Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fragrance Powder Detergent

Caricato da

Nur Amanina0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

143 visualizzazioni7 pagineThe patent is for perfumed laundry detergent powders with a ratio of total solid constituents to total liquid constituents of less than 30:1. The perfume is sorbed onto carrier particles that release at least 60% of the perfume and are inert. The carrier particles are preferably inorganic with a perfume content of at least 25% by weight. The powders have reduced agglomeration problems compared to conventional powders.

Descrizione originale:

Fragrance Powder Detergent

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe patent is for perfumed laundry detergent powders with a ratio of total solid constituents to total liquid constituents of less than 30:1. The perfume is sorbed onto carrier particles that release at least 60% of the perfume and are inert. The carrier particles are preferably inorganic with a perfume content of at least 25% by weight. The powders have reduced agglomeration problems compared to conventional powders.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

143 visualizzazioni7 pagineFragrance Powder Detergent

Caricato da

Nur AmaninaThe patent is for perfumed laundry detergent powders with a ratio of total solid constituents to total liquid constituents of less than 30:1. The perfume is sorbed onto carrier particles that release at least 60% of the perfume and are inert. The carrier particles are preferably inorganic with a perfume content of at least 25% by weight. The powders have reduced agglomeration problems compared to conventional powders.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

USOO584O668A

United States Patent (19) 11 Patent Number: 5,840,668

Behan et al. (45) Date of Patent: *Nov. 24, 1998

54 PERFUMED LAUNDRY DETERGENT 56) References Cited

POWDERS U.S. PATENT DOCUMENTS

75 Inventors: John Martin Behan, Kennington; 4,394,127 7/1983 Melville et al. ............................ 8/137

Richard Arthur Birch, Hythe, John 4.954,285 9/1990 Wierenga et al. .. 252/174.11

Leake, Chester; Jeremy Nicholas Ness, 4,973,422 11/1990 Schmidt .................................. 510/337

Canterbury; Anthony Nock, 5,336,665 8/1994 Garner-Grey et al. ..................... 512/4

Warrington; Keith Douglas Perring, 5,691,303 11/1997 Pan et al. .................................... 512/4

Ashford, all of Great Britain FOREIGN PATENT DOCUMENTS

73 Assignee: Quest International B.V., Naarden, 3254.57 European Pat. Off..

7/1989

Netherlands O332259 European Pat. Off..

9/1989

0332260 European Pat. Off..

9/1989

334490 European Pat. Off..

9/1989

* Notice: This patent issued on a continued pros O425277 European Pat. Off..

5/1991

ecution application filed under 37 CFR 478326 4/1992 European Pat. Off..

1.53(d), and is subject to the twenty year 2140820 12/1984 United Kingdom.

patent term provisions of 35 U.S.C. OTHER PUBLICATIONS

154(a)(2).

Chemical Abstracts, vol. 115, No. 6, Aug. 12, 1991, abstract

21 Appl. No.: 481,483 No. 52294m, K.Mizuo “Granular Laundry detergent com

22 PCT Filed: Dec. 23, 1993 positions having high bulk density and containing perfumes

for fabrics”, p. 148; see abstract & JP, A, 03 035 100, 15 Feb.

86 PCT No.: PCT/EP93/03695 1991.

S371 Date: Nov. 14, 1995 Primary Examiner Paul Lieberman

Assistant Examiner Kery A. Fries

S 102(e) Date: Nov. 14, 1995 Attorney, Agent, or Firm- Pillsbury Madison & Sutro LLP

87 PCT Pub. No.: WO94/16046 57 ABSTRACT

PCT Pub. Date:Jul. 21, 1994 The invention concerns perfumed, free flowing concentrated

30 Foreign Application Priority Data laundry detergent powders (concentrates), having a ratio of

total Solid constituents to total liquid constituents of less

Jan. 11, 1993 EP European Pat. Off. .............. 933001.47 than 30:1, wherein the perfume is sorbed onto carrier

Jan. 13, 1993 EP European Pat. Off. .............. 9330018O particles which release at least 60% w/w/ of the perfume in

51) Int. Cl. ............................... A61K 7/00; C11D 3/08; the Perfume Release Test and which are inert as defined by

C11D 3/50 the Perfume Stability Test. The invention also concerns

perfume-on-carrier Systems designed for perfuming free

52 U.S. Cl. .......................... 510,349; 510/101; 510/102; flowing concentrated laundry detergent powderS. Preferably

510/103; 510/104; 510/105; 510/106; 510/107; the carrier particles are inorganic and have a perfume

510/349; 510/438: 510/441; 510/446; 510/466 content of at least 25% w/w.

58 Field of Search ..................................... 510/105-107,

510/349, 438, 441, 446, 466; 512/4 10 Claims, No Drawings

5,840,668

1 2

PERFUMED LAUNDRY DETERGENT Thus a concentrate may be defined for the purposes of the

POWDERS present specification as comprising at least 15% (and pref

erably at least 20%) w/w total surfactant actives and at least

FIELD OF THE INVENTION 0.1% w/w perfume, preferably at least 0.4% w/w. A conse

The invention relates to perfumed laundry detergent pow quence of these differences between regulars and concen

derS and to perfume-on-carrier Systems for incorporation trates is that the ratio of total Solid to total organic liquid

into laundry detergent powders. components for certain concentrates may be less than 30:1,

or even less than 10:1, and problems can arise in manufac

BACKGROUND OF THE INVENTION ture and Storage of the product due to "Stickiness” and lump

formation. In particular, for concentrates incorporating rela

Detergent powders for laundry use span a wide range of tively high levels of liquid non-ionic Surfactants, processing

compositions. Traditional (or “regular) products are typi problems may arise from agglomeration of particles, with

fied by a detergent surfactant level of between 8% and 20% handling difficulties during production, and with the possi

by weight in total, more commonly 10% to 15%. The bility of forming large powder conglomerates which are

Surfactants may be anionic, non-ionic, cationic, Zwitterionic 15 unacceptable to the end user of the product. Even after

or amphoteric in nature, and commercial products may optimisation of the powder formulation it may be found that

contain all classes of Surfactants, but the predominant form the addition of further liquid components Such as perfumes

is generally anionic (i.e. anionic Surfactants typically to these Systems will exacerbate the tendency for particle

account for 50% or more of the total Surfactants). Typical cohesion and agglomeration, especially when the perfume is

detergent Surfactants are described in detail in "Surfactant post-dosed into base powder, and when high levels of

Surface Agents and Detergents”, volume II by Schwartz, perfume are incorporated.

Perry and Birch, Interscience Publishers (1958). The The prior art literature provides many instances where

remainder of a laundry detergent composition generally perfume is delivered via the use of a Solid carrier, which may

comprises builders, fillers, moisture, Soil release and Soil be either organic or inorganic in nature, or both.

Suspension and anti-redeposition agents, and other optional 25

adjuncts Such as processing aids, optical brighteners, dyes, GB 2066839 discloses detergent powders containing per

foam control agents, anti-corrosion agents, perfumes, pH fume sorbed onto a porous carrier at a level of 10% to 65%

control agents, enzymes, Stabilisers, bleaches and bleach by weight. The carrier is a large Surface area Sorbent Selected

activators. The level of Solid components in regular laundry from a wide variety of Substrates Such as polyacrylates,

detergent compositions is high, usually above 75%, often polyvinyl chloride, urea-formaldehyde resins, polystyrene,

above 85%. Perfume loadings for such compositions are hydrated Silicon dioxide, titanium dioxide, aluminium

generally within the range 0.05% to 0.4%, more commonly trioxide, or mixtures thereof. The primary objective of the

0.1% to 0.3%, and the ratio of solid constituents to organic invention disclosed therein is to decrease perfume losses

liquid constituents in a regular detergent composition is through volatilisation and chemical attack during Storage of

usually at least 30:1, and is likely in practice to be consid 35

perfumed powder products.

erable higher, e.g. at least 150:1 and up to 500:1. GB 1306924 describes perfume particles in free-flowing

Laundry detergent powder concentrates and hyperconcen powder form” prepared from perfume and a particulate

trates (for the purposes of this specification further referred Silica, or more particularly from a mixture of a finely divided

to as “concentrates”) represent a relatively new product Silica and an absorbent Silica gel. The fragrance loading in

Segment which is assuming increasing commercial impor 40 these particles may be as high as 70%. Manufacture is

tance world-wide. These concentrated products have a rather economical and involves simple mixing of perfume oil with

different composition to that described above. the Silicas, followed by Sieving. Examples are disclosed of

The total level of detergent Surfactants in concentrates perfume particles Suitable for use in talcum powders, Scour

generally lies within the range 15% to 60% by weight of the ing powders, deodorants, toilet blocks, bath crystals and foot

powder, more usually 20% to 40%. In addition to the 45 powders. No disclosure is made of use in detergent powders,

difference in the level of Surfactants another major point of and nothing is revealed regarding perfume Stability within

difference concerns the level of low-functionality materials concentrates, nor are specific physical properties Such as

Such as fillers. In concentrates the level of Sodium Sulphate hydrophilic character or bulk density disclosed.

for example, is rarely above 6% or even 2% by weight, U.S. Pat. No. 4209417 teaches the use of perfume par

whereas in regular powders levels of 20% to 30% are 50 ticles prepared using a water-Soluble polymer together with

common. The composition of the actives may be similar to an emulsifier. The loading of perfume in these particles may

that in regular products, i.e. predominantly anionics, but not be high (30% to 70%), but the manufacturing process

restricted to this and, for example, a high proportion of involves drying large Volumes of aqueous dispersions, with

non-ionics may be used advantageously. The use of higher adverse consequences for throughput and economy. In

proportions of non-ionic Surfactants is reported to be a 55 addition, the perfume must be water-insoluble. The teach

Significant trend in the detergent industry, at least for ings of GB 2090278 are similar, except that the perfumed

Europe, as reported by Smulders and Krings (Chemistry and particle contains water but is rendered free flowing by the

Industry, March 1990, pages 160 to 163). Examples of inclusion of excess powdered hydratable material Such as

detergent powder formulations with high non-ionicS levels anhydrous alkali metal Salts. The maximum possible loading

are disclosed in EP 228011, EP 168102, EP 425277, and EP 60 of perfume is thereby Significantly reduced.

120492. Many non-ionic surfactants are liquid at ambient Perfume-on-carrier Systems for laundry detergent compo

temperatures. Yet another difference between “regulars” and sitions as disclosed in EP 334666 are designed to deliver

concentrates is that the percentage of perfume incorporated perfume to fabric efficiently through the use of fabric

into concentrates tends to be higher than that for regular Substantive carrierS Such as Selected Solid nonionic or cat

powder use, and lies generally above 0.1% by weight, 65 ionic Surfactants. The processing involves melt blending the

normally within the range 0.4% to 2.5% by weight of the components followed by Spray chilling, and the resulting

powder, more typically 0.5% to 1.5%. perfume loading is likely to be low (25% w/w or less).

5,840,668

3 4

Similar targeted delivery of perfume is provided by the at least 15% w/w, preferably at least 20% w/w, more

microcapsules described in EP 376385, where a complex preferably between 20 and 60% w/w of detergent

coacervate prepared from perfume and polycationic and surfactants (for brevity hereinafter referred to as

polyanionic materials is coated with a water-insoluble cat “surfactants”).

ionic fabric softener which facilitates perfume delivery to 5 less than 10% w/w, preferably less than 6% w/w, more

fabric. In both these inventions the cost of manufacture is preferably less than 2% of fillers, such as sodium

relatively high and relatively complicated processing Steps Sulphate.

are involved. Furthermore concentrates preferably have a bulk-density of

GB 2140820 and GB 2141730 describe perfume-on at least 600 g/l.

carrier Systems based on Zeolites or clayS, with an optional Finally, concentrates generally contain other components,

coating of a fabric-adhesive agent, wherein the perfume Such as builders (phosphates Such as Sodium

loading in these carriers is low (10% or less). The carrier tripolyphosphate, Zeolites or NTA), Soil Suspension and

Systems are designed to deliver perfume to fabric via the anti-redeposition agents, enzymes, optical brighteners, pro

Zeolite or clay, which are likely to contact fabric and be cessing aids, dyes, foam control agents, anti-corrosion

dispersed thereupon during laundering, and are hydrophobic

enough to retain Sufficient perfume even in the wash Solu 15 agents, pH control agents, Stabilisers. Bleaching detergents

tion. also contain bleaches and bleach activators.

EP332259 and EP332260 detail the use of silica perfume The invention is particularly concerned with concentrates

carriers in detergent powders and fabric Softeners, respec in which a substantial proportion, i.e. 35% w/w or more, of

tively. The Silicas Span a wide range of types, with particle the Surfactants is liquid at ambient temperature. In this

size of from 0.001 micron (fumed silica) through to 15 respect it should be taken into account that in many cases a

micron (silica gel), with a surface area of 100-800 m/g. For particular Surfactant is in fact a mixture of chemically

laundry detergent powders the preferred Silica is a fumed closely related but slightly different components, e.g. a

type, with particle size in the range 0.007 micron. to 0.025 mixture of polymers with varying degrees of polymeriza

micron, although Silica gels may also be used, the preferred tion. Therefore, Such products do not have a sharp melting

particle Size being 1 to 8 micron. These Silica carriers are 25 point. For the purposes of this invention a Surfactant is

optimised for application in detergent compositions provid considered liquid when at a temperature of 25 C. and above

ing perfume at a level of 0.01 to 0.5%, and where the it contains no more than 50% solids.

perfume includes components which require protection from Under this definition the vast majority of anionic,

hostile bleaching agents present in the detergent composi cationic, Zwitterionic and amphoteric Surfactants are Solids

tion. The detergent compositions contain preferably 10% to and Surfactants falling in the category of liquids are pre

25% of detersive Surfactants. The examples given are high dominantly nonionics, although many other nonionics are

in anionic type Surfactants, and have high Solid to organic Solids.

liquid ratios. It is stated in EP332259 that “in addition to The invention is therefore also particularly concerned

Separating and protecting the perfume from the bleach, it is with concentrates in which a Substantial part of the Surfac

believed that the Silica particles deposit on fabrics and 35 tant is of the nonionic type. In one embodiment it is

enhance the delivery of the perfume to the fabrics”. concerned with concentrates comprising mainly nonionic

and anionic Surfactants in which the ratio of nonionic to

SUMMARY OF THE INVENTION anionic Surfactant is at least 3:2 and wherein at least 35%

It is the purpose of the present invention to provide a W/w of the total quantity of Surfactants is liquid. Thus, in

method for incorporating perfumes in particulate form into 40 these concentrates generally at least 60% w/w of the non

concentrates So as to not adversely affect the flow properties ionics is liquid. In another embodiment it is concerned with

of the detergent powder by the addition of perfume. It is concentrates in which all of the Surfactants are nonionics, of

another purpose of the invention to provide perfume-on which at least 35% w/w is liquid.

carrier Systems for incorporation into concentrates in which The concentrates according to the invention contain the

perfumes retain their integrity and which can release Sub 45 perfume-on-carrier Systems according to the invention in a

Stantially all their fragrance to the wash liquor during quantity to give at least 0.1% w/w (calculated on the total

conventional laundering. concentrate) of perfume in the concentrate, preferably

DETAILED DESCRIPTION OF THE 0.4-2.5% of perfume, more preferably 0.5-1.5% w/w of

INVENTION perfume in the concentrate. The actual quantity of perfume

50 on-carrier System to be added thus also depends on the

In one aspect the invention provides perfumed, free perfume content in the perfume-on-carrier System as here

flowing concentrated laundry detergent powders inbelow described.

(concentrates), having a ratio of total Solid constituents to As used herein the term “perfume' denotes a substantially

total liquid constituents of less than 30:1 and containing at water-insoluble composition of matter consisting of one or

least 0.1 W/w of perfume, wherein the perfume is sorbed 55 more perfume components, optionally mixed with a Suitable

onto carrier particles which release at least 60% w/w of the Solvent or diluent, which is used to impart a desired odour

perfume in the Perfume Release Test as described herein to the detergent product to which it is added and/or to the

below and which are inert as defined by the Perfume wash liquor, the skin, hair or the fabric.

Stability Test described herein below. Perfume components are those constituents of a perfume

In another aspect the invention provides perfume-on 60 which are added thereto only or primarily for their olfactive

carrier Systems wherein the carrier particles release at least contribution. Perfume components may be natural products

60% w/w of the perfume in the Perfume Release Test as Such as extracts, essential oils, absolutes, resinoids, resins,

described herein below and are inert as defined by the concretes etc., but also Synthetic materials. Such as

Perfume Stability Test described herein below. hydrocarbons, alcohols, aldehydes, ketones, ethers, acids,

For the purposes of this invention a concentrated laundry 65 esters, acetals, ketals, nitriles, etc., including Saturated and

detergent powder (or “concentrate”) is defined as a detergent unsaturated compounds, aliphatic, carbocyclic and hetero

powder comprising: cyclic compounds. Such perfume components are

5,840,668

S 6

mentioned, for example, in S. Arctander, Perfume and perfume quantity, and preferably no more than 10%, in

Flavor Chemicals (Montclair, N.J., 1969), in S. Arctander, microencapsulated form (e.g. as spray dried Starch

Perfume and Flavor Materials of Natural Origin (Elizabeth, encapsulates).

N.J., 1960) and in “Flavor and Fragrance Materials-1991”, The POC systems are conveniently prepared by mixing

Allured Publishing Co. Wheaton, Ill. USA. the perfume with the carrier particles. The mixing of the

Examples of perfume components are: geraniol, geranyl perfume and the carrier may be carried out in a variety of

acetate, linalol, linallyl acetate, tetrahydrolinalol, citronellol, ways known to the practitioner in the art, for example by

citronellyl acetate, dihydromyrcenol, dihydromyrcenyl Spraying the perfume onto the particles contained in a rotary

acetate, tetrahydromyrcenol, terpineol, terpinyl acetate, drum or positioned on a conveyor belt. A non-limiting

nopol, nopyl acetate, 2-phenylethanol, 2-phenylethyl example of a Suitable procedure involves the use of a

acetate, benzyl alcohol, benzyl acetate, benzyl Salicylate, Tatham-Forberg mixer in a low Speed, short duration opera

Styrallyl acetate, benzyl benzoate, amyl Salicylate, dimeth tion. The equipment comprises a twin-drum assembly with

ylbenzyl carbinol, trichloromethylphenylcarbinyl acetate,

p-tert-butyl cyclohexyl acetate, isononyl acetate, Vetiveryl a rotary twin-shaft arrangement. Attached to each shaft is a

acetate, Vetiverol, C-hexylcinnamaldehyde, 2-methyl-3-(p- Set of carefully profiled paddles positioned at Specific

tert-butylphenyl)propanal, 2-methyl-3-(p-isopropylphenyl) 15 angles. The powder charge is fluidised by the paddle rotation

propanal, 3-(p-tert-butyl-phenyl)-propanal, tricyclodecenyl and the perfume oil is sprayed on and mixing is continued

acetate, tricyclodecenyl propionate, 4-(4-hydroxy-4-methyl until perfume take up is complete. The perfumed particle

pentyl)-3-cyclohexenecarbaldehyde, 4-(4-methyl-3- mass is then dropped through the bottom of the mixer into

pentenyl)-3-cyclohexene carbaldehyde, 4-acetoxy-3- a Suitable container.

p enty lite tra hydrop y ran, 3-carb oxy methyl-2- Absorption or adsorption of perfumes into or onto inert

pentylcyclopentane, 2-n-heptylcyclopentanone, 3-methyl-2- carrier particles will not necessarily protect the perfumes

pentyl-2-cyclopen tenone, n-decanal, n-dodecanal, against attack by bleaching compounds. Thus, for use in

9-decenol-1, phenoxyethyl isobutyrate, phenylacetaldehyde concentrate formulations containing bleaching agents

dimethylacetal, phenylacetaldehyde diethylacetal, geranyl (which are particularly hostile to perfume components) the

nitrile, citro nellyl nitrile, c e dryl acetate, 25 perfume is preferably one which is resistant to Such attack

3-isocamphylcyclohexanol, cedryl methyl ether, and retains high performance even when Stored in the

isolongifolanone, aubepine nitrile, aubepine, heliotropin, presence of Such hostile ingredients. Suitable non-limiting

coumarin, eugenol, Vanillin, diphenyl oxide t examples are disclosed in EP 299561 and U.S. Pat. No.

hydroxy citro nellal, ion one S, methyl ion one S, 4663068.

isomethylionones, irones, cis-3-hexenol and esters thereof, The POC systems of the present invention may be incor

indan muskS tetralin musks isochroman muskS macrocyclic porated into concentrates using Standard powder handling

ketones, macrolactone musks ethylene brassylate, aromatic equipment, known in the art, e.g. by utilisation of weigh

nitromuskS. belts.

Suitable Solvents and diluents for perfumes as mentioned

above are, for example, diethyl phthalate, triethyl citrate, 35 CONCENTRATE FORMULATION EXAMPLES

ethanol, isopropanol, dipropylene glycol, etc.

The perfume-on-carrier systems (hereinafter for brevity High non-ionic Surfactant content concentrates within the

referred to as “POC systems”) according to the invention Scope of application defined herein are detailed in the

comprise a perfume as defined above and an inert particulate references cited above, and two examples are shown below

carrier. InertneSS of the carrier is tested with a test perfume 40 in Tables I and II.

as described below in the “Perfume Stability Test”. For the

purposes of this invention a carrier is considered inert if each TABLE I

component in the test perfume 1 of Table 1 below suffers no CONCENTRATE "A" % w/w

more than 5% deterioration under the test conditions.

Also the POC systems should easily release a substantial 45 Zeolite 4A 33.2

proportion of its perfume content when immersed in a Sodium carbonate 11.2

Dobanol 23-3 12.1

laundry wash liquor. This ability requires the carrier to be Dobanol 23-6.5 10.2

sufficiently hydrophobic and the suitability of a carrier can Sodium LAS 6.2

be determined with the “Perfume Release Test' described Sodium sulphate 3.8

below. For the purposes of this invention a carrier is con 50 Polyacrylate (m.w 3000-4000) 3.5

Sodium silicate 1.9

sidered to pass the test if under the test conditions it is found Sodium soap 2.6

to release at least 60% of the test perfume 2 of Table 2 below. POC system particles 2.O

The POC systems comprise preferably at least 25% w/w Enzymes 1.3

of perfume, more preferably at least 40% and most prefer Anti-redeposition agent O.9

Antifoam 0.4

ably at least 70% w/w. Yet the POC system should remain 55 Sodium EDTA 0.4

free-flowing. Water, dye, minor components 10.3

Conveniently the inert carrier particles have a mean

diameter in the range 5-50 microns, preferably in the range 1OO

10-50 microns, more preferably in the range 15-50 microns,

most preferably in the range 20-50 microns. Also, they 60

should preferably have a surface area in the range 100-450 TABLE II

m/g, more preferably in the range 100-350m/g, most

preferably in the range 100-300 m /g. Preferably an inor CONCENTRATE "B" % w/w

ganic carrier is used, Such as a Silica, Zeolite or clay. Zeolite 4A 29.8

Typically the carrier particles are of amorphous Silica. 65 Sodium perborate 15.6

In addition to the POC system the concentrates according Sodium carbonate 9.7

to the invention may comprise up to 20% w/w of the total

5,840,668

7 8

TABLE II-continued TABLE 2

CONCENTRATE "B" % w/w Perfume Test Mixture 2

TAED granules** 8.2 Material wfw %

Dobanol 23-3 8.7

Dobanol 23-6.5 7.3 Benzyl acetate 2O

Sodium LAS 5.1 Hexylcinnamic aldehyde 2O

Polyacrylate (m.w 3000-4000) 3.1 PTBCHA 2O

Sodium sulphate 1.6 Tetrahydrolinalol 2O

POC system particles 1.2 1O Tonalid 2O

Sodium soap 1.5

Sodium silicate 1.5 KEY: "Tonalid" is a trademark for 1,1,2,4,4,7-hexamethyl-6-acetyl-1,2,3,4-

Enzymes O.8 tetrahydronaphthalene

Anti-redeposition agent 0.4 "PTBCHA" is 4-tert.butylcyclohexyl acetate

Sodium EDTA O.3

Antifoam O.3 15

Water, dye, minor components 4.9 Perfume Release Test

1OO The POC system under evaluation (containing at least

*monohydrate 20% by weight of Perfume Test Mixture 2, Table 2) were

**tetraacetalythylene diamine sodium salt equilibrated for 3 days and then added at ambient tempera

ture to an aqueous model wash liquor at a level yielding a

theoretical maximum perfume concentration of 40 ppm. The

Perfume Stability Test wash liquor (10 g) comprised ca. 0.05% of a mixture of a

non-ionic surfactant (Dobanol 25TM, a mixture of ethoxy

lated fatty alcohols with an average of 7 ethoxyl groups) and

A particulate sample (2 g) was prepared by incorporating 25 an anionic Surfactant (Sodium lauryl Sulphate) in a weight

20% of the perfume test mixture 1 detailed in Table 1 into ratio of 2.3 to 1.

an inorganic carrier under evaluation. The Sample was Stored The mixture was shaken for 10 seconds and immediately

in glass vials (10 ml) for one week at 37° C. prior to analysis. placed in a centrifuge and spun for 5 minutes at 2000 RPM.

The vials were tightly sealed and free movement of air The bulk of the Supernatant liquid was withdrawn (ca.

throughout the test System was minimised by packing the 95% by weight of the aqueous phase, measured accurately)

free headspace Volume with cotton wool. and filtered prior to extraction with ethyl acetate (10 g,

Analysis was carried out by extraction of the sample using containing hexadecane as an internal standard). The ethyl

acetate was obtained by centrifugation and was analysed by

ethyl acetate, followed by determination of the residual mass 35 gas chromatography. The amount of perfume released into

of the indicator materials using Standard gas chromato the aqueous phase was then calculated.

graphic techniques. A perfume release efficiency of 60% or over is taken as

Suitable carriers according to this test are those for which indicative of bulk release of the perfume under actual wash

each of the indicator materials Suffer no more than 5% conditions where temperatures of 35 C. to 65 C. or higher

degradation (i.e. each component in the System displays at 40 are common, and longer wash times are likely (e.g. 15-30

least 95% stability). Such carriers are defined as passing the minutes, or longer in a Soak regime). Carrier materials

Perfume Stability Test for the purposes of the present achieving this are considered to pass the Perfume Release

Test.

application.

45 Carrier material test examples

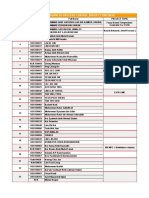

TABLE 1.

A range of commercial inorganic particles was Subjected

Perfume Test Mixture 1

to the above tests. The results of these tests together with

Material wfw %

other relevant data are shown in Tables 3 and 4. It can be

50

Seen that the two precipitated Silicas meet the criteria

Benzyl acetate 25 specified above, Neosyl GPTM and HP 39TM.

Limonene 25

Tetrahydrolinalol 25

Inert internal standard 25 TABLE 3

*e.g. Tetradecane Mean

55 Surface Particle Perfume

Area Size Loading Stability

Perfume Loading Carrier mfS. micron % w/w BA Lim THL

Gasil 750 4.6 2O 95 90 1OO

Equal amounts of carrier material were placed in a Series 2008

60 Neosyl 2OO 18 65 95 95 95

of glass Vials and various aliquots of a mixture of perfume GP*

components were added (Perfume Test Mixture 2 as shown Aerosil 2OO O.O1 8O 1OO 90 1OO

in Table 2). Each carrier/perfume System was agitated with 2OO**

Zeolite 3O 85 85 1OO

a spatula, Sealed in the Vial and Stored at ambient tempera 4A

ture for 24 hours prior to inspection. “Perfume Loading” was 65 Gasil 32O 9 55 1OO 85 1OO

taken as the loading at which the perfume-on-carrier mixture EBN*

ceased to flow easily as judged by eye.

5,840,668

9 10

Application Example 5

TABLE 3-continued

A Starch encapsulate was prepared containing 40% per

Mean

Surface Particle Perfume fume oil. The Starch was a modified waxy maize Starch

Area Size Loading Stability 5 (CapsulTM, National Starch) and the perfume was a freshness

Carrier m2/S. micron % w/w BA Lim THL

accord (Fragrance C, Table 7) of perfume materials Suscep

tible to attack by bleach components in laundry powder. The

HP39* 3OO 11 65 95 95 95 encapsulate was prepared by normal Spray-drying

Aerosil 3OO O.O1 75 95 90 1OO

3OO** procedures, well known to those experience in the art. An

Neosyl >400 12 25 90 95 1OO emulsion of 40% starch in water was prepared and sufficient

LD*

perfume added to constitute 40% of the total of starch and

Key: BA-Benzyl acetate Lim-Limonene THL-tetrahydrolinalol (i.e. the per perfume. This emulsion was then spray-dried using a con

fume components of Perfume Test Mixture 1) ventional spray-dryer (Niro Mobile Minor) with rotary

15 atomizer, inlet temperature 240 C., outlet temperature 100

C.

TABLE 4

Perfume Release

POC system particles containing 50% perfume were

prepared from Neosyl GPTM and fragrance “B” (see Table 6).

Carrier % Perfume released These were mixed into a concentrate powder (formulation B,

Aerosil 200** 52

Table 1) at a level of 1.1% to yield a perfume loading of

Aerosi R812** 42 0.55%. To this product was then mixed in 0.2% of the starch

Gas 2OO** 2O encapsulate detailed above, yielding an overall perfume

HP39* 70

Neosyl GP* 68

level of 0.63%. The powder was stored in domestic lami

25 nated cardboard containers at 37° C./70% RH for 4 weeks

Key: */** as for Table 4 and examined. No adverse effect was noted on powder flow

properties.

Application Example 1

TABLE 5

POC system particles containing 50% perfume were

prepared from Neosyl GpTM and fragrance “A” as specified Formulation of fragrance "A"

in Table 5. These were incorporated into concentrate powder Material Quantity %

(formulation A, Table 1) at a level of 1.1% to yield a perfume

loading of 0.55%. The powder was stored in domestic Anther (Q)

Coumarin

1.O

2.O

laminated cardboard containers at 37 C./70% RH (relative 35

Gyrane (Q) 0.5

humidity) for 4 weeks and examined. No adverse effect was Hexyl cinnamic aldehyde 18.0

noted on powder flow properties. Jasmacyclene (Q) 5.0

Jasmopyrane Forte (Q) 4.0

Application Example 2 Lilial (G) 1.O.O

Lixetone (Q) 8.0

POC system particles containing 50% perfume were 40 Methyl ionone alpha iso (Q) 5.0

prepared from Neosyl GPTM and fragrance “A” as specified 4-tert.butylcyclohexyl acetate (Q) 5.0

in Table 5. These were incorporated into a concentrate 2-Phenylethyl alcohol 15.O

Pivacyclene (Q) 0.5

powder (formulation B, Table 1) at a level of 1.1% to yield Tetrahydrolinalol 6.O

a perfume loading of 0.55%. The powder was stored in Traseolide (Q) 2O.O

domestic laminated carboard containers at 37 C./70% RH 45

(relative humidity) for 4 weeks and examined. No adverse Q: trade mark material available from Quest

G: trade mark material available from Givaudan

effect was noted on powder flow properties.

Application Example 3

TABLE 6

POC system particles containing 55% perfume were 50

prepared were prepared from Neosyl GPTM and fragrance Formulation of fragrance "B"

“B” as specified in Table 6. These were incorporated into a Material Quantity %

concentrate powder (formulation B, Table 1) at a level of

1.45% to yield a perfume loading of 0.8%. The powder was Dimethylbenzyl carbinyl acetate 15.O

stored in domestic laminated cardboard containers at 37 55 4-tert.butylcyclohexyl acetate (Q) 17.5

Tetrahydrolinalol 15.O

C./70% RH for 4 weeks and examined. No adverse effects Anther (Q) 3.5

was noted on powder flow properties. Traseolide (Q) 5.0

Decanol 5.0

Application Example 4 Phenylpropanol 6.O

Herboxane 1.O.O

POC system particles containing 55% perfume were 60

Diphenylmethane 5.0

prepared from HP 39TM and fragrance “B” as specified in Cedramber (IFF) 4.0

Table 6. These were incorporated into a concentrate powder Hexadecanolide 5.0

(formulation B, Table 1) at a level of 1.4% to yield a perfume 2-Phenylethyl alcohol 6.O

Dihydroterpineol 3.0

loading of 0.8%. The powder was stored in domestic lami

nated carboard containers at 37 C./70% RH for 4 weeks and 65 Q: trade mark material available from Quest

examined. No adverse effect was noted on powder flow IFF: trade mark material available from IFF

properties.

5,840,668

11 12

3. A detergent powder according to claim 1 or 2 wherein

TABLE 7 the amount of detergent surfactant is at least 20% w/w and

the amount of filler is less than 6% w/w.

Formulation of fragrance "C" 4. A detergent powder according to claim 1, wherein at

Material Quantity % least 35% w/w of the surfactants are liquids.

5. A detergent powder according to claim 4 comprising

Adoxal (G) 1.O nonionic and anionic detergent Surfactants wherein the ratio

Aldehyde C950% in DEP 7.0 of nonionic detergent Surfactants to anionic detergent Sur

Aldehyde C10 50% in DEP 16.O

Aldehyde C11 (undecylenic) 50% in DEP 3O.O factants is at least 3:2 and at least 60% w/w of the nonionic

Aldehyde C12 50% in DEP 1O.O detergent Surfactants is liquid.

Methylnonyl acetaldehyde 50% in DEP 36.0 6. A detergent powder according to claim 4 wherein all

G: trade mark material supplied by Givaudan detergent Surfactants are nonionic of which at least 35% are

DEP: diethylphthalate (diluent) liquid.

7. A detergent powder according to claim 1 wherein the

We claim: 15 carrier particles carry at least 40% w/w of perfume.

1. A perfumed, free flowing concentrated laundry deter 8. A detergent powder according to claim 7, wherein the

gent power comprising: carrier particles have a surface area in the range 100-350

at least 15% w/w of detergent surfactants, m/gram.

less than 10% w/w of fillers, 9. A perfume-on carrier System consisting of amorphous

having a ratio of total Solid constituents to total liquid having a mean diameter in the range of 20–50 microns

constituents of less than 30:1 and containing at least 0.1% which further have a surface area in the range of 100-450

W/w of perfume, wherein the perfume is added as a perfume m/gram and which carry at least 25% w/w of perfume,

on-carrier System consisting of amorphous Silica having a which release at least 60% w/w of the perfume in a Perfume

mean diameter in the range of 20–50 microns which further Release Test and which are inert as defined by a Perfume

have a surface area in the range of 100-450 m/gram which 25 Stability Test.

carry at least 25% w/w of perfume, which release at least 10. A perfume-on-carrier System according to claim 1,

60% w/w of the perfume in a Perfume Release Test and wherein the carrier particles have a Surface area in the range

which are inert as defined by a Perfume Stability Test. 100-350 mi/gram.

2. A detergent powder according to claim 1, having a bulk

density of at least 600 g/l.

Potrebbero piacerti anche

- Carrier Oils What Are They and How Are They MadeDocumento2 pagineCarrier Oils What Are They and How Are They MadekatNessuna valutazione finora

- Book On Surfactants Acid Slurry Formulations TechnologyDocumento6 pagineBook On Surfactants Acid Slurry Formulations TechnologyDinesh KumarNessuna valutazione finora

- Olive Oil and Argan Oil Based Cold Process Antistatic and Sensitive Soft Conditioner Formulation and Production e BookDocumento6 pagineOlive Oil and Argan Oil Based Cold Process Antistatic and Sensitive Soft Conditioner Formulation and Production e BookLuis MateranNessuna valutazione finora

- Laundry Detergents - Moving From Solid To LiquidDocumento6 pagineLaundry Detergents - Moving From Solid To LiquidJeanette ChenNessuna valutazione finora

- Detergent FormulationDocumento4 pagineDetergent FormulationJehonadab Nwankwo67% (3)

- HarpicDocumento12 pagineHarpicreptilia89Nessuna valutazione finora

- Pine Oil FormulationsDocumento2 paginePine Oil FormulationsMaruf MominNessuna valutazione finora

- Technic For Bead PerfumeDocumento5 pagineTechnic For Bead Perfumetopguitar100% (1)

- Denim 2Documento18 pagineDenim 2ADINAN MOHAMMED100% (1)

- 5 - Transparent and Translucent Soaps PDFDocumento10 pagine5 - Transparent and Translucent Soaps PDFBianca AlvesNessuna valutazione finora

- 8cosmetics Formulation LIQUID HAND SOAPDocumento57 pagine8cosmetics Formulation LIQUID HAND SOAPFADZAI DUBENessuna valutazione finora

- High Quality Detergent PowderDocumento2 pagineHigh Quality Detergent PowderTrftyfty YutyutNessuna valutazione finora

- How To Make PerfumeDocumento4 pagineHow To Make PerfumeJerel Grecia100% (1)

- 571 SummaryDocumento3 pagine571 SummarySimbu Arasan100% (1)

- Deodorants 503312724Documento12 pagineDeodorants 503312724Pavan KumarNessuna valutazione finora

- Best Detergent PDFDocumento5 pagineBest Detergent PDFShakeel NajmiNessuna valutazione finora

- Making Good Scents - Summer 98: The newsletter of homemade cosmetics, perfumes, and soapsDa EverandMaking Good Scents - Summer 98: The newsletter of homemade cosmetics, perfumes, and soapsNessuna valutazione finora

- GEMSS-M-15 Rev 02 - Desalination Plant and Desalinated Water TanksDocumento20 pagineGEMSS-M-15 Rev 02 - Desalination Plant and Desalinated Water TanksKaramSobhyNessuna valutazione finora

- Household and I&I Formul Ation GuideDocumento15 pagineHousehold and I&I Formul Ation Guidezaryab khanNessuna valutazione finora

- Chem Project2Documento17 pagineChem Project2Hitesh PatidarNessuna valutazione finora

- Room Perfume Aerosol Spray Free ExampleDocumento7 pagineRoom Perfume Aerosol Spray Free ExampleKhan SajjadNessuna valutazione finora

- Soap Detergent MFG DD 1974Documento217 pagineSoap Detergent MFG DD 1974Noman Sunny100% (1)

- How To Formulate A DetergentDocumento8 pagineHow To Formulate A DetergentJuanGuillermoCarmonaOcampo100% (4)

- Soap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantDa EverandSoap-Making Manual. A practical Handbook on the RControl in the modern Soap PlantValutazione: 5 su 5 stelle5/5 (2)

- Ellipsoidal Head Closure: Design SpecificationDocumento1 paginaEllipsoidal Head Closure: Design SpecificationNur AmaninaNessuna valutazione finora

- Detergent (Group 1,2)Documento29 pagineDetergent (Group 1,2)Sourav SutradharNessuna valutazione finora

- DetergentPowders PDFDocumento12 pagineDetergentPowders PDFKhaled SlevinNessuna valutazione finora

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocumento10 pagineEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddNessuna valutazione finora

- Conditioner FormulasDocumento4 pagineConditioner FormulasCarolina TarifNessuna valutazione finora

- MIGC Catalogue Personal & Home Care ProductsDocumento14 pagineMIGC Catalogue Personal & Home Care ProductsFaisal IqbalNessuna valutazione finora

- How+to+DeFi 101Documento10 pagineHow+to+DeFi 101Nur Amanina100% (1)

- Surfactant SDocumento53 pagineSurfactant SPamela Mendoza100% (1)

- Continuous Direct Dryers: Drying EquipmentDocumento60 pagineContinuous Direct Dryers: Drying EquipmentNur AmaninaNessuna valutazione finora

- Aerosol Glass Cleaner - 179Documento2 pagineAerosol Glass Cleaner - 179mndmattNessuna valutazione finora

- Industria Chimica Panzeri S.R.L. Cosmetic-CatalogueDocumento18 pagineIndustria Chimica Panzeri S.R.L. Cosmetic-CatalogueTo Ra100% (2)

- PF Ebook Berje Floral Complete2 Opt-2Documento61 paginePF Ebook Berje Floral Complete2 Opt-2tmlNessuna valutazione finora

- Gas MigrationDocumento39 pagineGas MigrationAli AliievNessuna valutazione finora

- Science 7 ExamDocumento5 pagineScience 7 Examangge21Nessuna valutazione finora

- FTA Chemical PlantDocumento109 pagineFTA Chemical PlantNur AmaninaNessuna valutazione finora

- Perfumes en DetergentesDocumento30 paginePerfumes en DetergentesSilvia Nathalia Contreras100% (1)

- Niir Soaps Detergents Disinfectants Technology HandbookDocumento12 pagineNiir Soaps Detergents Disinfectants Technology Handbookjinnah143640% (1)

- Liquid DetergentDocumento7 pagineLiquid Detergentmagdy100% (1)

- A Project On DetergentDocumento47 pagineA Project On Detergentmldc2011100% (1)

- SoapDocumento7 pagineSoapShivansh Rajput100% (1)

- From Our Formulary: Linen & Room SprayDocumento1 paginaFrom Our Formulary: Linen & Room SprayWangari Lothaire RachealNessuna valutazione finora

- Manufacture High Quality Neem Based White Phenyle Using Classimulse NEDocumento10 pagineManufacture High Quality Neem Based White Phenyle Using Classimulse NERajesh Kumar SSNessuna valutazione finora

- SugaNate 160NCDocumento2 pagineSugaNate 160NCmndmattNessuna valutazione finora

- Soap Manufacturing ProcessDocumento15 pagineSoap Manufacturing ProcessMarjhel HalligNessuna valutazione finora

- Zahras Arabian Oud CatalogDocumento77 pagineZahras Arabian Oud CatalogZahra Gaj100% (2)

- Castor Oil & Its Derivatives Oleoresin, Turkey Red Oil, Dco, Hco, Sebacic Acid, 12-Hydroxy Stearic AcidDocumento5 pagineCastor Oil & Its Derivatives Oleoresin, Turkey Red Oil, Dco, Hco, Sebacic Acid, 12-Hydroxy Stearic Acidkunal agiwaleNessuna valutazione finora

- Product Safety Data Sheet: Section 1: IDocumento17 pagineProduct Safety Data Sheet: Section 1: ILiemar EstayNessuna valutazione finora

- Niir Complete Technology Book On Detergents 2nd Revised EditionDocumento11 pagineNiir Complete Technology Book On Detergents 2nd Revised EditionMukesh BeldarNessuna valutazione finora

- PerfumeryDocumento14 paginePerfumerychidambaramr100% (2)

- PerfumeDocumento13 paginePerfumePaul Michael Joules Salise100% (1)

- Maptrons Glass Cleaner KitDocumento2 pagineMaptrons Glass Cleaner KitAbhay Singh100% (1)

- SoapDocumento4 pagineSoapSi OneilNessuna valutazione finora

- FixativesDocumento6 pagineFixativesmazen jamalNessuna valutazione finora

- Final Soap Production 1Documento13 pagineFinal Soap Production 1SuvamNessuna valutazione finora

- Fabric Softener: 14% Concentration (Cold Process)Documento2 pagineFabric Softener: 14% Concentration (Cold Process)Chemist TechnologistNessuna valutazione finora

- Making Cold Process Soap PDFDocumento3 pagineMaking Cold Process Soap PDFCosmina Georgiana0% (1)

- Toilet Cleaner Powerfull Flus and Strong ThickerDocumento1 paginaToilet Cleaner Powerfull Flus and Strong ThickerMurtaza sherwaniNessuna valutazione finora

- Soaps, Detergents & Toiletries ReviewDocumento15 pagineSoaps, Detergents & Toiletries ReviewArun AryaNessuna valutazione finora

- The Manufacturing of Soaps Consist of A Comprehensive Range of Processing and Packaging ActivitiesDocumento6 pagineThe Manufacturing of Soaps Consist of A Comprehensive Range of Processing and Packaging ActivitiesBirhanu TeshaleNessuna valutazione finora

- Deepam OilDocumento2 pagineDeepam OilSri VaishaliniNessuna valutazione finora

- Homemade Liquid Soap-3 PDFDocumento8 pagineHomemade Liquid Soap-3 PDFThe QueendomNessuna valutazione finora

- Homemade Hand Sanitizer - Learn How to Make Your Own Natural Hand Sanitizer Recipes for a Healthier LifestyleDa EverandHomemade Hand Sanitizer - Learn How to Make Your Own Natural Hand Sanitizer Recipes for a Healthier LifestyleNessuna valutazione finora

- Make Home Made SoapDocumento17 pagineMake Home Made SoapML03100% (1)

- Biariq SLES 70% TDSDocumento2 pagineBiariq SLES 70% TDSAbdullah AzzamNessuna valutazione finora

- Template For Poster DesignDocumento1 paginaTemplate For Poster DesignNur AmaninaNessuna valutazione finora

- Authorized MFi Manufacturing LicenseesDocumento19 pagineAuthorized MFi Manufacturing LicenseesNur AmaninaNessuna valutazione finora

- Us 8492597Documento7 pagineUs 8492597Nur AmaninaNessuna valutazione finora

- DO - Luara - HW-3Documento3 pagineDO - Luara - HW-3Nur AmaninaNessuna valutazione finora

- Q: Describe The Concept of Equivalence in A Way That Your Brother in Law Can Understand ItDocumento36 pagineQ: Describe The Concept of Equivalence in A Way That Your Brother in Law Can Understand ItNur AmaninaNessuna valutazione finora

- Membrane ProcessesDocumento49 pagineMembrane ProcessesNur AmaninaNessuna valutazione finora

- Kkek4305: Advanced Process Control (Project Partner)Documento2 pagineKkek4305: Advanced Process Control (Project Partner)Nur AmaninaNessuna valutazione finora

- 26octDocumento15 pagine26octNur AmaninaNessuna valutazione finora

- AVEVA Malaysia Training ScheduleDocumento1 paginaAVEVA Malaysia Training ScheduleNur AmaninaNessuna valutazione finora

- Question 2 (C) : %non-Linear ModelDocumento2 pagineQuestion 2 (C) : %non-Linear ModelNur AmaninaNessuna valutazione finora

- Environmental Impact of Synthetic DetergentsDocumento20 pagineEnvironmental Impact of Synthetic DetergentsNur AmaninaNessuna valutazione finora

- Process Synthesis KEK3157: Homework 1Documento2 pagineProcess Synthesis KEK3157: Homework 1Nur AmaninaNessuna valutazione finora

- What Is Dehumidification?: Psychrometric ChartDocumento1 paginaWhat Is Dehumidification?: Psychrometric ChartNur AmaninaNessuna valutazione finora

- Lewis RelationDocumento3 pagineLewis RelationNur AmaninaNessuna valutazione finora

- L17 Basic Catalysis and MechanismsDocumento29 pagineL17 Basic Catalysis and MechanismsNur AmaninaNessuna valutazione finora

- Phytochemical Andanti-Inflammatory Studies On Thehexane Extract of The Stem Bark Ofsteganotaenia AraliaceahoschtsDocumento93 paginePhytochemical Andanti-Inflammatory Studies On Thehexane Extract of The Stem Bark Ofsteganotaenia AraliaceahoschtsPrily R PadjaNessuna valutazione finora

- Ur m60Documento3 pagineUr m60Goran JurisicNessuna valutazione finora

- Biology Unit PlanDocumento10 pagineBiology Unit Planapi-246097943Nessuna valutazione finora

- Indion 850 Resin Engg Data SheetDocumento6 pagineIndion 850 Resin Engg Data SheetsoumitrabanNessuna valutazione finora

- Automatic Versionof Ostwald ViscometerDocumento4 pagineAutomatic Versionof Ostwald Viscometermuh. almusyafirNessuna valutazione finora

- ChemEngineering - Flash EvaporationDocumento3 pagineChemEngineering - Flash EvaporationmegakiranNessuna valutazione finora

- Chemguard c333 Ar-Afff 3% MsdsDocumento7 pagineChemguard c333 Ar-Afff 3% MsdsrendydunNessuna valutazione finora

- The Latent Heat of Fusion of IceDocumento4 pagineThe Latent Heat of Fusion of Iceeid elsayedNessuna valutazione finora

- History 2014Documento34 pagineHistory 2014Grace De León NopeNessuna valutazione finora

- Octahedral Molecular GeometryDocumento24 pagineOctahedral Molecular GeometryAnonymous gUjimJKNessuna valutazione finora

- Food Science Report - GroupDocumento23 pagineFood Science Report - GroupMuhammad Salihin JaafarNessuna valutazione finora

- Ec 1Documento443 pagineEc 1Chaitanya KumarNessuna valutazione finora

- Ridgid CD 100Documento271 pagineRidgid CD 100SmisliNestoNessuna valutazione finora

- Assignment For Iupac Nomenclature: CH - CH-CH - CHDocumento5 pagineAssignment For Iupac Nomenclature: CH - CH-CH - CHapi-233404189Nessuna valutazione finora

- Gate 2001Documento61 pagineGate 2001api-26818774Nessuna valutazione finora

- RSM 2008 RevisionDocumento51 pagineRSM 2008 RevisionphanthanhhungNessuna valutazione finora

- Wheatstone BridgeDocumento4 pagineWheatstone BridgeTasnim RahmanNessuna valutazione finora

- Unit 4 Study Guide Solutions - Kinetics & ThermoDocumento3 pagineUnit 4 Study Guide Solutions - Kinetics & ThermoPenguin/CatNessuna valutazione finora

- Butyl Diglycol Acetate ManufacturersDocumento4 pagineButyl Diglycol Acetate ManufacturersSomuSolventsNessuna valutazione finora

- L&T Document Number:: 0 1 ARN DDU ARN DDUDocumento56 pagineL&T Document Number:: 0 1 ARN DDU ARN DDUFayaz AhammedNessuna valutazione finora

- Phar 1205L Activity 2Documento6 paginePhar 1205L Activity 2Draco PhoenixNessuna valutazione finora

- Ter Fire SleeveDocumento8 pagineTer Fire SleeveAhmad FadhilNessuna valutazione finora

- Kelompok 10 - Metode Optimasi Senyawa PenuntunDocumento36 pagineKelompok 10 - Metode Optimasi Senyawa Penuntunapr_aprililianti100% (1)

- Solar ChimneyDocumento1 paginaSolar Chimneyh_shrNessuna valutazione finora

- Standard SpecificationsDocumento5 pagineStandard SpecificationsIan54321Nessuna valutazione finora