Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Truss Connection

Caricato da

Chinnaraja Gandhi0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

15 visualizzazioni5 pagineTruss connection

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTruss connection

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

15 visualizzazioni5 pagineTruss Connection

Caricato da

Chinnaraja GandhiTruss connection

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

UNCONVENTIONAL STEEL CONNECTIONS:

SOME NEW APPROACHES

To meet the special demands of modern bridge

construction, equipment designers have developed

innovative ways to connect steel

By Boris Levintov, Ph.D., P.E.

EXPECT THE UNEXPECTED

B

UILDERS AND ARCHITECTS

TODAY PLACE A HIGH PREMI-

It is axiomatic that connections in falls considerably short of these

UM on originality, vying

continually with one another to

steel structures are critical to struc- requirements, so that the results

obtained by the application of beam

“push the envelope” of daring

tural strength. Indeed, several well-

formulas are of questionable value

design. It is the structural engi-

publicized disasters in recent years

and may be misleading” (E. Gaylord,

neer, of course, who must come

have been attributed to the failure of

Design of Steel Structures; McGraw-

up with a sound structural

a single connection, which then

Hill, 2nd ed., 1972).

underpinning to support these

caused the collapse of an otherwise

lofty concepts. Very often, this

sound structure. At the same time, In practice, gusset plate thick- means the engineer must go far

the structural connections are often nesses are generally chosen in beyond the “standard” engineer-

the most complex elements within accordance with average values for ing literature. This is particu-

an overall design. This is especially similar structures rather than accord- larly true in the area of structur-

true with many of today’s highly ing to beam formulas. Experience al connections, where the

sophisticated and highly irregular thereby serves as a guide to current accepted standards may not be

bridge and building structures, which practice. But the designers of mod- sufficient to meet the stress and

do not always behave in a “textbook” ern, unique steel structures, unfortu- strength requirements posed by

fashion, and which therefore do not nately, do not always have a reliable non-traditional structures.

comfortably fit into the range of stan- model to imitate. Since standard One fruitful source of new

dard practice. empirical equations are not available approaches and solutions is

Despite this, there is a tendency for unique designs, engineers must bridge construction, and more

among designers to use the same rely on their intuition and experience specifically, in the innovative

theoretical tools for connection to assess unique conditions and designs of the unique steel

designs as for structural members. respond with appropriate solutions. equipment that has been devel-

Consider a commonly used bridge In short, reliable connections oped to meet the challenges of

truss, whose members are connect- demand a great deal of engineering advanced bridge construction.

ed by gussets. AASHTO guidelines skill and effort, more than is some- There is good historical prece-

specify that “gusset plates shall be times realized, and this issue dent for this, by the way: when

designed for shear, bending and an becomes more critical as structures Bradford Lee Gilbert announced

axial load by the conventional become more complex. In each of plans for the Tower Building,

‘Method-of-Section’ procedures.” In the examples in this article, the New York City’s first skyscraper,

other words, the elementary formu- designer was faced with connection in 1885, he declared that his

las for beams are considered applic- problems that had no obvious “text- intention was “to stand a steel

able to gusset plate connections as book” solutions. In each, it was nec- bridge structure on end.”

well. essary to devise unique connection

Yet it has been well known for details that would assure the integri- TRIANGULAR TRUSSES FOR

decades that this is not strictly true. ty and proper performance of the CANTILEVER CONSTRUCTION

As one textbook warns, these formu- equipment. The general lesson is Most three-dimensional steel

las “are valid only for beams whose that, when confronting undocument- trusses have rectangular cross-

span is more than twice the depth ed connection issues, structural sections, with the diagonals are

and at cross sections not closer to designers should be alert for situa- in either a vertical or a horizon-

concentrated loads than about half tions that demand an innovative tal plane. The state of the art for

the depth. The ordinary gusset plate design approach. design of rectangular trusses is

well established, and adequate

Modern Steel Construction / December 1996

connection details may be found

in any technical manual on steel

structures.

In many applications, triangu-

lar trusses can perform the same

function as rectangular trusses.

Moreover, with one top chord

instead of two and less bracing

between the chords, triangular

trusses offer the considerable

economic advantage of requiring

less steel. But the design of tri-

angular trusses is far more com-

plicated, since chords connect to

diagonals at oblique rather than

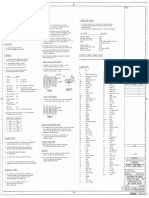

perpendicular angles, and there Fig. 1. Triangular truss designed with diago-

is no standard textbook solution nals welded to angled gusset plates

for the design of such connec-

tions.

The concept of a triangular

truss for a launching gantry was

recently developed for the can-

tilevered precast-concrete-box-

girder construction of sections of

Boston’s Central Artery Project.

In this application, two triangu-

lar trusses would be used as a

runway for a gantry crane that

transports and erects precast

segments. As each bridge span

is completed, the trusses are

advanced on that span and the

next span is constructed. Each

truss has to carry the moving Fig. 2. Cross-members

vertical load from the gantry connected to gusset

crane as it delivers the bridge plates welded to two

segments, the lateral force dissimilar girders

imposed by the moving crane on resulted in a homoge-

the top chord, and the lateral neous girder-truss sup-

force the advancing truss trans- port system

fers to the bottom chord. The

critical design issue was the

capacity of the top chord to with-

stand high moments created by

horizontal forces. chord’s stiffeners and the diago- GIRDER-TRUSS FOR SPAN-BY-

The truss designer proposed a nal gussets creates a rigid beam SPAN CONSTRUCTION

combination of vertical and that carries lateral forces and Span-by-span bridge construc-

inclined gusset plates welded to eccentricity moments to the diag- tion with precast concrete box

each other, to the top chord, and onals and bottom chords. segments often employs either

to the diagonals. As Figure 1 A similar arrangement of gus- trusses or girders to support

shows, the central vertical plate set plates was designed for the each segment under its wings

is in the plane of the top chord bottom chord. In addition, mini- prior to post-tensioning. In the

web; the two others are aligned trusses were introduced to bal- design of the Panchiao Viaduct

in the angles of the truss diago- ance forces between the flanges in China, the space under the

nals. This design permits the of the bottom chords. The pre- wings was too shallow for a

axial force to flow from the top- cise distribution of forces allowed stand-alone truss, and single

chord beam web to the vertical the designer to employ typical girders on either side would have

gusset plate, which then distrib- bolted shear splices for the top lacked the stability to support

utes the load between the diago- and bottom chords and typical either lateral adjustments or the

nal gusset plates. At the same pin connections at the diagonal whole supporting system as it

time, the combination of the end points. advances. Thus an unusual

Modern Steel Construction / December 1996

Fig. 4. During transport, bridge spans sat

on frames bolted to crown plates that were

connected by full-penetration welds to the

inclined tower legs.

girder-truss combination was

introduced.

The segment-supporting sys-

tem consisted of one tall and one

short girder connected by diago-

nal members. The tall girder

would bear the dead load of the

segment and the short girder,

acting as a truss chord, would

bear lateral loads during adjust-

ment of the segments. The space

truss was designed with diago-

nals and verticals to connect the

top and bottom flanges of the tall

girder with the short girder,

which itself became a truss

chord (Figure 2).

The design challenge was to

develop member connections to

convert this highly asymmetrical

system into a homogeneous

structure. The solution was to

weld gusset plates to the girder

stiffeners at oblique angles that

would accommodate vertical and

Fig. 3. Span of Coleman Bridge supported by unique barge-tower diagonal truss members in two

transport system. Tower design required innovative steel connections planes. Thus the stiffeners, in

described in article. combination with the girder

Modern Steel Construction / December 1996

webs, effectively became truss

members.

This unique gusset plate

design offered an efficient and

economical solution to a rare

truss/girder application.

BRIDGE-SPAN TRANSPORT

SYSTEM

A project to design 51’-tall

twin towers for transporting

fully constructed replacement

spans of the George P. Coleman Fig. 5. Tower bracing con-

Bridge on the York River in sisted of diaphragms and

Virginia offered a variety of diagonal pipes welded to

unprecedented opportunities for gusset plates.

developing original steel connec-

tions (Figure 3). In order to

meet a highly accelerated 12-day

schedule for replacing all above-

water spans of the bridge, the

contractor completed fabrication

of the replacements 40 miles

upriver and planned to transport

the structures on towers mount-

ed on linked barges to the pre-

existing piers.

In terms of connections, the

tower designer had four objec-

tives:

1. Stabilize the tower tops to

accommodate the spans,

which were up to 559 feet long

and weighed as much as 4128

tons; Fig. 6. One half of tower pivoting sys-

2. Brace the unusual V-shaped tem, showing base plate, tie, and legs,

tower-leg system; all connected by welds.

3. Develop a pivoting mechanism

at the tower base (the point of

the “V”) to enable the entire

system to adjust to lateral

forces; and Fig. 7. Design of A-

4. Transfer the lateral forces bracket that trans-

from the loaded tower system ferred lateral forces

to bulkheads below the barge from tower base to

deck. below-deck barge bulk-

At each tower top, a rectangu- heads.

lar frame was designed to

receive a four-point load; each

bridge span would therefore be

supported at eight points. The

frame was bolted to thick crown

plates that were welded to the

leg tops (Figure 4). A load from

a bridge span would thereby be

transmitted through the frame

diaphragms to the frame base,

through the crown plates, and

eventually to the tower legs.

The key to this detail was the

introduction of the crown plates,

Modern Steel Construction / December 1996

plates, were The basic approach of welding an

designed to slide in inner corner where three plates

the direction of the intersect may result in lamellar

elongation when a tearing and subsequent structur-

bridge span was al failure when sequential ten-

applied to the tow- sion forces are applied.

ers. Potential tension failure of an

Transverse inner knee connection was a

Forces. The com- major concern in the design of C-

bination of barge shaped hanger frames proposed

and tug motions for the construction of the Dame

and wind and Point Bridge in Jacksonville,

wave pressures Florida. The frames were to be

would create the used to support and advance

transverse compo- formtravelers for casting invert-

nent of the cargo ed-U bridge segments.

weight, a force The equipment designer pro-

comprising hun- posed that the necessary

dreds of kips of strength could be achieved by

random loading. fusing a square bar of low-sulfur

The design strate- steel to the inner intersection of

gy was to absorb the three hanger plates. Low-

these forces at the sulfur steel has an improved

tower base and through-thickness ductility, and

transfer them thus is highly resistant to lamel-

Fig. 8. C-hanger and detail of low-sulfur steel directly to the lar tearing. The bar was con-

bar welded to inner knee to resist tension forces. barge bulkheads. nected at the required angles to

To perform this the C-frame knee with a full-

function, large “A”-shaped brack- penetration weld, creating a

to which leg tops could be con- ets, which would serve as hori- homogeneous node (Figure 8).

nected by full-penetration welds. zontal restraints, were first C-frames containing this

Bracing Connections. Design installed near the bearing pins detail performed successfully in

of the bracing connections (Figure 7). The vertical tension the construction of both the

between the legs was complicat- component of the bracket would Dame Point Bridge and the

ed by the leg inclinations, by the be a T-shaped post anchored by Glebe Island Bridge in Australia.

box shape configurations of the vertical bars that passed Low-sulfur steel is manufactured

legs and the upper frame, and by through the deck where they by Bethlehem under the Integra

the inverted T-section shape of were welded to vertical plates. brand name and by Lukens

ties. The solution was to install The other ends of the plates were under the Fineline brand name.

diaphragms and gusset plates at in turn welded to the bulkheads.

different angles to connect the The key to this solution was to ART IN DESIGN

diagonal pipes with the rectan- also weld the tops of these plates Because of their complexity

gular boxes of the main members to the bottom of the 0.5-inch- and structural importance, con-

(Figure 5). thick barge deck. The deck and nections are among the most dif-

Pivoting System. The pivot- plate thereby acted together as a ficult and costly design and con-

ing system comprised two pin stiff beam to successfully carry struction details. For reasons of

bearings, thick base plates, and all applied loads to the bulk- safety and durability alone, the

a horizontal tie joining the “V” heads. author believes that connections

end points (Figure 6). The legs should be receiving the increased

were connected by full penetra- KNEE CONNECTIONS attention of design engineers.

tion welds to the vertical and Knee or haunch connections Because they serve as a visual

horizontal components of the tie. are common in building frames. focal point in many steel pro-

The welds created a smooth force The inner corners of such frames jects, innovative and well-

transition from each leg to the are typically strengthened with a designed connections also have

tie and to the bearing plates on welded compression node, a the potential to greatly enrich an

which the tie ends were seated. standard and well-developed overall design. Indeed, many

The tie spanned the space design. In contrast, methods to critics who address themselves

between the leg bottoms and strengthen inner knee-frame cor- to the aesthetic aspects of build-

ensured uniform movement of ners subjected to tension forces ings, bridges, and other engi-

the two leg sets. The pin bear- are not readily available in the neering and architectural works

ings, located under the base body of engineering standards. often give considerable attention

Modern Steel Construction / December 1996

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Lab 2.1Documento2 pagineLab 2.1Manjari Srivastava100% (3)

- Chap 8 Mechnical Properties of MetalDocumento41 pagineChap 8 Mechnical Properties of MetalAhmad Fakhrie Shah0% (1)

- DP1100Documento3 pagineDP1100tunradotNessuna valutazione finora

- Bsee201 B - Fluid MechanicsDocumento150 pagineBsee201 B - Fluid MechanicsMarvin GagarinNessuna valutazione finora

- UntitledDocumento1 paginaUntitledChinnaraja GandhiNessuna valutazione finora

- Youtube ChannelDocumento1 paginaYoutube ChannelChinnaraja GandhiNessuna valutazione finora

- The Personal Mastery Journal - DailyDocumento85 pagineThe Personal Mastery Journal - DailyChinnaraja GandhiNessuna valutazione finora

- Grandma ThoughtDocumento3 pagineGrandma ThoughtChinnaraja GandhiNessuna valutazione finora

- PassportDocumento1 paginaPassportChinnaraja GandhiNessuna valutazione finora

- Wiac - Info PDF Learn Telugu Through Tamil PRDocumento3 pagineWiac - Info PDF Learn Telugu Through Tamil PRChinnaraja GandhiNessuna valutazione finora

- PassportDocumento1 paginaPassportChinnaraja GandhiNessuna valutazione finora

- Dunes International School: L.15-Knowledge Is PowerDocumento3 pagineDunes International School: L.15-Knowledge Is PowerChinnaraja GandhiNessuna valutazione finora

- Famous Person (Autosaved)Documento5 pagineFamous Person (Autosaved)Chinnaraja GandhiNessuna valutazione finora

- Metals and Non - MetalsDocumento3 pagineMetals and Non - MetalsChinnaraja GandhiNessuna valutazione finora

- Dunes International SchoolDocumento3 pagineDunes International SchoolChinnaraja GandhiNessuna valutazione finora

- Dunes International SchoolDocumento4 pagineDunes International SchoolChinnaraja GandhiNessuna valutazione finora

- Palker Food Forest Model: Land Area: 16'x16' Model-6Documento1 paginaPalker Food Forest Model: Land Area: 16'x16' Model-6Chinnaraja GandhiNessuna valutazione finora

- NEROLAMDocumento56 pagineNEROLAMChinnaraja GandhiNessuna valutazione finora

- Loadout AnalysisDocumento23 pagineLoadout AnalysisChinnaraja GandhiNessuna valutazione finora

- Dunes International School: Worksheet Answer Key Subject: SST Class: 5 Section: NameDocumento4 pagineDunes International School: Worksheet Answer Key Subject: SST Class: 5 Section: NameChinnaraja GandhiNessuna valutazione finora

- General NotesDocumento12 pagineGeneral NotesChinnaraja GandhiNessuna valutazione finora

- HKTS 9/16: Home Theater Speaker SystemDocumento14 pagineHKTS 9/16: Home Theater Speaker SystemChinnaraja GandhiNessuna valutazione finora

- 2021 Calendar: January 2021 February 2021Documento1 pagina2021 Calendar: January 2021 February 2021Chinnaraja GandhiNessuna valutazione finora

- ZDM BrochureDocumento24 pagineZDM BrochureChinnaraja GandhiNessuna valutazione finora

- Natwest Inter Cricket Session PlansDocumento30 pagineNatwest Inter Cricket Session PlansChinnaraja GandhiNessuna valutazione finora

- Juniors Cricket Coaching GuideDocumento78 pagineJuniors Cricket Coaching GuideChinnaraja GandhiNessuna valutazione finora

- Water Tank DesignDocumento1 paginaWater Tank DesignChinnaraja GandhiNessuna valutazione finora

- Blue Footed BoobyDocumento4 pagineBlue Footed BoobyChinnaraja GandhiNessuna valutazione finora

- Spectral Fatigue Flow Chart PDFDocumento1 paginaSpectral Fatigue Flow Chart PDFChinnaraja GandhiNessuna valutazione finora

- SingingDocumento3 pagineSingingChinnaraja GandhiNessuna valutazione finora

- ManualDocumento9 pagineManualRonit DattaNessuna valutazione finora

- KEDDCO BinderDocumento74 pagineKEDDCO BinderWillian FigueroaNessuna valutazione finora

- Scarifier 9 Piecies Tooth TypeDocumento2 pagineScarifier 9 Piecies Tooth Typeangga setyawanNessuna valutazione finora

- 02 MF Anchors PDFDocumento13 pagine02 MF Anchors PDFThaksenNessuna valutazione finora

- CENG6206 Soil Dynamics ExerciseProblemDocumento4 pagineCENG6206 Soil Dynamics ExerciseProblemFekadu Wub100% (1)

- DP Chipset 15045 DriversDocumento592 pagineDP Chipset 15045 DriversRajesh1146Nessuna valutazione finora

- First-Man-Up User ManualDocumento24 pagineFirst-Man-Up User ManualJoshuaNessuna valutazione finora

- Da10 Air Cooled Engine (Appn Code D3.2007 & D3Documento26 pagineDa10 Air Cooled Engine (Appn Code D3.2007 & D3Sandeep NikhilNessuna valutazione finora

- Catalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoDocumento78 pagineCatalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoAlexis SanchezNessuna valutazione finora

- Case Study 11 Centralia Underground Mine FireDocumento11 pagineCase Study 11 Centralia Underground Mine Firemigire kennedyNessuna valutazione finora

- Pakistani Radio MarketDocumento72 paginePakistani Radio MarketNajeeb Anwar100% (1)

- Data SheetDocumento2 pagineData SheetAsalamEilujNessuna valutazione finora

- Unit 01 AssignmentDocumento12 pagineUnit 01 Assignmentvipul unagarNessuna valutazione finora

- Earned Schedule - Walt LipkeDocumento27 pagineEarned Schedule - Walt LipkeKatie BensonNessuna valutazione finora

- Brickwork ApparatusDocumento4 pagineBrickwork ApparatusRoslie AbdullahNessuna valutazione finora

- 91 194 DCDocumento57 pagine91 194 DCGusdeluxeNessuna valutazione finora

- VocationalDocumento2 pagineVocationalMegha RoyNessuna valutazione finora

- Drawing & Document List Cisanggiri 2 X 1.5 MWDocumento4 pagineDrawing & Document List Cisanggiri 2 X 1.5 MWZoebairNessuna valutazione finora

- Chapter - I: Hydro DriveDocumento19 pagineChapter - I: Hydro Drivekuldeep ududholiraNessuna valutazione finora

- Aerospace MaterialsDocumento68 pagineAerospace MaterialsAykut Üçtepe100% (1)

- 4 Contamination Control 2Documento61 pagine4 Contamination Control 2Vijay RajaindranNessuna valutazione finora

- 16PPE723Documento2 pagine16PPE723DrArun KaliappanNessuna valutazione finora

- FD100 CatalogoDocumento4 pagineFD100 CatalogoKaren VásconezNessuna valutazione finora

- Jura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineDocumento15 pagineJura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineyangNessuna valutazione finora

- 04 Surveys Cattell PDFDocumento16 pagine04 Surveys Cattell PDFBrenda MaggNessuna valutazione finora

- Digital Pressure Gauge XP2i PSI Data Sheet USDocumento5 pagineDigital Pressure Gauge XP2i PSI Data Sheet USAbdurrachman JalaludinNessuna valutazione finora