Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mixed Bed Deionisers - Anion Regeneration Parameters Calculation

Caricato da

Zi Wei Leong0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

33 visualizzazioni1 paginaSample Calculation steps for determining MB deioniser regeneration parameters.

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSample Calculation steps for determining MB deioniser regeneration parameters.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

33 visualizzazioni1 paginaMixed Bed Deionisers - Anion Regeneration Parameters Calculation

Caricato da

Zi Wei LeongSample Calculation steps for determining MB deioniser regeneration parameters.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

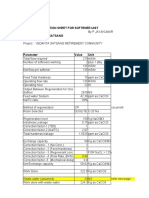

Anion Exchanger Parameters

STEP 1 - Regenerant required Resin Manufacturer DOW

Anion Tank Size (inches) 58 84 Resin Brand Amberlite IR402 Cl

3

Anion Tank Volume 3.64 m Recommended regenerant level:

Anion Resin Bed Volume 500 L NaOH 60-150 g chemical/L resin

Regenerant Chemical NaOH

Regenerant Conc. 48 %

Regenerant SG 1.5 kg/L

Chosen regenerant level 150 g/L

Regenerant required 75 kg of NaOH

Regenerant required (sol) 104 L of 48 % NaOH ( 3 chemical carboys )

STEP 2 - Chemical uptake concentration Recommended regen conc. NaOH 2-4 %

Chemical uptake cycle time 50 mins

m1v1 = m2v2 (Minimum contact time 30 mins)

Chemical supply conc., m1 48 %

3

Regenerant required (sol), v1 0.125 m /hr

3

Feed water flow during regen cycle, vF 1.5 m /hr

3

Total volume of liquid contacting resin, v2 1.565 m /hr

Chemical uptake conc., m 2 3.83 %

STEP 3 - Slow rinse Recommended rinse volume 2 (BV)

3

Rinse water volume required 1m

3

Slow rinse feed flow rate 1.5 m /hr

Cycle time required 40 mins

STEP 4 - Fast rinse Recommended rinse volume 4-8 (BV)

3 2

Rinse water volume required 2m Recommended surface loading 8-12 gpm/ft

3 2

Slow rinse feed flow rate 7 m /hr Surface loading 1.7 gpm/ft

Cycle time required 17.1429 mins

*Recommended parameters taken from resin product data sheet.

Prepared by: Zi Wei Leong Eratreat Engineering Sdn. Bhd vv

Potrebbero piacerti anche

- Equipment List and CalculationDocumento25 pagineEquipment List and CalculationAzman Bin Kadir100% (1)

- STP Design PDFDocumento151 pagineSTP Design PDFMark Anthony AcangNessuna valutazione finora

- Excel Sheet 1Documento5 pagineExcel Sheet 1Phạm LinhNessuna valutazione finora

- Water Softner Design VedantaDocumento5 pagineWater Softner Design Vedantajaianit89Nessuna valutazione finora

- WWTP+sizing SampleDocumento1 paginaWWTP+sizing Sampleerlima pengasinanNessuna valutazione finora

- Design Inputs QTY Unit: CalculationDocumento7 pagineDesign Inputs QTY Unit: CalculationHemant Kale100% (1)

- Design Calculation Sheet For Softener Unit Client: TECHPRODocumento5 pagineDesign Calculation Sheet For Softener Unit Client: TECHPROkunjansutharNessuna valutazione finora

- Hydraulic Profile - Rev. 1.1Documento8 pagineHydraulic Profile - Rev. 1.1unconformistNessuna valutazione finora

- Advanced Waste-Water Treatment: Indian Institute of Technology Jodhpur RajasthanDocumento9 pagineAdvanced Waste-Water Treatment: Indian Institute of Technology Jodhpur RajasthanDeepak Manihar (M20CI002)Nessuna valutazione finora

- Yanbu WWTW Process Group PresentationDocumento52 pagineYanbu WWTW Process Group Presentationyxp2237Nessuna valutazione finora

- V-Type: Turbidity: 1 NTUDocumento3 pagineV-Type: Turbidity: 1 NTUIsmi AnitaNessuna valutazione finora

- Lista Detalhada de Equipamentos ETADocumento3 pagineLista Detalhada de Equipamentos ETADimitri DiogoNessuna valutazione finora

- Softener CalculationDocumento5 pagineSoftener CalculationAri WijayaNessuna valutazione finora

- Design and Commissioning of The Landfill LeachateDocumento7 pagineDesign and Commissioning of The Landfill LeachateShriprakash SpNessuna valutazione finora

- Ft. Lauderdale 12-MGD Water Treatment Plant Double Hybrid RO and NF DesignDocumento12 pagineFt. Lauderdale 12-MGD Water Treatment Plant Double Hybrid RO and NF Designzerocool86Nessuna valutazione finora

- KubotaSMU PreliminaryStudy GreenBay Rev2Documento10 pagineKubotaSMU PreliminaryStudy GreenBay Rev2Artland MaulanaNessuna valutazione finora

- 1.03 MLD Sbr-Process DesignDocumento4 pagine1.03 MLD Sbr-Process DesignHemant KaleNessuna valutazione finora

- Bai Bao 1 - LibyaDocumento7 pagineBai Bao 1 - LibyaNguyễn Bình MinhNessuna valutazione finora

- Spesifikasi Teknis IpalDocumento4 pagineSpesifikasi Teknis IpalMitra PersadaNessuna valutazione finora

- PerhitunganDocumento8 paginePerhitungantsaniya.mardhiyahNessuna valutazione finora

- Case-Study-Leachate KMGreen SBK Oct2016Documento6 pagineCase-Study-Leachate KMGreen SBK Oct2016이기호Nessuna valutazione finora

- WaterDocumento33 pagineWaterahmedNessuna valutazione finora

- 1m3-Calculation Design - AnzirDocumento8 pagine1m3-Calculation Design - AnzirMohammad MahediNessuna valutazione finora

- Operation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFDocumento19 pagineOperation of A Submerged Hollow Fiber Membrane Bioreactor For Wastewater Treatment On Meeting Reclamation Criteria PDFShiva Kumar S MNessuna valutazione finora

- Explanation The Wastewater Treatment System 120m3day 29.8.2022Documento13 pagineExplanation The Wastewater Treatment System 120m3day 29.8.2022Nghi VoNessuna valutazione finora

- TCD 70 Data Sheet EngDocumento2 pagineTCD 70 Data Sheet EngPerc AleksandarNessuna valutazione finora

- Sizing 2x50% AdequacyDocumento3 pagineSizing 2x50% AdequacySagaya Raj YNessuna valutazione finora

- User Manual 50 LPH Ro Skid: Ion Exchange (India) LTDDocumento8 pagineUser Manual 50 LPH Ro Skid: Ion Exchange (India) LTDAnand SachanNessuna valutazione finora

- Specification Water Treatment Plant R1Documento18 pagineSpecification Water Treatment Plant R1Zachi Uki100% (1)

- Technical Proposal RO PT Sarana Tirta Utama 28072021Documento11 pagineTechnical Proposal RO PT Sarana Tirta Utama 28072021Budi Iswahyudi100% (1)

- Swimming Pool CalculationsDocumento62 pagineSwimming Pool CalculationswanroyNessuna valutazione finora

- Consequence AnalyserDocumento23 pagineConsequence AnalyserGlacier RamkissoonNessuna valutazione finora

- 1st Appraisal Presentation 2Documento17 pagine1st Appraisal Presentation 2Talha Jamil MalikNessuna valutazione finora

- Inge - UF For SWRO Pretreatment - Case - 0Documento5 pagineInge - UF For SWRO Pretreatment - Case - 0shrikantNessuna valutazione finora

- Water QuotationDocumento12 pagineWater Quotationanand sahuNessuna valutazione finora

- A. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesDocumento7 pagineA. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesshekharshindeNessuna valutazione finora

- Evaluation Statement For Zero PDDocumento2 pagineEvaluation Statement For Zero PDAnonymous i3lI9MNessuna valutazione finora

- Swimming Pool Calculation-April 3Documento1 paginaSwimming Pool Calculation-April 3Efren CahatianNessuna valutazione finora

- UHS-620A Projection For WTP Plant 50LPSDocumento9 pagineUHS-620A Projection For WTP Plant 50LPSirwan_souk100% (1)

- 18.12.2019 Proposal For 70 KLD Etp On UasbrDocumento24 pagine18.12.2019 Proposal For 70 KLD Etp On Uasbrgnbuildtech Pvt ltdNessuna valutazione finora

- Rapid and Reliable Detection of Dissolved Gases in Water: Key WordsDocumento5 pagineRapid and Reliable Detection of Dissolved Gases in Water: Key WordstalebNessuna valutazione finora

- Design Calculation Sheet: Pool DimensionsDocumento2 pagineDesign Calculation Sheet: Pool DimensionsBashir SherifNessuna valutazione finora

- FGD Dual Alkali Data Sheet FilledDocumento5 pagineFGD Dual Alkali Data Sheet FilledowngauravNessuna valutazione finora

- Study On Nitrogen Removal Capacity of Anammox Existed in Sludge of Soy Sauce WastewaterDocumento5 pagineStudy On Nitrogen Removal Capacity of Anammox Existed in Sludge of Soy Sauce WastewaterDangVanDienNessuna valutazione finora

- Ecoprocesstm SBR Design NotesDocumento3 pagineEcoprocesstm SBR Design NotesTrilok ChandraNessuna valutazione finora

- Whirlpool Service Manual Dishwasher ADP9411WHDocumento19 pagineWhirlpool Service Manual Dishwasher ADP9411WHasafhoxlNessuna valutazione finora

- Disinfection Technology Using Bromic DisinfectantsDocumento8 pagineDisinfection Technology Using Bromic DisinfectantsSuprio KamalNessuna valutazione finora

- Standard Membrane Bioreactor ComputationsDocumento8 pagineStandard Membrane Bioreactor ComputationsSwaminathan ThayumanavanNessuna valutazione finora

- 3 57 Boracay Engineers Report PDFDocumento12 pagine3 57 Boracay Engineers Report PDFAngela Emanuelle V. Estil100% (1)

- Environment & Pollution ControlDocumento4 pagineEnvironment & Pollution ControlMd.HassanNessuna valutazione finora

- XXXXXXXXX Cocoa Plant - 200lpdDocumento5 pagineXXXXXXXXX Cocoa Plant - 200lpdReneesh KcNessuna valutazione finora

- Process Design: Value Unit Parameter 1. Mass BalanceDocumento3 pagineProcess Design: Value Unit Parameter 1. Mass BalanceunconformistNessuna valutazione finora

- Edoc - Pub Calculation STP MBR 50kldDocumento13 pagineEdoc - Pub Calculation STP MBR 50kldyoucef tecNessuna valutazione finora

- DJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADocumento3 pagineDJM MBA PCS CA 004B Liquid Liquid Equalizer REV ADIANTORONessuna valutazione finora

- Q-SEP Projection25419Documento3 pagineQ-SEP Projection25419Андрей БелоусовNessuna valutazione finora

- MBBR Pack - GB - 1.0 - 06-10-2015Documento8 pagineMBBR Pack - GB - 1.0 - 06-10-2015SvetlanaNessuna valutazione finora

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsDa EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNessuna valutazione finora

- Geomorphological Processes: Studies in Physical GeographyDa EverandGeomorphological Processes: Studies in Physical GeographyValutazione: 5 su 5 stelle5/5 (1)

- CREATEC FCT8350-operational-manualDocumento26 pagineCREATEC FCT8350-operational-manualZi Wei Leong100% (1)

- Eratreat Engineering Sdn. BHD.: Your One Stop Water Treatment System Service ProviderDocumento10 pagineEratreat Engineering Sdn. BHD.: Your One Stop Water Treatment System Service ProviderZi Wei LeongNessuna valutazione finora

- Data Sheet: LG BW 400 EsDocumento1 paginaData Sheet: LG BW 400 EsZi Wei LeongNessuna valutazione finora

- TSG 007A-15 Optima HX Marketing Brief-LRDocumento2 pagineTSG 007A-15 Optima HX Marketing Brief-LRZi Wei LeongNessuna valutazione finora

- Membrane LG BW 400RDocumento1 paginaMembrane LG BW 400RPT Deltapuro IndonesiaNessuna valutazione finora

- Procedure & Data SheetDocumento2 pagineProcedure & Data SheetZi Wei LeongNessuna valutazione finora

- Sample Work Breakdown ScheduleDocumento1 paginaSample Work Breakdown ScheduleZi Wei LeongNessuna valutazione finora

- Hydranautics ESPA2 LD LDocumento1 paginaHydranautics ESPA2 LD LZi Wei LeongNessuna valutazione finora

- Wings of Prey ManualDocumento20 pagineWings of Prey ManualRaphael DoukkaliNessuna valutazione finora

- PM 2.5 Sampler Model Aas-127: Advantages: FeaturesDocumento1 paginaPM 2.5 Sampler Model Aas-127: Advantages: FeaturesRajesh MishraNessuna valutazione finora

- Backhoe Loaders: 820 860 SX 860 Elite 970 Elite 880 SX 880 Elite 980 EliteDocumento4 pagineBackhoe Loaders: 820 860 SX 860 Elite 970 Elite 880 SX 880 Elite 980 EliteJuan Carranza LeonNessuna valutazione finora

- Team 6 - Crystal MazeDocumento56 pagineTeam 6 - Crystal MazeLohith YadavNessuna valutazione finora

- Jetking Rajajinagar MinDocumento7 pagineJetking Rajajinagar MinNeha ShekarNessuna valutazione finora

- Ground Water Recharge Techniques 2Documento141 pagineGround Water Recharge Techniques 2Ravi Bhushan SharmaNessuna valutazione finora

- Premier University Department of Computer Science and Engineering (DCSE) Class Schedule (Updated) Session: Fall 2020Documento6 paginePremier University Department of Computer Science and Engineering (DCSE) Class Schedule (Updated) Session: Fall 2020X streamNessuna valutazione finora

- NBN Co Network Design RulesDocumento50 pagineNBN Co Network Design Rulesmisr1972Nessuna valutazione finora

- Oncell 5004/5104-Hspa Series: Industrial Five-Band Gsm/Gprs/Edge/Umts/Hspa Cellular RoutersDocumento2 pagineOncell 5004/5104-Hspa Series: Industrial Five-Band Gsm/Gprs/Edge/Umts/Hspa Cellular Routersudaya kumarNessuna valutazione finora

- Chandrayan 2Documento11 pagineChandrayan 2SELVALAKSHMI S VNessuna valutazione finora

- Product Data: Convertible Air Handlers 1-1/2 - 5 TonDocumento28 pagineProduct Data: Convertible Air Handlers 1-1/2 - 5 TonJonathan CapraNessuna valutazione finora

- Cylinder Valve Assembly Series: CV Series PCV SeriesDocumento2 pagineCylinder Valve Assembly Series: CV Series PCV SeriesAli OsmanNessuna valutazione finora

- A Bendable and Wearable Cardiorespiratory Monitoring Device Fusing Two Noncontact Sensor PrinciplesDocumento10 pagineA Bendable and Wearable Cardiorespiratory Monitoring Device Fusing Two Noncontact Sensor PrinciplesMd arshatNessuna valutazione finora

- Cat 772 Catálogo de Peças PDFDocumento937 pagineCat 772 Catálogo de Peças PDFTom Souza100% (1)

- Slope Stability Manual 8Documento12 pagineSlope Stability Manual 8YawgmothNessuna valutazione finora

- Syed Ansar Ahmed: Quantity EngineerDocumento7 pagineSyed Ansar Ahmed: Quantity EngineerRavi YadavNessuna valutazione finora

- PPC Porcelain Solid Core Post Insulators and Operating RodsDocumento23 paginePPC Porcelain Solid Core Post Insulators and Operating RodsCHRISTIANNessuna valutazione finora

- Skim Mik Powder MSDSDocumento6 pagineSkim Mik Powder MSDSVampireSuicideNessuna valutazione finora

- Treybal DistDocumento5 pagineTreybal DistJay CeeNessuna valutazione finora

- NPSHHHHDocumento5 pagineNPSHHHHMumtaz Ahmed Ghumman100% (1)

- Loadsand Load PathsDocumento34 pagineLoadsand Load PathsAnonymous pD2ymRUgu0% (1)

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDocumento7 pagineDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9Nessuna valutazione finora

- Plue InformationDocumento34 paginePlue InformationBisam AlhafizNessuna valutazione finora

- A-Dec 571 and 6300 Dental Light PDFDocumento24 pagineA-Dec 571 and 6300 Dental Light PDFSergio RodriguezNessuna valutazione finora

- Nokia 5310 Service Manual Level 1 and 2Documento16 pagineNokia 5310 Service Manual Level 1 and 2adybosss100% (1)

- MD Primer ErcolessiDocumento52 pagineMD Primer ErcolessiAjinBaby MyladiyilNessuna valutazione finora

- Application of FiberDocumento33 pagineApplication of FiberReem OmerNessuna valutazione finora

- LIDO Introduction PDFDocumento127 pagineLIDO Introduction PDFStiliyana Bakalova100% (2)

- Network AssignmentDocumento4 pagineNetwork AssignmentOsamah ElaiwahNessuna valutazione finora