Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hot Rolled Steel

Caricato da

abhishekDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hot Rolled Steel

Caricato da

abhishekCopyright:

Formati disponibili

Hot rolled steel- Hot rolled steel is more malleable, allowing it to be forced into a variety of different shapes

during cooling without losing ductility due to high temperature along this they will have a blue-gray finish that

feels rough to the touch. Large size and shape of section can be made.

Cold Rolled Steel- A rolling process at temperatures that are close to normal room temperature are used to create

cold rolled steel. This increases the strength of the finished product through the use of strain hardening by as much

as 20 percent. High quality steel in Connecticut that has been processed in this manner has a gray finish that feels

smooth to the touch.

The cold rolled process creates a finished product that is more precise dimensionally than a hot rolled product. This

is because it is already closer to the finished dimension since it has already gone through the cooling process.

All the standard size of I beam or channel section have flange slope from inside is 16.67%.

CLASSIFICATION OF STRUCTURES - The structures are also classified as shell structures and framed structures. The

shell roof covering of large buildings, air planes, rail road cars, ship wells, tanks etc are the examples of shell

structures. The plates or sheets serve functional and structural purposes. The plates act as a load carrying elements.

The plates are stiffened by frames which may or may not carry the principal loads. The framed structures are built by

assemblies of elongated members. The truss frames, truss girders, rigid frames etc are the examples of framed

structures. The main members are used for the transmission of loads.

STRUCTURAL STEEL

The structural steel is the steel used for the manufacture of rolled structural steel sections, fastenings and other

elements for use in structural steel works. Steel is an alloy of iron, carbon and other elements in varying percentages.

The strength, hardness and brittleness of steel increases and ductility of steel decreases with the increase of

percentage of carbon. Depending on the chemical composition, the different type of steel are classified as mild steel,

medium carbon steel, high carbon steel, low alloy steel and high alloy steel. The mild steel, medium carbon steel and

low alloy steel are generally used for steel structures. The copper bearing quality of steel contains small percentage

of copper contents. The corrosive resistance of such steel is increased.

Mild steel is used for the manufacture of rolled structural steel sections, rivets and bolts. The following operations

can be done easily on mild steel 1.Cutting, 2. Punching, 3.Drilling, 4. Machining, 5. Welding and 6. Forging when

heated.

Potrebbero piacerti anche

- Unit 2steel AlloyDocumento29 pagineUnit 2steel AlloyLn VedanayagamNessuna valutazione finora

- RSW BT YongDocumento10 pagineRSW BT Yongfraniancis0922Nessuna valutazione finora

- Ebook Civil Engineering Materials 1St Edition Sivakugan Solutions Manual Full Chapter PDFDocumento28 pagineEbook Civil Engineering Materials 1St Edition Sivakugan Solutions Manual Full Chapter PDFtironcolossald30y100% (10)

- Civil Engineering Materials 1st Edition Sivakugan Solutions ManualDocumento7 pagineCivil Engineering Materials 1st Edition Sivakugan Solutions Manualbinhlinhh9ih100% (32)

- Building Construction & Materials - V: Steel As Construction Material Adharsh.S GCAD/18/304Documento11 pagineBuilding Construction & Materials - V: Steel As Construction Material Adharsh.S GCAD/18/304Adharsh SelvarajNessuna valutazione finora

- Lesson 4. Steel Construction MaterialsDocumento25 pagineLesson 4. Steel Construction MaterialsJay-r MiñozaNessuna valutazione finora

- History: Structure Steel Steel FramedDocumento9 pagineHistory: Structure Steel Steel FramedSelendra BeleNessuna valutazione finora

- Steel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionDocumento6 pagineSteel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionSAMANTHA SARAH PURBANessuna valutazione finora

- Light Gauge Steel FramingDocumento14 pagineLight Gauge Steel Framingremon100% (4)

- Payra, Jimwell L, AR 4C ES433, Research Work 2 (Finals)Documento23 paginePayra, Jimwell L, AR 4C ES433, Research Work 2 (Finals)Jimwell Linsangan PayraNessuna valutazione finora

- By - Shaik ShahidDocumento22 pagineBy - Shaik ShahidAnonymous q6SfMddJDoNessuna valutazione finora

- Types of Steel According To Deoxidation PracticeDocumento2 pagineTypes of Steel According To Deoxidation PracticeSyed Raheel AdeelNessuna valutazione finora

- INtro To SteelDocumento29 pagineINtro To SteelAnima PNessuna valutazione finora

- Structural SteelDocumento26 pagineStructural Steeldiya.nithanya.barch22Nessuna valutazione finora

- Dcq10033 Topic 1 Metal and Non MetalDocumento46 pagineDcq10033 Topic 1 Metal and Non Metalfarhan selamatNessuna valutazione finora

- ReinforcementDocumento6 pagineReinforcementakinyemioaNessuna valutazione finora

- Structure and PropertiedDocumento43 pagineStructure and PropertiedJalaj GaurNessuna valutazione finora

- Carbon SteelDocumento9 pagineCarbon SteelArfanAliNessuna valutazione finora

- Bgtech 5Documento7 pagineBgtech 5Raynier LigayaNessuna valutazione finora

- Chapter One - Introduction To Steel StructuresDocumento8 pagineChapter One - Introduction To Steel StructuresJohn Philip Molina NuñezNessuna valutazione finora

- BEC6Documento6 pagineBEC6angelolagfNessuna valutazione finora

- Materials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CDocumento25 pagineMaterials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CNidhi MehtaNessuna valutazione finora

- Advantages of Steel in ConstructionDocumento2 pagineAdvantages of Steel in ConstructionkionlowNessuna valutazione finora

- Buildning Materials:: Reinforcing SteelDocumento17 pagineBuildning Materials:: Reinforcing SteelNitin RaoNessuna valutazione finora

- Steel As A Building MaterialDocumento11 pagineSteel As A Building MaterialPriyank Soni100% (1)

- Steel Thermal Expansion Coefficient ConcreteDocumento4 pagineSteel Thermal Expansion Coefficient Concretejohny BavitoNessuna valutazione finora

- Forms of Steel Used For Building Construction: Submitted By, Varsha Das 38 s3Documento13 pagineForms of Steel Used For Building Construction: Submitted By, Varsha Das 38 s3Varsha DasNessuna valutazione finora

- Cold Formed SteelDocumento5 pagineCold Formed SteelYeeYern LimNessuna valutazione finora

- Protective CoatingsDocumento203 pagineProtective CoatingsGopalakrishnan KuppuswamyNessuna valutazione finora

- What Grade of Steel Is Used For ShipsDocumento9 pagineWhat Grade of Steel Is Used For ShipsAbdallah AlbeityNessuna valutazione finora

- Carbon Steel and Mild Steel DifferenceDocumento8 pagineCarbon Steel and Mild Steel DifferenceSteinol SolutionsNessuna valutazione finora

- Final MT-4 & 5Documento31 pagineFinal MT-4 & 5RajasekharKosuruNessuna valutazione finora

- Building Home Using Steel:: SupervisionDocumento14 pagineBuilding Home Using Steel:: SupervisionDoha anaNessuna valutazione finora

- Lesson Title: Types of MetalsDocumento8 pagineLesson Title: Types of MetalsEric LamNessuna valutazione finora

- Structural SteelDocumento5 pagineStructural Steelnazlie1707Nessuna valutazione finora

- SteelDocumento21 pagineSteelCyrus RivasNessuna valutazione finora

- BJTC 2023 Construction Technology: Chapter 5 - Steel and Other MetalsDocumento50 pagineBJTC 2023 Construction Technology: Chapter 5 - Steel and Other MetalsHermioneNessuna valutazione finora

- Materials NotesDocumento15 pagineMaterials NotesShermar BerkleyNessuna valutazione finora

- L3-Structural SteelDocumento58 pagineL3-Structural SteelTjia Tjie100% (1)

- Steel ManufacturingDocumento29 pagineSteel ManufacturingNDTInstructor100% (3)

- Uses of Various Steel in Civil Engineering: BY:-Engr. Ahmad Sameer Nawab Kardan University Kabul, AfghanistanDocumento33 pagineUses of Various Steel in Civil Engineering: BY:-Engr. Ahmad Sameer Nawab Kardan University Kabul, AfghanistanVenkataLakshmiKorrapatiNessuna valutazione finora

- Steel Frame ConstructionDocumento47 pagineSteel Frame Constructionapi-386384775Nessuna valutazione finora

- Characteristics Properties and Uses in MetalDocumento13 pagineCharacteristics Properties and Uses in MetalIvy DillaNessuna valutazione finora

- Advantages of Light Gauge Steel Framing ConstructionDocumento2 pagineAdvantages of Light Gauge Steel Framing ConstructionAlemtsehay ShiferawNessuna valutazione finora

- Sheet Material Untuk Proses PressingDocumento4 pagineSheet Material Untuk Proses PressingeltonNessuna valutazione finora

- A Complete Guide To Stainless SteelDocumento16 pagineA Complete Guide To Stainless SteelRahul SinghNessuna valutazione finora

- Steel Thermal Expansion Coefficient ConcreteDocumento4 pagineSteel Thermal Expansion Coefficient ConcreteAllenNessuna valutazione finora

- Steel Used in Ship BuildingDocumento26 pagineSteel Used in Ship Buildingxxxvishnu100% (2)

- Structural Steel 8768Documento43 pagineStructural Steel 8768ravi 127Nessuna valutazione finora

- Steel Building Constructions AristyaDocumento7 pagineSteel Building Constructions AristyaWilly GarcioNessuna valutazione finora

- Steel StructureDocumento6 pagineSteel StructureONG VNessuna valutazione finora

- Construction Materials AssignmentDocumento45 pagineConstruction Materials AssignmentDB FasikaNessuna valutazione finora

- SteelDocumento36 pagineSteelLikhitaKaranamNessuna valutazione finora

- Type of ReinforcementDocumento3 pagineType of ReinforcementKartik JainNessuna valutazione finora

- Steel Materials WikipediaDocumento12 pagineSteel Materials WikipediaSam AlaxNessuna valutazione finora

- Structural Steel 8768Documento43 pagineStructural Steel 8768Nidhi MehtaNessuna valutazione finora

- Field Research#5 in STEEL FRAME CONSTRUCTIONDocumento16 pagineField Research#5 in STEEL FRAME CONSTRUCTIONKITNessuna valutazione finora

- Types of Steel Used in ConstructionDocumento12 pagineTypes of Steel Used in ConstructionMary FelisminoNessuna valutazione finora

- Area of Intrest: ConclusionDocumento6 pagineArea of Intrest: ConclusionabhishekNessuna valutazione finora

- Class Test - 2016: Civil EngineeringDocumento11 pagineClass Test - 2016: Civil EngineeringabhishekNessuna valutazione finora

- Environment Engg SolutionDocumento17 pagineEnvironment Engg SolutionabhishekNessuna valutazione finora

- An Application of Forecasting ModelDocumento7 pagineAn Application of Forecasting ModelabhishekNessuna valutazione finora

- Class Test - 2016: Civil EngineeringDocumento11 pagineClass Test - 2016: Civil EngineeringabhishekNessuna valutazione finora

- New Doc 2017-03-08Documento19 pagineNew Doc 2017-03-08abhishekNessuna valutazione finora

- Final Cover+Declaration+Certf+AcknowledgmentDocumento4 pagineFinal Cover+Declaration+Certf+AcknowledgmentabhishekNessuna valutazione finora

- Updated!! Irrigation!Documento30 pagineUpdated!! Irrigation!abhishekNessuna valutazione finora

- Irrigation 2nd SessDocumento37 pagineIrrigation 2nd SessabhishekNessuna valutazione finora

- About EIL 2018 Likely To Be RevisedDocumento4 pagineAbout EIL 2018 Likely To Be RevisedabhishekNessuna valutazione finora

- Steel Structure - ConnectionsDocumento2 pagineSteel Structure - ConnectionsabhishekNessuna valutazione finora

- PA Process: Thermal EngineeringDocumento8 paginePA Process: Thermal Engineeringlulis171Nessuna valutazione finora

- Kathleen Steele ResumeDocumento2 pagineKathleen Steele Resumeapi-336824202Nessuna valutazione finora

- Lab 2 WorksheetDocumento3 pagineLab 2 WorksheetPohuyistNessuna valutazione finora

- TSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaDocumento2 pagineTSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaIronko Pepe100% (1)

- The Masterbuilder - July 2013 - Concrete SpecialDocumento286 pagineThe Masterbuilder - July 2013 - Concrete SpecialChaitanya Raj GoyalNessuna valutazione finora

- Card Authentication Kit (B) Operation Guide: ECOSYS P2040dn ECOSYS P2040dwDocumento5 pagineCard Authentication Kit (B) Operation Guide: ECOSYS P2040dn ECOSYS P2040dwClic CsiNessuna valutazione finora

- Tvs Motors FinalDocumento68 pagineTvs Motors FinalNikhil SakleshpurNessuna valutazione finora

- PM Trailer 16T General Purpose RevBDocumento60 paginePM Trailer 16T General Purpose RevBHANNESNessuna valutazione finora

- Clel083e138 MVSWG Exe WDG 601Documento40 pagineClel083e138 MVSWG Exe WDG 601arielaparicioNessuna valutazione finora

- CPPDocumento22 pagineCPPShahmeer Ali MirzaNessuna valutazione finora

- Hydraulic SealsDocumento2 pagineHydraulic SealsVahid ShalchiNessuna valutazione finora

- Week 5Documento20 pagineWeek 5UMAIR JAVEDNessuna valutazione finora

- Yamaha XJ6 2009 - Service Manual (Inglês)Documento554 pagineYamaha XJ6 2009 - Service Manual (Inglês)fabiokruse70% (10)

- MS Samsung Ar7000 Inverter Airconditioning PDFDocumento2 pagineMS Samsung Ar7000 Inverter Airconditioning PDFMacSparesNessuna valutazione finora

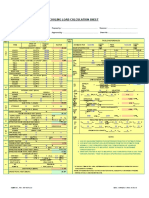

- Cooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/DoorDocumento6 pagineCooling Load Calculation Sheet: X X X X X X X X X X X X X X X X Cfm/Person Cfm/Doorashfaq-matte-799375% (4)

- IBM IVA White PaperDocumento4 pagineIBM IVA White PaperTarek FahimNessuna valutazione finora

- Lab Exercise - Ethernet: ObjectiveDocumento11 pagineLab Exercise - Ethernet: ObjectiveTakaskiNessuna valutazione finora

- Chapter 3 Dec 50143Documento29 pagineChapter 3 Dec 50143Kohilan VenugopalNessuna valutazione finora

- Machine LearningDocumento4 pagineMachine LearningKrishna Chivukula100% (2)

- Standard Competency Based Interview Questions OrtusDocumento14 pagineStandard Competency Based Interview Questions OrtusLiv YamNessuna valutazione finora

- 2015 Motorcycle Catalogue NGK 3Documento114 pagine2015 Motorcycle Catalogue NGK 3Ginger BrubakerNessuna valutazione finora

- Capacity 5,0 m3 (1) New CraneDocumento64 pagineCapacity 5,0 m3 (1) New CraneAnonymous iI88LtNessuna valutazione finora

- TMP 20364 Asia Pacific Rail 2018 Brochure 114805717Documento13 pagineTMP 20364 Asia Pacific Rail 2018 Brochure 114805717jasminetsoNessuna valutazione finora

- Shindengen: Stepping Motor Driver IcsDocumento2 pagineShindengen: Stepping Motor Driver IcsEngin UzunNessuna valutazione finora

- Crafting and Executing Strategy The Quest For Competitive Advantage Concepts 21st Edition Thompson Test BankDocumento26 pagineCrafting and Executing Strategy The Quest For Competitive Advantage Concepts 21st Edition Thompson Test BankWilliamDavisbzotg100% (51)

- HR Calculation-HotelDocumento6 pagineHR Calculation-Hotelmunim87Nessuna valutazione finora

- 32 Bahrain Bridge 0914RBDocumento3 pagine32 Bahrain Bridge 0914RBAshutoshAparaj100% (1)

- CattronControl Excalibur by Cattron - Industrial Wireless Remote Control PDFDocumento2 pagineCattronControl Excalibur by Cattron - Industrial Wireless Remote Control PDFJose Gabriel Aguirre AndradeNessuna valutazione finora

- Water Mist System On ShipDocumento10 pagineWater Mist System On ShipRahul Naik100% (1)

- CIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumDocumento8 pagineCIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumEmil-Wendtland100% (1)