Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PH: ACCORDING TO EN ISO 9606-1:2013

Caricato da

Matthew HaleTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ISO 9606-1 Ss NB 141 T BW Fm4 S s3.6 D60 PH: ACCORDING TO EN ISO 9606-1:2013

Caricato da

Matthew HaleCopyright:

Formati disponibili

Welder’s qualification test certificate

ACCORDING TO EN ISO 9606-1:2013

Designation examples of this Standard

ISO 9606-1 141 T BW FM4 S s3.6 D60 PH ss nb

INTERNATIONAL product type filler material

STANDARD weld details

type of weld dimension of

welding process test piece

filler material

grouping welding position

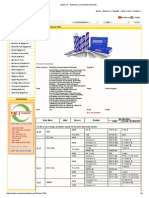

welding processeses types of weld welding positions weld details

according to EN ISO 4063 BW butt weld according to EN ISO 6947 BW butt weld

FW fillet weld ss single side welding

111 manual metal arc welding PA flat position mb material backing

114 self-shielded tubular cored arc welding PB horizontal vertical position nb welding with no material backing

121 submerged arc welding with solid wire electrod (partly mechanized) PC horizontal position gb gas backing

125 submerged arc welding with tubular cored electrode (partly mechanized) FW PD horizontal overhead position fb flux backing

131 MIG welding with solid wire electrode PE overhead position bs welding from both sides

135 MAG welding with solid wire electrode PF vertical up position ci consumable insert

136 MAG welding with flux cored electrode PG vertical down position

138 MAG welding with metal cored electrode H-L045 inclined position welding upwards FW fillet weld

141 TIG welding with solid filler material (wire/rod) J-L045 inclined position welding downwards sl single layer

142 autogenous TIG welding PH pipe position for welding upwards ml multi-layer

143 TIG welding with tubular cored filler material (wire/rod) PJ pipe position for welding downwards

145 TIG welding using reducing gas and solid filler material (wire/rod) BW 311 oxyacetylene welding

15 plasma arc welding lw leftward welding

311 oxyacetylene welding rw rightward welding

product types filler material

T Tube covered electrodes

P Plate Route A plate flat position

A acid covering

P B basic covering or electrode core – basic

vertical down

T C cellulosic covering

R rutile covering or electrode core – rutile, slow-freezing slag position

RA rutile – acid covering

RB rutile – basic covering

RC rutile – cellulosic covering

RR rutile – thick covering

vertical up

Route B position

03 rutile basic covering

10 cellulosic covering

11 cellulosic covering

horizontal

12 rutile covering vertical position

13 rutile covering

14 rutile + iron powder covering

15 basic covering

16 basic covering

filler material grouping 18

19

basic + iron powder covering

limenite covering

20 iron oxide covering

J-L045

24 rutile + iron powder covering inclined position

Group Filler material for welding of Examples of applicable standards 27 iron oxide + iron powder covering welding

28 basic + iron powder covering downwards

FM1 Non-alloy and fine grain steels ISO 2560, ISO 14341, ISO 636, ISO 45 basic covering

14171, ISO 17632 48 basic covering

FM2 High-strength steels ISO 18275, ISO 16834, ISO 26304, H-L045

ISO 18276 inclined

cored wire

FM3 Creep-resisting steels Cr < 3,75 % ISO 3580, ISO 21952, ISO 24598, M metal cored electrode or metal powder position horizontal

ISO 17634 P electrode core – rutile, fast-freezing slag welding position

V electrode core – rutile or basic/fluoride upwards

FM4 Creep-resisting steels 3,75 < Cr < 12 % ISO 3580, ISO 21952, ISO 24598, W electrode core – basic/fluoride, slow-freezing slag

ISO 17634 Y electrode core – basic/fluoride, fast-freezing slag

Z electrode core – other types

FM5 Stainless and heat-resisting steels ISO 3581, ISO 14343, ISO 17633

FM6 Nickel and nickel alloys ISO 14172, ISO 18247 any other el ds

S solid wire electrode – solid rod tt w

nm no filler material

bu

horizontal

overhead position

vertical down

position

dimensions of test piece

et welds

s deposited thickness fil l

t material thickness vertical up

D outside tube diameter D position

overhead position

www.dvs-ev.de/DVS-Pruefstellen

Notified bodies for the welder‘s qualification test are regulated by European directives,

t

regulations or standards which apply to approved certification personnel or to accreditation

according to DIN EN ISO / IEC 17024 for the holding of the welder‘s qualification test.

WELDING

e

Issu Issue

The

Welding

Institute

03

2011

03

2011

VALUE

The ng

Weldi te

Institu

Blue Evolution ® Training for a High Quality Standard

© DVS Media GmbH, Düsseldorf

sses

proce processes

allied and allied

g and for welding

eldin Technical journal

rn a l for w

utti ng.ninfo

ic al jou

ing-an d-c Te ch

www.weld

fo

ng.in

d-cutti

in g-an s

.weld tronic

www / Sola

r Elec

logy rprise.

chno by su d«

ng Te unity »col

s / Weldi lding

comm really is exact

at c and

System the we ess th

s take weld proc res a sta

ble ar and light

-

/// simply more ng

GSI - Gesellschaft für Schweißtechnik International mbH • www.gsi-slv.de

ar gi ea el,

ery Ch ry id T), a en su d ste tering,

/ Batt lutiona sfer (C M . And that inium an mal spat ore?

r revo

Detail

Tran welding een alum es: m

ini m

EWM HIGHTEC WELDING GmbH / Dr.Günter-Henle-Str. 8 / D-56271 Mündersbach / www.ewm-group.com ain, ou ld Metal vantag Want to

know

Precision in

e and ag ith Co IG /M AG

in s betw r ad .

M

/ Tim d with entional u we

ld jo . Othe

of re

sults

ey di thick

As th red to conv T lets yo m (0.01 in) ucibility

CM

compa s-control. only 0.3

m reprod s:

100% ide contour

m

proces sheets fro geability, de and outs

s, fine insi es

e

gaug nt gaap p brid nius.com Small hole revolutionis

exce

lle w.fro

w on of Contour Cut

k out:

ww

the precisi l.

Chec ing of mild stee

plasma cutt al

out addition

nology with

A new tech !

components

cos ts and grated as

Con tour Cut is inte

Becaus e

s systems.

all HiFocu

Anzeige_Poster_Schweissverfahren_engl.indd 1 26.04.2012 15:09:19 standard in

g.de

plas ma@kjellber

0 · E-mail:

3531 – 500

Phone: +49 a

bH rg.de/plasm

chinen Gm www.kjellbe

ma und Mas

terwalde Plas terwalde

World wide

Kjellberg Fins · 03238 Fins

r Straße 82

· Leipzige

Germany

ng of

Get your free issue!

cracki

sion l

corro ethano king of

Stress steel in Stress corr

osion crac

carbon ethanol

ous met als: carb on steel in

welding!

s:

etallding ferr

us mWe be sure of

e

ding trad ding fe rro of

re can you

isstec“ wel How

su

el u be preheat?

Third “Schwe LandesmesseW can yo t?accurate

fair in the new How te prehea

de

June 2011

intra accu

ra

eldirtng

Stuwttga

sstec“ messe

www.welding-and-cutting.info

wei es

“Sch nd

Third the new La 2011

fair in t in June

ar

Stuttg

Carl Cloos Schweißtechnik GmbH | D-35708 Haiger www.cloos.de

www.teka.eu info@teka.eu 0 800 / 835 22 25

DVS_Anzeige_08-2013.indd 1 28.8.2013 09:33:00

Potrebbero piacerti anche

- Welding-Standards 23-03-2014Documento1 paginaWelding-Standards 23-03-2014givali100% (7)

- Spot Welding Interview Success: An Introduction to Spot WeldingDa EverandSpot Welding Interview Success: An Introduction to Spot WeldingNessuna valutazione finora

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Documento1 pagina(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- ISO 9606 Revised 4 SeptDocumento34 pagineISO 9606 Revised 4 Septaravindan100% (5)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- ISO Standards On WeldingDocumento22 pagineISO Standards On Weldingmoxshyde100% (1)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDa EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNessuna valutazione finora

- WPS As Per ISO 15609 Ref.Documento3 pagineWPS As Per ISO 15609 Ref.AnilNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- ISO 3834 by SelvaDocumento83 pagineISO 3834 by Selvaaravindan100% (11)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Welding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListDocumento7 pagineWelding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListeliiiiiiNessuna valutazione finora

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalDa EverandFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalValutazione: 4.5 su 5 stelle4.5/5 (3)

- Din en Iso 3834 5Documento17 pagineDin en Iso 3834 5Eduardo Elí Garcia Jimenez100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- ISO 6520 Defects Overview PDFDocumento27 pagineISO 6520 Defects Overview PDFalinor_tn100% (4)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- List of Welding Codes PDFDocumento3 pagineList of Welding Codes PDFAlienshow100% (2)

- Welding Qualification SeminarDocumento66 pagineWelding Qualification SeminarsoparlNessuna valutazione finora

- Böhler Folder Strip Cladding EN WEB PDFDocumento0 pagineBöhler Folder Strip Cladding EN WEB PDFCarlos Bermejo AlvarezNessuna valutazione finora

- Flux Cored WireDocumento38 pagineFlux Cored WireKentDemeterioNessuna valutazione finora

- Welding Course PDFDocumento46 pagineWelding Course PDFRogerio Salvagni100% (1)

- List 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & BarsDocumento76 pagineList 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & Barskhan4luvNessuna valutazione finora

- Welding PresentationDocumento48 pagineWelding Presentationedu_canete100% (2)

- GM Aw and GT Aw ConsumablesDocumento118 pagineGM Aw and GT Aw Consumablessepe00Nessuna valutazione finora

- Technical Data Handbook of TK CorporationDocumento172 pagineTechnical Data Handbook of TK CorporationGerard Adrian Bautista AnonuevoNessuna valutazione finora

- Welding EngineeringDocumento338 pagineWelding EngineeringMuhammed Sulfeek100% (3)

- QC General NotesDocumento21 pagineQC General NotesBilly Kurniawan100% (2)

- Welding Consumables For The Offshore IndustryDocumento24 pagineWelding Consumables For The Offshore IndustryLuis DuarteNessuna valutazione finora

- Aladin SDocumento4 pagineAladin SJeffrey BeanNessuna valutazione finora

- Welders Training Program ManualDocumento140 pagineWelders Training Program ManualAlmario Sagun100% (1)

- Lloyds Approved Plate ManufacturerDocumento82 pagineLloyds Approved Plate ManufacturerUTTAM JAINNessuna valutazione finora

- List1 Lloyd's RegisterDocumento74 pagineList1 Lloyd's RegisterAdrian VintilaNessuna valutazione finora

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Documento45 pagineBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraNessuna valutazione finora

- PDF Engineering) Esab Welding Handbook - 5 EditionDocumento143 paginePDF Engineering) Esab Welding Handbook - 5 Editionmarshall, of course100% (3)

- Cutting Materials, Tools and CoolantsDocumento63 pagineCutting Materials, Tools and CoolantsLeonardo BarabasNessuna valutazione finora

- BK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Documento45 pagineBK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Kev Tra100% (1)

- UTP MaintenanceDocumento28 pagineUTP MaintenanceAnonymous PkAjjOZBNessuna valutazione finora

- List 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & BarsDocumento75 pagineList 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & Barswyvren88Nessuna valutazione finora

- Katalogas enDocumento20 pagineKatalogas enEman AdelNessuna valutazione finora

- 6 Series Tube FittingsDocumento43 pagine6 Series Tube FittingsNilesh MistryNessuna valutazione finora

- General Information Theory - LindabDocumento27 pagineGeneral Information Theory - LindabaudithanNessuna valutazione finora

- Catalogue MetalweldDocumento17 pagineCatalogue MetalweldRadivojevic SasaNessuna valutazione finora

- Welding ElectrodesDocumento36 pagineWelding ElectrodesMersudin Saric100% (4)

- General: Part Number: Status: Overview: DescriptionDocumento2 pagineGeneral: Part Number: Status: Overview: DescriptionhkchingNessuna valutazione finora

- QC Interview Questions IMPDocumento10 pagineQC Interview Questions IMPAnonymous bIe9JSMphsNessuna valutazione finora

- Conexao de Dupla Anilha RotarexDocumento68 pagineConexao de Dupla Anilha RotarexElias Barros de FigueiredoNessuna valutazione finora

- Fundamentals MIG WeldingDocumento3 pagineFundamentals MIG WeldingSreejith MenonNessuna valutazione finora

- Basic Welding Terms - Lincoln Electric PDFDocumento88 pagineBasic Welding Terms - Lincoln Electric PDFpacrabbNessuna valutazione finora

- WeldingDocumento71 pagineWeldingg4gohar100% (2)

- Ductile Iron Grooved Fittings and Couplings: Mech Flow SuppliesDocumento42 pagineDuctile Iron Grooved Fittings and Couplings: Mech Flow SuppliesAna Carolina SantosNessuna valutazione finora

- Pipelines Welding HandbookDocumento64 paginePipelines Welding HandbookSixto GerardoNessuna valutazione finora

- Intellectual Welding TrainingDocumento45 pagineIntellectual Welding Traininggaganesan1972100% (1)

- 100 Series PyroDocumento8 pagine100 Series PyroomkarvadlooriNessuna valutazione finora

- Sample Forms AWS, ASME and APIDocumento14 pagineSample Forms AWS, ASME and APIaamirtec301Nessuna valutazione finora

- 20 Pin Molex 3mmDocumento2 pagine20 Pin Molex 3mmvighnesh shanbhagNessuna valutazione finora

- Iiwhistory1990 2015v1 PDFDocumento233 pagineIiwhistory1990 2015v1 PDFvonipkoNessuna valutazione finora

- Spray TimeDocumento24 pagineSpray TimevonipkoNessuna valutazione finora

- 008 2015 en GL BW Bestseller WebDocumento48 pagine008 2015 en GL BW Bestseller WebNaveen SolankiNessuna valutazione finora

- Iso 9606-2 2004 PDFDocumento40 pagineIso 9606-2 2004 PDFvonipkoNessuna valutazione finora

- Aws Welding Marketplace 2019Documento20 pagineAws Welding Marketplace 2019vonipkoNessuna valutazione finora

- Iiwhistory1990 2015v1 PDFDocumento233 pagineIiwhistory1990 2015v1 PDFvonipkoNessuna valutazione finora

- Gmaw Arc FundaDocumento11 pagineGmaw Arc FundavonipkoNessuna valutazione finora

- Selection Chart XZDocumento1 paginaSelection Chart XZvonipkoNessuna valutazione finora

- Welding Codes and How They Re UsedDocumento5 pagineWelding Codes and How They Re Usedprasad_kcpNessuna valutazione finora

- Corus Prevention of Corrosion On Structural Steelwork PDFDocumento28 pagineCorus Prevention of Corrosion On Structural Steelwork PDFvonipkoNessuna valutazione finora

- FSV Phase2 Overview Report PDFDocumento79 pagineFSV Phase2 Overview Report PDFvonipkoNessuna valutazione finora

- Weld Inspection and RepairDocumento10 pagineWeld Inspection and RepairDeepak Kumar Kant KesriNessuna valutazione finora

- Welding Quality Control Plan ReqDocumento2 pagineWelding Quality Control Plan ReqPaul MathewNessuna valutazione finora

- 14 Day KetoDocumento37 pagine14 Day KetoKrisna May Buhisan PecoreNessuna valutazione finora

- MNL46 ForewordDocumento16 pagineMNL46 ForewordvonipkoNessuna valutazione finora

- Poster Weldingpositions enDocumento1 paginaPoster Weldingpositions enslowmosquitoNessuna valutazione finora

- ETouch L1Documento42 pagineETouch L1vonipkoNessuna valutazione finora

- Wpar S690 138Documento3 pagineWpar S690 138vonipkoNessuna valutazione finora

- ESIS Newsletter55Documento25 pagineESIS Newsletter55vonipkoNessuna valutazione finora

- Navigator 2011-04 PDFDocumento68 pagineNavigator 2011-04 PDFvonipkoNessuna valutazione finora

- Fro Bro Vs247317 EngDocumento4 pagineFro Bro Vs247317 EngvonipkoNessuna valutazione finora

- EBSCO Egs CoverageDocumento39 pagineEBSCO Egs CoveragevonipkoNessuna valutazione finora

- Welding Research CoolingDocumento7 pagineWelding Research CoolingHoangNessuna valutazione finora

- QWS Best Practices GuideDocumento34 pagineQWS Best Practices GuidechowhkNessuna valutazione finora

- AWS Welders Training Sense - Presentation PDFDocumento24 pagineAWS Welders Training Sense - Presentation PDFvonipkoNessuna valutazione finora

- Targus SpecificationDocumento23 pagineTargus SpecificationvonipkoNessuna valutazione finora

- Crude Oil Storage Tanks-BasicsDocumento176 pagineCrude Oil Storage Tanks-BasicsPandipperumal Sankaralingam100% (44)

- Hist QA Module 2Documento7 pagineHist QA Module 2vonipkoNessuna valutazione finora

- Slip Rings: SRI085 V100 - XX - XX - Xxx1XxDocumento3 pagineSlip Rings: SRI085 V100 - XX - XX - Xxx1XxMatheus Henrique MattiaNessuna valutazione finora

- Chem 1211 Lab ReportDocumento9 pagineChem 1211 Lab Reportansleybarfield0% (1)

- Water Levels Forecast in Thailand: A Case Study of Chao Phraya RiverDocumento6 pagineWater Levels Forecast in Thailand: A Case Study of Chao Phraya RiverErna UtamiNessuna valutazione finora

- C191HM Powermeter and Harmonic Manager CommunicationsDocumento30 pagineC191HM Powermeter and Harmonic Manager CommunicationsRoberto GarridoNessuna valutazione finora

- Chapter 6 - Process Capability AnalysisDocumento21 pagineChapter 6 - Process Capability AnalysisKaya Eralp AsanNessuna valutazione finora

- Entropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6Documento14 pagineEntropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6HarishChoudharyNessuna valutazione finora

- Tutoriales Mastercam V8 6-11Documento128 pagineTutoriales Mastercam V8 6-11Eduardo Felix Ramirez PalaciosNessuna valutazione finora

- SR-X Script Reference - EDocumento24 pagineSR-X Script Reference - EDomagoj ZagoracNessuna valutazione finora

- Lab Assignment - 2: CodeDocumento8 pagineLab Assignment - 2: CodeKhushal IsraniNessuna valutazione finora

- L4 Subdivision of PlotsDocumento20 pagineL4 Subdivision of PlotsKenny BoatNessuna valutazione finora

- Practical Report Guideline EEE250Documento8 paginePractical Report Guideline EEE250MOHD ASYRAAF BIN SAIDINNessuna valutazione finora

- Teaching Tactics and Teaching Strategy: Arthur W. Foshay'Documento4 pagineTeaching Tactics and Teaching Strategy: Arthur W. Foshay'Ahmed DaibecheNessuna valutazione finora

- Vertical Ow Constructed Wetland Planted With Heliconia Psittacorum Used As Decentralized Post-Treatment of Anaerobic Ef Uent in Southern BrazilDocumento10 pagineVertical Ow Constructed Wetland Planted With Heliconia Psittacorum Used As Decentralized Post-Treatment of Anaerobic Ef Uent in Southern BrazilAlfonso Ruiz PérezNessuna valutazione finora

- Three - Dimensional Viscous Confinement and Cooling of Atoms by Resonance Radiation PressureDocumento6 pagineThree - Dimensional Viscous Confinement and Cooling of Atoms by Resonance Radiation PressureWenjun ZhangNessuna valutazione finora

- The Number MysteriesDocumento3 pagineThe Number Mysterieskothari080903Nessuna valutazione finora

- Incompressible Flow in Pipe Networks.Documento7 pagineIncompressible Flow in Pipe Networks.Ayub Ali WehelieNessuna valutazione finora

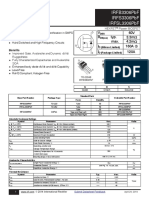

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocumento12 pagineIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligNessuna valutazione finora

- Magnetism NotesDocumento14 pagineMagnetism Notesapi-277818647Nessuna valutazione finora

- A Simulation-Based Process Model For Managing Complex Design ProcessDocumento13 pagineA Simulation-Based Process Model For Managing Complex Design ProcessMetehan AgacaNessuna valutazione finora

- Cleats CatalogueDocumento73 pagineCleats Cataloguefire123123Nessuna valutazione finora

- Trigonometric Ratios LPDocumento3 pagineTrigonometric Ratios LPjoshgarciadlt100% (2)

- Combined Geo-Scientist (P) Examination 2020 Paper-II (Geophysics)Documento25 pagineCombined Geo-Scientist (P) Examination 2020 Paper-II (Geophysics)OIL INDIANessuna valutazione finora

- Ug CR RPTSTDDocumento1.014 pagineUg CR RPTSTDViji BanuNessuna valutazione finora

- Workshop 2 Electrical Installations Single PhaseDocumento3 pagineWorkshop 2 Electrical Installations Single PhaseDIAN NUR AIN BINTI ABD RAHIM A20MJ0019Nessuna valutazione finora

- Completing The Square PDFDocumento10 pagineCompleting The Square PDFgreg heffleyNessuna valutazione finora

- Driver LCI 150W 500-850ma FlexC NF h28 EXC3 enDocumento7 pagineDriver LCI 150W 500-850ma FlexC NF h28 EXC3 enMoustafa HelalyNessuna valutazione finora

- University of Cambridge International Examinations General Certificate of Education Advanced LevelDocumento4 pagineUniversity of Cambridge International Examinations General Certificate of Education Advanced LevelHubbak KhanNessuna valutazione finora

- 5R55W-S Repair DiagnosisDocumento70 pagine5R55W-S Repair Diagnosisaxallindo100% (2)

- Data Mining ConceptsDocumento175 pagineData Mining ConceptsNikolya SmirnoffNessuna valutazione finora

- (Complete) Electrolysis of Copper SulphateDocumento4 pagine(Complete) Electrolysis of Copper SulphateNoooooNessuna valutazione finora