Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

An Experimental Study On Partial Replacement of Fine Aggregate Using Steel Slag

Caricato da

GRD JournalsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

An Experimental Study On Partial Replacement of Fine Aggregate Using Steel Slag

Caricato da

GRD JournalsCopyright:

Formati disponibili

GRD Journals | Global Research and Development Journal for Engineering | National Conference on Emerging Trends in Electrical, Electronics

and

Computer Engineering (ETEEC-2018) | April 2018

e-ISSN: 2455-5703

An Experimental Study on Partial Replacement of

Fine Aggregate using Steel Slag

1R. Mahalingam 2G. Sri Durga 3N. Varshini 4M. Sharmila 5R. Vishnu Priya

1

Assistant Professor 2,3,4,5Student

1,2,3,4,5

Department of Civil Engineering

1,2,3,4,5

Sri Vidya College Engineering & Technology, India

Abstract

Modification of concrete properties by the addition of appropriate materials is a popular field of concrete research. In this study

we are focusing on the use of selected waste of steel industry (steel slag) as a partial replacement for fine aggregate in the production

of concrete. In this research study, concretes were made with steel slag as substitution for raw fine aggregate. Fine aggregate was

replaced by these wastes in different proportions (20%, 40%, & 60 %,) by weight of fine aggregate. The aim of this study is to

investigate the compressive strength, split tensile strength and Material properties of concrete with steel chips as a partial

replacement for fine aggregate. The experimental results indicates that, the concrete mixed with steel chips have better strength

than conventional concrete, while in the case of concrete mixed with the scale of 40%, it attains the maximum strength.

Keyword- Fine Aggregates, Steel Slag, Compressive Strength, Split Tensile Strength

__________________________________________________________________________________________________

I. INTRODUCTION

Steel slag exist as by-product during melting of steel scrap from the impurities and fluxing agents, which form the liquid slag

floating over the liquid steel in are or induction furnaces, or other melting units. The ferroalloys industry has generated historically

substantial solid waste. Great amount of wasted materials is generated by industries and has caused tremendous harm to both the

environment and ecology. The waste removed from the furnace separately in a rate of about (10- 15%) of the produced steel. Reuse

of waste material has become very important during the past decade because of the reinforcement of environmental regulations

that require minimizing waste disposal In India, there is a great demand of aggregates mainly from civil engineering industry for

road and concrete constructions. The construction of highways and development of several expressways for high-speed corridors

exert tremendous pressure on natural resources. Mainly highway agencies, private organization individuals are in the process of

completing a wide variety of studies and research projects concerning the feasibility, environmental suitability, and performance

of using waste industrial products in highway construction. These studies to match society's need for safe and economic disposal

of waste materials with the highway industries need for better and more cost-effective construction materials.

A. Utilization of Steel Slag

In the past 20"century, steel slag was found to be excellent aggregate for road paving. Chemical composition of typical waste

material, which would have a promising future in the steel slag consist mainly Si0 2, Al2O3, CaO, MnO, MgO, TiO2, P205 and

fe203. The steel slag is considered as the material for various types of structures due to its durability in construction field. Concrete

is a widely used construction. For a long time it was considered as the durable material requiring a little or no maintenance. In

recent times it was too harsh environments, deterioration of concrete will occur found that, when reinforced concrete structures are

exposed due to many reasons like chloride and sulphate attack, acid attack, corrosion failure etc. On the contrary the aggregates

used for the concrete are facing the greater demand. Utilization of industrial soil waste or secondary materials has been encouraged

in the construction field for the production of cement and concretes. There are very less investigators on the use of Steel slag in

cement concrete. Not much research has been carried out in India and other countries concerning the incorporation of Steel slag in

concrete. Therefore, to generate specific experimental data on strength and other characteristics of Steel slag as aggregate, this

work is performed.

B. Scope

The scope of this research was to investigate the properties of concrete with steel slag aggregates. The fresh and hardened properties

of concrete were tested with steel slag aggregates. In addition to this research several tests were also included such as compressive

strength, split tensile strength and the flexural strength of concrete with steel slag aggregates.

C. Purpose

The purpose of this research was to explore the feasibility of utilizing the steel slag as a replacement for natural aggregate in the

concrete. Steel slag aggregates generally exhibit the potential to expand due to the presence of un- hydrated free lime and

All rights reserved by www.grdjournals.com 12

An Experimental Study on Partial Replacement of Fine Aggregate using Steel Slag

(GRDJE / CONFERENCE / ETEEC - 2018 / 003)

magnesium oxides which hydrate in humid environments. If such a product is used in the concrete, it influences both the mechanical

and physical properties of concrete along with its durability Researchers in the past have successfully incorporated this industrial

by- product as aggregates for hydraulically bound mixtures for road bases. The use of this material as a construction aggregate is

being studied, and further research is ongoing in the United State.

II. LITERATURE REVIEW

1) Experimental study of blast furnace slag concrete - Authors : Gurjeet singh, sanja sangwan, Mohd.usman

Ultra-fine aggregate. Various strength parameters like compressive strength, flexural strength, split tensile strength etc. are

evaluated and showed that by incorporating slag partially or fully in concrete, the mechanical properties of concrete can be improve.

However, the use of blast furnace slag as a fine aggregate has not been studied yet. Hence, in the present study, blast furnace slag

is used as fine aggregate in different proportion i.e. 0%, 20%, 40%, 60%, 80% and 100%. The compressive strength, split tensile

strength and flexural behaviour of reinforced beams are evaluated and compared with that the strength of control mix.

2) Utilization of steel slag in concrete as a partial replacement material for fine aggregate - Authors: P.S kothai, Dr.R.Malathy

A comprehensive study of the potential health risks Associated with the environmental application (eg. Fill, road base, landscaping)

of iron and steel making was performed using characterization data for 73 samples of slag collected from blast furnaces, basic

oxygen furnaces and electric arc furnace. Characterization data were compared to regulatory health based “screening” bench marks

to determine constituent of interest anatomy, Beryllium, Cadmium, Trivalent and hexavalent chromium, manganese, thallium and

vanadium were measured above screening levels and were assessed. This research was intended to study the effectiveness of using

steel slag aggregate (SSA) in improving the engineering properties of locally produced asphalt concrete (AC) mixes. The research

started by evaluating the toxicity and chemical and physical properties of the steel slag. Then structures are exposed due to many

reasons like chloride and sulphate attack, acid attack, corrosion failure etc. On the contrary the aggregates used for the concrete

are facing the greater demand. Utilization of industrial soil waste or secondary materials has been encouraged in the construction

field for the production of cement and concretes. There are very less investigators on the use of Steel slag in cement concrete. Not

much research has been carried out in India and other countries concerning the incorporation of Steel slag in concrete. The replacing

up to 75% of the lime stone coarse aggregate by SSA improved the mechanical properties of the AC mixes. The results also showed

that the 25% replacement was the optimal replacement level.

III. MATERIALS AND METHOD

A. Cement

Ordinary Portland cement of grade 53 was used. The initial setting time of cement is 30 minutes and the specific gravity of cement

is 3.15.

B. Fine Aggregate

Fine aggregate used was clear sand passing through 4.75 mm sieve with a specific gravity of 2.6. The grading zone of aggregate

was zone II.

C. Coarse Aggregate

Coarse aggregate used was angular crushed aggregate with a specific gravity of 2.67.

D. Water

Portable drinking water having pH value of 7 and conforming to IS 456 – 2000 used for concreting.

E. Steel Slag

Steel slag is by product obtained either from conversion of iron to steel in a Basic Oxygen Furnace(BOF), or by the melting of

scrap to make steel in the Electric Arc Furnace(EAF).

Fig. 1: steel slag

All rights reserved by www.grdjournals.com 13

An Experimental Study on Partial Replacement of Fine Aggregate using Steel Slag

(GRDJE / CONFERENCE / ETEEC - 2018 / 003)

S.No. Designation Properties

Light to dark

1 Colour

Brown

2 Shape Highly angular

3 Bulk density 3

1911.11 Kg/m

4 pH (in water) 8

5 Combustibility Non-combustible

6 Surface Texture Rough

7 Specific Gravity 2.93

Table 1: Physical Properties of steel slag

Composition

S.No. Constituent

(%)

1 Calcium Oxide (Cao) 40 - 52

2 Silica (SiO2) 10 - 19

3 Iron Oxide (FeO) 10 - 40

Manganese Oxide 5 -8

4

(MnO)

Magnesium Oxide

5 5 – 10

(MgO)

Aluminium Oxide 1 -3

6

(Al2O3)

Phosphorous Oxide

7 0.5 – 1

(P2O5)

Table 2: Chemical Properties of steel slag

S.No Mix F.A % S.S %

1 CC 100 -

2 CSS1 80 20

3 CSS2 60 40

4 CSS3 40 60

Table 3: Mix Proportions

IV. COMPRESSIVE STRENGTH

The specimens are placed in the machine in such a manner that the load is applied to opposite sides of the cubes as cast. The axis

of the specimen is carefully aligned with the centre of thrust of the spherically seated plate. A spherically seated block is brought

to bear on the specimen; the movable portion is rotated gently by hand so that uniform seating may be obtained. The compressive

strength machine of 1000kN capacity is used, to apply the axial force of compression results shown in Graph.

Fig. 2: Compressive strength

All rights reserved by www.grdjournals.com 14

An Experimental Study on Partial Replacement of Fine Aggregate using Steel Slag

(GRDJE / CONFERENCE / ETEEC - 2018 / 003)

Fig. 3: Compressive strength

A. Split Tensile Strength Test

Align the specimen so that the lines marked on the ends of vertical and centre over the bottom plate. Place the other plywood strip

above the specimen. Bring down the upper plate to touch the plywood strip. Apply the load continuously without shock at a rate

of approximately 14.1kg/cm2/minute and the split tensile strength results shown in Graph.

Fig. 4: Split Tensile Test

Fig. 5: Split Tensile Strength Test Results

All rights reserved by www.grdjournals.com 15

An Experimental Study on Partial Replacement of Fine Aggregate using Steel Slag

(GRDJE / CONFERENCE / ETEEC - 2018 / 003)

V. CONCLUSION

The compressive strength decreases after 40 %replacement of steel slag. The split tensile strength increases with increase in

percentage of steel slag by 40 % by weight of fine aggregate. From the results of compressive strength, split tensile strength of 7

days, 14 days, 28 days curing, 40 % replacement of fine aggregate by steel slag is the optimum percentage of replacement of M30

grade concrete and decreases considerably in further replacement of slag in concrete.

REFERENCES

[1] Baha Vural KOK, Necati Kuloglu- "Effects of Steel Slag usage us Aggregate on indirect tensile and creep modulus of hot

mix asphalt. G.U Journal of Science, 21(3): 97- 103, 2008.

[2] Abdulaziz I. Al-Negheimish, Faisal H. Al- Sugair and Rajeh Z. Al-Zaid Utilization of Local Steelmaking Slag in Concrete-

King SaudUniv. Vol. 9. Eng. Sri. (1). pp. 39 55 (A.H. 1417/1997).

[3] Indian Standard Recommended guidelines for concrete mix design IS 10262 -2009.

[4] John Winterbom, Joseph J. Green Natural Slug Association Report November 1998.

[5] IS 383-1970 Indian Standard specification for coarse and fine aggregates from natural sources for concrete.

[6] Review of steel slag utilization in Saudi Arabia, Ziauddin a. Khan1, rezqallah. Malkawi 2, khalaf a. Alofi3, and nafis ullah

khan.

All rights reserved by www.grdjournals.com 16

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankDocumento5 pagineDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsNessuna valutazione finora

- Image Based Virtual Try On NetworkDocumento4 pagineImage Based Virtual Try On NetworkGRD JournalsNessuna valutazione finora

- GRDJEV06I060005Documento7 pagineGRDJEV06I060005GRD JournalsNessuna valutazione finora

- Optimization of Xanthan Gum Fermentation Utilizing Food WasteDocumento11 pagineOptimization of Xanthan Gum Fermentation Utilizing Food WasteGRD JournalsNessuna valutazione finora

- Chronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningDocumento8 pagineChronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningGRD JournalsNessuna valutazione finora

- Automatic Face Recognition Attendance System Using Python and OpenCvDocumento7 pagineAutomatic Face Recognition Attendance System Using Python and OpenCvGRD Journals100% (1)

- Evaluate The Performance of MongoDB NoSQL Database Using PythonDocumento5 pagineEvaluate The Performance of MongoDB NoSQL Database Using PythonGRD JournalsNessuna valutazione finora

- Simulation and Prediction of LULC Change Detection Using Markov Chain and Geo-Spatial Analysis, A Case Study in Ningxia North ChinaDocumento13 pagineSimulation and Prediction of LULC Change Detection Using Markov Chain and Geo-Spatial Analysis, A Case Study in Ningxia North ChinaGRD JournalsNessuna valutazione finora

- Grdjev06i010003 PDFDocumento4 pagineGrdjev06i010003 PDFGRD JournalsNessuna valutazione finora

- Design and Simulation of LNA Using Advanced Design Systems (ADS)Documento6 pagineDesign and Simulation of LNA Using Advanced Design Systems (ADS)GRD JournalsNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Me6004 UcmpDocumento93 pagineMe6004 UcmpRam100% (1)

- Cu 1600-4 - 201704251640386596Documento4 pagineCu 1600-4 - 201704251640386596taibi aliNessuna valutazione finora

- Step by Step Log House ConstructionDocumento62 pagineStep by Step Log House ConstructionSteve Peachey100% (3)

- Weldlok Steel GratingDocumento16 pagineWeldlok Steel GratingAKarkiNessuna valutazione finora

- ACI Shrinkage CalculationDocumento15 pagineACI Shrinkage Calculationaavlv100% (1)

- HPLC Accessories: PEEK FittingsDocumento9 pagineHPLC Accessories: PEEK FittingsJaycer AsbyssNessuna valutazione finora

- Method Statement For The Under Ground&Above Ground Drainage SysytemDocumento4 pagineMethod Statement For The Under Ground&Above Ground Drainage Sysytemராஜேஷ் குமார் அசோகன்Nessuna valutazione finora

- Laminated GlassDocumento2 pagineLaminated GlassPranav ShethNessuna valutazione finora

- Bolt Shear Strength - MetricDocumento1 paginaBolt Shear Strength - MetricJoseph Cloyd LamberteNessuna valutazione finora

- Mcs 2022Documento206 pagineMcs 2022Maria Monica Campos RamirezNessuna valutazione finora

- Finalkuchhtour 160504150108Documento10 pagineFinalkuchhtour 160504150108Ar Ayoushika AbrolNessuna valutazione finora

- Durability and Corrosion Studies in Prestressed Concrete Made With Blended CementDocumento10 pagineDurability and Corrosion Studies in Prestressed Concrete Made With Blended CementAshfaq AhmedNessuna valutazione finora

- Recycling Asphalt Pavements-A Strategy RevisitedDocumento12 pagineRecycling Asphalt Pavements-A Strategy RevisitedGiora RozmarinNessuna valutazione finora

- Conductivity of Metals Sorted by Resistivity - Eddy Current TechnologyDocumento6 pagineConductivity of Metals Sorted by Resistivity - Eddy Current TechnologyAddi VitryNessuna valutazione finora

- Azolla TenderDocumento4 pagineAzolla TenderprashantkothariNessuna valutazione finora

- Truing N Dressing WheelsDocumento13 pagineTruing N Dressing WheelsKrishnamani TiwariNessuna valutazione finora

- Barduc - Pur-Inox 382 Mhf-As enDocumento1 paginaBarduc - Pur-Inox 382 Mhf-As enhojo coNessuna valutazione finora

- Wind Load Resistance Chart (BS 6262 Part 3)Documento2 pagineWind Load Resistance Chart (BS 6262 Part 3)Tj TanNessuna valutazione finora

- Combined Test Piece For X-Ray ScreenerDocumento2 pagineCombined Test Piece For X-Ray Screenersanjeev kumar verma88% (8)

- Performance EvaluationDocumento3 paginePerformance EvaluationHabtamu DesalegnNessuna valutazione finora

- Company Profile MseDocumento21 pagineCompany Profile MseErik GrimesNessuna valutazione finora

- Weld Defect - WikeepidiaDocumento5 pagineWeld Defect - Wikeepidiapuri16Nessuna valutazione finora

- Simpson CatalogDocumento235 pagineSimpson Catalogasghar7Nessuna valutazione finora

- Study On Ready Mix ConcreteDocumento6 pagineStudy On Ready Mix ConcreteHafiz FizuNessuna valutazione finora

- Next Generation Coatings For ProtectionDocumento10 pagineNext Generation Coatings For ProtectionBobby SatheesanNessuna valutazione finora

- Steel: Steel Is An Alloy of Iron and Carbon, and Sometimes Other Elements. Because of Its HighDocumento15 pagineSteel: Steel Is An Alloy of Iron and Carbon, and Sometimes Other Elements. Because of Its HighRam TejaNessuna valutazione finora

- TN31Documento21 pagineTN31Anthony RuthNessuna valutazione finora

- RDocumento161 pagineRJignesh PandyaNessuna valutazione finora

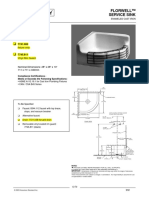

- Cornered Service SinkDocumento1 paginaCornered Service Sinkfarshan296015Nessuna valutazione finora