Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sample WPS Format PDF

Caricato da

ait.koufiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sample WPS Format PDF

Caricato da

ait.koufiCopyright:

Formati disponibili

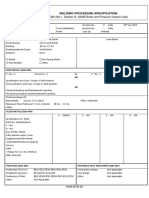

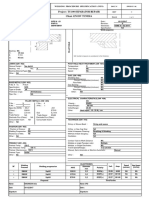

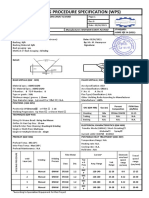

Sample Welding Procedure Specification Sample

(www.weldingandndt.com) (WPS) (www.weldingandndt.com)

WPS No: Revision: Date: Client:

PQR No: Revision: Date: Third Party Agency:

Code: Welding Process(es): Company Name:

Page: Type(s): Project:

JOINTS (QW-402) POST WELD HEAT TREATMENT (QW-407)

Holding Temperature Range: (ASME BPVC SEC VIII DIV 1-Nonmandatory Appendix R)

Joint Design:

Backing: □ Yes □ No Holding Time :

Backing Material (Type): Heating Rate:

□ Base Metal □Nonfusing Metal Cooling Rate:

□ Nonmetallic □Weld Metal PWHT Chart:

Root Openning: Root Face : GAS: (QW-408) (ASME SEC IIC SFA-5.32)

Groove Angle: Radius (J-U): Percent Composition:

Back Gouging: Gas(es): Mixture: flow rate:

BASE METAL: (QW-403) Shielding

P No: (Table Group No: (Table

Group No: P No:

QW/QB-422) QW/QB-422) Trailing:

Specification Type & Grade Specification Type & Grade Backing:

(Table QW/QB-422) TO (Table QW/QB-422) ELECTRICAL CHARACTERISTICS: (QW-409)

Chemical Analysis & Mech. Prop: Chemical Analysis & Mech. Prop: Current AC or DC: Polarity:

(ASME SEC IIA) (ASME SEC IIA) Amps .(Range):

Thickness Range : Volt .(Range):

Base Metal : (QW-451.1) Groove: Fillet : Tungsten Electrode Size and Type: (ASME SEC IIC SFA-5.12)

Pipe Dia. Range : Mode of Metal Transfer for GMAW: (ASME SEC IIC SFA-5.18)

FILLER METAL: (QW-404) Electrode Wire Feed Speed Range:

Spec.No.(SFA): (ASME SEC IIC) AWS NO.(Class): (ASME SEC IIC) Heat input Allowance:

F-No: (Table QW-432) A-No: (Table QW-442)

Size of Filler Metals: Weld Metals: Deposited Thickness WELDING TECHNIQUE: (QW-410)

Electrode-Flux(Class): Groove: (Table QW-451.1) Stringer/Weave Bead:

Brand Name: Fillet: Orifice or Gas Cup Size:

Consumable Insert: Initial & Interpass cleaning :

Other: Metode of Back Gouging:

POSITIONS: (QW-405) Oscillation:

Position of Groove: Contact Tube to Word Distance:

Welding Progressions: □ Up Hill □ Down Hill Multiple or Singel Pass(per side):

Position(S) of Fillet: Multiple or Singel Electrodes:

PREHEAT (QW-406) Travel Speed (Range):

Preheat Temp.min:

Peening:

(ASME BPVC SEC VIII DIV 1-Nonmandatory Appendix R)

Inter Pass Temp.max: Other:

Preheat Maintenace:

WELDING PROCEDURE:

Joint Details

Filler Metal Current (ASME SEC IIC)

Heat Input Travel Speed

Pass Process

(kj/mm) (mm/min)

Class Dia Polarity Volt AMP

RUN SEQUENCE

1.Fit Up 2.Welding*/Cleaning 3.Visual Inspection 4.NDT(RT,UT,PT,MT)**

*:Distortion Control Shall be Consider. ** As Per Quality specs and Documents ( QCP )

Prepared By: Approved By: Inspector: Client:

Date: Date: Date: Date:

Sign: Sign: Sign: Sign:

Potrebbero piacerti anche

- Wps Format Asme Sec - IxDocumento2 pagineWps Format Asme Sec - IxDeepu ChandranNessuna valutazione finora

- Joint Detail (Qw-402)Documento2 pagineJoint Detail (Qw-402)Nitesh Patel100% (3)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocumento5 pagineWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNessuna valutazione finora

- Comparision of ISO 9712 & ASNTDocumento6 pagineComparision of ISO 9712 & ASNTMurali Krishnan Selvaraja100% (1)

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Documento2 pagineLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNessuna valutazione finora

- PQR FormatDocumento2 paginePQR FormatBE GNessuna valutazione finora

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Documento2 pagineWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- QW483Documento2 pagineQW483Sc TanNessuna valutazione finora

- WPS PQR ProcedureDocumento31 pagineWPS PQR Proceduresudeesh kumarNessuna valutazione finora

- WPS PQR Procedure PDFDocumento31 pagineWPS PQR Procedure PDFsudeesh kumarNessuna valutazione finora

- WPS E6013+e7018Documento2 pagineWPS E6013+e7018Anvesh Vaddi100% (1)

- Wps Blank Form 2sheetDocumento4 pagineWps Blank Form 2sheetdidi sudiNessuna valutazione finora

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocumento10 pagineWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Piping WPS SMAWDocumento2 paginePiping WPS SMAWJk KarthikNessuna valutazione finora

- Procedure Qualification Record (PQR)Documento3 pagineProcedure Qualification Record (PQR)surjithkocherilNessuna valutazione finora

- Welding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic MachineDocumento1 paginaWelding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic Machinesoroushsadeghi60Nessuna valutazione finora

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocumento6 pagineWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNessuna valutazione finora

- QW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToDocumento2 pagineQW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToattaullaNessuna valutazione finora

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Documento2 pagineQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNessuna valutazione finora

- Wps For Steel RodsDocumento5 pagineWps For Steel RodsHamid MansouriNessuna valutazione finora

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Documento4 pagineWelding Procedure Specification (WPS) : JOINTS (QW-402)Andhira FarizkiNessuna valutazione finora

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Wps FormatDocumento2 pagineWps FormatParminder SinghNessuna valutazione finora

- 19403955-WPS M.S. Is 2062Documento10 pagine19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Documento2 pagineQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNessuna valutazione finora

- WPS&PQR For PipeDocumento5 pagineWPS&PQR For PipeKAMALNessuna valutazione finora

- Ex Wps Train 01Documento2 pagineEx Wps Train 01aidil30Nessuna valutazione finora

- PWPS CS To SS446-3Documento5 paginePWPS CS To SS446-3BIIS QAQC Babu SivaNessuna valutazione finora

- WPS FormatDocumento3 pagineWPS Formatvivek bhangaleNessuna valutazione finora

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocumento2 pagineQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNessuna valutazione finora

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Documento2 pagineTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNessuna valutazione finora

- WPQ FormatDocumento8 pagineWPQ FormatsanjaykumarmauryaNessuna valutazione finora

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocumento3 pagineWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNessuna valutazione finora

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Documento3 pagineAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNessuna valutazione finora

- WPS FormDocumento1 paginaWPS FormNabil RadyNessuna valutazione finora

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocumento5 pagineWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNessuna valutazione finora

- Welding Procedure Specification: JOINT (QW-402)Documento10 pagineWelding Procedure Specification: JOINT (QW-402)Lipika GayenNessuna valutazione finora

- QW-482 (WPS) GTAW 4MM FilletDocumento4 pagineQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNessuna valutazione finora

- WPS 10Documento2 pagineWPS 10Arab WeldersNessuna valutazione finora

- WPS No. ST-CS-02-2Documento1 paginaWPS No. ST-CS-02-2Hussein JassimNessuna valutazione finora

- WPS-035 - (Pno.15e To Pno.7) - 2Documento2 pagineWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNessuna valutazione finora

- Final WPS - ItdcDocumento2 pagineFinal WPS - ItdcsarancivilrajNessuna valutazione finora

- WPS PQR CompleteDocumento49 pagineWPS PQR CompleteGulfam HussainNessuna valutazione finora

- QW-482 Suggested Format For Welding ProcDocumento2 pagineQW-482 Suggested Format For Welding Procsachin0% (1)

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Documento1 paginaProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNessuna valutazione finora

- WC9Documento5 pagineWC9Suresh KrishnanNessuna valutazione finora

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocumento4 pagineQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Nessuna valutazione finora

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocumento2 pagineWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobiniNessuna valutazione finora

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocumento2 pagineWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNessuna valutazione finora

- Welding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxDocumento4 pagineWelding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxLipika GayenNessuna valutazione finora

- Aic Asf PQR 0119Documento2 pagineAic Asf PQR 0119AHMED MEDANYNessuna valutazione finora

- Qw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocumento2 pagineQw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Nessuna valutazione finora

- WPS For Carbon Steel THK 7.11 GTAWDocumento1 paginaWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocumento1 paginaWps For Carbon Steel THK 7.11 GtawAli MoosaviNessuna valutazione finora

- Ejemplo Prueba 991003Documento2 pagineEjemplo Prueba 991003MARIO ALBANessuna valutazione finora

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Documento2 pagineWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiNessuna valutazione finora

- F5-Welding Procedure SpecificationDocumento2 pagineF5-Welding Procedure Specificationveera Satya saiNessuna valutazione finora

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocumento1 paginaCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNessuna valutazione finora

- Form PQR 1 AsmeDocumento6 pagineForm PQR 1 AsmeZam Zam NoorNessuna valutazione finora

- Huawei LDS IDS SolutionDocumento19 pagineHuawei LDS IDS Solutionait.koufiNessuna valutazione finora

- BATD515 - Defect Assessment in PipelinesDocumento7 pagineBATD515 - Defect Assessment in Pipelinesait.koufiNessuna valutazione finora

- Leak Detection TechnologyDocumento49 pagineLeak Detection Technologyait.koufiNessuna valutazione finora

- The API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadDocumento32 pagineThe API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadthiagopontualNessuna valutazione finora

- Onepage V7 BDocumento2 pagineOnepage V7 Bait.koufiNessuna valutazione finora

- Atmos Wave AWAS-6: 3 Channel, High-Speed, High-Resolution, Pressure Data Acquisition UnitDocumento4 pagineAtmos Wave AWAS-6: 3 Channel, High-Speed, High-Resolution, Pressure Data Acquisition Unitait.koufiNessuna valutazione finora

- Inspection AutomtiqueDocumento21 pagineInspection Automtiqueait.koufi100% (1)

- Inspection AutomtiqueDocumento21 pagineInspection Automtiqueait.koufi100% (1)

- Depliant - Integrated Solutions Safety-V1Documento2 pagineDepliant - Integrated Solutions Safety-V1boulemiaNessuna valutazione finora

- Surface PreparationDocumento15 pagineSurface PreparationsawwahwahNessuna valutazione finora

- Surface Preparation Guide PDFDocumento13 pagineSurface Preparation Guide PDFait.koufiNessuna valutazione finora

- Brochure GEKKO v2.3Documento8 pagineBrochure GEKKO v2.3KoufiNessuna valutazione finora

- Job Description - Welding Engineer - ViergeDocumento2 pagineJob Description - Welding Engineer - Viergeait.koufiNessuna valutazione finora

- GGGGGGDocumento140 pagineGGGGGGMerdas ChamseddineNessuna valutazione finora

- NORDTEST DOC GEN 010 Edition6 Version2 PDFDocumento8 pagineNORDTEST DOC GEN 010 Edition6 Version2 PDFRohit GadekarNessuna valutazione finora

- Data Overview - Workshop SupervisorDocumento1 paginaData Overview - Workshop SupervisorMunavir kNessuna valutazione finora

- NORDTEST DOC GEN 010 Edition6 Version2 PDFDocumento8 pagineNORDTEST DOC GEN 010 Edition6 Version2 PDFRohit GadekarNessuna valutazione finora

- Data Overview - Workshop SupervisorDocumento1 paginaData Overview - Workshop SupervisorMunavir kNessuna valutazione finora

- Sample WPS Format PDFDocumento1 paginaSample WPS Format PDFait.koufiNessuna valutazione finora

- CV-AIT KOUFI Metallurgist Engineer - QAQC Welding NDT Coating Head DPT - EnGDocumento3 pagineCV-AIT KOUFI Metallurgist Engineer - QAQC Welding NDT Coating Head DPT - EnGait.koufiNessuna valutazione finora

- الحروب الصليبية في شمال افريقياDocumento797 pagineالحروب الصليبية في شمال افريقياAbdalrahim Al RantisiNessuna valutazione finora

- ASME Sec VIII Div 1Documento120 pagineASME Sec VIII Div 1kanchanabalaji96% (23)