Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steam HX

Caricato da

rajachemCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Steam HX

Caricato da

rajachemCopyright:

Formati disponibili

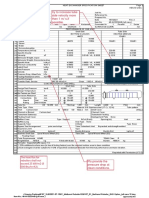

1 HEAT EXCHANGER SPECIFICATION SHEET

2

3

4 Job No. --

5 Customer --- Reference No. --

6 Address --- Proposal No. --

7 Plant Location --- Date 3/15/2018 Rev 0

8 Service of Unit Steam to Steam heat exchangers Item No.

9 Size 800- 2050 x 8000 mm Type DKU Horizontal Connected In 1 Parallel 1 Series

10 Surf/Unit (Gross) 217.56 m2 Shell/Unit 1 Surf/Shell (Gross) 217.56 m2

11 PERFORMANCE OF ONE UNIT

12 Fluid Allocation Shell Side Tube Side

13 Fluid Name LP Steam / Feed water HP Steam / Condensate

14 Fluid Quantity, Total kg/hr 110000 132430

15 Vapor (In/Out) kg/hr 110000 132430

16 Liquid kg/hr 110000 132430

17 Steam kg/hr

18 Water kg/hr

19 Noncondensables kg/hr

20 Temperature (In/Out) C 148.02 147.90 538.00 347.19

21 Density kg/m3 918.86 2.4031 47.890 585.63

22 Viscosity cP 0.1851 0.0139 0.0310 0.0672

23 Molecular Weight, Vapor

24 Molecular Weight, Noncondensables

25 Specific Heat Capacity kcal/kg-C 1.0282 0.5673 0.6679 2.2531

26 Thermal Conductivity kcal/hr-m-C 0.5884 0.0262 0.0738 0.3815

27 Latent Heat kcal/kg

28 Inlet Pressure kgf/cm2-A 4.604 163.15

29 Velocity (Mid-Point) m/s 6.15 5.60

30 Pressure Drop, Allow/Calc kgf/cm2 0.028 0.510 0.393

31 Fouling Resistance (min) m2-hr-C/kcal 0.000205 0.000205

32 Heat Exchanged 55671069.000 kcal/hr MTD (Corrected) 227.20 C

33 Transfer Rate, Service 983.79 kcal/m2-hr-C Clean 2275.7 kcal/m2-hr-C Actual 1103.6 kcal/m2-hr-C

34 CONSTRUCTION OF ONE SHELL Sketch (Bundle/Nozzle Orientation)

35 Shell Side Tube Side

36 Design/Test Pressure barG 5 / Code 176 / Code

37 Design Temperature C 200 550

38 No Passes per Shell 1 2

39 Corrosion Allowance mm 3.2 mm (except tubes) --

40 Connections In 1 @ 6" #150 WNRF 1 @ 12" WE

41 Size & Out 1 @ 24 #150 WNRF 1 @ 8" WE

42 Rating Intermediate @ @

43 Tube No. 206U OD 25.400 mm Thk(Avg) 2.769 mm Length 8.000 m Pitch 25.400 mm

44 Tube Type Plain Seamless Material SA 213 TP 347 Tube pattern 90

45 Shell SA 516 Gr 70 ID 1100.0 OD mm Shell Cover

46 Channel or Bonnet SA 240 347H Channel Cover

47 Tubesheet-Stationary SA 182 F 347 Tubesheet-Floating

48 Floating Head Cover Impingement Rods CS

49 Baffles-Cross SA 285 Gr C Type Supports %Cut (Diam) Spacing(c/c) 739.04 Inlet mm

50 Baffles-Long Seal Type

51 Supports-Tube U-Bend Type

52 Bypass Seal Arrangement pairs seal strips Tube-Tubesheet Joint Strength Welded

53 Expansion Joint Type

54 Rho-V2-Inlet Nozzle kg/m-s2 Bundle Entrance Bundle Exit kg/m-s2

55 Gaskets-Shell Side Tube Side

56 -Floating Head

57 Code Requirements ASME Section VIII Division 1 TEMA Class R

58 Weight/Shell kg Filled with Water kg Bundle kg

59 Remarks:

60 Supports/Baffle space = 10

61 Vibration supports (if necessary) to be included at U bend region

62

63

64

65

66

67

68

69

70

THE INFORMATION DISCLOSED HEREIN INCLUDES PROPRIETARY RIGHTS OF THERMAL ENGINEERING INTERNATIONAL. NEITHER

THIS DOCUMENT NOR THE INFORMATION DISCLOSED HEREIN SHALL BE REPRODUCED OR TRANSFERRED TO OTHER DOCUMENTS

OR USED OR DISCLOSED TO OTHERS FOR MANUFACTURING PURPOSES, OR FOR ANY OTHER PURPOSE EXCEPT AS SPECIFICALLY

AUTHORIZED IN WRITING BY THERMAL ENGINEERING INTERNATIONAL.

Potrebbero piacerti anche

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Documento4 pagineSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINessuna valutazione finora

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Documento31 pagineDesign of Shell & Tube HX (Unprotected For Expert Excel Users)Sameer ChaturvediNessuna valutazione finora

- Burner DatasheetDocumento6 pagineBurner DatasheetHafiz Muhammad AbubakarNessuna valutazione finora

- CDA Data CollectionDocumento2 pagineCDA Data Collectiondford8583Nessuna valutazione finora

- XSteam Excel v2.6Documento3 pagineXSteam Excel v2.6pchanycNessuna valutazione finora

- Cone Design ToolDocumento1 paginaCone Design ToolPramod KumarNessuna valutazione finora

- Double FdexchangerDocumento8 pagineDouble FdexchangerBoško IvanovićNessuna valutazione finora

- TEMA SheetDocumento2 pagineTEMA SheetFrancisco RenteriaNessuna valutazione finora

- Final Energy Balance-Vizag DT 9-6-18Documento6 pagineFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNessuna valutazione finora

- EX Firetube Boiler Changed by Advances in Design TechnologyDocumento7 pagineEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroNessuna valutazione finora

- Questionaire For Drum Flaker - NEWDocumento2 pagineQuestionaire For Drum Flaker - NEWBhavin TalatiNessuna valutazione finora

- 503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFDocumento8 pagine503 Systems - Indirect Fired Heaters - Eng - Apr2010 PDFsvnaik14Nessuna valutazione finora

- Heat Loss From An Insulated Pipe: ParametersDocumento4 pagineHeat Loss From An Insulated Pipe: ParametersMohan BabuNessuna valutazione finora

- Cal. Dew PointDocumento1 paginaCal. Dew PointJuan Pablo ApazaNessuna valutazione finora

- Final Design Values of PHE C-510 CoolersDocumento4 pagineFinal Design Values of PHE C-510 CoolersRamji MishraNessuna valutazione finora

- Gas Conditioning System Specification Sheet: Process InformationDocumento3 pagineGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHNessuna valutazione finora

- Process Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsDocumento1 paginaProcess Data Sheet: Calculation of Pressure Drop in Fixed Catalyst BedsamitkrayNessuna valutazione finora

- Expansion Tank Capacity Calculation SheetDocumento5 pagineExpansion Tank Capacity Calculation SheetDEX TERRNessuna valutazione finora

- Vent Sizing (61-65)Documento26 pagineVent Sizing (61-65)mieiroluiz12Nessuna valutazione finora

- FTDocumento1 paginaFTmanodipNessuna valutazione finora

- Heat Exchanger Design and HT Coefficent Calculation From RC-6 BookDocumento20 pagineHeat Exchanger Design and HT Coefficent Calculation From RC-6 BookJag KhadseNessuna valutazione finora

- SDP CalculationDocumento11 pagineSDP CalculationNITIN P SHAHNessuna valutazione finora

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocumento1 paginaCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNessuna valutazione finora

- XSteam Excel v2.6 USDocumento12 pagineXSteam Excel v2.6 USOnkarabile MatomeNessuna valutazione finora

- FL1627Documento2 pagineFL1627Isaac Montero BarreraNessuna valutazione finora

- Values Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesDocumento7 pagineValues Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesaltruismNessuna valutazione finora

- Piping CalculationsDocumento3 paginePiping CalculationsAkhilesh Dhar DiwediNessuna valutazione finora

- BoilersDocumento6 pagineBoilersdnageshm4n244Nessuna valutazione finora

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocumento6 pagineSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNessuna valutazione finora

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocumento2 pagineRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisNessuna valutazione finora

- Fgas Refrigerant CalculatorDocumento10 pagineFgas Refrigerant CalculatorKumar sssssNessuna valutazione finora

- Heat Conduction Pipe InsulationDocumento1 paginaHeat Conduction Pipe InsulationJogender DhayalNessuna valutazione finora

- Calculation of Heat and Mass BalanceDocumento16 pagineCalculation of Heat and Mass BalanceHEMANTNessuna valutazione finora

- 1 TPH 10.54 KG, Vapi Care PharmaDocumento16 pagine1 TPH 10.54 KG, Vapi Care PharmashastrysnNessuna valutazione finora

- E PipeAlator08Documento9 pagineE PipeAlator08nguyentienphatNessuna valutazione finora

- Detailing For ATFE Installation For Xylene Distillation QPDocumento27 pagineDetailing For ATFE Installation For Xylene Distillation QPPrathmesh GujaratiNessuna valutazione finora

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocumento4 pagineAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalNessuna valutazione finora

- STM Dosing and Feeding Systems For Air Pollution ControlDocumento42 pagineSTM Dosing and Feeding Systems For Air Pollution ControlJoseph RileyNessuna valutazione finora

- Standard Hook-Up Wires & Cables For ElectronicsDocumento124 pagineStandard Hook-Up Wires & Cables For ElectronicsdlstoneNessuna valutazione finora

- Latest Design of ChimneysDocumento2 pagineLatest Design of ChimneysHussam Udein0% (1)

- Flash CalculationsDocumento10 pagineFlash CalculationsHamza AliNessuna valutazione finora

- TANK Module Package: Sample PrintoutDocumento20 pagineTANK Module Package: Sample PrintoutSIVANessuna valutazione finora

- Made by Date: Top BTM Condition Condition Braced ? SS Slenderness Status Lo LeDocumento12 pagineMade by Date: Top BTM Condition Condition Braced ? SS Slenderness Status Lo LeT Satheesh KumarNessuna valutazione finora

- Cone Layout ToolDocumento1 paginaCone Layout ToolSaravanan ManiNessuna valutazione finora

- h-101 TwiceDocumento20 pagineh-101 TwiceAdela ShofiaNessuna valutazione finora

- NFPA Pipe Sizing EXAMPLEDocumento4 pagineNFPA Pipe Sizing EXAMPLEMatt AndersonNessuna valutazione finora

- Safety Valve Technical DetailsDocumento5 pagineSafety Valve Technical DetailsvineethvskkdNessuna valutazione finora

- 11005312-IBR Pipe CalculationDocumento40 pagine11005312-IBR Pipe CalculationTrishul Nath PallayNessuna valutazione finora

- Adiabatic Flame Temperature CalculationDocumento8 pagineAdiabatic Flame Temperature CalculationLuis VargasNessuna valutazione finora

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocumento1 paginaDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyNessuna valutazione finora

- Sop For Fan SizingDocumento3 pagineSop For Fan SizingHsein WangNessuna valutazione finora

- Psuextension Particle Size 4mm MetricDocumento8 paginePsuextension Particle Size 4mm MetricRed RedNessuna valutazione finora

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocumento44 pagineNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelNessuna valutazione finora

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocumento8 pagineHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNessuna valutazione finora

- Air Cooled HX Data SheetDocumento1 paginaAir Cooled HX Data SheetHoney TiwariNessuna valutazione finora

- Pressure Testing Request FormDocumento1 paginaPressure Testing Request FormSyed Mahmud Habibur RahmanNessuna valutazione finora

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocumento4 pagineSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINessuna valutazione finora

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Documento3 pagineSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINessuna valutazione finora

- Heat Exchanger Specification Sheet SI-BARG UnitsDocumento2 pagineHeat Exchanger Specification Sheet SI-BARG Unitsshahbaz akramNessuna valutazione finora

- 240-05-DTS-009 V-501 Air ReceiverDocumento20 pagine240-05-DTS-009 V-501 Air ReceiverEmran NazirNessuna valutazione finora

- Karthik Updated ResumeDocumento2 pagineKarthik Updated ResumerajachemNessuna valutazione finora

- Kast O Lite 97 L - DatasheetDocumento1 paginaKast O Lite 97 L - DatasheetrajachemNessuna valutazione finora

- Field Experience With The Blasch VectorWall Reaction Furnace Checkerwall PTQ Q1 2014Documento7 pagineField Experience With The Blasch VectorWall Reaction Furnace Checkerwall PTQ Q1 2014rajachemNessuna valutazione finora

- Mole Fraction Volume FractionDocumento9 pagineMole Fraction Volume FractionameyckulkarniNessuna valutazione finora

- Preliminary Feasibility Study Co2 Carrier Ship Based Ccs Unmanned Offshore FacilityDocumento112 paginePreliminary Feasibility Study Co2 Carrier Ship Based Ccs Unmanned Offshore FacilityrajachemNessuna valutazione finora

- TF-08 Therminol 66Documento8 pagineTF-08 Therminol 66rajachemNessuna valutazione finora

- Sample Chapter Steam TurbineDocumento53 pagineSample Chapter Steam TurbineShawn WairisalNessuna valutazione finora

- Hysys V8.0 Tutorial - Part 1 PDFDocumento109 pagineHysys V8.0 Tutorial - Part 1 PDFrajachem100% (1)

- Greencast 94 PlusDocumento1 paginaGreencast 94 PlusAHMAD FAHRUR ROZAQNessuna valutazione finora

- Hysys V8.0 Tutorial - Part 1 PDFDocumento109 pagineHysys V8.0 Tutorial - Part 1 PDFrajachem100% (1)

- Boiling Heat TransferDocumento16 pagineBoiling Heat Transferrr1819Nessuna valutazione finora

- PV Newslette June 2015Documento20 paginePV Newslette June 2015sklatakeNessuna valutazione finora

- Boiling Heat TansferDocumento33 pagineBoiling Heat TansferVineet K. MishraNessuna valutazione finora

- Dowtherm BookDocumento30 pagineDowtherm BookMeghnad M GavitNessuna valutazione finora

- CO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaseDocumento2 pagineCO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaserajachemNessuna valutazione finora

- BPHE Process Gas Waste Heat Recovery System EDocumento20 pagineBPHE Process Gas Waste Heat Recovery System ErajachemNessuna valutazione finora

- Fuel Oil AdditivesDocumento2 pagineFuel Oil AdditivesrajachemNessuna valutazione finora

- PetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016Documento5 paginePetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016rajachemNessuna valutazione finora

- Choosing API 650 and API 620 TanksDocumento7 pagineChoosing API 650 and API 620 TanksrajachemNessuna valutazione finora

- C - 533 - 95 Calcium Silicate Block and Pipe Thermal InsulationDocumento4 pagineC - 533 - 95 Calcium Silicate Block and Pipe Thermal Insulationhamid vahedil larijaniNessuna valutazione finora

- Hairpin Heat ExchangersDocumento9 pagineHairpin Heat ExchangersrajachemNessuna valutazione finora

- Choosing API 650 and API 620 TanksDocumento7 pagineChoosing API 650 and API 620 TanksrajachemNessuna valutazione finora

- C - 533 - 95 Calcium Silicate Block and Pipe Thermal InsulationDocumento4 pagineC - 533 - 95 Calcium Silicate Block and Pipe Thermal Insulationhamid vahedil larijaniNessuna valutazione finora

- ASTM Grades For Insulating Fire BrickDocumento2 pagineASTM Grades For Insulating Fire BrickrajachemNessuna valutazione finora

- Hairpin Heat ExchangersDocumento9 pagineHairpin Heat ExchangersrajachemNessuna valutazione finora

- 110-Nb1 Anton Marco Fantolini SaipemDocumento21 pagine110-Nb1 Anton Marco Fantolini SaipemrajachemNessuna valutazione finora

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocumento11 pagineProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNessuna valutazione finora

- 110-Nb1 Anton Marco Fantolini SaipemDocumento21 pagine110-Nb1 Anton Marco Fantolini SaipemrajachemNessuna valutazione finora

- PetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016Documento5 paginePetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016rajachemNessuna valutazione finora

- Ujian Nasional Bahasa Inggris SMA Tahun 1994Documento6 pagineUjian Nasional Bahasa Inggris SMA Tahun 1994Andhika A. SetiyonoNessuna valutazione finora

- Avogadro's NumberDocumento5 pagineAvogadro's NumberM J RhoadesNessuna valutazione finora

- Self Inductance of A CoilDocumento7 pagineSelf Inductance of A CoilIANDU PCNessuna valutazione finora

- Colin MaclaurinDocumento6 pagineColin MaclaurinChristian David PecsonNessuna valutazione finora

- HTTPSWWW - Mathsgenie.co - Ukresources4 Plans and Elevations PDFDocumento8 pagineHTTPSWWW - Mathsgenie.co - Ukresources4 Plans and Elevations PDFruth.ameyxxNessuna valutazione finora

- NandhiniDocumento11 pagineNandhiniSravan KumarNessuna valutazione finora

- Dr. Mukesh Kumar Department of Earthquake Engineering, NED University, KarachiDocumento37 pagineDr. Mukesh Kumar Department of Earthquake Engineering, NED University, KarachiMukesh KumarNessuna valutazione finora

- Milpass - Catalogo Alluminio EN PDFDocumento174 pagineMilpass - Catalogo Alluminio EN PDFStefanus AndreNessuna valutazione finora

- 2011 Exam GeotechnicalDocumento9 pagine2011 Exam GeotechnicalAhmed AwadallaNessuna valutazione finora

- Mcqs For MCATDocumento26 pagineMcqs For MCATHashir Ahmad KhanNessuna valutazione finora

- The Comparative Study For Scale Inhibition On Surface of RO Membranes in Wastewater Reclamation: CO2 Purging Versus Three Different AntiscalantsDocumento9 pagineThe Comparative Study For Scale Inhibition On Surface of RO Membranes in Wastewater Reclamation: CO2 Purging Versus Three Different AntiscalantsKashif ButtNessuna valutazione finora

- JL Torero - Buoyancy Effects On Smoldering of Polyurethane FoamDocumento229 pagineJL Torero - Buoyancy Effects On Smoldering of Polyurethane FoamIsraelNessuna valutazione finora

- Question and Ans.3Documento153 pagineQuestion and Ans.3gangoorsgNessuna valutazione finora

- Catalogo PTP 2011 Cadena Transportadoras 10818 - ENDocumento136 pagineCatalogo PTP 2011 Cadena Transportadoras 10818 - ENAriel Linder Ureña MontenegroNessuna valutazione finora

- Rutherford Scattering - MITDocumento5 pagineRutherford Scattering - MITBrayan Stiven Pardo RuizNessuna valutazione finora

- Specifications: Comparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2018-09Documento1 paginaSpecifications: Comparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2018-09omerNessuna valutazione finora

- An Introduction To British RomanticismDocumento21 pagineAn Introduction To British RomanticismyasiraNessuna valutazione finora

- James Wilberding-Plotinus' Cosmology - A Study of Ennead II.1 (40) - Text, Translation, and Commentary (2006) PDFDocumento281 pagineJames Wilberding-Plotinus' Cosmology - A Study of Ennead II.1 (40) - Text, Translation, and Commentary (2006) PDFRobert BrennerNessuna valutazione finora

- Life Cycle of Star LabDocumento19 pagineLife Cycle of Star LabanicitoaNessuna valutazione finora

- Vivo Nex 3 5GDocumento11 pagineVivo Nex 3 5GEvery DayNessuna valutazione finora

- Hot Plate WeldingDocumento2 pagineHot Plate WeldingsyuepiNessuna valutazione finora

- Test 2 Semester 2, 2022Documento3 pagineTest 2 Semester 2, 2022Kalana GamageNessuna valutazione finora

- Project - Silicon Solar Cell-CoDocumento55 pagineProject - Silicon Solar Cell-CoSudheer SebastianNessuna valutazione finora

- Incozol 4 TDSDocumento1 paginaIncozol 4 TDSsriatul2006Nessuna valutazione finora

- Priyanka Patel Resume r6Documento2 paginePriyanka Patel Resume r6api-288092186Nessuna valutazione finora

- Teodolito Con Distanciometro South NT-023Documento2 pagineTeodolito Con Distanciometro South NT-023JoséLuis100% (1)

- Speed Control (Switch) - Test 01-03-2010Documento9 pagineSpeed Control (Switch) - Test 01-03-2010harikrishnanpd3327Nessuna valutazione finora

- Herschel 400 2 Log BookDocumento29 pagineHerschel 400 2 Log BookEveraldo FaustinoNessuna valutazione finora

- A Simulation of Roll Wear in Hot Rolling ProcessesDocumento336 pagineA Simulation of Roll Wear in Hot Rolling ProcessesVinay Rajput100% (1)

- Hydrology PracticalsDocumento5 pagineHydrology PracticalsVaibhav GuptaNessuna valutazione finora