Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Epe 2013112110290960 PDF

Caricato da

FernandoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Epe 2013112110290960 PDF

Caricato da

FernandoCopyright:

Formati disponibili

Energy and Power Engineering, 2013, 5, 1474-1477

doi:10.4236/epe.2013.54B279 Published Online July 2013 (http://www.scirp.org/journal/epe)

Calculation of the Choked Back Pressure for Steam

Turbines with Air Cooled Condensers

Haisheng Yang, Shuping Chang, Ruitao Wu

Thermal Technology Department, Hebei Electric Power Research Institute, Shijiazhuang, Hebei PRC.

Email: haisheng.yang@gmail.com, hbdyycsp@163.com, hbdyywrt@163.com

Received September, 2012

ABSTRACT

The choked back pressure characteristic of the steam turbine unit with air cooled condenser is very different with the

unit with wet cooling technology, and the understanding of the choked back pressure performance change with opera-

tion load is important to guide the economic operation of the unit. One simplified Variable Operation Condition Analy-

sis Method was put forward for calculation of the unit output-turbine back pressure characteristics. Based on this

method, the choked back pressure for each operation load can be determined. An example was given for a super-critical,

regenerative single-shaft, 2-casing with 2-exhaust steam turbine generation unit with air cooled condenser. The calcula-

tion result was provided and compared with the result of the unit with wet cooling technology.

Keywords: Air Cooled Condenser; Steam Turbine; Choked Back Pressure Characteristic; Calculation

1. Introduction pressure under which the steam flow speed at the exit of

the turbine last blade is close to the local sound speed

In the past years, many of the large capacity steam tur-

(Mach number around 0.95). The choked back pressure

bine generation units with air-cooled condensers (ACCs)

is related to the turbine inlet steam flow, that is, with the

have been put into operation. It is shown that the safe

change of the inlet steam flow, the choked back pressure

operation of the units has been solved based on the op-

also varies.

eration experiences of the built units. On the other hand,

Under normal operation condition, to keep the unit

very few attentions have been paid to the economic op-

generator output stable and constant, the turbine inlet

eration of the units with ACCs.

steam flow decreases with the lowering down of the tur-

The major difference between the normal generation

bine back pressure. But if the decreasing of back pressure

units with wet cooling technology and the units with

exceeds a limit or the turbine choked back pressure, the

ACCs is the steam turbine cold end design. For steam

steam inlet flow increases to maintain the same generator

turbines with ACCs, special designed LP last blading is

output.

used, and the resulted characteristic of generator output

For the units with ACCs, it is possible that the actual

versus turbine back pressure is completely different with

operation turbine back pressure is controlled below the

the turbines using wet cooling technology. For choked

choked back pressure limit, thus the unit performance

back pressure the steam turbines with ACCs, few calcu-

will deteriorate. This could be avoided by lowering down

lation and testing results has been published except some

of speed the ACC fans.

discussions on the theoretical principles of the choked

back pressure.

2.1. The Calculation of the Steam Turbines

Analysis of the change of turbine choked back pres-

Choked Back Pressure

sure with the operation load can provide direct guidance

on the economic operation of the generation units. This It can be deduced from the definition of the turbine

paper will analyze this issue theoretically, and provide a choked back pressure that under the constant turbine inlet

simplified method for calculation. flow, the generator output will increase with the de-

creasing of the turbine back pressure until a critical back

2. Calculation Model of Choked Back pressure value is reached. If the back pressure is con-

Pressure for Steam Turbine with tinuously decreased than this critical back pressure, the

Air-cooled Condensers unit power output will not increase but decrease. This

critical back pressure can be regarded as the turbine

The turbine choked back pressure refers to the back

choked back pressure.

Copyright © 2013 SciRes. EPE

H. S. YANG ET AL. 1475

Therefore, the solution of the turbine choked back expansion line end point. Thus the new LP turbine ex-

pressure can be change into a problem of how to deter- pansion line end point enthalpy can be calculated by:

mine the turbine power output change as a function of helep ' h jq h jr ' elep (1)

the turbine back pressure change.

When the impact of the turbine back pressure on unit The steam parameters of the LP turbine extractions

output is considered, the commonly used calculation can be determined by similar method. First calculate the

method adopted is described in [1], using the detailed extraction steam flow for the LP heaters, and calculate

variable operation analysis for the LP turbine last blading. the new corrected extraction pressure. The new extrac-

Yet many of the difficulties need to be solved for this tion parameters can be found using the corrected extrac-

method, including: tion pressure and the same LP turbine expansion line.

Many of the parameters related to the detailed This iteration process continues until the parameter dif-

variable operation analysis can’t be collected. ference of the two iterations is lower than certain error.

Based on the LP turbine exhaust flow calculated in the

Many of the turbine last stages are curved and above Simplified Variable Operation Condition Analysis,

twisted. But many of the equations in the variable and the last stage exhaust loss curve provided by the tur-

operation analysis for the last stage are still de- bine manufacture, the LP turbine last stage exhaust loss

duced from one dimension condition. This can’t and the LP turbine used energy end point enthalpy hUEEP

guarantee the accuracy of the calculated results. can be calculated, and the final generator output change

can be calculated using the heat balance method.

2.2. The Application of the Simplified Variable This Simplified Variable Operation Condition Analy-

Operation Condition Analysis Method sis Method considers both the LP turbine last stage ex-

When the turbine steam inlet control valves are set to a haust loss change and the extraction steam flow change

position and kept unchanged (such as under the boiler of the LP heaters for turbine back pressure change condi-

follow operation mode), the flow passage area of the tions.

control stages and thus the steam inlet flow is constant This Simplified Variable Operation Condition Analy-

when the turbine back pressure has some variations. The sis Method is used in [2] for analyzing the generator

control stage efficiency can be regarded as constant, and output change with the turbine back pressure. The calcu-

the efficiency of the following turbine pressure stages is lation result matches the real situation for one 600MW

unchanged under turbine operation change conditions. sub-critical generation unit.

The only exception is the LP turbine last stage, where the

operation condition of the LP last stage will be influ- 3. Calculation Example of Turbine Choked

enced by the turbine back pressure change and the stage Back Pressure for Steam Turbine with

efficiency will be affected. In summary, the LP turbine is ACCs

the only part where the turbine back pressure change has For one example generation unit, the 660MW steam tur-

impact on turbine work. bine is a critical, single-shaft, two-casing two-exhaust

The LP turbine expansion process is shown on Figure

1. Where the hlpi is the LP turbine inlet enthalpy under

baseline condition, pc is the LP turbine back pressure

under baseline condition, helep is the LP turbine expan-

sion line end point enthalpy under baseline condition,

hel is the LP turbine last stage exhaust loss under base-

line condition, hid is the LP turbine ideal enthalpy

drop under baseline condition. The symbols with “’”

represent the operation condition with changed turbine

back pressure.

It can be shown on Figure 1 that during normal opera-

tion, when the LP turbine inlet steam condition is stable,

the LP turbine exhaust volumetric flow will decrease

with the rising of the turbine back pressure, which will

lead to a smaller exhaust loss and thus a higher LP tur-

bine efficiency UEEP (indicated by the slope of the

dashed line on Figure 1). For the LP turbine, it can be Figure 1. LP turbine expansion line under different LP tur-

reasonably assumed that the LP turbine expansion line bine back pressure operation conditions.

shape and expansion process is unchanged except for the condensing steam turbine with ACCs. There are totally

Copyright © 2013 SciRes. EPE

1476 H. S. YANG ET AL.

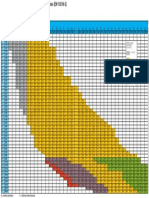

28 stages in the turbine, including 1 control stage and 9 The turbine choked back pressure result is shown in Ta-

pressure stages for the HP turbine, 6 pressure stages for ble 2 and Figure 3.

the IP turbine, and 2×6 pressure stages for the LP turbine.

The LP turbine last blade has a height of 939.8 mm. The Table 1. Main design data of the steam turbine.

steam turbine is controlled by nozzles. The steam flow

Item Unit THA TRL

into the four nozzle groups on the HP turbine is con-

trolled by the four mail control valves. The ACC system Unit Output kW 660.01 660.00

is the mechanically drafted direct air-cooled system pro- Unit Heat Rate kJ/kWh 7778.31 8225.81

duced by the domestic manufacture.

Main Steam Pressure MPa(a) 24.20 24.20

The main design data of the steam turbine is summa-

rized in Table 1. Hot Reheat Steam Pressure MPa(a) 3.71 3.94

HP Turbine Exhaust Pressure MPa(a) 4.12 4.38

3.1. The Calculation Result of the Steam

Turbines Choked Back Pressure Main Steam Temperature ℃ 566.00 566.00

Based on the turbine last stage exhaust loss curve, the Hot Reheat Steam Temperature ℃ 566.00 566.00

turbine exhaust steam used energy end point enthalpy HP Turbine Exhaust Temperature ℃ 305.07 312.13

and the exhaust loss and the final generator output are

Main Steam Flow t/h 1878.42 2013.35

calculated for various turbine back pressure operation

conditions. For each load condition, the turbine back Reheat Steam Flow t/h 1600.90 1701.48

pressure corresponding to the maximum generator output Turbine Back Pressure kPa 16 33

can be regarded as the turbine choked back pressure.

LP Turbine Exhaust Enthalpy kJ/kg 2454.67 2550.0

Using this method, the turbine choked back pressures

under different operation load conditions are calculated. LP Turbine Exhaust Flow t/h 1254.78 1349.40

On Figure 2, the generator output change with the back Makeup Water % 0 3

pressure is shown for various operation load conditions.

Final Feedwater Temperature ℃ 273 277.2

4

Unit Output Relative Change (%

0 THA

0 5 10 15 20 25 30 35 40

90%THA

75%THA

-2

50%THA

-4

-6

-8

-10

Turbine Back Pressure (kPa)

Figure 2. Performance curves of the unit output with turbine back pressure.

Copyright © 2013 SciRes. EPE

H. S. YANG ET AL. 1477

12

Turbine Choked Back Pressure (kPa)

10

0

40 50 60 70 80 90 100 110 120

Unit Load Rate (%)

Sub-Critical 600MW Unit with Wet Cooling T echnology

Super-Critical 600MW Unit with ACC

线性 (S b C i i l 600MW U i i h W C li T h l )

Figure 3. Performance curves of the turbine choked back pressure with unit load.

Table 2. Calculation results of choked back pressure under Based on the clear definition of the turbine choked back

various operation loads. pressure, the solution of the choked back pressure is

Operation Load (%) Turbine Choked Back Pressure (kPa) changed into a problem of how to determine the turbine

power output change as a function of the turbine back

100 9.0

pressure change.

90 8.2 The proposed simplified variable operation condition

75 7.0 analysis method is adopted for one sub-critical genera-

50 5.0 tion unit with ACCs. The performance curve of the

power output versus the turbine back pressure under

For comparison purpose, the choked back pressure for various operation loads is given, and curve of the turbine

600 MW four-casing four-exhaust sub-critical generation choked back pressure under different loads is provided.

unit with wet cooling technology is illustrated on Figure These curves provide valuable guidance for the economic

3. operation of the power plant units.

It can be shown from the Table 2 and Figure 3 that

the turbine choked back pressure is in nearly linear rela- REFERENCES

tionship with the operation loads. For the choked back

pressure curves, there is a significant increasing of the [1] H. Lin, “Calculation and Correction of the Impact of Tur-

bine Back Pressure on Turbine Output,” Turbine Tech-

chocked pressure values for the units with ACCs com- nology, Harbin China, Vol. 46 No. 1, 2004, pp. 18-21.

pared with the similar curve of the units with wet cooling

[2] H. S. Yang, “Simplified Calculation Method of Turbine

technology. Back Pressure Correction Curves,” Turbine Technology.

Harbin China, Vol. 49, No. 1, 2007, pp. 32-34.

4. Conclusions

Copyright © 2013 SciRes. EPE

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Optimum LG RatioDocumento8 pagineOptimum LG RatioSajal GuptaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- PETREL 1 Structural Modeling PDFDocumento42 paginePETREL 1 Structural Modeling PDFKuala Tambora100% (1)

- Hs 342Documento45 pagineHs 342Fernando Martinez ContrerasNessuna valutazione finora

- Emerson-Valve Sizing Calculations (Traditional Method)Documento21 pagineEmerson-Valve Sizing Calculations (Traditional Method)iqtorresNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- D 4176Documento4 pagineD 4176Salma FarooqNessuna valutazione finora

- Astm C680 PDFDocumento47 pagineAstm C680 PDFFernando67% (3)

- DBB Vs DIBDocumento3 pagineDBB Vs DIBrsb72Nessuna valutazione finora

- Effects of Geopathic Stress and VastuDocumento12 pagineEffects of Geopathic Stress and VastuDeepak Singh RaghuvansheNessuna valutazione finora

- Angles of ElevationDocumento25 pagineAngles of ElevationAngelu bonaganNessuna valutazione finora

- High Speed CastingDocumento7 pagineHigh Speed Castingferdlh9Nessuna valutazione finora

- Maintenance and Overhaul of Steam TurbinesDocumento46 pagineMaintenance and Overhaul of Steam Turbinessubbusenthil78% (9)

- Astm A790Documento8 pagineAstm A790eayujigNessuna valutazione finora

- ZKG IndiaDocumento36 pagineZKG Indiajoe_kudo0% (1)

- Anderson Greenwood Crosby - Pressure Safety Valves - Considerations On Their Use & Sizing - Juli 2009Documento48 pagineAnderson Greenwood Crosby - Pressure Safety Valves - Considerations On Their Use & Sizing - Juli 2009김크크Nessuna valutazione finora

- Moduflex Brochure Uk 2014Documento12 pagineModuflex Brochure Uk 2014FernandoNessuna valutazione finora

- E 205 11 PDFDocumento60 pagineE 205 11 PDFWan Ah-LunNessuna valutazione finora

- 135 Feuerborn 2013Documento15 pagine135 Feuerborn 2013FernandoNessuna valutazione finora

- Stack Adequacy Form InstructionsDocumento13 pagineStack Adequacy Form InstructionsFernandoNessuna valutazione finora

- ANSI B16.25 Butt Welding Pipe DimensionsDocumento4 pagineANSI B16.25 Butt Welding Pipe DimensionsFernandoNessuna valutazione finora

- Manufacturing Program EN10216 2 PDFDocumento1 paginaManufacturing Program EN10216 2 PDFFernandoNessuna valutazione finora

- DCS Hazardous AreasDocumento8 pagineDCS Hazardous AreasAnonymous v5uipHNessuna valutazione finora

- Epe 2013112110290960 PDFDocumento4 pagineEpe 2013112110290960 PDFFernandoNessuna valutazione finora

- Manufacturing program wall thickness EN 10216-2Documento1 paginaManufacturing program wall thickness EN 10216-2FernandoNessuna valutazione finora

- Pipe Schedule PDFDocumento1 paginaPipe Schedule PDFSrinivasan SeenuNessuna valutazione finora

- Determining Electric Load: MotorDocumento6 pagineDetermining Electric Load: MotorFernandoNessuna valutazione finora

- 14 - A Critical Investigation Into +++Documento13 pagine14 - A Critical Investigation Into +++FernandoNessuna valutazione finora

- The Success of Glass Flake Epoxies PDFDocumento2 pagineThe Success of Glass Flake Epoxies PDFBoris CardenasNessuna valutazione finora

- Failure of Circulating Water Pumps Discharge Header Cross Connect Valve - Optimum SolutionsDocumento3 pagineFailure of Circulating Water Pumps Discharge Header Cross Connect Valve - Optimum SolutionsFernando100% (1)

- Cooling Tower Performance AnalysisDocumento6 pagineCooling Tower Performance AnalysisFernandoNessuna valutazione finora

- Power Plant Engineering Chapter 5 Condenser and Evaporative Cooling TowersDocumento7 paginePower Plant Engineering Chapter 5 Condenser and Evaporative Cooling TowersBabis PapadopoulosNessuna valutazione finora

- Series440 BrochureDocumento8 pagineSeries440 BrochureFernandoNessuna valutazione finora

- Mel709 41Documento32 pagineMel709 41naveen reddyNessuna valutazione finora

- The Influence of The Equivalent Hydraulic Diameter On The Pressure Drop Prediction of Annular Test SectionDocumento9 pagineThe Influence of The Equivalent Hydraulic Diameter On The Pressure Drop Prediction of Annular Test SectionFernandoNessuna valutazione finora

- AcknowledgmentsDocumento2 pagineAcknowledgmentsFernandoNessuna valutazione finora

- AcknowledgmentsDocumento2 pagineAcknowledgmentsFernandoNessuna valutazione finora

- Omicron CMC 256plus Brochure EnuDocumento6 pagineOmicron CMC 256plus Brochure EnuDuško TovilovićNessuna valutazione finora

- Nuclei QB XiiDocumento23 pagineNuclei QB XiiToshani GuptaNessuna valutazione finora

- Osmosis and Diffusion Lab VocabularyDocumento3 pagineOsmosis and Diffusion Lab Vocabularydannyf09Nessuna valutazione finora

- Secondary DatabasesDocumento21 pagineSecondary DatabasesDaljit SinghNessuna valutazione finora

- Spectrum OFDMFDocumento1 paginaSpectrum OFDMFvcazacuNessuna valutazione finora

- Simple and Inexpensive Microforge: by G. HilsonDocumento5 pagineSimple and Inexpensive Microforge: by G. Hilsonfoober123Nessuna valutazione finora

- 1Documento10 pagine1Amit KumarNessuna valutazione finora

- Igat6 D PL Me SPC 0007 01 Spec For Barred TeeDocumento9 pagineIgat6 D PL Me SPC 0007 01 Spec For Barred Teeamini_mohi100% (1)

- Work Sheet IDocumento5 pagineWork Sheet IgrmdrjNessuna valutazione finora

- CFD Application Tutorials 2Documento35 pagineCFD Application Tutorials 2Jubril AkinwandeNessuna valutazione finora

- ENG1002 Project 2 SpecificationDocumento6 pagineENG1002 Project 2 SpecificationChiu Park ChuanNessuna valutazione finora

- Experiment 2Documento2 pagineExperiment 2vijaysai77Nessuna valutazione finora

- Intensive and Extensive Properties Crowther-Robitaille 2019Documento6 pagineIntensive and Extensive Properties Crowther-Robitaille 2019provocator74Nessuna valutazione finora

- TDS PH MacTexMXL May2014Documento1 paginaTDS PH MacTexMXL May2014Catherine MagnayeNessuna valutazione finora

- Reinforced Concrete Structures Analysis and DesignDocumento4 pagineReinforced Concrete Structures Analysis and DesignJulio Cesar ValdiviesoNessuna valutazione finora

- MS27069GDocumento7 pagineMS27069Gawesome_600Nessuna valutazione finora

- L2.5 Using A Compound Light Microscope OptDocumento8 pagineL2.5 Using A Compound Light Microscope Optochattc100% (1)

- .Fraunhofer - Diffraction.at - The.slit.Documento6 pagine.Fraunhofer - Diffraction.at - The.slit.NCHE BORISNessuna valutazione finora

- Charging Processes ExplainedDocumento4 pagineCharging Processes ExplainedMa'am Joana Joy PalomaresNessuna valutazione finora

- 4.15.MP75 CVL 015 STRL Des CriteriaDocumento27 pagine4.15.MP75 CVL 015 STRL Des CriteriaLandon MitchellNessuna valutazione finora

- Drilled MicropilesDocumento8 pagineDrilled MicropilesGuoqiang LiuNessuna valutazione finora

- The PA Bible Addn 13 The Electric Guitar Loudspeaker PDFDocumento3 pagineThe PA Bible Addn 13 The Electric Guitar Loudspeaker PDFjosiasns5257Nessuna valutazione finora

- CIS221-Design of Concrete Structures: BY Dr. Abdallah MostafaDocumento20 pagineCIS221-Design of Concrete Structures: BY Dr. Abdallah Mostafamagdy makramNessuna valutazione finora

- PGZ Schwenken EnglDocumento36 paginePGZ Schwenken EngljonNessuna valutazione finora