Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

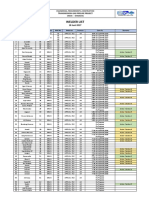

WPQ Flux Core

Caricato da

alberto jaya0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

139 visualizzazioni1 paginaWPQ Flucore

Titolo originale

WPQ Flux core

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoWPQ Flucore

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

139 visualizzazioni1 paginaWPQ Flux Core

Caricato da

alberto jayaWPQ Flucore

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

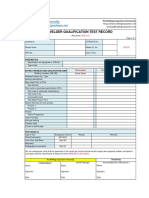

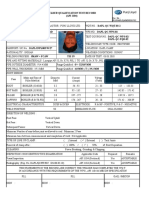

PROJECT:

WELDER PERFORMACE QUALIFICATION (WPQ)

PLANTA DE ACEITE ASOPALNORTE

ID of WPS followed SM-WPS-002

Specification of base metal(s) ASTM A-36 to ASTM A-36 thickness: 16 to 42,00 mm

Name Welder: ID: Stamp: Date:

HENRY MARTINEZ CABEZAS CC 16,499,643 HMC 15/01/2018

WELDING VARIABLES ACTUAL VALUES RANGE QUALIFIED

Process FLUXCORE+SMAW FLUXCORE+SMAW

Type(ie; manual, semi-automatic) used MANUAL MANUAL

Baking (with-without) FCAW: WITHOUT FCAW: WITHOUT

SMAW: WHIT SMAW: WHIT

X Plate Pipe (diameter if pipe or tube) 16 to 42,00mm BUTT AND FILLET

Base metal P-Number to P- Number P-No. 1 P-No. 1 *See below

Filler metal or electrode specification (SFA)(Inf. Only) 5.29 ALL IN FN

Filler metal F-Number 6 ALL F-No.1/2/3/4

Consumable insert (GTAW or PAW) NONE NONE

Fillet type (solid/powder or flux cored/powder)(GTAW OR PAW) SMAW SMAW

Process 1: FLUX CORE X Yes No 16 42

Process 2: SMAW Yes X No - -

Posotion qualified (ALL) 3G+4G ALL POSITIONS

Vertical Progression (uphill or downhill) UPHILL UPHILL

Type of fuel gas (OFW) N.A N.A

Inert gas backing (GTAW, PAW,GMAW) N.A N.A

Transfer mode (spray/globular or pulse to short circuit-GMAW) N.A N.A

GTAW Current type/polarity (AC,DCEO,DCEN) N.A N.A

*P-No.1 Through P-No.15F, P-No.34 AND P-No.41 Through P-No.49

RESULTS

Visual Examination of Completed Weld ACCEPTABLE

Bend test Transverse face and root Longitudinal Side

Pipe bend specimen, corrosion- resistan overlay Plate bend specimen, corrosion- resistan overlay

Pipe specimen, macro test for fusion Plate specimen, macro test for fusion

TYPE RESULT TYPE RESULT TYPE RESULT

−−−−−−−−− −−−−−−−−− −−−−−−−−− −−−−−−−−− −−−−−−−−− −−−−−−−−−

−−−−−−−−− −−−−−−−−− −−−−−−−−− −−−−−−−−− −−−−−−−−− −−−−−−−−−

Alternative Volumetric Examination Result X RT or UT

RT RESULTS

Radiographic plate Interpretacion Qualification

0-40 P.A OK

Fillet weld - fracture test N.A Lenght and percent of defects N.A

Film or specimens evaluated by WILMER DURAN R2 C0254 NIVEL II Laboratory test No. −−−−−−−−−−−−−−−−

We certify that the statements in this record are record are correct and that the test coupons were prepared welded and

tasted and acordance with the requirements of Section IX of the ASME BOILER AND PRESSURE VESEEL CODE.

Firma y nombre del inspector Responsable de la Prueba Fecha: 15 Enero de 2018

Potrebbero piacerti anche

- WPQ WeldCanada PDFDocumento1 paginaWPQ WeldCanada PDFAhmad DanielNessuna valutazione finora

- WPQDocumento1 paginaWPQjuda823Nessuna valutazione finora

- Welder Qualification Test Record: Base MetalsDocumento1 paginaWelder Qualification Test Record: Base Metalsmurshid badshahNessuna valutazione finora

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Documento1 paginaTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- WPQDocumento3 pagineWPQmoonstar_dmeNessuna valutazione finora

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Documento1 paginaWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPQT FormatDocumento176 pagineWPQT FormatRafiqKu50% (2)

- WPQTDocumento18 pagineWPQTMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- NoticeDocumento1 paginaNoticeAnirban Sen SharmaNessuna valutazione finora

- Materials WQTDocumento2 pagineMaterials WQTZohaib AnserNessuna valutazione finora

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 pagine163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocumento2 pagineJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNessuna valutazione finora

- Wqt-Visual-Mag - BS 2Documento24 pagineWqt-Visual-Mag - BS 2KyNessuna valutazione finora

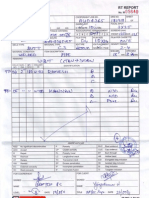

- Radiographic Testing: Inspection ReportDocumento2 pagineRadiographic Testing: Inspection Reportsuria qaqcNessuna valutazione finora

- Welder Card - 6G and 3GDocumento1 paginaWelder Card - 6G and 3GRavi singhNessuna valutazione finora

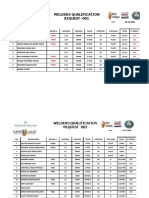

- Welders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJDocumento3 pagineWelders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJel_sharkawy2011Nessuna valutazione finora

- Welder Job Clearance Card: Nesma/TanmiaDocumento8 pagineWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNessuna valutazione finora

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocumento5 pagineDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- WQT For CSDocumento5 pagineWQT For CSkumar08686Nessuna valutazione finora

- A4-Jgs1ep-Epc1-Qp-014 Rev. B (Welding Repair Procedure Ag&p)Documento12 pagineA4-Jgs1ep-Epc1-Qp-014 Rev. B (Welding Repair Procedure Ag&p)Darrel Espino AranasNessuna valutazione finora

- Gtaw Smaw 6 Inch 6G CSDocumento1 paginaGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- WQT Form (ASME) 04-23Documento1 paginaWQT Form (ASME) 04-23hanz bermejoNessuna valutazione finora

- Gmaw WQTDocumento23 pagineGmaw WQTDera LesmanaNessuna valutazione finora

- GMAWDocumento12 pagineGMAWsushant47Nessuna valutazione finora

- WPS SampleDocumento182 pagineWPS Sampleaymenfr23Nessuna valutazione finora

- WQT Parameter Sheet - WPS 29 Ni To NiDocumento12 pagineWQT Parameter Sheet - WPS 29 Ni To NiSankar KrishnanNessuna valutazione finora

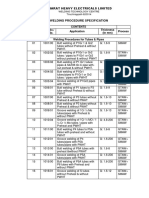

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocumento2 pagineWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNessuna valutazione finora

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocumento50 pagineASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNessuna valutazione finora

- WQT 03Documento1 paginaWQT 03ruhul01Nessuna valutazione finora

- Welder Qualification Test RecordDocumento2 pagineWelder Qualification Test RecordEngr Saeed AnwarNessuna valutazione finora

- WOPQ Form English1Documento2 pagineWOPQ Form English1oaperuchenaNessuna valutazione finora

- WPS Indosol 001 (ASME) RDocumento2 pagineWPS Indosol 001 (ASME) RDoni HardiNessuna valutazione finora

- GTL WPSDocumento6 pagineGTL WPSYoucef ChorfaNessuna valutazione finora

- PQR - PipeDocumento3 paginePQR - PipeAdvanced Quality Centre AQC100% (1)

- QW-482 Suggested Format For Welding ProcDocumento2 pagineQW-482 Suggested Format For Welding Procsachin0% (1)

- Welder List: 18 Juni 2017Documento4 pagineWelder List: 18 Juni 2017Ijo QueenNessuna valutazione finora

- Wps For Aluminium WeldingDocumento8 pagineWps For Aluminium WeldingMohammed MusaNessuna valutazione finora

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Documento21 pagineTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- Technics Offshore Engineering Pte LTD: Material & Weld Traceability RecordDocumento17 pagineTechnics Offshore Engineering Pte LTD: Material & Weld Traceability RecordHanuman RaoNessuna valutazione finora

- QW 483Documento2 pagineQW 483delta lab sangliNessuna valutazione finora

- 8 - Welding Procedures SummaryDocumento12 pagine8 - Welding Procedures SummaryHaleemUrRashidBangashNessuna valutazione finora

- WQT - WPS 02Documento33 pagineWQT - WPS 02Gururaj P KundapurNessuna valutazione finora

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocumento5 pagineQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Nessuna valutazione finora

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocumento3 pagineN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNessuna valutazione finora

- Dayang Enterprise Sdn. BHD.: INSPECTION AND TEST PLAN (Vessel Buttering Repair)Documento3 pagineDayang Enterprise Sdn. BHD.: INSPECTION AND TEST PLAN (Vessel Buttering Repair)AmyNessuna valutazione finora

- Course Module 4Documento6 pagineCourse Module 4Makise AghataNessuna valutazione finora

- Wps GT 9b Cvn90 Rev 1 PDFDocumento6 pagineWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNessuna valutazione finora

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 pagineCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNessuna valutazione finora

- Saipem Wps ListDocumento2 pagineSaipem Wps ListookaNessuna valutazione finora

- PQR TipsDocumento4 paginePQR TipsWaqas WaqasNessuna valutazione finora

- Carbon Steel Pipes - Comparing AmericanDocumento2 pagineCarbon Steel Pipes - Comparing AmericanKazi Anwarul Azim SohelNessuna valutazione finora

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Documento4 paginePQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNessuna valutazione finora

- Brief of Variables: Smaw Gtaw Gmaw SawDocumento3 pagineBrief of Variables: Smaw Gtaw Gmaw SawAdilMunirNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Gtaw SawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNessuna valutazione finora

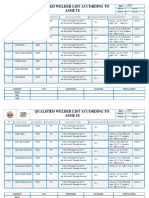

- Qualified Welder List According To Asme IxDocumento5 pagineQualified Welder List According To Asme IxAhmad Nabil ElsharkawyNessuna valutazione finora

- Weld GaugesDocumento15 pagineWeld GaugessojeckNessuna valutazione finora

- WPQ PDFDocumento0 pagineWPQ PDFstanleyNessuna valutazione finora

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Documento2 pagineSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNessuna valutazione finora

- WPS, PQR, WPQDocumento2 pagineWPS, PQR, WPQESL100% (1)

- Senior Schedule Control Engineer PDFDocumento1 paginaSenior Schedule Control Engineer PDFalberto jayaNessuna valutazione finora

- Welder, Welding Operator, or Tack Welder Qualification Test ReportDocumento15 pagineWelder, Welding Operator, or Tack Welder Qualification Test Reportalberto jayaNessuna valutazione finora

- Rup Persona NaturalDocumento98 pagineRup Persona Naturalalberto jayaNessuna valutazione finora

- TT2 Boiler GADocumento24 pagineTT2 Boiler GAalberto jayaNessuna valutazione finora

- Alberto Jaya: Has Successfully Completed The EF SET Certificate and Has Earned The English LevelDocumento3 pagineAlberto Jaya: Has Successfully Completed The EF SET Certificate and Has Earned The English Levelalberto jayaNessuna valutazione finora

- An Introduction To Technical CommunicationDocumento20 pagineAn Introduction To Technical Communicationmithu11100% (1)

- WQU Program CatalogDocumento51 pagineWQU Program Catalogalberto jayaNessuna valutazione finora

- Project: Welder Performace Qualification (WPQ) : Type (Ie Manual, Semi-Automatic) UsedDocumento4 pagineProject: Welder Performace Qualification (WPQ) : Type (Ie Manual, Semi-Automatic) Usedalberto jayaNessuna valutazione finora

- Evidence My Presentation OutlineDocumento6 pagineEvidence My Presentation OutlineMáick Asprilla67% (6)

- How Aircraft Are Built UopeopleDocumento2 pagineHow Aircraft Are Built Uopeoplealberto jayaNessuna valutazione finora

- Matlab Finite Element Modeling For Materials Engineers Using MATLABDocumento74 pagineMatlab Finite Element Modeling For Materials Engineers Using MATLABPujara ManishNessuna valutazione finora

- Evidence My Presentation OutlineDocumento6 pagineEvidence My Presentation OutlineMáick Asprilla67% (6)

- Internetworking: 1 Coms22101 Lecture 9Documento12 pagineInternetworking: 1 Coms22101 Lecture 9Pradeep RajaNessuna valutazione finora

- 1 SMDocumento6 pagine1 SMDejan DoslicNessuna valutazione finora

- Wärtsilä NOXDocumento35 pagineWärtsilä NOXDeepesh MerchantNessuna valutazione finora

- Kohler - Part Leveling MachinesDocumento12 pagineKohler - Part Leveling MachinesAli BÜLBÜLNessuna valutazione finora

- Cooling Water CircuitDocumento3 pagineCooling Water CircuitJamil AhmedNessuna valutazione finora

- Lipid WorksheetDocumento2 pagineLipid WorksheetMANUELA VENEGAS ESCOVARNessuna valutazione finora

- DME - Assignment - IDocumento3 pagineDME - Assignment - ISathis KumarNessuna valutazione finora

- Hubert de Sousleau - Witchcraft Ghosts and AlchemyDocumento7 pagineHubert de Sousleau - Witchcraft Ghosts and AlchemyErrovioNessuna valutazione finora

- Silver Nanoparticles DataDocumento6 pagineSilver Nanoparticles DataSanwithz SittiNessuna valutazione finora

- MATLAB AssignmentsDocumento12 pagineMATLAB AssignmentsnilimaNessuna valutazione finora

- ESM Upgrade To 72 PDFDocumento46 pagineESM Upgrade To 72 PDFsantoshs2002848Nessuna valutazione finora

- SANS5847 - Flakiness Index of Course AggregatesDocumento7 pagineSANS5847 - Flakiness Index of Course AggregatesAndrew MwindililaNessuna valutazione finora

- Recent Advances in Biophoton Research and Its Applications - Quantum Theory of Biophoton EmissionDocumento54 pagineRecent Advances in Biophoton Research and Its Applications - Quantum Theory of Biophoton Emissionfrederic dugenouxNessuna valutazione finora

- FFT Analysis of Poorly Organized NanoporesDocumento5 pagineFFT Analysis of Poorly Organized NanoporesJuly Gonzalez BonagasNessuna valutazione finora

- Study of Selected Petroleum Refining Residuals Industry StudyDocumento60 pagineStudy of Selected Petroleum Refining Residuals Industry StudyOsama AdilNessuna valutazione finora

- On The Theories of Plates and Shells at The Nanoscale: Holm Altenbach and Victor A. EremeyevDocumento34 pagineOn The Theories of Plates and Shells at The Nanoscale: Holm Altenbach and Victor A. EremeyevAbr. MengistuNessuna valutazione finora

- REvision Test - 1Documento2 pagineREvision Test - 1JagendraNessuna valutazione finora

- Quiz Sectiunea 7Documento5 pagineQuiz Sectiunea 7Bogdan BrkicNessuna valutazione finora

- IMO Resuts - Science Olympiad FoundationDocumento2 pagineIMO Resuts - Science Olympiad FoundationAbhinav SinghNessuna valutazione finora

- Urban Transportation PlanningDocumento10 pagineUrban Transportation PlanningkiranNessuna valutazione finora

- CAPTAIN250DITEINCOMPLETEAug 2020Documento15 pagineCAPTAIN250DITEINCOMPLETEAug 2020billal toufik BendjimaNessuna valutazione finora

- 3 Types of Emergency Shutdown and Emergency Isolation ValvesDocumento4 pagine3 Types of Emergency Shutdown and Emergency Isolation ValvesMateusz KonopnickiNessuna valutazione finora

- Chapter 01 Properties of SolutionDocumento70 pagineChapter 01 Properties of SolutionYo Liang SikNessuna valutazione finora

- Data Analysis PDFDocumento70 pagineData Analysis PDFMark De Guzman100% (1)

- Comparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistanDocumento10 pagineComparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistannithyaNessuna valutazione finora

- Vmware Vsphere 4: The Best Platform For Building Cloud InfrastructuresDocumento5 pagineVmware Vsphere 4: The Best Platform For Building Cloud InfrastructuresAshok Reddy AdurintiNessuna valutazione finora

- MPDFDocumento1 paginaMPDFVipul WankarNessuna valutazione finora

- Pilot Optd. Pr. Relief Valve Modular Construction: MPPR 06Documento3 paginePilot Optd. Pr. Relief Valve Modular Construction: MPPR 06Dillibabu RNessuna valutazione finora

- Pay It ForwardDocumento4 paginePay It ForwardAndrew FarrellNessuna valutazione finora