Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MS Outfall 20170502

Caricato da

Mohamed ThowfeekCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MS Outfall 20170502

Caricato da

Mohamed ThowfeekCopyright:

Formati disponibili

CLIENT PMC CONSULTANT CONTRACTOR

METHOD STATEMENT

GEOTECHNICAL SURVEY

Project: Yas South Development -

Infrastructure, Tunnel and Ramps

Client: M/S: Hilal Bil Badi & Partners

Cont. Co. (Hilalco)

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 1 of 11

CLIENT PMC CONSULTANT CONTRACTOR

INDEX

1. Scope of Works .............................................................................................................................. 3

2. Drilling of Boreholes ..................................................................................................................... 3

3. Continuous Soil Sampling From Boreholes ................................................................................ 3

4. Sampling From Boreholes ............................................................................................................ 4

5. Field Testing in Boreholes ............................................................................................................ 4

6. Piezometer Installation ................................................................................................................. 4

7. Cone Penetration Test .................................................................................................................. 4

8. Laboratory Testing .............................................................................................................. ......... 5

9. Reporting ............................................................................................................................. .......... .6

10. Reinstatement of Boreholes and House Keeping .........................................................................6

11. Access to the Site Area .................................................................................................................. 7

12. ACES Staff & Equipment............................................................................................................. .7

13. Testing Durations .......................................................................................................................... 7

14. Location & Site Drawing .............................................................................................................. 7

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 2 of 11

CLIENT PMC CONSULTANT CONTRACTOR

1. Scope of Works

The site investigation will be carried out to determine the surface and subsurface conditions at the

proposed site of the project and to determine the physical, chemical and mechanical properties of

the foundations ground in order to provide the structural Engineer with sufficient information for

the design of most suitable and safe foundations and pavements.

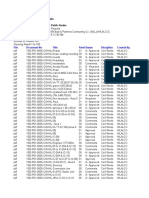

Below Table – 1 summarizes the scope of work:

Item Depth Quantity

25mm 5

28mm 6

Boreholes (Windowless Sampling) 30mm 14

33mm 4

35mm 2

cone Penetration Test 10mm or Refusal 31

Piezometer - 6

Table - 1

2. Drilling of Boreholes

The boreholes will be drilled to determine the nature, type and properties of the subsurface soil

and/or rock and the water table. Boreholes will be drilled down to the required depth as

mentioned in Table – 1.

The drilling will be executed by open-hole drilling. Continuous sampling will be done for non-

cohesive soils and Shelby tube sampling for cohesive soils. Rotary Drill Machine will be used

with mud circulation or casing for rock formations. The exact locations of the boreholes will be

determined in close coordination between our staff and your representative.

3. Continuous Soil Sampling From Boreholes

Large Split Tube Sampler with 3.0inch outer diameter samples will be obtained from the boreholes. The

sampler will be driven by the SPT Hammer blows to the full length (70cm) of the sampler irrespective of

the blow count. Sampler will then be taken out and the soil samples will be collected from the split spoon.

This sampling will be repeated continuously (with no gap between sampling levels) until the bedrock level

(if encountered).

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 3 of 11

CLIENT PMC CONSULTANT CONTRACTOR

4. Sampling From Boreholes

Disturbed, split spoon and undisturbed (intact) samples will be obtained from the boreholes. The

intact samples will be obtained, wherever is applicable and possible, using double tube core barrel

76mm inside diameter for the rock samples in accordance with ASTM D 2113. For cohesive soil

if encountered, thin walled tube sampling of soil will be used in accordance with ASTM D 1587.

The sample recovered shall be examined, described and classified by our Geotechnical Engineer

using ASTM D 2488 and shall be placed in proper sequence in wooden boxes to be taken to our

laboratories for testing. The moist samples will be placed in water proof plastic bags before

placing in the wooden boxes.

Ground water samples will be collected from each borehole, care will be taken to ensure that the

ground water samples are representative and that have not been contained or diluted by surface

water or water used for boring.

5. Field Testing in Boreholes

Standard Penetration Tests (S.P.T.) will be performed at various depths in all boreholes to obtain

approximate consistencies and relative densities of the ground materials, the test will be

performed also every 1.0m upto 10m or bedrock and at interval of 1.5m below that and every

change of strata down to bedrock level (if encountered). The test will be performed in accordance

with:

BS 1377: Part 9:1990, “Determination of Penetration Resistance Using the Split-barrel Sampler

(SPT)”.

6. Piezometer Installation

Total Six (6 Nos.) of Piezometers will be installed at the specific drilled boreholes as per the methodology

explained in Attachment - 1.

7. Cone Penetration Test

The Cone Penetration test shall be carried out at Thirty-one (31 Nos.) locations in accordance

with ASTM D5788 or BS 1377: Part: 1990: Test 3.1 Amd. 8264-95. The CPTu tests will be

carried out at the specified locations.

EQUIPMENT:

Self Anchoring Penetrometer (Self Propelled) 200 kN Capacity – PAGANI TG

73-200.

Cone with a projected area of 10sq.cm., apex angle of 600 and friction sleeve

area of 150sq.cm..

Electric Piezocone

Truck Mounted CPT Rig

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 4 of 11

CLIENT PMC CONSULTANT CONTRACTOR

PROCEDURE:

The test is carried out by penetrometer tip with electric sensors permitting continuous reading and

instant readout and Piezometric sensors.

The following are continuously recorder through data acquisition system (TGAS06).

Tip resistance (Mpa)

Sleeve friction (Kpa)

Pore pressure (Kpa)

TEST RESULTS:

The graphical presentation of results shall include the following:

Plot of Cone Resistance vs depth

Plot of Sleeve Friction vs. depth

Plot of friction ratio vs. depth

Plot of pore water pressure vs. depth

INTERPRETATION OF RESULTS:

Interpretation of results shall be carried out by the following methods.

1. Meyerhof’s method

2. Schmertmann’s Method

3. Recommendations of “International Symposium on Cone Penetration

Testing”. Sweden, Vol. 1-3, 1995

4. Robertson and Campanella Method

REFUSAL CRITERIA:

The CPTu test will be terminated in case of refusal if any of the following occurs:

1. Tip Resistance reaches upto 40 MPa

2. Sleeve Friction exceeds 800 KPa

3. Inclination angle reaches 12º or sudden abrupt increase in inclination angle

8. Laboratory Testing

The required laboratory tests will be carried out at the laboratories of the ARAB CENTER FOR

ENGINEERING STUDIES. All available equipment are in accordance with the American

Standards (ASTM) or British Standards (BS). There is a full range of equipment at ACES for

performing physical, mechanical, chemical and compressibility tests on soils and rocks, some of

which will be used as appropriate. Program of testing will be decided in close co-ordination with

the Engineer.

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 5 of 11

CLIENT PMC CONSULTANT CONTRACTOR

On samples from bore-holes

- Particle size distribution

- Atterberg limits

- Moisture content

- Unconfined compressive strength on rock

- Chemical analysis on soil/water (CL, SO3 & pH)

- Carbonate content

- Direct Shear Test

- Specific Gravity

- Consolidation Test

- Triaxial Test

All tests will be carried out in accordance with the specified standards. In-house computer

facilities will be used for the calculations and analysis of tests results.

9. Reporting

A final report for the investigation will be prepared after the completion of the field and

laboratory testing. The final report will contain project characteristics, site description, field

investigation, all field and laboratory testing, the method of calculation such as foundation depth

and type allowable bearing pressure capacity of the soil, earth pressure, excavation methods and

recommendations for cement type and quantities.

The report will also contain detailed lithological description for each borehole, all the obtained

field information and test results in addition to generalized subsurface profiles along with all the

requirements and will address all the requirement of the scope of work.

Reports shall be submitted as detailed in inquiry scope of work.

10. Reinstatement of Boreholes and House Keeping

All the trial pits and boreholes excavated to be reinstated as per the following procedures:

1. Upon completion of all field testings, sampling required in the boreholes/trial pits and approval

of M/S Hilal Bil Badi & Partners Cont. Co. (Hilalco) the reinstatement and backfilling starts.

2. Trial Pits shall backfilled by the same material in 150mm layers.

3. The boreholes will be refilled by removing all casings and gradually grouting with bentonite

slurry consisting of 1:3 Cement to Bentonite ratio avoiding any subsequent settlement.

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 6 of 11

CLIENT PMC CONSULTANT CONTRACTOR

The site condition upon completion of reinstatement will be at least equal to before

commencement of work and all excavated surplus materials arising on any part of the site will be

disposed.

11. Access to the Site Area

The site area were visited and explored and ACES will access to the site using the approved

roads/routes available on the site area and all safety measures and precautions in driving and

parking and movement in the site area will be maintained.

ACES will follow strictly the rules for security, access and traffic management to access the site.

12. ACES Staff & Equipment

For execution of the required scope of work the following staff & equipment will be utilized:

ACES Field Staff:-

One Site Supervisor

Two Drillers

Five Assistants

One Heavy Driver

Equipment/Vehicles:

Two Drilling rigs

Two Vehicles

13. Testing Durations

The testing durations for the various tests to be carried out in the site area (provided that all

access, permits, and safety arrangements are done) will be as follows:

Borehole: 15m / Day / Rig

14. Location & Site Drawing

Location and site drawings will be used as provided by M/S Hilal Bil Badi & Partners Cont. Co.

(Hilalco).

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 7 of 11

CLIENT PMC CONSULTANT CONTRACTOR

Attachment No. 1:

Piezometer Installation

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 8 of 11

CLIENT PMC CONSULTANT CONTRACTOR

AMENDMENT SHEET

Issue Revision Date Nature of Revision

Designation Signature

Assistant Branch Manager

Review By:

Branch Manager, ACES Abu

Approved by: Dhabi

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 9 of 11

CLIENT PMC CONSULTANT CONTRACTOR

This SOP describes the general procedure for installing a standpipe piezometer to be used for

monitoring of ground water table and ground water sampling. The details of installation may

vary based on specific projects requirements and as may be requested by clients.

1. SCOPE OF WORKS

Installation of standpipe piezometer for monitoring of ground water table and sampling of

ground water samples.

2. MATERIALTO BE USED

1. 50mm internal diameter factory slotted upvc Screen (1mm nominal slot size) with

bottom capping with threaded ends. Others sizes can also be used as required.

2. 50mm internal diameter plain PVC standpipe with threaded ends (pretend).

3. Washed Gravel pack of appropriate size-typically 1-5mm grain size.

4. Bentonite.

5. Cement –bentonite grout, typical mixed in a ratio 1:4:12: (Cement: Bentonite: Water).

6. Geotextile sheet (Optional, to be used only in boreholes with very fine soils at the

level of the screen).

7. Steel casing with lockable cap. A protective steel casing with a lockable cap is

installed approx.. 0.5-1m into the grout seal of each monitoring well (Optional – to be

used in permanent installations only and when contractually agreed).

8. Water level (Dip Meter) with appropriate measuring range to fit the fit the

measurement depth.

9. Measuring Tape (weighted) with appropriate range to fit the measurement depth.

10. Suitable baskets and drums for collection of the drillings, flushed water, etc, as well

as, for preparation of the grout.

11. Grouting pump and flexible hoses, if applicable.

3. PROCEDURE

3.1 Site instruction

The project engineer shall prepare a site instruction for the field personnel (Form-S-

20H) in accordance with agreed project requirements in which the following information

shall be clearly mentioned.

1. Location of the piezometer

2. Drilling method for preparation of the borehole

3. Diameter of the borehole and diameter of the piezometer

4. Depth of the piezometer

5. Location of the screened section with respect to the ground water table

6. Use of casing and lockable cover

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 10 of 11

CLIENT PMC CONSULTANT CONTRACTOR

3.2 Drilling of Piezometer Boreholes

Standpipe piezometer are typical installed in drilled boreholes of diameter 120mm. The

borehole shall be drilled to the required depth using rotary drilling, hollow-stem augering

or cable percussion method as per project specification.

METHOD STATEMENT FOR GEOTECHNICAL SURVEY Page 11 of 11

Potrebbero piacerti anche

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- As Built Drawing RegisterDocumento23 pagineAs Built Drawing RegisterMohamed ThowfeekNessuna valutazione finora

- Non Conformance Report Log /status As On 13-Jun-18Documento13 pagineNon Conformance Report Log /status As On 13-Jun-18Mohamed ThowfeekNessuna valutazione finora

- Administration Manager, Hilalco Abudhabi: Request For Salary IncrementDocumento1 paginaAdministration Manager, Hilalco Abudhabi: Request For Salary IncrementMohamed Thowfeek100% (1)

- Cut & Bend DivisionDocumento6 pagineCut & Bend DivisionMohamed ThowfeekNessuna valutazione finora

- Rules That Should Be Followed by Driver IncludeDocumento1 paginaRules That Should Be Followed by Driver IncludeMohamed ThowfeekNessuna valutazione finora

- Transmittal Template Method StatementsDocumento2 pagineTransmittal Template Method StatementsMohamed ThowfeekNessuna valutazione finora

- Transmittal Template Method Statements4Documento2 pagineTransmittal Template Method Statements4Mohamed ThowfeekNessuna valutazione finora

- As Built Drawing RegisterDocumento20 pagineAs Built Drawing RegisterMohamed ThowfeekNessuna valutazione finora

- Non Conformance Report Log /status As On 13-Jun-18Documento13 pagineNon Conformance Report Log /status As On 13-Jun-18Mohamed ThowfeekNessuna valutazione finora

- Detail of ConsultantDocumento3 pagineDetail of ConsultantMohamed ThowfeekNessuna valutazione finora

- Material Inspection Request RegisterDocumento256 pagineMaterial Inspection Request RegisterMohamed ThowfeekNessuna valutazione finora

- Updated Communication MatrixDocumento7 pagineUpdated Communication MatrixMohamed ThowfeekNessuna valutazione finora

- Emirates Ticket 1Documento2 pagineEmirates Ticket 1Mohamed ThowfeekNessuna valutazione finora

- Correspondence RegisterDocumento4 pagineCorrespondence RegisterMohamed ThowfeekNessuna valutazione finora

- The Human Resource/Admin Manager Hilalco M.O Abu Dhabi, UAEDocumento3 pagineThe Human Resource/Admin Manager Hilalco M.O Abu Dhabi, UAEMohamed ThowfeekNessuna valutazione finora

- Yas South Development: Client PMC Supervision Consultant Cost ConsultantDocumento3 pagineYas South Development: Client PMC Supervision Consultant Cost ConsultantMohamed ThowfeekNessuna valutazione finora

- Daily Programme: Resource Availability / HSE StatisticsDocumento8 pagineDaily Programme: Resource Availability / HSE StatisticsMohamed ThowfeekNessuna valutazione finora

- Monthly HSE Performance Report April 2018-AD 540Documento70 pagineMonthly HSE Performance Report April 2018-AD 540Mohamed ThowfeekNessuna valutazione finora

- Manpower Req HilalcoDocumento1 paginaManpower Req HilalcoMohamed ThowfeekNessuna valutazione finora

- Distribution Records: Client PMC Consultant ContractorDocumento2 pagineDistribution Records: Client PMC Consultant ContractorMohamed ThowfeekNessuna valutazione finora

- Progress Meeting No. 01 - Meeting Agenda Al Forsan Development - Sewerage and TSE ConnectionsDocumento1 paginaProgress Meeting No. 01 - Meeting Agenda Al Forsan Development - Sewerage and TSE ConnectionsMohamed ThowfeekNessuna valutazione finora

- ExportDocs 20170522 - 09 12Documento8 pagineExportDocs 20170522 - 09 12Mohamed ThowfeekNessuna valutazione finora

- Report AD537 - 03-12-2016Documento24 pagineReport AD537 - 03-12-2016Mohamed ThowfeekNessuna valutazione finora

- cv4444369 FileDocumento3 paginecv4444369 FileMohamed ThowfeekNessuna valutazione finora

- H-F-05, Risk Register Rev#2Documento1 paginaH-F-05, Risk Register Rev#2Mohamed ThowfeekNessuna valutazione finora

- Signed: Signed:: For and On Behalf of Party A For and On Behalf of Party BDocumento1 paginaSigned: Signed:: For and On Behalf of Party A For and On Behalf of Party BMohamed ThowfeekNessuna valutazione finora

- H-F-07 EHS Monthly Performance Report REV#01Documento28 pagineH-F-07 EHS Monthly Performance Report REV#01Mohamed ThowfeekNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Syllabus Rhe306 Onramps C Fall 2018 CDocumento8 pagineSyllabus Rhe306 Onramps C Fall 2018 Capi-213784103Nessuna valutazione finora

- Literary CriticismDocumento3 pagineLiterary CriticismAnnabelle LerioNessuna valutazione finora

- Wafer Check Valves - O&MDocumento4 pagineWafer Check Valves - O&MjayakumarNessuna valutazione finora

- Calibers InfotechDocumento6 pagineCalibers InfotechshitalNessuna valutazione finora

- TDS - 2 Pack PU Clear Sealer - Exterior (F92N0ECS)Documento2 pagineTDS - 2 Pack PU Clear Sealer - Exterior (F92N0ECS)Krishna Vacha100% (1)

- Spontaneous Harmonization EffectsDocumento20 pagineSpontaneous Harmonization EffectsMaría Victoria100% (1)

- Fluid IIDocumento2 pagineFluid IIJefara 01Nessuna valutazione finora

- UBG 04LX F01 Datasheet2Documento6 pagineUBG 04LX F01 Datasheet2malirezazadeh5549Nessuna valutazione finora

- 203 - The Poky Little Puppy - See, Hear, ReadDocumento28 pagine203 - The Poky Little Puppy - See, Hear, ReadAndrew Rukin100% (2)

- Solution of Midterm Exam 322E Power Transmission Syst Spring 2009Documento13 pagineSolution of Midterm Exam 322E Power Transmission Syst Spring 2009Aslı ÇakırNessuna valutazione finora

- MAN 6266 - Interview Assignment PDFDocumento2 pagineMAN 6266 - Interview Assignment PDFjoseNessuna valutazione finora

- Blinx01's Ultimate DVD Subbing GuideDocumento12 pagineBlinx01's Ultimate DVD Subbing GuideloscanNessuna valutazione finora

- Keywords: Choice of Jurisdiction, Choice of Law, International Business Disputes in IndonesiaDocumento32 pagineKeywords: Choice of Jurisdiction, Choice of Law, International Business Disputes in IndonesiaLee Xiang'sNessuna valutazione finora

- Little ASP Net Core BookDocumento124 pagineLittle ASP Net Core Booklauhom130% (1)

- Engine Start Button E46 MANUALDocumento6 pagineEngine Start Button E46 MANUALBilly GeorgiouNessuna valutazione finora

- Bernhard FrankenDocumento20 pagineBernhard FrankenManimegalai Prasanna0% (1)

- Ref Book 19edDocumento230 pagineRef Book 19edLuis LunaNessuna valutazione finora

- Ultrapad: Graphics Tablets For Cad and DTP ProfessionalsDocumento4 pagineUltrapad: Graphics Tablets For Cad and DTP ProfessionalsOluwatomi AdewaleNessuna valutazione finora

- IOT Practical 2021-22Documento25 pagineIOT Practical 2021-22Abhi AbhiNessuna valutazione finora

- Q8-Auto-JK - en PDSDocumento1 paginaQ8-Auto-JK - en PDSagnovNessuna valutazione finora

- Binding MaterialsDocumento4 pagineBinding MaterialsSalih MohayaddinNessuna valutazione finora

- Cis 252 Lab1Documento4 pagineCis 252 Lab1Jack RyanNessuna valutazione finora

- IEA PVPS Trends 2018 in Photovoltaic Applications PDFDocumento88 pagineIEA PVPS Trends 2018 in Photovoltaic Applications PDFCarlos Tadeo CapistranNessuna valutazione finora

- Ballsim DirectDocumento58 pagineBallsim DirectDiego GaliciaNessuna valutazione finora

- SynopsysDocumento27 pagineSynopsyssalmanNessuna valutazione finora

- Email Gateway DefenceDocumento8 pagineEmail Gateway DefenceNiven MaharjanNessuna valutazione finora

- There Are 4 Way Is The Factor AnalysisDocumento8 pagineThere Are 4 Way Is The Factor Analysisapi-279431750Nessuna valutazione finora

- Wnba Marketing ProposalDocumento6 pagineWnba Marketing Proposalapi-338282536Nessuna valutazione finora

- Types of EntreprenursDocumento2 pagineTypes of EntreprenursValar Morghulis100% (2)

- Determination of Iron and Fluoride Exp No: 5 Date AimDocumento2 pagineDetermination of Iron and Fluoride Exp No: 5 Date AimkuthappadyNessuna valutazione finora