matter generated from 5.0 TPH Boiler will be controlled by using

cyclone separator followed by bag filters. The sulphur dioxide (SO2) and oxides of

nitrogen (NOX) from boiler will be dispersed in to atmosphere by providing adequate

stack height of 32 meters for effective dispersion and dilution.

The predicted ground level concentrations when added to Baseline scenario, the

overall scenario levels of PM, SO2 and NOX are well within the permissible limits as

specified by CPCB.

4.3 Existing & Proposed Effluent Water Details

The existing waste water generation is 7.40 KLD, proposed waste water generation

will be 131.07 KLD which is from process, floor & reactor washes, cooling tower

blow down, boiler blow down, scrubber, DM plant and domestic usage. The effluent

generation and its HTDS & LTDS effluent details are given below.

TABLE-16: EXISTING EFFLUENT GENERATION DETAILS

S. No Purpose Effluent In

KLD

1 Process 5.00

2 Washings & QC Lab 1.00

3 Boiler & Cooling towers 0.80

Blow down

4 DM Plant regeneration 0.10

5 Domestic 0.50

Total 7.40

TABLE-17: EXISTING HTDS & LTDS EFFLUENT DETAILS

HTDS LTDS Effluent

S. No Purpose Disposal Method

In KLD In KLD In KLD

1 Process & Washings 2.36 3.64 6.00 Forced Evaporation in the

2 Boiler & Cooling stripper, Double Effect

0.80 0.00 0.80

towers Blow down Evaporator (DEE).

3 DM Plant regeneration 0.10 0.00 0.10 The Condensate first forerun

4 to distillate for recovery of

solvents at onsite & to reuse.

The secondary condensate

to reuse for makeup of

Domestic 0.00 0.50 0.50

cooling towers.

RO rejects to DEE and

permeate for recycling in

Cooling towers.

Total 3.26 4.14 7.40

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 15

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE-18: PROPOSED EFFLUENT GENERATION DETAILS AFTER

EXPANSION

Effluent

S. No Purpose Details

In KLD

1 Process 85.57

2 Washings 5.00

3 Boiler Blow down 6.00

4 Cooling towers Blow down 26.00

5 DM Plant regeneration 4.00

6 Scrubbing system 2.00

7 Domestic 2.50

8 Gardening 0.00

Total 131.07

TABLE-19: PROPOSED HTDS & LTDS EFFLUENT DETAILS AFTER

EXPANSION

HTDS LTDS Effluent

S. No Purpose In In In Disposal Method

KLD KLD KLD

1 Process 85.32 0.25 85.57 HTDS Effluent sent to ETP

2 Washings 0.00 5.00 5.00 with MEE system.

3 Boiler Blow down 6.00 0.00 6.00

4 Cooling towers LTDS effluents treated in

0.00 26.00 26.00 ETP. RO Rejects to MEE

Blow down

5 DM Plant system and RO permeate to

4.00 0.00 4.00 reuse; Condensate from

regeneration

6 MEE to Biological Treatment

followed by RO and reuse.

Scrubbing system 2.00 0.00 2.00 MEE residue to ATFD for

drying

7 Septic tank followed by

Domestic 0.00 2.50 2.50

Soak pit

Total 97.32 33.75 131.07

Effluent Treatment / Disposal: Zero Liquid Discharge (ZLD) concept consisting of

steam stripper, MEE system, ATFD, Biological Treatment and RO will be installed to

treat the effluents generated from plant and to reuse the treated water.

The MEE System with 200 KLD capacity, Biological Treatment with 60KL capacity

and RO system with 150 KLD Capacity will be installed for treatment of effluents

generated from plant operations.

The details of MEE system given in Draft EIA Report Chapter-10.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 16

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

4.4 Noise Environment

The main sources of noise pollution in the plant are Boilers, Reactors, DG Sets,

compressors and other Noise generating units. Vehicular movements during

operation phase for loading / unloading of raw materials and finished products and

transporting activity may also increases the noise levels.

All the noise generating equipments like motor’s, gear boxes and compressors are

regularly maintained with lubricating material to avoid noise generation. All the DG

sets are providing with acoustic enclosures. A thick greenbelt will be developed

along the periphery of the plant boundaries to minimize the noise pollution from the

source.

4.5 Land Environment

The proposed plant activities are unlikely to alter the land-use pattern in the project

site. The unit will take adequate measures for storage, handling and disposal of

hazardous waste. Hence, there will be no significant adverse impact on land

environment.

4.6 Ecological Environment

Detailed flora and fauna studies were carried in the study area. As per baseline

studies, there are no endangered, threatened & protected plants and animal species

were recorded in the study area. Hence, no significant adverse impact is envisaged

on ecology.

4.7 Existing & Proposed Solid Waste Details

The Solid waste generated and disposal methods from existing and proposed project

are given below.

TABLE- 20: EXISTING SOLID & HAZARDOUS WASTE GENERATION AND

DISPOSAL

Quantity

S. No Description Method Of Disposal

In Kg/Day

1 Organic Solid Waste 130.00 Sent to Cement Industries

2 Inorganic solid waste/FE

271.00 Sent to TSDF

Residue

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 17

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 21: PROPOSED SOLID WASTE & HAZARDOUS WASTE GENERATION,

DISPOSAL DETAILS AFTER EXPANSION

S. No Description Quantity Method Of Disposal

In Kg/Day

SOLID WASTE GENERATION, DISPOSAL DETAILS

1 Organic Solid Waste 1300.00 Sent to Cement Industries

2 Spent Carbon 456.00 Sent to Cement Industries

3 ETP Sludge 120.00 Sent to TSDF

4 Coal ash from Boiler 5880.00 Sent to Brick Manufacturers

5 MEE salts 4920.00 Sent to TSDF

6 Inorganic solid waste 260.00 Sent to TSDF

7 Solvent Distillation bottom 410.00

Sent to Cement Industries

Residue

HAZARDOUS WASTE GENERATION, DISPOSAL DETAILS

1 100 Liters / SPCB Authorized Agencies for

Waste Oils & Grease

Annum Reprocessing/Recycling

2 After Detoxification sent back to

Detoxified Containers & 400 No’s /

suppliers / SPCB Authorized

Container Liners Month

Parties

3 6 No’s / Send back to suppliers for

Used Lead Acid Batteries

Year buyback of New Batteries

4.8. Risk Assessment and Disaster Management Plan

The Risk assessment studies have been conducted for identification of hazards, to

calculate damage distances and to spell out risk mitigation measures. The details

are discussed in detail in Chapter – 7 of Draft EIA Report.

5.0 ENVIRONMENTAL MANAGEMENT PLAN

5.1 ENVIRONMENT MANAGEMENT PLAN FOR CONSTRUCTION PHASE

Adequate and effective environment protection measures will be planned and

designed to minimize the impacts due to activities related to pre-construction

(preparatory phase) of the project, machinery installation and commissioning stages

and end with the induction of manpower and start up. The impacts identified during

the construction phase are mainly due to site preparation, foundation work, material

handling, and construction of buildings and installation of the machinery.

All possible care will be taken to reduce the noise levels due to construction activity.

Also, noise prone activities shall be restricted to the extent possible during night

particularly during the period of 10 PM to 6 AM in order to have minimum

environmental impact.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 18

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

5.2 ENVIRONMENT MANAGEMENT PLAN FOR OPERATIONAL PHASE

A) Air Pollution Management

Gaseous emissions from reactions shall be scrubbed in a two stage scrubber

to control the gaseous emissions into the atmosphere.

Fugitive emissions will be reduced by providing vent condensers to the

storage tanks and all the reactors are will be provided with primary and

secondary condensers with cooling water and chilled brain circulation

respectively to avoid fugitive emissions and solvent losses which ensures

the recovery of 95% and also controlled by closed operations and suitable

handling methods.

Adequate stack height of 32 meters will be provided to the proposed boiler for

effective dispersion of pollutants’ and stack monitoring facilities for the

periodic monitoring of the stack flue gases to verify the compliance of the

stipulated norms.

To prevent the particulate matter delivering from the boilers will be arrested by

providing Cyclone separator followed by Bag filters.

B) Water Pollution Management

The HTDS effluents will be collected and treated in steam stripper, MEE system &

ATFD. Condensate along with LTDS effluent will be sent to biological treatment

including R.O system for treatment and reuse. There will be no discharge of effluent

outside the plant premises. The unit will be treated as ZLD unit. Salts from ATFD

and sludge from the ETP will be sent to TSDF for land fill.

C) Noise Pollution Management

Extensive oiling, lubrication and preventive maintenance will be carried out for

the machineries and equipments to reduce noise generation.

Green Belt Development around plant boundaries and within plant in an area

of 4.4 Acres (17806.03 SQM).

A thick Greenbelt along the periphery of the compound wall arrests the Noise

pollution from the plant.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 19

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

D) Solid Waste Management

The hazardous wastes generated from the industry will be from solvents distillation,

Process, ETP, Boilers, MEE, discarded containers and bags which will properly

stored in a hazardous waste storage area with leachate collection system and then

transported and properly disposed.

The entire organic residues will be disposed to cement industries for incineration and

Inorganic residues sent to TSDF for secure land fill.

E) Green Belt

The industry proposed to develop greenbelt on all sides of the industry in an area of

4.4 Acres (17806.03 SQM) from the total area of 13.32 Acres (53903.71 SQM) of

land, with an amount of Rs.6, 00,000 /- for greenbelt. The amount will be spent

during the period of Three years. First year amount will be Rs.3, 00,000 for

plantation. Second year amount will be Rs.2, 00,000/- for development of plants.

Third year amount will be Rs. 1, 00,000/- for maintenance and development. A list of

plants suitable for greenbelt and to the local agro climatic conditions is given in the

Draft EIA report.

F) Solvent Recovery

The solvents like Acetone, Ethyl acetate, THF, n- Hexane, Isopropyl alcohol,

Methanol and Toluene will be recovered up to 95 % by using distillation and the

remaining 5% will be the loss.

5.3 ENVIRONMENT MANAGEMENT CELL

M/s. Symed Labs Ltd. Unit - IV, will provide a dedicated Environmental

Management Cell with trained staff to look after the proper environmental

management of the proposed plant including operation & maintenance of all

facilities.

5.4 ENVIRONMENT MONITORING PROGRAM

Regular monitoring of environmental parameters is of immense importance to

assess the status of environment during project operation. The regular monitoring

will be carried out with the MoEFCC registration / NABL accredited laboratory.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 20

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

6. PROPOSED ROOF WATER HARVESTING

Rainwater harvesting is a mechanism involved in collecting, storing and using. A

rainwater harvesting system comprises various stages – flow of rainwater through

pipes or drains, filtration and storage in tanks for reuse or recharge. Roof top area is

considered for harvesting rainwater for this project and other areas are excluded due

to possibility of chemical contamination. Roof top rainwater harvesting is one of the

appropriate options for augmenting ground water recharge/ storage in urban areas

where natural recharge is considerably reduced due to increased urban activities

and not much land is available for implementing any other artificial recharge

measure.

FIGURE-2: PROPOSED ROOF WATER HARVESTING STRUCTURE

7. EMP BUDGET

The unit has proposed for 337.0 Lakhs as capital cost and 24.0 Lakhs as recurring

cost for environment pollution control measures.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 21

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 22: PROPOSED BUDGETS FOR ENVIRONMENTAL MANAGEMENT

PLAN [EMP] AFTER EXPANSION

Proposed Recurring

S. No Particulars Capital Cost Cost

(Rs. Lac) (Rs. Lac)

Pollution Control Equipment

1 (Scrubbers, Cyclone separator, Bag filter , 20.0 2.5

Sampling port arrangements etc.,)

ZLD System (MEE , RO, necessary modification

2 300.0 13.0

of ETP system)

Rain Water Harvesting

3 (Roof top water collection pit and Roof top water 6.0 0.0

towards the rain water harvesting pit)

Green Belt Development

4 6.0 2.0

(Plantation and Maintenance)

Health & Safety

5 5.0 3.5

(PPEs, Medical Surveillances expenses etc.,)

Environmental Monitoring

6 (Air, Water, Noise, VOCs, Boiler Stack flue 0.0 3.0

gases, DG sets stack monitoring expenses etc.,)

337.0 24.0

Total

8.0 SOCIO-ECONOMIC DEVELOPMENT

It is predicted that socio-economic impact due to this project will positively increase

the chance of more employment opportunities for local peoples. There are no

Resettlement and Rehabilitation issues involved in this project. The project

infrastructures will be of use to people of the area. The revenue of the village will be

definitely increasing due to the project.

9.0 PROJECT BENEFITS

Proposed expansion project will result in considerable growth and up liftments of

local community in the nearby villages by providing the employment. The proposed

project will generate direct and indirect employment to the nearby villages and the

unavailable technical persons will be recruited from outside.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 22

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

10.0 CONCLUSION

M/s. Symed Labs Ltd. Unit - IV, has committed to implement all the pollution control

measures to protect the surrounding environment – adapting Zero-Liquid-Discharge

System for all its Effluents, by controlling process emissions and Safe-Disposal of all

Solid Wastes – generated either as process wastes or packing wastes.

The project can definitely improve the regional, state and national economy.

Industrial growth is an indication of all-round Socio-Economic Development – by

generating local Employment and Business Opportunities. The implementation of

this project will definitely improve the physical and social infrastructure of the

surrounding area.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 23

EXECUTIVE SUMMARY OF

DRAFT EIA REPORT

OF

M/s. SYMED LABS LIMITED, UNIT - IV.

FOR

Expansion of Existing Drug Intermediate

Manufacturing Unit to Bulk Drug &

Intermediate Manufacturing Unit

AT

SURVEY NOs.163,163/A,163/B,164/A,164/B & 167,

PITTAMPALLY VILLAGE, CHITYAL MANDAL,

NALGONDA DISTRICT, TELANGANA STATE,

PREPARED BY

Rightsource Industrial Solutions Pvt. Ltd

Plot No: 203, H.No:5-36/203, Prashanthi Nagar,

IDA, Kukatpally, Hyderabad – 500072.

Ph: 040-65873137, 23070602, 23075699, 40126589.

Fax: 040-23070602. Mail: info@rightsource.co.in

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

1. INTRODUCTION

M/s. Symed Labs Ltd. Unit - IV, is an established Drug Intermediates

manufacturing unit at Survey Nos.163/A & 164/A, Pittampally Village, Chityal

Mandal, Nalgonda District, Telangana State.

Existing plant is in 2.24 Acres (9064.88 SQM) and acquired an additional land of

11.08 Acres (44838.82 SQM-Survey Nos.163, 163/B, 164/B, &167) adjacent to the

existing land. Now, the total Land area is 13.32 Acres (53903.71 SQM) having

Survey Nos.163,163/A,163/B,164/A,164/B &167. The company wishes to modify

their Drug Intermediates manufacturing facility to Bulk Drug & Intermediates

manufacturing facility. The company wishes to manufacture the proposed products

by replacing existing products after expansion.

The company proposes to invest an additional amount of Rs.40.0 Crores towards its

modernization and pollution control equipment.

The proposal is to obtain Environmental Clearance from the Ministry of Environment,

Forests and Climate Change (MoEFCC) and Consent Orders from SPCB to

manufacture proposed products with a total production capacity of 102.25 T/Month.

Draft EIA report is prepared considering the Terms of Reference (ToR) issued by

MoEFCC vide F. No. J-11011/87/2014-IAII (I) Dated 21st October 2014 and

Amended TOR issued on 29-07-2015.

1.1. PROJECT DESCRIPTION

The salient features of the unit are furnished below.

TABLE-1: SALIENT FEATURES OF THE PROJECT

Project location Details

Name of the project M/s. Symed Labs Ltd. Unit - IV

Survey Nos: 163, 163/A, 163/B, 164/A,

Location of the project 164/B, &167, Pittampally Village, Chityal

Mandal, Nalgonda District, Telangana State.

Latitude: 170 12’28.38” North

Latitude & Longitude Longitude: 790 00’ 56.28” East

Land acquired for the plant 13.32 Acres (53903.71SQM)

Present Land use of the project site Existing Industrial Land

Nearest village Pittampally - 2.57 Kms (ENE)

Nearest Mandal Chityala - 10 Kms (ENE)

Major urban Settlements Hyderabad - 48 KMs (WNW)

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 1

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

National Highway NH-9 -

Nearest Highway (Hyderabad- Vijayawada) – 2.6 Kms (NNW)

Chityala Railway Station – 13 Kms (E)

Nearest Railway station

Rajiv Gandhi International Airport (Hyderabad) -

Nearest Airport 60 Kms (WNW)

Major Industries near the plant site Adarsh steel Pvt Ltd

Nosch Labs Pvt Ltd

Divis Laboratories Ltd

Water Bodies with in 10kms radius Kandala vagu - 2.62 Kms (SW)

Ramalingeshwara cheruvu - 3.3 Kms (NW)

Halia vagu - 4.4 Kms (WNW)

Jalu vagu - 4.7 Kms (SW)

Devuni cheruvu - 5.3 Kms (NW)

Chinna vagu - 6.3 Kms (S)

Pedda vagu - 9.7 Kms (S)

2.0 PROCESS DESCRIPTION

The manufacturing process of Bulk Drug & Intermediates consists of chemical

synthesis extending to stages of processing involving different type of chemical

reactions. Total production capacity of Existing is 109.2 TPA and Proposal will be

1227.0 TPA. (Given in Table - 2 & 3). The unit will take adequate control measures

for storage and handling of Raw materials, solvents and cylinders with in factory

premises.

TABLE- 2: EXISTING PRODUCTS AND QUANTITIES

Therapeutic Quantity In Quantity In

S. No Product Name CAS Number

Category Kg/Month Kg/Day

Epalrestat Intermediate

Drug

1 (2-Methyl-3-Phenyl- 5445-77-2 500.00 16.67

Intermediate

Propenal)

Linezolid Intermediate

(5-Aminomethyl-3-(3-

Drug 240.00

2 Fluoro-4-Morpholin-4- 168828-90-8 7200.00

Intermediate

Yl-Phenyl)-

Oxazolidin-2-One)

Mosapride Citrate

Dihydrate Intermediate

(4-Amino-5-Chloro-2-

112885-41-3 Drug

3 Ethoxy-N-[4-(4-Fluoro- 1644.00 54.80

Intermediate

Benzyl)-Morpholin

-2-Ylmethyl]-

Benzamide)

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 2

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Racecadotril

Intermediate

Drug

4 (2-Benzyl- Not available 1900.00 63.33

Intermediate

Acryloylamino)-Acetic

Acid Benzyl Ester)

Thalidomide

Intermediate

Drug

5 ( 2-(2, 6-Dioxo- 53602-85-0 500.00 16.67

Intermediate

Tetrahydro-Pyran-3-Yl)-

Isoindole-1, 3-Dione)

Total 9100.00 303.34

The industry is permitted to manufacture only two products at any given

point of time.

TABLE- 3: PROPOSED PRODUCTS AND QUANTITIES AFTER EXPANSION

Quantity

Quantity In

S. No Product Name CAS Number Therapeutic Category In

Kg/Day

MT/Month

1 Amisulpride 71675-85-9 Neuroleptic agent 1.00 33.33

2 Carbidopa 93357-67-6 Anti parkinsonian agent 4.00 133.33

3 Carvedilol 72956-09-3 Cardiovascular Agent 4.00 133.33

Carvedilol

4 610309-89-2 Antihypertensive agent 0.20 6.67

Phosphate

Cinitapride

5 Hydrogen 66564-14-5 Gastroprokinetic Agent 0.10 3.33

tartrate

Dapoxetine

6 129938-20-1 Antidepressant 1.00 33.33

Hydrochloride

7 Epalrestat 82159-09-9 Oral anti diabetic agent 3.00 100.00

Non barbiturate

8 Eszopiclone 138729-47-2 0.05 1.67

Hypnotic

9 Fluconazole 86386-73-4 Antifungal 6.00 200.00

10 Iron sucrose 8047-67-4 Iron supplement 20.00 666.67

Itopride

11 122892-31-3 Antiulcer 4.00 133.33

Hydrochloride

Ketorolac

12 74103-07-4 Antipyretic agent 8.00 266.67

Tromethamine

Levocetirizine

13 130018-87-0 Antihistamine agent 0.60 20.00

Dihydrochloride

14 Levosulpiride 23672-07-3 3.00 100.00

Antiemetic agent

15 Linezolid 165800-03-3 Antibiotic 18.00 600.00

Mosapride citrate

16 63582-62-2 Gastroprokinetic 4.00 133.33

dihydrate

Ondansetron

17 Hydrochloride 103639-04-9 Antiemetic 1.00 33.33

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 3

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

18 Pregabalin 148553-50-8 Neuropathic Pain Agent 10.00 333.33

19 Racecadotril 81110-73-8 Anti diarrheals 6.00 200.00

Tamsulosin

20 106463-17-6 Anti-adrenergic 0.10 3.33

Hydrochloride

Tizanidine

21 64461-82-1 Skeletal muscle relaxant 0.10 3.33

Hydrochloride

22 Topiramate 97240-79-4 Anticonvulsant 6.00 200.00

23 Zotepine 26615-21-4 Neuroleptic agent 2.00 66.67

24 Zopiclone 43200-80-2 Nonbarbiturate Hypnotic 0.10 3.33

Total 102.25 3408.33

2.1 RESOURCE REQUIREMENT & INFRASTRUCTURE FACILITIES

A) Land Use Details:

M/s. Symed Labs Ltd. Unit - IV, is established plant is in 2.24 Acres (9064.88 SQM)

and acquired an additional land of 11.08 Acres (44838.82 SQM-Survey Nos.163, 163/B,

164/B, &167) adjacent to the existing land. Now, the total Land area is 13.32 Acres

(53903.71 SQM) having Survey Nos.163,163/A,163/B,164/A,164/B &167. The usage

details are given table 4.

TABLE- 4: EXISTING & PROPOSED LAND USE DETAILS

Area In SQM

S. No Description Existing Proposed

(After expansion)

1 Built up land 1311.34 12520.50

2 Roads 8640.02

3 Parking area 3218.82 2690.50

4 Open area 12246.66

5 Greenbelt area 4534.72 17806.03

Total 9064.88 53903.71

33% Of Land Allotted For Green Belt.

B) Existing & Proposed Water Consumption Details

The existing water consumption is 25.94 KLD, details are given below table.

TABLE- 5: EXISTING WATER CONSUMPTION DETAILS

S. No Purpose Water

Consumption

In KLD

1 Process &Washings 9.34

2 Boiler & Cooling Towers Make Up 14.00

3 DM Plant 0.10

4 Domestic 0.50

5 Gardening 2.00

Total 25.94

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 4

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

The Total water consumption for the proposed project is 271.22 KLD. Water

consumption details are given in below Table. No.6. Water requirement will be met

through Ground Water.

TABLE- 6: PROPOSED WATER CONSUMPTION DETAILS AFTER EXPANSION

Water Consumption

S. No Purpose

Details In KLD

1 Process 79.22

2 Washings 5.00

3 Boiler Daily Make up 41.00

4 Cooling towers Daily Make up 131.00

5 DM Plant 4.00

6 Scrubbing system 2.00

7 Domestic Usage 3.00

8 Gardening 6.00

Total 271.22

Out of Total Water consumption of 271.22 KLD an amount of 71.30 KLD of

water will be recovered by the ZLD system and reused, Hence, Total fresh

water requirement is 199.92 KLD and will be met from Ground Water.

C) Energy Requirement

Power requirement of proposed expansion project will be made available through

Telangana State Southern Power Distribution Corporation Limited [TSSPDCL]. Total

power requirement of proposed plant shall be 1100KVA.

D) Utilities:

For generation of Steam, the industry dropping existing 1.0 TPH coal fired boiler and

proposing 5.0TPH coal fired boiler, and 2.0TPH coal fired boiler as stand by. The

coal requirement will be met from government allocation or from local authorized

sources.

Dropping existing 125 KVA DG set, and proposing 500 KVA, 320 KVA & 250 KVA

DG sets for usage during the power failures. These DG sets are sufficient even for

the proposed expansion. The emission details are presented in bellow table No.7, 8

& 9.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 5

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 7: DETAILS OF UTILITIES FOR EXISTING & PROPOSED

Existing Proposed

S. No Description Capacity after

Dropped Continued

expansion

1.0TPH Dropped -

1 Coal fired 5.0TPH - - Proposed

boilers 2.0TPH - - Proposed

1 X 125 KVA Dropped -

2 DG Sets 1 X 500 KVA - - Proposed

1 X 250KVA - - Proposed

1 X 320KVA - - Proposed

3 Cooling 3X500 TR - - Proposed

Towers 2X300 TR - - Proposed

1X250 TR - - Proposed

1X200 TR - - Proposed

4 Electricity 850 KVA - Continued -

supply from - - Proposed

1100 KVA

TSSPDCL.

TABLE- 8: EMISSION CHARACTERISTIC DETAILS OF PROPOSED BOILERS

AFTER EXPANSION

5.0 TPH Coal fired *2.0 TPH Coal fired

Particulars Units Boiler Boiler

(Proposed) (standby)

Type of Fuel -- Indian Coal Indian Coal

Coal Consumption TPD 12.5 5.0

Ash Content % 47 47

Sulphur Content % 0.8 0.8

Nitrogen Content % 1.07 1.07

No. of Stacks No 1 1

Height of the Stack m 32 30

Diameter of Stack m 0.60 0.60

o

Temperature of Flue Gas C 110 95

Velocity of Flue Gas m/s 8.5 6.5

Particulate Matter at gm/sec 0.27 0.21

outlet of Bag filter (Based

on 115 mg/Nm3 at outlet)

Sulphur dioxide emission gm/sec 1.15 0.46

Oxides of Nitrogen gm/sec 1.54 0.57

emission

Multi cyclone Multi cyclone

Pollution control separator followed by separator followed by

-

equipment suitable pack of Bag suitable pack of Bag

filters filters

* 2.0 TPH coal fired boiler is kept as standby.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 6

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 9: STACK EMISSION DETAILS OF PROPOSED DG SETS AFTER

EXPANSION

Capacity Emission Emission Emission Stack Flue Gas Stack Flue gas

In KVA of SPM in Of SO2 in of NOx dia. Temp. in Height Velocity

mg/Nm3 mg/Nm3 In mg/Nm3 In m O

C in m In m/sec.

500 KVA 80.0 190.0 235.0 0.30 150 10 23.20

250KVA 65.0 110.0 135.0 0.30 250 10 18.50

320KVA 70.0 135.0 160.0 0.30 290 10 20.50

E) Pollution Control Equipment:

i) Cyclone separator: The denser particles which are carried away by boiler flue

gases will get separated in the cyclone separator and collected in the bottom of the

cyclone separator at a definite interval.

ii) Bag Filter: The boiler flue gases from cyclone separator enter into pack of bag

filters, where particulate matter will be separated leaving as cake on bags surface.

They are cleared by shaking or vibrating by pulse jet causing the filter cake to be

loosened and to fall in the Hopper.

iii) Boiler Stack: The adequate stack height (30-32 mts) will be provided for

pollutants (SO2, NOx, PM & CO) dispersed in a very large area so that ground level

concentration is within CPCB permissible limits.

iv) Scrubbers: Two scrubbers of 2-Stage are proposed to scrub the SO2. The

packing media in the scrubber is 25mm poly propylene rings.

The SO2 emissions are scrubbed by using C.S lye solution. The scrubbing system

will have two circulation pumps and scrubbing liquid tanks as required.

3. BASELINE ENVIRONMENTAL STATUS

3.1 Study Area Included In Environmental Setting

Studies were carried out in about 10 km radius area from the site with respect to

meteorology, flora, fauna, land and socio-economies of the area. Further sampling

and analysis of air quality, water quality, noise level and soil quality were carried out.

The air quality, water quality, noise level and soil quality in the study area is

evaluated based on this physical sampling and analysis.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 7

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

The base line data were monitored during the study period of October 2014 –

December 2014. The study team conducted site surveys and field experiments for

gathering the information on air quality, water quality, noise quality and soil quality.

3.2 CLIMATE OF THE STUDY AREA

A. Temperature:

During the study period the minimum and maximum temperatures were recorded as

14.80 °C and 32.50°C respectively.

B. Relative Humidity:

During the study period the minimum and maximum relative humidity at project site,

was recorded as 38.00 % and 63.00 % respectively.

C. Wind Pattern during Study Period

The analysis of the average wind pattern shows predominant winds from NNW,

WNW and N with wind frequencies of 12.3, 12.0 and 11.5 % respectively. The calm

conditions were prevailed for 30.2 % of the total time. Average wind speed 1.49 m/s.

D. Rainfall

No rainfall is observed during the study period at project site. The normal annual

rainfall in the District is 674.00 mm (Source: Central Ground Water Board).

3.3 SAMPLING LOCATION DETAILS

Total Seven locations were selected for Base line status. Air, Water & Noise results

are presented in Table 10, 11 & 12 respectively.

3.4 AMBIENT AIR QUALITY

The ambient air monitoring was carried out for 24 hours a day, twice a week for 12

week per location in the study area. Ambient Air Quality Monitoring (AAQM) was

carried out at eight locations during period of October 2014 – December 2014.

Particulate Matter (PM10): Maximum value of 61.55 μg/ m3 was recorded at

Plant Site.

Particulate Matter (PM2.5): Maximum value of 20.94 μg/ m3 was recorded at

Pisatigudem.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 8

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Sulphur Dioxide (SO2): Maximum value of Sulfur dioxide of 12.49 μg/ m3

obtained near the sampling location of Gundrampalli.

Oxides of Nitrogen (NOx): A maximum value of 16.23 μg/ m3 was prevailing

at the time of sampling at Gundrampalli sampling station.

Carbon Monoxide (CO): Maximum value of Carbon Monoxide of 0.64 mg/ m3

obtained near the sampling location of Pisatigudem.

Ammonia (NH3): Maximum value of Ammonia of 19.91 μg/ m3 obtained near

the sampling location of Plant Site.

Volatile Organic Compounds (VOCs)

Volatile Organic Compounds (VOCs) concentration in study area was found to

be Below Detectable Limit of I ppm

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 9

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 10: THE MAXIMUM, MINIMUM & 98 TH PERCENTILE VALUES FOR ALL THE

SAMPLING LOCATIONS

3 3 3 3 3 3

Name of PM10 (µg/M ) PM 2.5 (µg/M ) SO2 (µg/M ) NOX (µg/M ) CO (mg/M ) NH3 (µg/M )

Code Sampling

Min Max 98 th Min Max 98 th Min Max 98 th Min Max 98 th Min Max 98 th Min Max 98 th

Location

A1 Project Site 54.58 61.58 61.55 15.25 19.85 19.62 7.83 12.10 11.86 11.65 16.45 16.17 0.21 0.56 0.55 12.32 20.14 19.91

A2 Pisatigudem 43.12 55.63 55.45 14.21 21.63 20.94 8.26 11.25 11.20 12.11 15.54 15.41 0.33 0.64 0.64 11.14 17.58 17.52

A3 Bongonicheruvu 42.24 54.14 53.91 9.30 16.40 16.40 8.10 10.80 10.75 12.20 14.80 14.66 0.25 0.56 0.56 11.11 18.32 18.27

A4 Pitampally 44.21 57.25 56.92 14.28 19.21 18.67 8.14 11.63 11.46 12.14 15.33 15.20 0.21 0.58 0.57 12.28 17.21 16.90

A5 Chinna Kaparti 40.14 52.74 52.57 15.14 20.21 20.18 8.59 12.05 11.93 13.01 16.05 15.77 0.22 0.56 0.56 11.25 16.85 16.73

A6 Perepalli 45.32 55.14 54.73 14.14 21.22 20.73 8.25 11.25 11.25 12.20 15.54 15.30 0.24 0.59 0.59 11.22 17.11 16.76

A7 Gundrampalli 46.12 51.90 51.76 16.23 20.15 20.15 8.25 12.54 12.49 13.01 16.23 16.23 0.15 0.36 0.34 10.31 17.21 16.82

CPCB Standards’ 100.00 60.00 80.00 80.00 2.00 400.00

* VOCs Values monitored was Below Detectable Limit i. e 1 ppm

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 10

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

3.5 WATER QUALITY

Water sampling and subsequent analysis was carried out to determine both the

groundwater and surface water quality of the study area.

Ground water samples are collected at 7 locations and surface water samples was

collected at 4 locations in the study area. These samples were analyzed for physical

and chemical parameters to ascertain the Baseline status in the existing surface

water and ground water bodies.

TABLE-11: WATER ANALYSIS RESULTS

Ground water Surface water

S. No Parameters

Min Max Min Max

1 pH 7.18 7.65 7.89 8.56

2 Total dissolved solids (mg/l) 288.57 941.10 600.00 1246.70

3 Total hardness (mg/l) 180.00 420.00 300.00 400.00

4 Chlorides (mg/l) 49.98 314.90 189.90 499.80

5 Fluoride (mg/l) 0.78 1.8 <0.1 <0.1

6 Sulphates (mg/l) 23.55 104.30 65.56 106.40

Ground water samples collected from 7 locations within 10 km radius of the

plant site analyzed as per the Standard methods and the water quality of the

study area is found to be above limits for some parameters. And Heavy

Metals concentration in the analysis results is BDL (Below Detectable Limits)

with in 10KMs Radius.

Surface Water samples collected at 4 locations within 10 km radius from the

plant and water quality of the study area is found to be above limits for some

parameters. And Heavy Metals concentration in the analysis results is BDL

(Below Detectable Limits) with in 10KMs Radius.

3.6 NOISE ENVIRONMENT

Noise level monitoring was carried out at seven locations during the period of

October 2014 – December 2014.

During monitoring period, the LEQ (dB (A)) noise levels varied between 64.90 dB (A)

to 66.20 dB (A) during day time in the study area respectively.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 11

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Noise levels varied between 53.0 dB (A) to 55.70 dB (A) during night time in the

study area respectively.

The noise level varied at the same place at different times due to fluctuations in

traffic movements as well as commercial and domestic activities going on in the

study area but it was under the permissible limit as prescribed by CPCB.

TABLE-12: NOISE LEVELS OF THE STUDY AREA

CPCB CPCB

Name of the Day Time Night Time

S. No NORMS NORMS

place In Leq In Leq

(Day time) (Night time)

1. Plant Site 65.9 55.7

2. Pisatigudem 65.1 53.9

3. Bongoni cheruvu 64.9 53.0

4. Pitampally 65.5 55.1 75dB (A) 70dB (A)

5. Chinnakaparti 65.3 53.5

6. Perepalli 66.2 54.7

7. Gundrampalli 64.9 54.0

3.7 SOIL ENVIRONMENT

On data obtained, the soil quality at around the site is appropriate and normal in

terms of soil contaminants.

3.8 LAND USE/ LAND COVER OF THE STUDY AREA

Land use / Land cover map is prepared by visual interpretation of high-resolution

satellite data (Satellite Imagery Acquisition: 09-11-2014) and with the help of Survey

of India Topographic maps on 1: 50,000 scale. Two seasons’ data (Khariff year

2014) is used for the delineation of different units. The units are confirmed by the

ground truth/field visits.

TABLE-13: LAND USE / LAND COVER OF THE STUDY AREA

Area in Percentage

S. No LANDUSE Area in Sq. Km

(%)

1 Built- Up Land 14.130 4.5

2 Water bodies 20.096 6.4

3 Crop Land 232.046 73.9

4 Forest 1.256 0.40

5 Wastelands 46.472 14.80

Total 314.00 100

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 12

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

3.9 DEMOGRAPHIC AND SOCIO-ECONOMIC PROFILE

This Detailed Study of the Base-Line Data of Population, Gender Ratio, Rural &

Semi-Urban Demographic Distribution, Literacy Rate, Social Amenities available in

the study Area like, Transport, Sanitation, Drinking Water, Medical & Health

Facilities, Employment Rate and other Developmental Indices of Six Villages, falling

within 10 KMs of the Project-Influence Area and especially, that of ‘Pittampally’

Village, where the project site is located, are obtained from Primary Sources.

The total population of the study area is 19,002 in which 51.18% with

male population and 48.82% with female population while, the Demographic

distribution is 100% & 0% for Rural & Semi-Urban areas, respectively.

The Average Literacy rate in the study areas is 56.19 % while the rate

of Illiteracy is at an alarmingly high i.e., 53.85 % for Women and 34.23% for

Men Populations.

The total population of the study area is 19,002 out of which 9,169 are

employed, 9,206 are Other Non-Working Population while 627 are

Unemployed or still Employable.

All the Villages, in the study area, are electrified – both for Domestic Purpose

and common facilities like, Street Lights, Public Water Pumping, etc. and also

are provided with Domestic Water.

4.0 IDENTIFICATION, PREDICTION & MITIGATION MEASURES

4.1 Existing & Expected Air Environment

Existing Process Emissions Details

The Existing process emission from reactions are Sulfur dioxide (SO2) which is

scrubbed by using C. S. Lye solution, & Carbon dioxide (CO2) & Hydrogen (H2), and

is dispersed into Atmosphere.

TABLE-14: EXISTING PROCESS EMISSION DETAILS

Quantity In

S. No Name of the Gas Treatment Method

Kg/Day

Polluting Process Emission Details

1 Sulfur dioxide 44.00 Scrubbed by using C. S. Lye solution

Non- Polluting Process Emission Details

1 Carbon dioxide 26.00 Dispersed in to Atmosphere

2 Hydrogen Diffused by using Nitrogen through

0.80

Flame arrestor

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 13

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

Expected Process Emissions Details

The Predicted Process emissions are SO2, CO2, and H2 which are liberated from

manufacturing process of proposed products.

TABLE-15: EXPECTED PROCESS EMISSION DETAILS

Quantity In

S. No Name of the Gas Treatment Method

Kg/Day

Expected Polluting Process Emission Details

1 Sulfur dioxide 88.00 Scrubbed by using C. S. Lye solution

Expected Non- Polluting Process Emission Details

1 Carbon dioxide 58.00 Dispersed in to Atmosphere

2 Hydrogen Diffused by using Nitrogen through

2.00

Flame arrestor

4.2 PROPOSED PROCESS EMISSION CONTROL SYSTEM

Scrubbers with 300 mm (Diameter) X 3 meters (Height) & 300mm (Diameter) X 3

meters (Height) capacities will be installed for control of process emissions. The

Schematic diagram of emission control system is given below.

FIGURE-1: SCHEMATIC DIAGRAM OF PROPOSED EMISSION CONTROL

SYSTEM

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 14

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

The Particulate matter generated from 5.0 TPH Boiler will be controlled by using

cyclone separator followed by bag filters. The sulphur dioxide (SO2) and oxides of

nitrogen (NOX) from boiler will be dispersed in to atmosphere by providing adequate

stack height of 32 meters for effective dispersion and dilution.

The predicted ground level concentrations when added to Baseline scenario, the

overall scenario levels of PM, SO2 and NOX are well within the permissible limits as

specified by CPCB.

4.3 Existing & Proposed Effluent Water Details

The existing waste water generation is 7.40 KLD, proposed waste water generation

will be 131.07 KLD which is from process, floor & reactor washes, cooling tower

blow down, boiler blow down, scrubber, DM plant and domestic usage. The effluent

generation and its HTDS & LTDS effluent details are given below.

TABLE-16: EXISTING EFFLUENT GENERATION DETAILS

S. No Purpose Effluent In

KLD

1 Process 5.00

2 Washings & QC Lab 1.00

3 Boiler & Cooling towers 0.80

Blow down

4 DM Plant regeneration 0.10

5 Domestic 0.50

Total 7.40

TABLE-17: EXISTING HTDS & LTDS EFFLUENT DETAILS

HTDS LTDS Effluent

S. No Purpose Disposal Method

In KLD In KLD In KLD

1 Process & Washings 2.36 3.64 6.00 Forced Evaporation in the

2 Boiler & Cooling stripper, Double Effect

0.80 0.00 0.80

towers Blow down Evaporator (DEE).

3 DM Plant regeneration 0.10 0.00 0.10 The Condensate first forerun

4 to distillate for recovery of

solvents at onsite & to reuse.

The secondary condensate

to reuse for makeup of

Domestic 0.00 0.50 0.50

cooling towers.

RO rejects to DEE and

permeate for recycling in

Cooling towers.

Total 3.26 4.14 7.40

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 15

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE-18: PROPOSED EFFLUENT GENERATION DETAILS AFTER

EXPANSION

Effluent

S. No Purpose Details

In KLD

1 Process 85.57

2 Washings 5.00

3 Boiler Blow down 6.00

4 Cooling towers Blow down 26.00

5 DM Plant regeneration 4.00

6 Scrubbing system 2.00

7 Domestic 2.50

8 Gardening 0.00

Total 131.07

TABLE-19: PROPOSED HTDS & LTDS EFFLUENT DETAILS AFTER

EXPANSION

HTDS LTDS Effluent

S. No Purpose In In In Disposal Method

KLD KLD KLD

1 Process 85.32 0.25 85.57 HTDS Effluent sent to ETP

2 Washings 0.00 5.00 5.00 with MEE system.

3 Boiler Blow down 6.00 0.00 6.00

4 Cooling towers LTDS effluents treated in

0.00 26.00 26.00 ETP. RO Rejects to MEE

Blow down

5 DM Plant system and RO permeate to

4.00 0.00 4.00 reuse; Condensate from

regeneration

6 MEE to Biological Treatment

followed by RO and reuse.

Scrubbing system 2.00 0.00 2.00 MEE residue to ATFD for

drying

7 Septic tank followed by

Domestic 0.00 2.50 2.50

Soak pit

Total 97.32 33.75 131.07

Effluent Treatment / Disposal: Zero Liquid Discharge (ZLD) concept consisting of

steam stripper, MEE system, ATFD, Biological Treatment and RO will be installed to

treat the effluents generated from plant and to reuse the treated water.

The MEE System with 200 KLD capacity, Biological Treatment with 60KL capacity

and RO system with 150 KLD Capacity will be installed for treatment of effluents

generated from plant operations.

The details of MEE system given in Draft EIA Report Chapter-10.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 16

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

4.4 Noise Environment

The main sources of noise pollution in the plant are Boilers, Reactors, DG Sets,

compressors and other Noise generating units. Vehicular movements during

operation phase for loading / unloading of raw materials and finished products and

transporting activity may also increases the noise levels.

All the noise generating equipments like motor’s, gear boxes and compressors are

regularly maintained with lubricating material to avoid noise generation. All the DG

sets are providing with acoustic enclosures. A thick greenbelt will be developed

along the periphery of the plant boundaries to minimize the noise pollution from the

source.

4.5 Land Environment

The proposed plant activities are unlikely to alter the land-use pattern in the project

site. The unit will take adequate measures for storage, handling and disposal of

hazardous waste. Hence, there will be no significant adverse impact on land

environment.

4.6 Ecological Environment

Detailed flora and fauna studies were carried in the study area. As per baseline

studies, there are no endangered, threatened & protected plants and animal species

were recorded in the study area. Hence, no significant adverse impact is envisaged

on ecology.

4.7 Existing & Proposed Solid Waste Details

The Solid waste generated and disposal methods from existing and proposed project

are given below.

TABLE- 20: EXISTING SOLID & HAZARDOUS WASTE GENERATION AND

DISPOSAL

Quantity

S. No Description Method Of Disposal

In Kg/Day

1 Organic Solid Waste 130.00 Sent to Cement Industries

2 Inorganic solid waste/FE

271.00 Sent to TSDF

Residue

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 17

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

TABLE- 21: PROPOSED SOLID WASTE & HAZARDOUS WASTE GENERATION,

DISPOSAL DETAILS AFTER EXPANSION

S. No Description Quantity Method Of Disposal

In Kg/Day

SOLID WASTE GENERATION, DISPOSAL DETAILS

1 Organic Solid Waste 1300.00 Sent to Cement Industries

2 Spent Carbon 456.00 Sent to Cement Industries

3 ETP Sludge 120.00 Sent to TSDF

4 Coal ash from Boiler 5880.00 Sent to Brick Manufacturers

5 MEE salts 4920.00 Sent to TSDF

6 Inorganic solid waste 260.00 Sent to TSDF

7 Solvent Distillation bottom 410.00

Sent to Cement Industries

Residue

HAZARDOUS WASTE GENERATION, DISPOSAL DETAILS

1 100 Liters / SPCB Authorized Agencies for

Waste Oils & Grease

Annum Reprocessing/Recycling

2 After Detoxification sent back to

Detoxified Containers & 400 No’s /

suppliers / SPCB Authorized

Container Liners Month

Parties

3 6 No’s / Send back to suppliers for

Used Lead Acid Batteries

Year buyback of New Batteries

4.8. Risk Assessment and Disaster Management Plan

The Risk assessment studies have been conducted for identification of hazards, to

calculate damage distances and to spell out risk mitigation measures. The details

are discussed in detail in Chapter – 7 of Draft EIA Report.

5.0 ENVIRONMENTAL MANAGEMENT PLAN

5.1 ENVIRONMENT MANAGEMENT PLAN FOR CONSTRUCTION PHASE

Adequate and effective environment protection measures will be planned and

designed to minimize the impacts due to activities related to pre-construction

(preparatory phase) of the project, machinery installation and commissioning stages

and end with the induction of manpower and start up. The impacts identified during

the construction phase are mainly due to site preparation, foundation work, material

handling, and construction of buildings and installation of the machinery.

All possible care will be taken to reduce the noise levels due to construction activity.

Also, noise prone activities shall be restricted to the extent possible during night

particularly during the period of 10 PM to 6 AM in order to have minimum

environmental impact.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 18

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

5.2 ENVIRONMENT MANAGEMENT PLAN FOR OPERATIONAL PHASE

A) Air Pollution Management

Gaseous emissions from reactions shall be scrubbed in a two stage scrubber

to control the gaseous emissions into the atmosphere.

Fugitive emissions will be reduced by providing vent condensers to the

storage tanks and all the reactors are will be provided with primary and

secondary condensers with cooling water and chilled brain circulation

respectively to avoid fugitive emissions and solvent losses which ensures

the recovery of 95% and also controlled by closed operations and suitable

handling methods.

Adequate stack height of 32 meters will be provided to the proposed boiler for

effective dispersion of pollutants’ and stack monitoring facilities for the

periodic monitoring of the stack flue gases to verify the compliance of the

stipulated norms.

To prevent the particulate matter delivering from the boilers will be arrested by

providing Cyclone separator followed by Bag filters.

B) Water Pollution Management

The HTDS effluents will be collected and treated in steam stripper, MEE system &

ATFD. Condensate along with LTDS effluent will be sent to biological treatment

including R.O system for treatment and reuse. There will be no discharge of effluent

outside the plant premises. The unit will be treated as ZLD unit. Salts from ATFD

and sludge from the ETP will be sent to TSDF for land fill.

C) Noise Pollution Management

Extensive oiling, lubrication and preventive maintenance will be carried out for

the machineries and equipments to reduce noise generation.

Green Belt Development around plant boundaries and within plant in an area

of 4.4 Acres (17806.03 SQM).

A thick Greenbelt along the periphery of the compound wall arrests the Noise

pollution from the plant.

Prepared By Rightsource Industrial Solutions Pvt. Ltd. Page 19

Executive Summary of Draft EIA Report M/s. Symed Labs Ltd. Unit - IV

D) Solid Waste Management