Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2004 Infiniti G35 Coupe Quick Reference Specs

Caricato da

nikkon1Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2004 Infiniti G35 Coupe Quick Reference Specs

Caricato da

nikkon1Copyright:

Formati disponibili

2004 G35 Coupe – VQ Engine Mark Actual

Notes

To Confirm

VQ35DE

Engine Oil SAE 5W-30 API SG/SH I & II or SJ, Energy Conserving Oil

With Oil Filter 5.0 qt

Without Oil Filter 4 5/8 qt

Tune up

Spark Plugs (Platinum)

Standard Type PLFR5A-11

Hot Type PLFR4A-11

Cold Type PLFR6A-11

Plug Gap 0.043 in. (1.1mm)

Ignition Timing 15° ± 5° btdc

Idle Speed 650 ± 50 rpm

Idle Mixture Ratio 0.7 - 9.9 % CO

Valve Clearance Intake Exhaust

cold 0.010 - 0.013 in 0.011 - 0.015 in

(0.26 - 0.34 mm) (0.29 - 0.37 mm)

hot (176° F) 0.012 - 0.016 in 0.012 - 0.017 in

(0.304 - 0.416 mm) (0.308 - 0.432 mm)

T/Position Sensor 1

T/V Closed More than 0.36 V

T/V Open Less than 4.75 V

T/Position Sensor 2

T/V Closed Less than 4.75 V

T/V Open More than 0.36 V

Radiator Fill

Coolant Type Ethylene Glycol

Coolant Capacity 9-1/4 qt

Compression

Standard 185 psi

Minimum 142 psi

Diff Between Cyl. 14 psi

Fuel System

Fuel Pressure @ Idle 51 psi

Recommended Fuel 91 Octane

Fuel Pump Ω

At 77°F (25°C) Approx. 1.0 Ω

Fuel Injector Ω

At 77°F (25°C) 13.5 - 17.5 Ω

Sensors

Mass Air Flow Sen

Supply Volt. 11 - 14 V

Output Volt. Idle 1.1 - 1.5 V

Mass Air Flow

At Idle 2.0 - 6.0 gm/sec

2500 rpm 7.0 - 20.0 gm/sec

2004 G35 Coupe – Quick Reference – VQ Engine 1

Coolant Temp Sensor Ω

68°F (20°C) 2.1 - 2.9 kΩ

122°F (50°C) 0.68 - 1.00 kΩ

194°F (90°C) 0.236 - 0.260 kΩ

O2 Sen Heater 1 Ω

At 77°F (25°C) 3.3 - 4.0 Ω

O2 Sen Heater 2 Ω

At 77°F (25°C) 5.0 - 7.0 Ω

Intake Air Temp Sensor

77°F (25°C) 1.9 - 2.1 kΩ

176°F (80°C) 0.31 - 0.37 kΩ

Crankshaft/Camshaft P/Sen POS/Phase

At 77°F (25°C) Except 0 Ω or infinite Ω

Fuel Tank Temp Sensor

68°F (20°C) 2.3 - 2.7 kΩ

122°F (50°C) 0.79 - 0.90 kΩ

Throttle Control Motor Ω

At 77°F (25°C) Approx. 1 - 15 Ω

Electrical

Ignition System

Firing Order 1-2-3-4-5-6

Battery Specs.

Type USA 80D23L

Capacity (V/AH) 12 V/ 52AH

Cold Crank Current 582 A @ 0°F (-18°C)

Charging System

Alternator Type A3TG0191

Nom. Rated Out 12 V/ 110 A

Reg. Volt 14.1 - 14.7 V

Hot Out Amp (A/rpm) More than 37 /1300

More than 92 /2500

More than 103 /5000

VQ35DE - Coupe

EPA Mileage Estimate A/T M/T

(city/highway) 19/26 20/27

2004 G35 Coupe – Quick Reference – VQ Engine 2

2004 G35 Coupe – VQ Engine

PREPARATION

Make sure that the following parts are in order.

1. Battery

2. Ignition system

3. Engine oil and coolant levels

4. Fuse

5. ECM harness connector

6. Vacuum hoses

7. Air intake system (Oil filler cap, oil level, etc.)

8. Fuel pressure

9. Engine compression

10. Throttle valve

11. Evaporative emission canister purge control valve.

Note:

• On A/C equipped vehicles, turn A/C "Off" for testing.

• Transmission should be in "Park" or "Neutral".

• "CO" probe should be inserted into exhaust approximately 16 inches.

• Turn off headlamps, heater blower, rear defogger, etc.

• Front wheels pointed straight.

• Perform inspection with cooling fans "Off".

2004 G35 Coupe – Quick Reference – VQ Engine 3

2004 G35 Coupe – A/T Mark Actual

Notes

To Confirm

RE5R05A

Trans Code 91x18

A/T Fluid Type Nissan Matic 'J' ONLY (P/N 999MP-MTJ00P)

Oil Capacity 10 7/8 qt

A/T Cooler Type Fin Type Structure

Up-Shift Schedule Range (at normal operating temp.) mph(km/h)

Half Throttle Full Throttle

D1 → D2 29 - 31 (46 - 50) 36 - 39 (58 - 62)

D2 → D3 44 - 49 (71 - 79) 56 - 61 (90 - 98)

D3 → D4 66 - 73 (107 - 117) 87 - 93 (140 - 150)

D4 → D5 84 - 90 (135 - 145) 125 - 131 (201 - 211)

Complete Clutch Lock-Up mph(km/h)

Lock-up ON Lock-up OFF

Closed Throttle 35 - 40 (56 - 64) 33 - 38 (53 - 61)

Half Throttle 104 - 109 (168 - 176) 81 - 86 (131 – 139)

Slip Lock-Up mph(km/h)

Closed Throttle Lock-up ON Lock-up OFF

Slip Lock-up OFF (D4) 23 - 28 (37 - 45) 21 - 26 (34 - 42)

Slip Lock-up ON (D5) 27 - 32 (44 - 52) 25 - 30 (41 - 49)

Stall Rpm

R, D, 2, 1 position 2,600 - 2,900 rpm

2

Line Pressure psi(kg/cm )

At Curb Idle At Stall rpm

R - Position 57 - 64 (4.0 - 4.5) 247 - 274 (17.3 - 19.3)

D,M - Position 54 - 61 (3.8 - 4.3) 190 - 218 (13.3 - 15.3)

Solenoid Valves Resistance Pin Number

Line Pressure Sol. Valve 3-9Ω 7

Torque Converter Clutch Sol. Valve 3-9Ω 8

Input Clutch Sol. Valve 3-9Ω 6

High & Low Rev. Clutch Sol. Valve 3-9Ω 3

Front Brake Sol. Valve 3-9Ω 5

Direct Clutch Sol. Valve 3-9Ω 4

Low Coast Brake Sol. Valve 20 - 40 Ω 2

A/T Fluid Temp. Sensor

Condition ATF Temp Sensor 1 ATF Temp Sensor 2

32° F (0° C) 2.2 V, 15 kΩ 2.2 V, 10 kΩ

68° F (20° C) 1.8 V, 6.5 kΩ 1.7 V, 4 kΩ

176° F (80° C) 0.6 V, 0.9 kΩ 0.45 V, 0.5 kΩ

Revolution Sensor

Test Condition: Use CONSULT-II pulse frequency measuring function.

th

Sensor. 1: Veh. Speed 31 mph in 4 gear, with closed throttle position switch "OFF".

st

Sensor. 2, & Rev sensor: Veh. Speed 12 mph in 1 gear, with closed throttle position switch "OFF".

Turbine Rev. Sensor 1 & 2 1.3 kHz

Rev Sensor 185 Hz

2004 G35 Coupe – Quick Reference – A/T 4

2004 G35 Coupe – A/T

PRECAUTIONS

• Before performing any diagnostic test, vehicle should be driven for approximately 10 minutes

to raise transmission to the proper operating temperature of 122° to 176°.

• During stall testing, never hold throttle wide open for more than 5 seconds at a time. Extended

stall testing can overheat transmission and cause serious damage.

• Nissan Matic 'J' ATF is the only fluid accepted for warranty, service contracts and goodwill

repairs.

• Before performing any internal repairs, thoroughly clean the outside of the transmission case

to prevent contamination.

• Use lint free cloth or towels for wiping parts. Common shop towels can leave contaminating

fibers on the transmission parts and cause improper transmission operation.

• When servicing the valve body, valves, sleeves, plugs, etc. should slide along the bores in the

valve body under their own weight.

• Before assembly, apply a coat of ATF to all internal transmission parts. Use petroleum jelly to

protect o-rings and seals, or to hold bearings and washers in place during assembly.

Important Note: Nissan Matic 'J' must be used in performing repairs paid by Infiniti for the 2003

and later G35 Coupe, such as warranty, service contract, or good-will repairs. There will not be

reimbursement for repairs when non-genuine Nissan Matic 'J' is used.

2004 G35 Coupe – Quick Reference – A/T 5

2004 G35 Coupe – M/T Mark Actual

Notes

To Confirm

FS6R31A

Clutch

Clutch Control System Hydraulic

Master Cyl. Inner Dia. 5/8 in (15.87 mm)

Operating Cyl. Inner Dia. 3/4 in (19.05 mm)

Clutch Disc

(outer, inner, thickness) 9.84 x 6.69 x 0.126 in (250 x 170 x 3.2 mm)

Wear Limit 0.012 in (0.3 mm)

Runout Limit 0.028 in (0.7 mm) or less

[measured at 9.45 in (240 mm) diameter]

Clutch Cover Model 250

Set-load 880 kg (8,630 N)

Diaphragm spring

Lever height 1.555 - 1.634 in (39.5 - 41.5 mm)

Uneven limit of diaphragm

spring toe height 0.02 in (0.5 mm)

Clutch Pedal

Clearance “C” 0.004 - 0.039 in (0.1 - 1.0)

Refill Capacity (75W-85 API GL-4)

FS6R31A 3-1/4 qt

Gear End Play

Counter gear 0.0 - 0.004 in (0.0 - 0.1 mm)

Main drive gear 0.0 - 0.004 in (0.0 - 0.1 mm)

Main shaft front side 0.0 - 0.004 in (0.0 - 0.1 mm)

Main shaft rear side 0.0 - 0.004 in (0.0 - 0.1 mm)

Clearance Between Baulk Ring And Gear

Standard Wear Limit

1st 3rd, & 4th

gear Inner (A) 0.02 - 0.028 in 0.012 in

(0.5 - 0.7 mm) (0.3 mm)

1st gear Outer (B) 0.039 - 0.059 in 0.028 in

(1.0 - 1.5 mm) (0.7 mm)

3rd, & 4th gear (B) 0.033 - 0.059 in 0.028 in

(0.85 - 1.35 mm) (0.7 mm)

2nd gear Inner (A) 0.02 - 0.028 in 0.012 in

(0.5 - 0.7 mm) (0.3 mm)

2nd gear Outer (B) 0.02 - 0.028 in 0.012 in

(0.5 - 0.7 mm) (0.3 mm)

2nd Main gear taper

cone (C) 0.028 - 0.049 in 0.012 in

(0.7 - 1.25 mm) (0.3 mm)

5th & 6th Gear 0.028 - 0.049 in 0.02 in

(0.7 - 1.25 mm) (0.5 mm)

Reverse 0.03 - 0.047 in 0.02 in

(0.75 - 1.2 mm) (0.5 mm)

Snap Rings

See service manual MT section, “Service Data and Specifications (SDS) for details.

2004 G35 Coupe – Quick Reference – M/T 6

2004 G35 Coupe – M/T

PRECAUTIONS

• Infiniti does not recommend flywheel resurfacing. If flywheel is not within specification,

replacement is recommended.

• Refill transmission with the proper viscosity and amount of gear lube for the anticipated

temperatures.

• To help prevent clutch judder, avoid excessive grease to clutch disc splines, input shaft and

throwout bearing. Be sure to clean off any excessive grease.

• On rear wheel drive vehicles, inspect the shift control lever bushing for wear and proper

alignment prior to reinstallation of a removed transmission.

• To avoid transmission contamination, inspect the shift lever dust boot for cracks or

damage, and replace if needed. Install plastic wire ties to insure a tight fit of the boot to the

shifter and housing.

• Before reinstallation of a removed transmission, inspect the engine to transmission

alignment dowels for damage. Damaged dowels can cause misalignment of the engine to

transmission, and this can cause the transmission to jump out of gear.

2004 G35 Coupe – Quick Reference – M/T 7

2004 G35 Coupe – Htr & A/C Mark Actual

Notes

To Confirm

AIR CONDITIONER

Compressor

Make Calsonic Kansei V-6

Type V-6 Variable Displacement

Compressor Clutch

Disc-to-Pulley Clearance 0.012 - 0.024 in (0.25 - 0.60 mm)

Refrigerant

Type HFC-134a (R134a)

Capacity 1.21 lb (.55 kg)

Refrigerant Oil

Type Nissan Type "S" Lub.

Capacity 6.0 fl oz

Oil to AddPer Evaporator 2.5 oz (75 ml)

Condenser 1.2 oz (35 ml)

*Liquid Tank 0.3 oz (10 ml)

Large Refrig. Leak 1.0 oz (30 ml)

Compressor

(*Add only if comp. is not replaced.)

Engine Idle w/A/C On

(in Neutral) More than 775 rpm

Performance Test (approximate values for Sedan and Coupe)

Recirculating-to-Discharge Air Temp

Recirc. Air Temp. at Discharge Air Temp. at

Blower Assy. Inlet Center Ventilator

Relative Humidity F°° (C°°) F°° (C°°)

50 - 60 % 68°(20°) 49 - 51° (9.2 - 10.4°)

77°(25°) 54 - 57° (12.0 - 14.0°)

86°(30°) 58 - 63° (14.4 - 17.4°)

95°(35°) 65 - 72° (18.2 - 22.0°)

104°(40°) 75 - 81° (23.8 - 27.4°)

60 - 70 % 68°(20°) 51 - 53° (10.4 - 11.8°)

77°(25°) 57 - 61° (14.0 - 16.0°)

86°(30°) 63 - 69° (17.4 - 20.8°)

95°(35°) 72 - 78° (22.0 - 25.2°)

104°(40°) 81 - 88° (27.4 - 31.0°)

Ambient Air Temp-to-Operating Pressure

Air temperature Relative Humidity 50-70%

F°° (C°°) High-pres. Low-pres.

68°(20°) 118 - 145 psi 32 - 38 psi

77°(25°) 139 - 168 psi 33 - 41 psi

86°(30°) 178 - 218 psi 37 - 44 psi

95°(35°) 174 - 212 psi 42 - 51 psi

104°(40°) 193 - 236 psi 49 – 59 psi

2004 G35 Coupe – Quick Reference – Heater & A/C 8

2004 G35 Coupe – Htr & A/C

PERFORMANCE TEST CONDITIONS

• Vehicle indoors or in the shade

• Doors closed

• Windows open

• Hood open

• Temperature on "Max" setting

• Discharge air on "Face Vent"

• Recirculation switch on "Recirc"

• Fan speed on "High"

• A/C switch "On" and verify A/C Clutch engagement

• Engine speed at idle

• Operate the A/C system for 10 minutes before taking measurements

Precautions:

1. When removing the compressor, store it in the same position as it is mounted in the vehicle.

Failure to do so may cause lubricant to enter the low pressure chamber and cause compressor

damage.

2. Allow components stored in cool areas to warm to area temperatures before removing seals.

This prevents condensation from forming inside A/C components.

2004 G35 Coupe – Quick Reference – Heater & A/C 9

2004 G35 Coupe – Suspension Mark Actual

Notes

To Confirm

WHEEL ALIGNMENT (UNLADEN)

Suspension Inspection

Ball Joint End Play

Axial End Play 0 in (0 mm)

Front Wheel Bearing

Axial End Play 0.0020 in (0.05 mm) or less

Rear Wheel Bearing

Axial End Play 0.00 in (0.0 mm)

Wheel Runout Max. Lateral / Radial Runout:

0.012 in (0.3 mm) or less

Wheel arch Height (Unladen)

Front Height (Hf) Rear Height (Hr)

225/50 R17 (Front) 27.2 in (691 mm) 27.64 in (702 mm)

235/50 R17 (Rear)

225/45 R18 (Front) 27.32 in (694 mm) 27.95 in (710 mm)

245/45 R18 (Rear)

Front Wheel Alignment

Toe-in Range Nominal

Total toe-in 0.08 - 0.0 in (2 - 0 mm) 0.04 in (1 mm)

Front Wheel Turning Angle

(full turn)

In/Wheel Range 35.75° - 39.75° (35° 45’ - 39° 45’)

In/Wheel Nominal 38.75° (38° 45’)

Out/Wheel Nominal 30.75° (30° 45’)

Camber

Range -1.25° to 0.75° (-1° 15’ to 0° 45’)

Nominal -0.50° (-0° 30’)

Lt/Rt Difference 0.75° (0° 45’) or less

Caster 17” Wheels 18” Wheels

Range 7.42° - 8.92° 7.25° - 8.75°

(7° 25’ - 8° 55’) (7° 15’ - 8° 45’)

Nominal 8.17° (8° 10’) 8.00° (8° 00’)

Lt/Rt Difference 0.75° (0° 45’) or less

Kingpin Offset

Range 4.17° - 5.67° (4° 10’ - 5° 40’)

Nominal 4.92° (4°55’)

Rear Wheel Alignment

Toe-in Range Nominal

Total toe-in 0.0 - 0.22 in (0.0 - 5.6 mm) 0.11 in (2.8 mm)

Camber

Range -1.75° to -0.75° (-1°45’ to -0°45’)

Nominal -1.25° (-1°15’)

W/Lug Nut Torque 72-87 ft/lb (10-12 kg/m)

2004 G35 Coupe – Quick Reference – Suspension 10

2004 G35 Coupe – Suspension

PRELIMINARY INSPECTION

• Check tires for wear and proper inflation

• Check wheel runout

• Check front wheel bearings excessive play

• Check front suspension for excessive play

• Check steering linkage for excessive play

• Check struts for leakage and condition

• Check vehicle for proper ride height

Precautions

1. When installing rubber parts, final tightening must be carried out under unladen conditions with

the tires on the ground.

2. Recheck alignment after installing removed suspension components.

2004 G35 Coupe – Quick Reference – Suspension 11

2004 G35 Coupe – Brakes Mark Actual

Notes

To Confirm

BRAKE SYSTEM

Standard System

Front Disc Brake Rear Disc Brake

Brake Model Code CLZ25VD AD14VE

Brake Fluid DOT 3 (Recommended)

Master Cyl. Bore Dia. 1.0 in (25.4 mm)

Cylinder Bore Dia. 2.252 in (57.2 mm) 1.6874 in (42.86 mm)

Brake Pad Dimensions

Length 4.94 in (125.6 mm) 3.268 in (83.0 mm)

Width 1.81 in (46.0 mm) 1.299 in (33.0 mm)

Thickness 0.43 in (11.0 mm) 0.335 in (8.5 mm)

Brake Pad Wear Limit

Min. Thickness 0.079 in (2.0 mm) 0.079 in (2.0 mm)

Brake Rotor Dimensions

Outer Diameter 11.665 in (296.0 mm) 11.50 in (292.0 mm)

Standard Thickness 0.945 in (24 mm) 0.63 in (16 mm)

Brake Rotor Repair/Wear Limits

Max. Runout 0.0014 in (0.035 mm) 0.0039 in (0.1 mm)

Min. Thickness 0.886 in (22.0 mm) 0.55 in (14 mm)

Max. Thk. Variation 0.0006 in (0.015 mm) 0.0006 in (0.015 mm)

Brembo System

Front Disc Brake Rear Disc Brake

Brake Model Code OPB27VA OPB13VB

Brake Fluid DOT 3 (Recommended)

Master Cyl. Bore Dia. 1.0626 in (26.99 mm)

Cylinder Bore Dia. 1.50 in x 2 + 1.73 in x 2 1.575 in x 2

(38 mm x 2 + 44 mm x 2) (40.0 mm x 2)

Brake Pad Dimensions

Length 4.61 in (117.1 mm) 3.016 in (76.6 mm)

Width 2.098 in (53.3 mm) 1.77 in (45.0 mm)

Thickness 0.366 in (9.3 mm) 0.358 in (9.1 mm)

Brake Pad Wear Limit

Min. Thickness 0.079 in (2.0 mm) 0.079 in (2.0 mm)

Brake Rotor Dimensions

Outer Diameter 12.76 in (324 mm) 13.07 in (332.0 mm)

Standard Thickness 1.181 in (30.0 mm) 0.87 in (22.0 mm)

Brake Rotor Repair/Wear Limits

Max. Runout 0.0020 in (0.050 mm) 0.0028 in (0.07 mm)

Min. Thickness 1.118 in (28.4 mm) 0.795 in (20.2 mm)

Max. Thk. Variation 0.0006 in (0.015 mm) 0.0006 in (0.015 mm)

2004 G35 Coupe – Quick Reference – Brakes 12

Brake Pedal Dimen.

Height (from dash M/T: 6.06 - 6.46 in (154 - 164 mm)

panel top surface) A/T: 6.38 - 6.77 in (162 - 172 mm)

Depressed Height M/T: 3.54 in (90 mm) or more

A/T: 3.74 in (95 mm) or more

Pedal Free Play 0.12 - 0.43 in (3.0 - 11.0 mm)

Switch Clearance 0.0291 - 0.0772 in (0.74 - 1.96 mm)

Brake Booster Vacuum Type

Input Rod Length 4.92 in (125 mm)

Parking Drum Brake DS17HF

Inside Diameter 6.77 in (172 mm)

Wear Limit Diameter 6.81 in (173 mm)

Brake Shoe Dimension

Thickness 0.126 in (3.2 mm)

Wear limit thickness 0.059 in (1.5 mm)

Parking Brake Control Foot Lever Type Hand Lever Type

Number of Notches 3–4 6–7

Warning Lamp On 1 Notch 1 Notch

Wheel Lug Nut 72-87 ft-lb (10-12 kg-m)

2004 G35 Coupe – Quick Reference – Brakes 13

2004 G35 Coupe – Brakes

PRECAUTIONS

1. Never reuse drained brake fluid.

2. Be careful not to splash brake fluid on painted surfaces.

3. Use clean brake fluid to clean or wash master cylinder wheel cylinders, and disc brake calipers

parts.

4. Mineral oils such as gasoline and kerosene should not be used. They can cause damage to

rubber parts of the hydraulic system.

5. Use flare nut wrench when removing or installing brake line fittings.

6. Always torque brake lines.

7. Always replace brake pad shims when replacing brake pads.

Warning:

Clean brake pads and shoes with a dust collector to minimize the hazard of airborne particles

or other materials.

2004 G35 Coupe – Quick Reference – Brakes 14

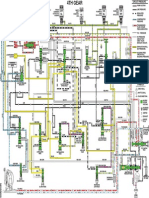

2004 G35 Coupe – Electrical

ELECTRICAL

Wire Color Code

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When a wire color is striped, the base color is given first, followed

by the stripe color. Example L/W = Blue with white stripe

Battery specification:

Type 80D23L

Capacity 12 V / 52 AH

Cold cranking current 582 A

Load test at 3 × AH for 15 seconds.

Battery charging rates:

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

Do not charge battery over 50 ampere rate.

Do not "quick charge" a fully discharged battery.

If battery electrolyte temperature rises above 140°F, stop charging.

Starter:

Type S114-880

Hitachi

Gear reduction type

No-load current Less than 90 A

No-load RPM More than 2,880

Alternator:

Type A3TG0191

Mitsubishi

Nominal Rating 12 V / 110 A

Output current A/RPM More Than 37 / 1,300

(with 13.5 V applied) More Than 92 A / 2,500

More Than 103 A / 5,000

Regulated Output Voltage 14.1 - 14.7

2004 G35 Coupe – Quick Reference – Electrical 15

Oil Pressure Switch:

Oil pressure PSI Engine Speed (rpm)

More Than 14 Idle

More Than 43 2000

More Than 57 6000

Bulb Specifications:

Exterior Interior

Item Wattage (12V) Item Wattage (12V)

Headlamp Low 35 (D2R Xenon) Glove box Lamp 1.4

High/Fog 60/55 (HB2) Ignition Key Hole Lamp 1.4

Front Turn Signal 21 (amber) Ashtray Lamp 1.4

Rear Turn Signal 21 Cigarette Lighter Lamp 1.4

Front Side Marker 3.8 Map Lamp 8

Rear Side Marker 3.8 Step Lamp 5

Parking Lamp 5 Trunk Room Lamp 3.4

Stop/Tail Lamp LED Vanity Mirror Lamp 1.32

Center Stop Lamp LED

Back-up Lamp 18

Front Side Marker 3.8

License Plate Lamp 5

How to perform voltage drop test: See Illustrations

2004 G35 Coupe – Quick Reference – Electrical 16

2004 G35 Coupe – Electrical

BATTERY CONDITION

Battery Sulphation:

A battery will be completely discharged if it is left unattended for a long time and the specific gravity

becomes less than 1.100. This may result in sulphation on the cell plates. To determine if a battery

has been sulfated, note its voltage and current when charging. If low current and higher voltage are

observed in the initial stages of charging a sulfated battery is likely. A sulfated battery may

sometimes be brought back into service by means of a long slow charge, 12 hours or more.

Checking Battery Specific Gravity With Hydrometer

Hydrometer temperature correction

Battery electrolyte temp. °C (°°F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (129) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) −0.004

16 (60) −0.008

10 (50) −0.012

4 (39) −0.016

−1 (30) −0.020

−7 (20) −0.024

−12 (10) −0.028

−18 (0) −0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

• Do not quick charge a fully discharged battery.

• After charging, if the specific gravity of any two cells varies more then .050, the battery should be

replaced.

2004 G35 Coupe – Quick Reference – Electrical 17

Potrebbero piacerti anche

- 1998 PONTIAC GRAND AM Service Repair Manual PDFDocumento49 pagine1998 PONTIAC GRAND AM Service Repair Manual PDFjhjfnsnef0% (1)

- Running RecallsDocumento1 paginaRunning RecallsWXYZ-TV Channel 7 DetroitNessuna valutazione finora

- Dmax V3.5 Coverage ChartDocumento16 pagineDmax V3.5 Coverage ChartSeun AlhassanNessuna valutazione finora

- 5 Transponders ClonablesDocumento8 pagine5 Transponders ClonablesJuniors CruzNessuna valutazione finora

- Passlock 1Documento13 paginePasslock 1briggstrainer100% (1)

- 2005 Infiniti G35Documento326 pagine2005 Infiniti G35manualavilaNessuna valutazione finora

- Syskey 2183452&from BcpiDocumento6 pagineSyskey 2183452&from BcpiGummiArchZzNessuna valutazione finora

- 2005 G35 QrefDocumento32 pagine2005 G35 QrefLochi MunasingheNessuna valutazione finora

- Factory Wiring Harness - Dodge Ram - ScoscheDocumento1 paginaFactory Wiring Harness - Dodge Ram - Scoscheajhillgolf67% (3)

- 2004 Infiniti G35 PDFDocumento272 pagine2004 Infiniti G35 PDFLakiLakicNessuna valutazione finora

- Guide to Modified Exhaust Systems: A Reference for Law Enforcement Officers and Motor Vehicle InspectorsDa EverandGuide to Modified Exhaust Systems: A Reference for Law Enforcement Officers and Motor Vehicle InspectorsNessuna valutazione finora

- Jeep Grand Cherokee 2005 2008 Sistem Antirobo PDFDocumento94 pagineJeep Grand Cherokee 2005 2008 Sistem Antirobo PDFNORCOM SACNessuna valutazione finora

- ChevroletDocumento3 pagineChevroletMarco FigueroaNessuna valutazione finora

- Honda CRF 250L PDFDocumento128 pagineHonda CRF 250L PDFBauroNessuna valutazione finora

- 1996 Ford Mustang 3.8L ManualDocumento332 pagine1996 Ford Mustang 3.8L ManualShafik960% (1)

- X100PRO Key Progamming Vehicle List: Programming KeysDocumento135 pagineX100PRO Key Progamming Vehicle List: Programming KeysClaudio CurbeloNessuna valutazione finora

- 17S09 - Coolant Level Sensor System Installation - 2013-2015 Ford - FordDocumento141 pagine17S09 - Coolant Level Sensor System Installation - 2013-2015 Ford - FordCatalin VulpeNessuna valutazione finora

- Programing RemoteDocumento21 paginePrograming RemoteAlfred Kojo NassarahNessuna valutazione finora

- OBDII U Trouble Code InfoDocumento6 pagineOBDII U Trouble Code Infobhanuka2009Nessuna valutazione finora

- Tech KnowledgebaseDocumento98 pagineTech KnowledgebaseMarcusblueNessuna valutazione finora

- Wiper, Washer, HornDocumento46 pagineWiper, Washer, HornPaolo MadambaNessuna valutazione finora

- CHEVROLET Identificacion de CarrosDocumento9 pagineCHEVROLET Identificacion de CarrosFrancisco100% (2)

- Autotec Guide Key & Remote CodingDocumento78 pagineAutotec Guide Key & Remote Codingmhcscribd67% (3)

- Vehicle Communication Interface Module (VCIM) Programming Not CompletedDocumento6 pagineVehicle Communication Interface Module (VCIM) Programming Not CompletedAngel Julian HernandezNessuna valutazione finora

- Lexus Key ProgrammingDocumento6 pagineLexus Key ProgrammingMike TsaiNessuna valutazione finora

- 6.14 - Manual - Ford Linc Mercury P.183 260 PDFDocumento78 pagine6.14 - Manual - Ford Linc Mercury P.183 260 PDFDaniel TorresNessuna valutazione finora

- CKM 200 Car Key Master ManualDocumento33 pagineCKM 200 Car Key Master ManualselereakNessuna valutazione finora

- Pesticide Applicator: Passbooks Study GuideDa EverandPesticide Applicator: Passbooks Study GuideNessuna valutazione finora

- Ford Expedition 2008-2011Documento4.577 pagineFord Expedition 2008-2011marcp22100% (8)

- 2019 GMC Sierra Limited Denali Owners ManualDocumento493 pagine2019 GMC Sierra Limited Denali Owners ManualJhon MechanicNessuna valutazione finora

- 2003 Expedition - Navigator Service ManualDocumento4.603 pagine2003 Expedition - Navigator Service Manualsc19605980% (15)

- Locksmith and Security Professionals' Exam Study GuideDa EverandLocksmith and Security Professionals' Exam Study GuideNessuna valutazione finora

- Ford Fusion Hybrid Workshop Repair and Service ManualDocumento1 paginaFord Fusion Hybrid Workshop Repair and Service Manualerwin_teichmannNessuna valutazione finora

- 2008-08-09 105818 Alarm 96 Jeep CherokeeDocumento9 pagine2008-08-09 105818 Alarm 96 Jeep CherokeeAxel FernandezNessuna valutazione finora

- New Vin Guide U.S.qxd 6/19/01 3:13 PM Page 6Documento2 pagineNew Vin Guide U.S.qxd 6/19/01 3:13 PM Page 6jechurch0% (1)

- Become an Automobile Expert: A Do It Yourself Guide to CarsDa EverandBecome an Automobile Expert: A Do It Yourself Guide to CarsNessuna valutazione finora

- Trans: Copyr GHT 2009, 2013 - Nat Onal Auto Lock Service, LNCDocumento26 pagineTrans: Copyr GHT 2009, 2013 - Nat Onal Auto Lock Service, LNCFrancisco LagosNessuna valutazione finora

- 2005 Chevrolet ChevyDocumento8 pagine2005 Chevrolet ChevyDavidNessuna valutazione finora

- Vehicle Theft Deterrent FuncionamientoDocumento14 pagineVehicle Theft Deterrent Funcionamientogrc800520Nessuna valutazione finora

- If 114 Anti Theft Bypass ModuleDocumento12 pagineIf 114 Anti Theft Bypass Moduleantoelyrom100% (4)

- 2005 AvalonDocumento405 pagine2005 Avalonkedwin vasquezNessuna valutazione finora

- 2010 Nissan VersaDocumento338 pagine2010 Nissan VersaChristian HammNessuna valutazione finora

- FMP User GuideDocumento24 pagineFMP User Guidekamaleon doradoNessuna valutazione finora

- ManualDocumento20 pagineManualpepw67% (3)

- 2005 Cadillac Cts OwnersDocumento436 pagine2005 Cadillac Cts OwnersPhilip KrebsNessuna valutazione finora

- GM Vehicle Theft Deterrent Relearn ProceduresDocumento4 pagineGM Vehicle Theft Deterrent Relearn ProceduresJonathan Thomas ColeNessuna valutazione finora

- Ford Brain User Manual and Instructions: This The Best Until We Will Make The Better OneDocumento25 pagineFord Brain User Manual and Instructions: This The Best Until We Will Make The Better OnemisternikiNessuna valutazione finora

- f150 ManualDocumento312 paginef150 ManualJon KnoppeNessuna valutazione finora

- ck100 Auto Key Programmer Car List PDFDocumento28 pagineck100 Auto Key Programmer Car List PDFjose luis choque pichaNessuna valutazione finora

- 11372chrysler ManualDocumento38 pagine11372chrysler Manualcarlosrafaelgil100% (2)

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualDa EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualValutazione: 4.5 su 5 stelle4.5/5 (2)

- 5305 and 5105 Installation Guide: © 2015 Directed, Vista, CA N5X05 2016-01Documento28 pagine5305 and 5105 Installation Guide: © 2015 Directed, Vista, CA N5X05 2016-01Luis MendozaNessuna valutazione finora

- Door Lock Cylinder Binds 4-20-2004 (03-068)Documento6 pagineDoor Lock Cylinder Binds 4-20-2004 (03-068)Rok BerlecNessuna valutazione finora

- Manual en Inglés de Alarma Prestige Aps997cDocumento32 pagineManual en Inglés de Alarma Prestige Aps997cJosé Luis Farías100% (1)

- Auto Electronics Projects: An Introduction to Your Car Electrics with Useful and Proven Self-Buld ProjectsDa EverandAuto Electronics Projects: An Introduction to Your Car Electrics with Useful and Proven Self-Buld ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Master PricelistDocumento98 pagineMaster PricelistGrady SandersNessuna valutazione finora

- Installation Instructions For Memsource Desktop Editor (Windows)Documento1 paginaInstallation Instructions For Memsource Desktop Editor (Windows)nikkon1Nessuna valutazione finora

- Aargau: My PlaceDocumento2 pagineAargau: My Placenikkon1Nessuna valutazione finora

- Where Is That Symbol?Documento59 pagineWhere Is That Symbol?nikkon1Nessuna valutazione finora

- Memsource User GuideDocumento8 pagineMemsource User Guidenikkon1Nessuna valutazione finora

- DA203 C1 Rev 10Documento1.290 pagineDA203 C1 Rev 10nikkon1Nessuna valutazione finora

- Water Sensor - M&EWS1213ENDocumento2 pagineWater Sensor - M&EWS1213ENnikkon1Nessuna valutazione finora

- 551 - 700 Parts Manual PDFDocumento272 pagine551 - 700 Parts Manual PDFReneeNessuna valutazione finora

- PMP - Useful FormulasDocumento6 paginePMP - Useful Formulasnikkon1Nessuna valutazione finora

- Lagarde List PDFDocumento54 pagineLagarde List PDFGeorge Mat0% (1)

- Young Researchers Seminar: The Contribution of The "Sea Motorways" To The European Transport PolicyDocumento27 pagineYoung Researchers Seminar: The Contribution of The "Sea Motorways" To The European Transport Policynikkon1Nessuna valutazione finora

- COMM 4 2010 Short OpenDocumento13 pagineCOMM 4 2010 Short Opennikkon1Nessuna valutazione finora

- Content Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersDocumento18 pagineContent Analysis of Studies On Cpec Coverage: A Comparative Study of Pakistani and Chinese NewspapersfarhanNessuna valutazione finora

- Hayek - Planning, Science, and Freedom (1941)Documento5 pagineHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- Design of AC Chopper Voltage Regulator Based On PIC16F716 MicrocontrollerDocumento4 pagineDesign of AC Chopper Voltage Regulator Based On PIC16F716 MicrocontrollerabfstbmsodNessuna valutazione finora

- Slip Ring Motor CheckDocumento3 pagineSlip Ring Motor CheckRolando LoayzaNessuna valutazione finora

- 3.1 MuazuDocumento8 pagine3.1 MuazuMon CastrNessuna valutazione finora

- Relay G30 ManualDocumento42 pagineRelay G30 ManualLeon KhiuNessuna valutazione finora

- Case Paul Foster Highlights of TarotDocumento76 pagineCase Paul Foster Highlights of TarotTraditionaltarot100% (6)

- DAB Submersible PumpsDocumento24 pagineDAB Submersible PumpsMohamed MamdouhNessuna valutazione finora

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDocumento11 pagineEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavNessuna valutazione finora

- TOA Project Presentation (GROUP 5)Documento22 pagineTOA Project Presentation (GROUP 5)Khadija ShahidNessuna valutazione finora

- 4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsDocumento4 pagine4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsRUSSELNessuna valutazione finora

- Student Workbook: Advance 3Documento31 pagineStudent Workbook: Advance 3Damaris VegaNessuna valutazione finora

- GoodElearning TOGAF Poster 46 - Adapting The ADMDocumento1 paginaGoodElearning TOGAF Poster 46 - Adapting The ADMFabian HidalgoNessuna valutazione finora

- Thesis StoryboardDocumento5 pagineThesis StoryboardJill Brown100% (2)

- Ge 6 Art Appreciationmodule 1Documento9 pagineGe 6 Art Appreciationmodule 1Nicky Balberona AyrosoNessuna valutazione finora

- Static Power Conversion I: EEE-463 Lecture NotesDocumento48 pagineStatic Power Conversion I: EEE-463 Lecture NotesErgin ÖzdikicioğluNessuna valutazione finora

- SKF CMSS2200 PDFDocumento2 pagineSKF CMSS2200 PDFSANTIAGONessuna valutazione finora

- Sap EwmDocumento2 pagineSap EwmsirivirishiNessuna valutazione finora

- Tensile Strength of Ferro Cement With Respect To Specific SurfaceDocumento3 pagineTensile Strength of Ferro Cement With Respect To Specific SurfaceheminNessuna valutazione finora

- Using Impact IX49 and 61 With Nektar DAW Integration 1.1Documento21 pagineUsing Impact IX49 and 61 With Nektar DAW Integration 1.1Eko SeynNessuna valutazione finora

- Tree Based Machine Learning Algorithms Decision Trees Random Forests and Boosting B0756FGJCPDocumento109 pagineTree Based Machine Learning Algorithms Decision Trees Random Forests and Boosting B0756FGJCPJulio Davalos Vasquez100% (1)

- EF3e Intplus Filetest 10aDocumento4 pagineEF3e Intplus Filetest 10aLin Shufen100% (1)

- The Role of Needs Analysis in Adult ESL Programme Design: Geoffrey BrindleyDocumento16 pagineThe Role of Needs Analysis in Adult ESL Programme Design: Geoffrey Brindleydeise krieser100% (2)

- 05-11 Trainer Interview QuestionsDocumento8 pagine05-11 Trainer Interview QuestionsqulaityNessuna valutazione finora

- Grimm (2015) WisdomDocumento17 pagineGrimm (2015) WisdomBruce WayneNessuna valutazione finora

- Retirement 01Documento2 pagineRetirement 01Nonema Casera JuarezNessuna valutazione finora

- 【SIEMENS】Cios Spin-FlyerDocumento8 pagine【SIEMENS】Cios Spin-FlyerAshleyNessuna valutazione finora

- AE HM6L-72 Series 430W-450W: Half Large CellDocumento2 pagineAE HM6L-72 Series 430W-450W: Half Large CellTaso GegiaNessuna valutazione finora

- Riveted JointsDocumento28 pagineRiveted Jointsgnbabuiitg0% (1)

- Planetary Yogas in Astrology: O.P.Verma, IndiaDocumento7 paginePlanetary Yogas in Astrology: O.P.Verma, IndiaSaptarishisAstrology50% (2)