Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

45 Belt Conveyor GT GB@GB PDF

Caricato da

Miguel OrhlTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

45 Belt Conveyor GT GB@GB PDF

Caricato da

Miguel OrhlCopyright:

Formati disponibili

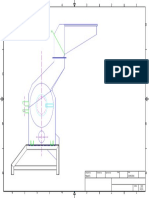

Data Sheet 45

Belt Conveyors GT

Cimbria belt conveyor type GT is fitted with a rubber conveyor The conveyors are supplied with a discharge spout suiting Cimbria

belt, made up of two layers and is suitable for the transportation of Q-flanges. The capacities stated are maximum capacities and are

dry free flowing material such as grain etc. The conveyor can also only applicable for dry and clean grain. Other materials will reduce

be supplied with oil- and fat resistant belts if required. the output per hour.

The GT belt is a trough formed unit and runs on duplex support

rollers. The trough formed unit gives a high capacity compared to

the belt width.

m³/h 100 160 260

Type GT-400 GT-500 GT-650

GT400 / 500 Min. 5000

Hollow shaft gear

GT650 Min. 5500 with norm motor

Inlet

G B

400 D

F

Q

C inner

L = 1000 L = 500, 1000, 3000

A A

336

336

mm/ A B C D E F G Outlet Drive Belt

Leg height

type inner Q pulley rollers

GT 400 Benhøjde

GT-400 400 618 490 159 715 250 894 Q20 ø 219 ø 57 GT 500 GT 650

GT-500 500 718 590 182 735 250 894 Q24 ø 219 ø 57

GT-650 650 890 740 218 822 300 1040 Q30 ø 254 ø 57

For loading of the grain a feeding system is supplied. This feeding Belt quality for foodstuff, type FDA

arrangement contains of an inlet hopper with sealing rails, which Indication set for stop of discharge car

are positioned against the belt. The standard inlet is used when

there is one and more inlets at the belt. Discharge car (data sheet 45.1):

The belt conveyors are supplied for fixed erection with two In case the belt conveyor is to discharge in several places, a

through-going side profiles on which supporting rollers as well as discharge car is used. The discharge car moves on build in

drive- and tension terminals are mounted. The side profiles are wheels. The discharge car can discharge along the total length of

also transport rails for a discharge car. The side profiles are the belt conveyors, up to 4 meters from the feeding end.

supported by legs available in lengths up to 1800 mm (Leg The discharge car is available with either manual positioning or

height). with motor for remote control of the discharge position. The

discharge is supplied with manual - or motor operated two way

Max. spacing of the legs Max. spacing of the legs valve for side outlet.

Type

without discharge car with discharge car

GT-400 10 m 6m Estimated effect for the belt conveyors

GT-500 10 m 6m 5

4 .5

GT-650 8m 4m

4 G T 650

Distance between the supporting rollers of the upper part of the 3 .5

conveyor belt is normally approximately 1.5 meters. Return rollers 3 G T 500

of the conveyor are to be 3 meters. Kw 2 .5

G T 400

2

The drive terminal is as standard delivered with a right mounted 1 .5

hollow shaft gear and supplied with scrapers in outlet spout. 1

Standard speed of transport is 2.0 m/s. 0 .5

0

Optional equipment: 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 M e te r

Top and bottom cover.

Oil resistant belt Speed of the belt 2 m/s

Copyright © - The right to alterations is reserved.

08.08

Cimbria Manufacturing A/S . Faartoftvej 22 . 7700 Thisted . Denmark . Tel. +45 9617 9000 . Fax +45 9617 9099

hvb

Web: www.cimbria.com . E-mail: manufacturing@cimbria.com . Member of the Cimbria Group of Companies

Potrebbero piacerti anche

- Health Safety and Environment PolicyDocumento2 pagineHealth Safety and Environment PolicyMiguel OrhlNessuna valutazione finora

- EEII CeramicHeating ProductFlyer 140129 ScreenDocumento2 pagineEEII CeramicHeating ProductFlyer 140129 ScreenMiguel OrhlNessuna valutazione finora

- Ehs - Company Policy: Environmental - Health - SafetyDocumento1 paginaEhs - Company Policy: Environmental - Health - SafetyMiguel OrhlNessuna valutazione finora

- RibbonBlendes PaulOAbbeDocumento4 pagineRibbonBlendes PaulOAbbeMiguel OrhlNessuna valutazione finora

- Chevron 2013 CR GlossaryDocumento1 paginaChevron 2013 CR GlossaryMiguel OrhlNessuna valutazione finora

- Chain Conveyor GB@GBDocumento8 pagineChain Conveyor GB@GBMiguel OrhlNessuna valutazione finora

- 34 2 1 Chain Conveyor RL RM in Line Shutter GB@GBDocumento1 pagina34 2 1 Chain Conveyor RL RM in Line Shutter GB@GBMiguel OrhlNessuna valutazione finora

- Rotary ConditionerDocumento7 pagineRotary ConditionerMiguel OrhlNessuna valutazione finora

- Tank Drawings Example PDFDocumento2 pagineTank Drawings Example PDFMiguel OrhlNessuna valutazione finora

- Motridal CocleeDocumento8 pagineMotridal CocleeMiguel OrhlNessuna valutazione finora

- UtlDocumento2 pagineUtlMiguel OrhlNessuna valutazione finora

- Nestix Cutting EsiteDocumento3 pagineNestix Cutting EsiteMiguel OrhlNessuna valutazione finora

- Weiler MixerSS ENGDocumento2 pagineWeiler MixerSS ENGMiguel OrhlNessuna valutazione finora

- Code of Business Conduct and EthicsDocumento5 pagineCode of Business Conduct and EthicsMiguel OrhlNessuna valutazione finora

- Nestix Cutting EsiteDocumento3 pagineNestix Cutting EsiteMiguel OrhlNessuna valutazione finora

- Integrated Talent MGT Matters 2844606Documento4 pagineIntegrated Talent MGT Matters 2844606Miguel OrhlNessuna valutazione finora

- Plano Mecánico Puente GruaDocumento1 paginaPlano Mecánico Puente GruaAbel Valderrama PerezNessuna valutazione finora

- Examplefile: Rendering Engine Browser Platform (S) Engine Version Css GradeDocumento1 paginaExamplefile: Rendering Engine Browser Platform (S) Engine Version Css GradeMiguel OrhlNessuna valutazione finora

- Automatic Car ShelterDocumento1 paginaAutomatic Car ShelterMiguel OrhlNessuna valutazione finora

- Automatic Wall Shutter-Single Panel MODEL 502: Ratings Features FrameDocumento1 paginaAutomatic Wall Shutter-Single Panel MODEL 502: Ratings Features FrameMiguel OrhlNessuna valutazione finora

- Conveyor Belt EBS 40 M1 100x450 2M8 U0 V U0 BR EasyDocumento2 pagineConveyor Belt EBS 40 M1 100x450 2M8 U0 V U0 BR EasyMiguel OrhlNessuna valutazione finora

- 2014 Invoice Style PDFDocumento1 pagina2014 Invoice Style PDFMiguel OrhlNessuna valutazione finora

- Auto Exhaust Damper MODEL 611: Ratings Features FrameDocumento1 paginaAuto Exhaust Damper MODEL 611: Ratings Features FrameMiguel OrhlNessuna valutazione finora

- 3 PDFDocumento1 pagina3 PDFMiguel OrhlNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- CPhI Japan InformationDocumento22 pagineCPhI Japan InformationctyvteNessuna valutazione finora

- Science 9-Quarter 2-Module-3Documento28 pagineScience 9-Quarter 2-Module-3Mon DyNessuna valutazione finora

- ME-317 Internal Combustion Engines - TurbochargingDocumento21 pagineME-317 Internal Combustion Engines - TurbochargingHamzaJavedNessuna valutazione finora

- Mass SpectrometryDocumento49 pagineMass SpectrometryUbaid ShabirNessuna valutazione finora

- Sudheer Kumar CVDocumento3 pagineSudheer Kumar CVGujjar Dhayki valeNessuna valutazione finora

- Lathe Operators Manual 96-8900 Rev A English January 2014Documento458 pagineLathe Operators Manual 96-8900 Rev A English January 2014coyoteassasin0% (1)

- Cooling SistemadeRefrigeracion RefroidissementDocumento124 pagineCooling SistemadeRefrigeracion RefroidissementPacoNessuna valutazione finora

- Grain Silo Storage SizesDocumento8 pagineGrain Silo Storage SizesTyler HallNessuna valutazione finora

- BlackCat ManualDocumento14 pagineBlackCat ManualNestor Marquez-DiazNessuna valutazione finora

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesDocumento29 pagineUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemNessuna valutazione finora

- Practice Problems Mat Bal With RXNDocumento4 paginePractice Problems Mat Bal With RXNRugi Vicente RubiNessuna valutazione finora

- Drill Site Audit ChecklistDocumento5 pagineDrill Site Audit ChecklistKristian BohorqzNessuna valutazione finora

- Api 579-2 - 4.4Documento22 pagineApi 579-2 - 4.4Robiansah Tri AchbarNessuna valutazione finora

- Durock Cement Board System Guide en SA932Documento12 pagineDurock Cement Board System Guide en SA932Ko PhyoNessuna valutazione finora

- Cooling Tower (Genius)Documento7 pagineCooling Tower (Genius)JeghiNessuna valutazione finora

- Umur Ekonomis Mesin RevDocumento3 pagineUmur Ekonomis Mesin Revrazali akhmadNessuna valutazione finora

- Userguide SW-MC V2 2015-W45 EN S034308Documento131 pagineUserguide SW-MC V2 2015-W45 EN S034308ReneNessuna valutazione finora

- D05 Directional Control Valves EngineeringDocumento11 pagineD05 Directional Control Valves EngineeringVentas Control HidráulicoNessuna valutazione finora

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDocumento1 paginaPoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswNessuna valutazione finora

- MSDS Lubriplate 105Documento2 pagineMSDS Lubriplate 105mackyyo0% (1)

- Certification "Products Made of Compostable Materials" Procedure No. 3355757Documento3 pagineCertification "Products Made of Compostable Materials" Procedure No. 3355757Rei BymsNessuna valutazione finora

- 感應馬達安裝、保養使用說明書31057H402E (英)Documento17 pagine感應馬達安裝、保養使用說明書31057H402E (英)Rosyad Broe CaporegimeNessuna valutazione finora

- Mbs KatalogDocumento68 pagineMbs KatalogDobroslav SoskicNessuna valutazione finora

- This Unit Group Contains The Following Occupations Included On The 2012 Skilled Occupation List (SOL)Documento4 pagineThis Unit Group Contains The Following Occupations Included On The 2012 Skilled Occupation List (SOL)Abdul Rahim QhurramNessuna valutazione finora

- Virtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonDocumento1 paginaVirtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonPlay Dos ChipeadaNessuna valutazione finora

- Rahu Yantra Kal Sarp Yantra: Our RecommendationsDocumento2 pagineRahu Yantra Kal Sarp Yantra: Our RecommendationsAbhijeet DeshmukkhNessuna valutazione finora

- Rar Vol11 Nro3Documento21 pagineRar Vol11 Nro3Valentine WijayaNessuna valutazione finora

- Kern County Sues Governor Gavin NewsomDocumento3 pagineKern County Sues Governor Gavin NewsomAnthony Wright100% (1)

- Annex 9: Guide To Good Storage Practices For PharmaceuticalsDocumento12 pagineAnnex 9: Guide To Good Storage Practices For PharmaceuticalsRyan Noel Perez de TagleNessuna valutazione finora

- Soal 2-3ADocumento5 pagineSoal 2-3Atrinanda ajiNessuna valutazione finora